What front brake discs should be installed on the Lada Granta

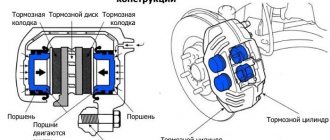

The front wheels of the Lada Granta are equipped with disc shoe brakes. What makes the pedal informative is that it makes it easy to calculate where to stop.

The power reserve with original parts can range from 50 to 120 thousand km. But sooner or later the need for replacement arises.

You can divide all supplied spare parts into two main categories: original and analogues. The former are more expensive. But at the same time, their maximum mileage is usually an order of magnitude greater than their analogues. There is multi-stage quality control in production. The downside is the high cost. Sometimes it is 2-3 times more than analogues.

The latter are distinguished by their availability. But not all parts are reliable. It is best to give preference to well-known brands that have proven themselves on the positive side.

Installing R14 brakes instead of R13

According to the data from the table, you can see that to switch from R13 to R14 brake discs, no modifications are required and the cost of modification is low (buy R14 brake discs and fixed caliper brackets).

Don't forget to check that the rims are at least R14 in diameter. We improve the brakes using the familiar instructions for replacing brake discs.

Most car owners, after installing R14 brake discs, feel a noticeable difference when braking and remain satisfied. However, this is not the limit, the brakes can be made even better!

Original

The advantage is exact compliance with the specified dimensions. After purchasing the part, there is no need to adjust it to size or grind it down:

| Name | vendor code | Cost per 1 piece, rubles |

| AvtoVAZ | 11180-3501012-10 | From 2 thousand rubles |

Various manufacturers can be the manufacturer of original parts of this type for cars. But the products are labeled as AvtoVAZ. The quality is up to the mark. A special alloy of cast iron is used. It is allowed to use pads whose friction linings include ceramics.

Common mistakes when assembling rear brakes

To avoid this problem, pay attention to this slot in the block.

This is where the spacer bar will be inserted.

Error one

If the spacer bar will be installed below this slot, for example, as in the image below.

In this case, you will not be able to put on the brake drum.

Error two

The next mistake concerns the spacer bar itself.

As you noticed, it has a narrow slot on one side and a wide one on the other. So, using a wide slot, the spacer bar is inserted into the block with a lever. You understand that the lever with the block needs a larger opening. If you put the bar the other way around, you won’t be able to put on the brake drum.

Error three

And one more reason that may prevent the brake drum from fitting freely is the brake cylinder. More precisely, not the cylinder itself, but the pistons of the brake cylinder moved apart to the sides.

After all, as the old pads wore out, the pistons in the brake cylinders moved outward more and more. Now that we have installed new ones in place of the old pads, the pistons of the brake cylinders must be returned to their original position, that is, compressed or pressed in. Otherwise, the brake drum may not fit on the new pads.

Methods for compressing rear brake cylinders

Method one. The most common way to compress brake cylinder pistons is shown in this illustration.

Here two mounting blades are used, one side rests against the brake casing and the other against the brake pads. When the blades are compressed, the pads press on the pistons of the brake cylinder and return them to their original position. It's simple.

And if you don’t have mounting blades on hand, what should you do?

Method two. You can use two front brake pads by first drilling through holes in them. This is what the device should look like.

The bolt on top serves as a kind of spacer. Instead, you can use an ordinary wooden block. But even if it is not possible to build such a device, there is another way.

Method three. We take a piece of wood and press the piston through it with a small hammer and light tapping.

The method is, of course, barbaric, but it works.

Analogs

The selection of replacements for original parts includes several dozen items. The highest quality and relatively inexpensive are the following:

| Name | vendor code | Cost, per 1 piece, rubles |

| Alnas Sport, ventilated perforated | 2112-3501070-03 | From 1 thousand rubles |

| Notched, “PowerDisc”ATE | 24.0320-0142.1 | From 1.5 thousand rubles |

| BREMBO MAX | 09.8903.75 | From 1.2 thousand rubles |

Required

- Ventilated brake discs R15 with a diameter of 284 mm. For example, from Kalina sport or Grants sport with catalog number: 11186-3501070-00 or 21905350107077;

- Caliper spacer/bracket (bones), catalog number 11196-3501025 (900 RUR);

- Wheel rims must be at least R15;

- For owners of R13 brake discs, you need to install a fixed caliper bracket from R14 (article: 2112-3501155).

By the way, using this drawing you can make “bones” yourself:

Along with replacing the brake discs, it is recommended to install new brake pads (see which ones are better to choose).

