The pump belongs to the vehicle's cooling system. In its unit, this part is the second most likely to break down. On a VAZ-2112 with a 16-valve engine, replacing the pump is quite easy, so even a novice motorist can do it.

The pump promotes stable circulation of coolant in the vehicle system. Therefore, if it malfunctions, leaks of this substance are possible, and air often gets into the system, which is very bad. It is much less common for valves to bend and the pump to jam, which may require a complete engine repair if we are talking about the 21120 model.

Which pump is better to choose for a 16-valve VAZ 2112?

Today we will tell you how to choose the right coolant pump, what to look for, and find out what experienced VAZ-2112 owners advise. After diagnosing various forums, we compiled a rating of all pumps that are popular among VAZ-2112 car enthusiasts and compiled a rating that can fully reveal all the advantages and disadvantages of each model.

The video explains how to distinguish an original pump from a fake, and what to look for when choosing this part:

FENOX

- Manufacturer: Republic of Belarus.

- Retail price: rubles.

- The pump from the manufacturer FENOX is one of the cheapest on the market. At low speeds it can withstand flow, while being able to withstand thermal shock. The workmanship is excellent, the packaging is high quality. The undoubted advantage of this pump is its low price and excellent performance with high crankshaft rotation speed. Among the minuses, users note the presence of red spots on the impeller after this pump has been in operation. One can only guess about their origin.

Differences in pump production technology

Signs of a fake pump. This is clearly not the famous Gates. That's why we didn't include it in our rating, there are too many fakes.

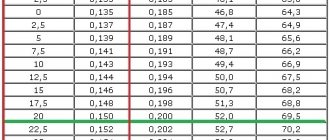

Pumps are produced with six and seven blades; they differ in manufacturer and technical characteristics. According to various tests carried out, those models with seven blades perform much better during operation than its limited counterpart. Below we will present you with a rating of the five best pumps, the performance of which varies in the same range.

Tips for choosing

Now a little about choosing a pump. Now the automotive spare parts market offers the widest selection of this unit from a variety of manufacturers. But, unfortunately, there are also a lot of fakes.

When choosing a water pump, it is advisable to give preference to the manufacturer who supplies its products to the automobile plant.

Before purchasing, you need to inspect the pump packaging - it should be made of hard cardboard, with printed information indicating the characteristics of the unit, as well as the manufacturer’s data. There must be a holographic sticker.

Inside, in addition to the assembly, there should be a gasket for it and fastening bolts (but not always), as well as a warranty card.

Attention must also be paid to the pump itself - when checking, there should be no play, and when rotating, there should be no wedging or jamming. Many manufacturers are upgrading pumps, especially the blades.

Many manufacturers are upgrading pumps, especially the blades.

In this case, look for driver reviews on forums about this device model; in most cases you will receive true information.

Review of water pumps for Lada

There are currently a variety of brands and manufacturers of water pumps on the market; each manufacturer claims that its products are the best. We will try to impartially figure out what’s what, and consider one of the most popular items - a pump for front-wheel drive eight-valve VAZ cars.

To avoid any confusion, let's clear things up right away. Eight-valve engines on front-wheel drive VAZs were constantly modernized and changed, so the pumps listed below are suitable for all engines equipped with the so-called “eighth” timing belt. If we take it by model, then these are VAZ 2108, 2109, 21099, 2110, 21013, 21014, 21015, as well as Kalinas and Prioras of the first years of production.

We purchased seven samples of pumps from different manufacturers - both domestic and foreign. But before we start introducing the products, I would like to explain some of the terms that are used below.

The impeller is a low impeller, which is located on the reverse side of the main impeller, its purpose is to relieve the shaft-housing seal. Equally important is the presence of holes in the base of the impeller - they also help reduce the load on the mechanical shaft seal with the housing.

A ball roller bearing is a bearing that has balls on one side and rollers on the other. Such a bearing can carry greater loads than a double-row ball bearing.

Double row ball bearing - balls installed on both sides.

Ceramic seal - a friction pair of two rings (moving and stationary) made of various materials (carbon graphites, metals, carbides (tungsten carbide with various bonds, silicon carbide), ceramics (metal oxides), plastics) both of the same material and in combination of various materials (stainless steel - carbon graphite, Al2O3 99% (ceramics) - carbon graphite). To ensure the necessary contact between the rings, a spring, a spring block or an elastic bellows is used.

The distance from the highest point of the impeller to the landing belt - this parameter characterizes the flow: the greater this distance, the better, the smaller the gap between the impeller blade and the mating part of the block - accordingly, suction losses are reduced.

Let's get started.

1.Fenox

Country of origin: Belarus

The pump is packaged in original packaging, a sealing gasket is included with the pump, a 7-blade plastic impeller, without an impeller. There is a product passport.

Warranty - 1 year from the date of sale.

2. TZA

Country of origin: Russia

The pump is packaged in a branded cardboard box, the kit includes a sealing gasket and a product data sheet, and a protective sticker is applied to the box label, which breaks when you try to open the box. On the lid of the box there is an identification number under a washable protective layer to determine the authenticity of the product; for the same purpose, a QR code is applied to the pump pulley. The pump body is used from a VAZ-2112 with a molding for mounting the bracket, this is also evidenced by the markings on the body. The impeller is plastic, 7-blade, with an impeller.

Warranty - 1 year from the date of manufacture.

3. LUZAR

Country of origin: Russia

The pump is packaged in original packaging, the impeller is 7-bladed, made of aluminum alloy, the kit includes not only a sealing gasket, but also fasteners, sealed in a separate bag. Also included is a product passport. The LUZAR marking is applied not only to the body, but also to the pump pulley.

Warranty - 2 years or 125 thousand km from the date of purchase.

4. Oberkraft

Country of manufacture not specified

Replacing a pump in an 8-valve system

Installation misalignment. Especially when it comes to gears and pulleys. This can be observed visually or by placing any flat object (for example, a ruler) in the same plane as the shafts and pump. In this case, the strip is often eaten.

The engine temperature rises significantly. And not only the engine, but also the coolant, as evidenced by the indicator light on the dashboard. In critical cases, the antifreeze will simply boil and water vapor will flow out of the cooler. However, the situation is critical and the use of the car is prohibited!

If at least one of the above symptoms of a water pump malfunction occurs, additional diagnostics of both the pump and the cooling system are required. When the first signs of a dying pump appear, you can still ride, but for how long this is unknown, and it is better not to tempt fate. In some cases, a car can run for 500 zlotys. 1000 km, and in other cases not even a hundred. In any case, the cooling system is not to be trifled with and must be promptly and fully diagnosed and repaired.

Depending on the brand and quality of the cooling system water pump, regulations recommend replacing it after approximately 60,000 km. km (depends on the specific case and is recommended by the manufacturer, relevant information can be found in the operating instructions)

The best timing drive and pump

The thorny path to replacing the timing belt and rollers has been completed, along with the water pump (coolant pump). It became thorny, firstly, due to the fact that for two years or 25 thousand kilometers I drove with a belt installed by the previous owner, which involuntarily destroyed the stereotype that car salesmen can no longer be trusted. He was a normal guy, he said to replace it in the spring, I replaced it two days later... The old belt, by the way, proudly demonstrated by the master (“Christina”), at the time of replacement, turned out to be cracked at least one of the teeth. The pump has also suffered over the past years - the play was no less proudly demonstrated, and upon leaving the service center I personally noted a decrease in the noise level from under the hood. The replacement of the latter was dictated more by the expediency of combining work than by real suspicions of an imminent end. The 124th engine does not bend the valves when the belt breaks, it was possible not to worry, but... perfectionism is a serious disease.

After all, thorniness is also due to the specifics of the choice of spare parts. I mean it's hard. And this is what was replaced (price + delivery cost): - INA timing drive kit

(Slovakia) - 1390+600=2000 rub.

// alsport.ru According to the website “ Used in motorsport.

Improved timing belt design from INA. Instead of neoprene, enriched nitrile is used, because When heated, neoprene becomes rigid and loses its elasticity. "

— coolant pump TZA Sport

(Togliatti) - 503+325=828 rub.

//nbklada.ru “ Produced as a modernization of the pump 21120-1307010-75

(only this is presented in Virazh, and at a price of 730 rubles - note theo51ab)

for 16-valve internal combustion engines of Kalina cars and other front-wheel drive cars "VAZ".

Design features: — New 8-blade impeller 21118 with a modified profile and direction of the blades, productivity above 170 l/min for use in internal combustion engines operating with increased loads; — Cassette type oil seal made in Italy; — Bearing made in Slovakia. This allowed: - to increase pump productivity by 20-40%; — improve the operation of the internal combustion engine cooling system; — improve the operation of the vehicle’s interior heating system; — increase the working life of the pump by 40%.

«.

Ordered through the specified official dealer of TZA products, in confirmation of which a certificate was presented during the correspondence. And don’t let anyone be confused by the fact that spare parts catalogs here are side by side with a recipe for moonshine—these speculators were discovered via a link from the manufacturer’s website. In addition to the pump itself, in a clapper film with a rubber-cork gasket, the packaging even contained a faceted glass, a product passport with the batch number and the packer’s mark!

The pump change was also marked by a replacement of the coolant - there is no need to skimp on antifreeze after last year's problems with antifreeze - AGA Z42 antifreeze

(10 liters of potion);

SCT fuel filter

(unfortunately there was no Knecht Mahle);

10W40 MotorGold oil

(5 liter canister, manufactured in 2012 - not only can this oil be bought in only two stores in the city, but also their 12th year can be considered a fresh batch...)

with a Knecht Mahle filter

;

oil seal

closest to the headlights due to detected fogging (Balakovo, FPM tires). Total: 960+130+(1100+130)+100=2420 rub. The total cost of the work was 1900 rubles. Some expensive update came out(

Symptoms of malfunction

- Pump noise when the engine is running. Extraneous noise is caused by bearing wear. It is recommended to replace the cooling system pump after one or every time replacement. If maintenance intervals are not observed, the rolling elements, inner and outer rings will wear, causing noise and whistling. Quite often, the cause of accelerated wear is antifreeze, which gets into friction pairs due to leakage of oil or rubber seals.

- Antifreeze leak. Like the pump bearing, the oil seal and rubber bushing have a limited service life. Play due to bearing wear will result in much less sealant leakage.

- Misalignment with respect to gears, shafts (pump is misaligned). Uneven stress distribution causes accelerated wear not only of the bearing, but also of the seal. Incorrect assembly or manufacturing defects, when the pulley rotates misaligned, leads to accelerated wear of the loaded part of the belt. Such a malfunction, even with low mileage, can break the timing belt and break valves with pistons.

- Engine overheating. When the impeller vanes break, the pump's performance drops, resulting in less coolant flow through the small circulation circuit.

A decrease in performance is often noticeable after applying sealant to repair a radiator leak. The mixture clogs the cooling system passages and sticks to the pump impeller.

Unless grease has clogged the body coolant drain, leaking sealant will not cause water pump failure. However, it is necessary to disassemble the pump and flush the system.

TOP 7 best pumps for VAZ (Lada)

Models from domestic manufacturers are extremely popular among Russian users due to their moderate cost and cheap maintenance. The problem with the machines is their minimal reliability - frequent breakdowns of internal components provoke unscheduled repairs and inspections. In this case, the engine compartment suffers most often. The following is the answer to the question, what is the best pump for a VAZ and how to prevent its early wear.

Shaft defects

Among the signs of a malfunctioning water pump, one should note the presence of deformation on the shaft. Upon inspection, it may appear bent or completely destroyed. If it is broken, it means the overload was sudden. Also, imbalances lead to similar consequences.

If the material from which the shaft is made has changed color (most often it acquires a blue tint), this indicates the gradual destruction of the shaft. This occurs due to excessive heat. The reason for this failure is the misalignment of the drive belt. This leads to shaft deformation or even fracture. Due to insufficient quality maintenance, significant vibrations appear in the system.

In this case, the pump is changed, and the belt drive is also checked. All elements of its system need to be inspected. You also need to evaluate the condition of the fan that is located on the pump (if it is provided in the engine system). If it is bent, other deformations are visible on it, this can destroy the shaft. Wear of the fan coupling and spacer ring also lead to a similar outcome.

Why do you need a pump?

If the information has reached an experienced motorist, you can safely skip this section. For beginners, before telling which pump is better to install on a VAZ, you should explain what it is and why it is needed.

The main task of the mechanism is to ensure proper circulation of antifreeze throughout the cooling system. If the design works correctly, the liquid maintains a stable temperature, and thermal shock due to sudden heating of the block when the speed increases is eliminated.

The pump also ensures normal operation of the stove. With good system circulation, the radiator quickly releases heat into the interior.

If the pump is missing, the motor will instantly overheat, which will cause its damage or complete destruction. A similar result occurs when it breaks.

Preparing to replace your pump

First of all, you need to make sure that all the necessary tools are available to replace the water pump.

You will need:

- key for 10 and 17;

- Screwdriver Set;

- hammer;

- timing clamping mechanism;

- rags;

- container for draining old coolant;

- new coolant – 2 l.

You should immediately decide on the time, since the process may take a little longer if you are performing this manipulation for the first time.

When to change your pump

A clear sign that the pump needs to be replaced are the following points.

- In the warm season, there is frequent overheating of the power plant, although there is enough antifreeze in the expansion tank.

- Leaks appearing at the pump connections. Failure can be detected by fogging of the case or the presence of wet spots of a characteristic composition.

- Extraneous noise coming from the pump when the engine is running - it can be knocking, rustling or crackling.

- In winter, the heater stops working even when the engine is normally warmed up.

Instructions

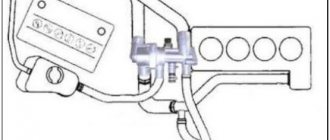

A detailed and sequential process for replacing the pump will be considered for a VAZ-2112 with a 16-valve 1.6 engine:

- Using a special pit in the garage or a lift it is easier to replace the water pump. But not everyone has them, so we will consider the replacement process in a simple garage without a pit.

- Remove the front wheel on the right.

- To give yourself access to the crankshaft pulley, remove the protective plastic splash guard by unscrewing the screws securing the element to the body and removing it.

- Secure the crankshaft from turning. This is in your own interests of safety and convenience, and is also necessary in order not to disrupt the valve timing.

- Loosen the alternator and timing belt using the tension roller, which just needs to be loosened slightly.

- Unscrew the crankshaft mount.

- After loosening the fastening, remove the pulley.

- Next, it is necessary to disassemble the gas distribution mechanism, during which all elements are dismantled - casing, pulleys and rollers.

- Only now we get to the pump. Unscrew its mounting bolts - 3 pieces. Dismantle the device.

- Pull out the pump completely.

- Installation is similar, but done in reverse order.

How to choose a pump for a VAZ

There are several signs that determine the correct choice of pump for a car. Moreover, each parameter is taken into account individually - there is no universal method.

The pump impeller can be:

- plastic;

- metal.

The first option has the advantage of having no inertial load, which makes it easier to unwind when the motor starts. The downside is the short service life and changes in the geometry of the wings under the influence of high temperatures - this reduces the efficiency of the pump. New foreign cars are equipped with impellers made of expensive materials that can withstand overheating and cavitation abrasion.

The second type is made of metal. Such impellers are heavier, take a long time to spin, but do not change geometry when heated. On the other hand, steel parts quickly become corroded when the wrong antifreeze or water is used in the cooling system, which critically reduces their performance.

According to the design, you should choose impellers with a minimum gap between the housing and the blades. This combination minimizes idle rotation of the mechanism and increases the efficiency of the unit.

The manufacturer recommends using parts of the same brand. If such pumps are not available, you should study reviews of the available company in advance and choose the best one at your own discretion.

Replacement sequence on an 8-valve engine

Having all this, you can start replacing:

It is advisable to place the car on a viewing hole and jack up the front right wheel. But this is not always possible, so in extreme cases, it is enough to simply turn the steering wheel to the right all the way. After this, remove the right front wheel fender liner protection; We remove the decorative panel from the engine and unscrew the absorber so that it does not interfere. In this case, there is no need to disconnect the wiring and tubes from it; after unscrewing it, it is enough to put it aside. The coolant can be drained immediately or later; Unscrew the bolts securing the plastic protective cover of the drive belt. After this, you can diagnose the condition of the pump. To do this, just start the engine and look at it - if play is clearly noticeable when it rotates, it definitely needs to be replaced. We install TDC on the first cylinder. To do this, turn the crankshaft clockwise until the marks on the timing gear align with the protrusion on the protective screen installed behind this gear. Then we check that the TDC is installed correctly. To do this, remove the inspection window plug on the clutch housing. We make sure that the marks on the flywheel and the housing also match. In this case, the coincidence control must be carried out on the flywheel, and not on the camshaft gear (a slight mismatch of the marks on the camshaft is allowed); We loosen the mount of the generator, feed it to the engine and remove its drive belt; Remove the crankshaft pulley. To do this, you can go in several ways: lock the crankshaft using a powerful screwdriver installed in the teeth of the flywheel and resting on the housing, or ask someone to engage 4th gear in the gearbox and squeeze the brakes. Both of these methods are good, and it’s up to you to decide which one to use; After removal, we check again that the marks match and correct them if necessary. Loosen the tension roller nut to remove tension from the belt. Carefully remove the belt first from the timing gear, and then from the crankshaft, unscrew the tension roller; Remove the timing gear. To do this, through the technological hole, using a wrench, we press against the rear screen mounting bolt to fix it, after which we loosen the bolt with the wrench. Then we check again that the marks match, correct everything if necessary, unscrew the bolt completely and remove the gear

You need to tighten it carefully, since there is a key on the shaft - it is important not to lose it; We unscrew all the bolts and nuts securing the rear screen, which at the bottom are also the pump mount. If the coolant has not been drained, then before unscrewing the mounting bolts, you need to place a wide container under the engine; Having unscrewed the bolts, remove the screen and, using light tapping movements, remove the pump from its place; Before installing a new pump, be sure to thoroughly clean its seat with a knife to remove any remnants of the old gasket. This is necessary so that after assembly there is no misalignment of the pump, this will lead to constant rapid wear of the drive belt; Before installing the new pump, lubricate its gasket on both sides with sealant and give it a little time to dry (10 minutes); We put the pump in place, then the screen, and only after that tighten the bolts that secure them.

Next, assembly is performed in the reverse order. It is important to check that the labels match. After installing the belt, tension it. Next, we check that the assembly is correct - we rotate the crankshaft several times, and then align the marks again. If the marks on the timing belt with the protrusion and the flywheel coincide with the housing, then everything is assembled correctly and you can reassemble the engine and fill in coolant. If they do not match, then you will have to set the marks on the flywheel, remove the belt, adjust the marks on the timing gear and put on the belt

This is necessary so that after assembly there is no misalignment of the pump, this will lead to constant rapid wear of the drive belt; Before installing the new pump, lubricate its gasket on both sides with sealant and give it a little time to dry (10 minutes); We put the pump in place, then the screen, and only after that tighten the bolts that secure them. Next, assembly is performed in reverse order.

It is important to check that the labels match. After installing the belt, tension it. Next, we check the correctness of assembly - rotate the crankshaft several times, and then align the marks again

If the marks on the timing belt with the protrusion and the flywheel coincide with the housing, then everything is assembled correctly and you can reassemble the engine and fill in coolant. If they do not match, then you will have to set the marks on the flywheel, remove the belt, adjust the marks on the timing gear and put on the belt.

Which pump is better for a VAZ car

The following is a list of popular market offers that are in great demand among domestic car enthusiasts. The top manufacturers are based on their prevalence in stores across the country and the frequency of their purchase. At the same time, some brands produce a limited number of modifications, which negatively affects popularity.

FENOX

The rating of pumps at VAZ opens with an extremely well-known organization in certain circles. The brand produces a large number of spare parts for classic and modern VAZs. When choosing which pump is better to install on a Niva, a classic or a new one, sellers often recommend installing the Phenox.

The company has production sites in the CIS countries and is focused on producing parts for “local filling” machines, which allows them to fully meet the requirements of manufacturers.

In 2022, brand pumps are not widely used due to their low cost and short service life. But with moderate driving and use of classics, the products show their best side.

- minimum cost;

- well-known company;

- good efficiency.

- there are defective pumps;

- a lot of fakes.

METELLI

The top popular company continues, whose production facilities are mainly located in Poland. The brand supplies pumps to the domestic market as replacement and original parts mounted on assembly lines. Due to the high quality of products, auto giants like Ferrari, Fiat and Peugeot order products from the manufacturer and put their logo on them.

Special quality control is emphasized - all pumps undergo rigorous tests and comply with the international standard ISO 9002, which guarantees their long-lasting operation. The second important factor is the almost complete absence of counterfeits - mechanisms are supplied mainly to official dealers or trusted stores. Therefore, when asked which pump is best to install on Kalina or a similar model, you can safely contact the company for a new part.

Among customer reviews, there are mostly positive comments, but there is also a small share of negativity.

- minimum number of defective parts;

- high-quality impeller design;

- sufficient performance;

- moderate price tag;

- long service life;

- presence of a rubber gasket included.

Flaws:

- The assortment does not have a price list for some popular cars.

According to motorists, the best VAZ 2107 pump is produced under the name of this brand. Also in the company's assortment you can find a wide range of pumps for other classic or modern cars.

The brand has been operating since 1934 and is a reliable company whose reputation has been proven over the years. The manufacturer focuses its attention exclusively on pumping equipment installed on trucks and cars, which allowed it to create extremely high-quality devices.

Thanks to its narrow focus, the manufacturer makes pumps for 95% of European cars. At the same time, without losing the quality of the products.

The notorious reliability of parts is due to the use of patented technology. The alloys used in the impellers are resistant to mechanical abrasion and cavitation wear, which eliminates the pouring of low-quality antifreeze or water into the cooling system.

- wide use;

- large selection of modifications;

- good protection against counterfeiting;

- long service life.

The next representative of the rating, originally from Sweden, has a large number of production sites throughout Europe and the CIS. Therefore, when choosing products, you should not get hung up on the country of origin - thanks to strict quality control, the products turn out to be of good quality, regardless of the place of manufacture.

The popular brand is in demand among domestic motorists due to its decent quality and reasonable cost. When asked which pump is better to install on a VAZ 2114 or its equivalent, you can safely buy a brand-name device. According to drivers, the pumps last up to 130,000 kilometers, which exceeds the performance of analogues by 20-30%.

Significant disadvantages of the brand's products include the abundance of copies on the market. Due to their widespread use, pumps are often counterfeited, which forces buyers to carefully select kits. The manufacturer insists that the original part is equipped with the mark of the assembly shop and markings on the box. If one of the elements is missing, the buyer is faced with a fake.

- sufficient level of technology;

- excellent quality of parts;

- moderate price tag;

- sold in most megazines.

- A large number of fakes.

If you need a good pump for an old or new generation Niva, experienced experts advise purchasing products from the brand described. The main difference between the brand and its analogues is that the manufacturer has its own research center that studies metal corrosion processes, which allows them to quickly make changes to the structure of the materials from which parts are made.

Natural product tests indicate a pump life of up to 90,000 kilometers, with average intensity of vehicle use. On the other hand, on display cases there are problematic mechanisms with a lack of lubrication in the bearings or minimal play in the main shaft.

The result of the work of engineers is high-quality pumps that can operate for a long time under moderate loads.

- sufficient reliability of the design;

- widespread throughout the CIS countries;

- reasonable price.

- There are defective parts.

BOSCH

The next representative of the top, indicating which is the best pump for Vesta, comes from Germany. The famous brand is engaged in the production and improvement of unique products of the highest quality.

The brand's controversial reputation is due to the presence of production facilities around the world. For example, at Russian factories, manufacturing standards and rules are softer than in Germany, which causes a drop in quality. Therefore, when purchasing a pump, you need to pay attention to the country of manufacture and choose products with a European logo.

Also frankly “stressful” is the abundance of counterfeit products. There are often surrogate pumps on the market, which is a consequence of insufficient copy protection.

- excellent workmanship;

- long service life;

- wide choice of modifications.

- abundance of fakes;

- often controversial quality;

- It is recommended to buy only European pumps.

VALEO

The next representative of the list is a world-famous brand that is a supplier of parts for famous automakers and their assembly lines. The main advantage of the company's pumps is that they are delivered to the customer along with guide rollers, timing belt and all gaskets. Such “stuffing” ensures reliable operation of components for 150,000-180,000 kilometers. If you buy an original set, the high cost is fully compensated by its durability. Therefore, when asked which pump is better to put on Vesta or something similar, you can safely turn to the brand.

Fluid leaking from the drain hole or from under the seating surface

There may be various symptoms of pump failure for VAZ-2109, 2107, 2114 and other car models. So if the coolant was of poor quality, there may be a leak in the drain hole area. In this case, leakage occurs, the formation of drops after the car is broken in. This can be determined by looking at the surface of the drain hole. Please note that a small leak in a new pump is normal. This happens during the first 10 minutes of engine operation. This is because the mechanical seal moves to the correct position.

If a new pump has a break-in period. If the pump is not operating properly but fluid continues to flow from the drain port, the pump is damaged. It is necessary to thoroughly flush the cooling system and install a new pump. Then you need to fill in the required amount of new antifreeze of acceptable quality.

If there is leakage from under the seating surface, this also indicates a malfunction. In this case, a sign of failure of the VAZ-2107, 2110, 2109 or other models is humidity, the appearance of drops, drops on the body or around a certain area. The cause of such a breakdown is incorrect installation of the pump or incorrect use of sealants and gaskets.

If the pump is new, remove it and check that it is installed correctly. It is especially important to pay attention to the tightening torques. If the pump is already old, it needs to be replaced.

VAZ 2112 pump 16 valves which one to choose

Causes of a dying pump Poor circulation of coolant, extraneous sounds from the timing belt casing Malfunctions of the VAZ pump The causes of breakdowns can be various, for example, the formation of play or jamming of a bearing. It is not uncommon for the impeller to start spinning freely, but separately from the shaft. If the pump is leaking or making noise, then it also needs to be replaced.

From the factory, VAZs are equipped with TZA pumps, which have a long service life.

How to distinguish a fake? The pump must be in a high-quality box, inside it is a warranty card with the date of manufacture and stamps and a gasket. There is a holographic sticker on the pump.

Which pump to choose for 124 engine: TZA 21120-1307010-75 or HEPU P625, difference 300r)))))

Comments 47

Hello everyone, installed HERU twice, ran for 90,000 km (two timing belt replacements), the penultimate time installed TZA (seems to be the original), it started leaking after 29,000. Replaced it with Belmag, drove for about 2,000. Total mileage 267,000

Before that I installed a regular tza (2112), the new one had some play, and it started making noise after 15 thousand. Possibly from incorrect belt adjustment. Therefore, I switched to the Priorovsky timing drive

I installed tza powerfull (21126),

TZA does not serve any purpose at all. Hepi have many marriages going through one.

The HEPU drove less than 30 thousand km and began to rattle and leak. delivered TZA Powerfull! at xx it pumps like 2000 rpm!

Give a damn, it’s still some kind of Germany, and not a craft from AvtoVAZ and the surrounding Kulibins.

One of the trucks has covered 75 thousand km, the second one has now covered 30 thousand kilometers

Both are most often counterfeited. Look for the original and preferably Hepu. As for the TZA, depending on your luck, I installed the TZA when replacing it, and it immediately whistled, although I checked it for authenticity. I took Hepu in existential, the original arrived, it works pah-pah-pah. But as already written, even a high-quality pump can easily be killed by an overtightened belt.

Today we will tell you how to choose the right coolant pump, what to look for, and find out what experienced VAZ-2112 owners advise. After diagnosing various forums, we compiled a rating of all pumps that are popular among VAZ-2112 car enthusiasts and compiled a rating that can fully reveal all the advantages and disadvantages of each model.

The video explains how to distinguish an original pump from a fake, and what to look for when choosing this part:

Other verification methods

First you need to remove the plastic cover and the timing belt cover. To remove the upper parts that separate the pulleys from the cylinder block, follow these steps in sequence. This is only possible after removing the camshaft timing belt and pulleys (sprockets and support pulley). Only after this can the pump be disassembled.

To gain access to the bottom cover mounting bolts, remove the right wheel. The pump can then be disassembled. Then follow the same steps as in the previous step. If the pump is installed incorrectly, it will leak. Therefore, it is important to follow the manufacturer's instructions.

Malfunctions in the operation of the pump occur, significant play on its shaft, failure of the seal, wear of the impeller (corrosion or cracking). All these shortcomings lead to the fact that the water pump in the car does not work properly, due to which the engine cooling system does not maintain the required pressure, which in turn leads to an increase in the temperature of the coolant to the boiling point. . You need to buy a new pump and install it in place of the old one.

There are only six main symptoms of a “dying” pump, by which we can say that the pump has partially (or even completely) failed and requires replacement. So, these symptoms include:

Differences in pump production technology

Signs of a fake pump. This is clearly not the famous Gates. That's why we didn't include it in our rating, there are too many fakes.

Pumps are produced with six and seven blades; they differ in manufacturer and technical characteristics. According to various tests carried out, those models with seven blades perform much better during operation than its limited counterpart. Below we will present you with a rating of the five best pumps, the performance of which varies in the same range.

TZA

- Manufacturer: Russia.

- Retail price: rubles.

- The second model that took first place in our rating is a model from TZA. This pump is supplied to VAZ-2112 cars directly from the factory. Despite the fact that the impeller is made of plastic, no contraindications were found for this. It, like its analogue from Luzar, showed high performance during operation and was distinguished by high reliability, quality of manufacture and assembly.

In general terms, in terms of price and quality ratio, TZA wins among VAZ-2112 owners, however, Luzar is not far behind, following in its footsteps.

Water pump HEPU VAZ 16V 2108-21099, 2110-2112, 2113-2115

- We guarantee fast processing of your order during business hours (we work from 11:00 to 20:00, Saturday and Sunday are days off).

- We guarantee reliable packaging of your order (when sending it by Russian Post or transport company).

- We guarantee the fastest possible dispatch of your paid order (within 1-4 business days after receipt of payment).

- We guarantee a refund or exchange for another product (with recalculation) within 14 days from the date of receipt of the order (the product must be in good condition, without traces of installation, delivery costs are not reimbursed).

- We guarantee a free exchange of goods (transportation costs at our expense) if the purchased goods turn out to be defective.

Water pump HEPU VAZ 16V 2108-21099, 2110-2112, 2113-2115

- We guarantee fast processing of your order during business hours (we work from 11:00 to 20:00, Saturday and Sunday are days off).

- We guarantee reliable packaging of your order (when sending it by Russian Post or transport company).

- We guarantee the fastest possible dispatch of your paid order (within 1-4 business days after receipt of payment).

- We guarantee a refund or exchange for another product (with recalculation) within 14 days from the date of receipt of the order (the product must be in good condition, without traces of installation, delivery costs are not reimbursed).

- We guarantee a free exchange of goods (transportation costs at our expense) if the purchased goods turn out to be defective.

HEPU Germany

HEPU's wide production program covers almost all water pumps for European cars and many models of Japanese and Korean passenger cars. HEPU company also produces pumps for Russian cars. HEPU company supplies its products to the conveyors of such automobile manufacturers as AUDI, BMW, MB, OPEL, PORSCHE, RENAULT, SAAB, VOLVO and others.

The latest manufacturing technologies, the shortest delivery times, a rich production program and high quality standards have earned HEPU first place among German manufacturers of liquid pumps. HEPU water pump for your car, you give preference to the quality of the original equipment and can count on reliability.

Possessing a huge modern scientific and technical base, HEPU designs pumps that provide maximum flow and pressure, and the use of materials based on the latest scientific developments allows long-term protection of HEPU from corrosion. Equipped with high quality bearings and hardened spindles, HEPU withstand high axial and radial loads. The use of specially designed seals eliminates fluid leakage.

HEPU antifreeze supplied for cooling systems also provides reliable protection against corrosion and overheating. At the same time, it prevents the formation of limescale. Varieties of this antifreeze meet the requirements of the automotive industry and also have a beneficial effect on the operation of HEPU .

Includes: water pump and gasket.

Source