What rear brake discs can be installed on the Lada Granta

Despite the fact that this car belongs to the budget class and is one of the cheapest among those sold in the Russian Federation, it is equipped with rear disc brakes. Which implies the need to replace individual components. The price of parts depends on their type, as well as other factors.

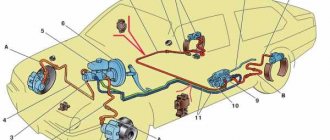

It is important to remember: the front and rear discs differ in the diameter of the mounting holes and other parameters. Installation can be done by yourself. The process itself is simple. But it requires some preparation. It is important to decide on a budget for parts in advance. All of them are divided into two main categories - analogues and originals. They differ in price and quality.

There are many types of discs. These are ventilated, with notches and various others. If the driver practices an aggressive driving style, then you should opt for ventilated models. They cool faster. They have more resources. The replacement process is no different from the others.

Standard set of disc brakes for a car

Some people will think that replacing rear drum brakes on a car is as simple as purchasing a set of front disc brakes and installing them on the rear hub. However, everything is not so simple. The following table will indicate the standard set of disc brakes for the car and the features of each component.

| Accessories | Peculiarities |

| Brake discs | Standard size brake discs may not always fit the rear hub exactly, so hub grooving may be necessary |

| Brake calipers | The location of the calipers on the rear hub will need to be adjusted so that they do not interfere with other rear suspension components. |

| Brake hoses | Standard front brake hoses will not fit due to their length; longer hoses will need to be selected |

| Plates (faceplates) for calipers | This spare part is non-standard, it will be necessary to order manual work to create them |

| Bolts and engraving washers | Standard equipment |

We will not describe the process of replacing the drum brake mechanism with disc brakes. For each individual car model, you can find instructions for this matter on the Internet.

Analogs

The cost of original components is an order of magnitude higher than analogues. Therefore, the choice of many vehicle owners falls on substitutes. The most advantageous offers:

| Name | vendor code | Cost, rubles |

| A.S.P. | 2702220 | 2 thousand rubles. for 1 piece |

| B.M. | BDV 885 | 1 thousand rubles for 1 piece. |

| Hella | 8DD355109331 | 1.6 thousand rubles for 1 piece. |

Grinding noise in the brake drum

At the very beginning of this article, we talked about a cut in the right brake drum that appeared after washing the car or driving through puddles. Upon examination, the cause was identified. The grinding noise was caused by accumulated dirt.

Pay attention to the size of some of the holes through which water should exit.

The holes are almost completely clogged - this is a sign that too much dirt has accumulated. To eliminate the grinding noise that occurs when braking, it is enough to clean the inside of the brake drum from accumulated slag. A regular screwdriver will do for this.

We simply scrape off the coked dirt. Carefully clean the groove located at the rear wall of the brake drum.

But how much slag was in the brake drum.

It was because of this that the unpleasant grinding noise appeared.

Why is there no grinding noise in the left wheel? This is due to your driving style. Many drivers try to drive through any puddle not in the middle, but from the side, if possible, so that the driver's side is outside the puddle. So that if something happens, you can go to “land” and not “to the open sea”. It turns out that the right wheel “bathes in mud” more often than the left one, which is why more dirt accumulates in the right brake drum.

Have you encountered problems when servicing rear brakes, the solution to which is not described in this article? If yes, please share your experience in the comments.

Replacing front brake discs

The replacement algorithm includes the main steps:

- it is necessary to remove the wheel and jack up the car;

- the old brake pads are removed - to do this, the guide bolts are unscrewed and the caliper is folded back;

- The bracket is carefully hung on the suspension, after which you can begin to remove the disk - two nuts are unscrewed;

- if for some reason the disk cannot be removed from the bolts, you need to lightly hit it with a hammer from the reverse side;

- The new disk is carefully installed.

The nuts are screwed into place. It is advisable to pre-lubricate the threads with graphite lubricant. This will prevent souring. It is advisable to change the pads along with the discs.

The better disc brakes

Drum brakes are different from disc brakes. The operating principle of these systems is different. The disc brake system is considered more modern and efficient, as it has a number of advantages:

- higher degree of heat dissipation generated from friction of brake pads;

- the possibility of uniform application of braking forces;

- shorter braking distance compared to a drum mechanism;

- shorter reaction time to force on the brake pedal.

Replacing rear brake discs

The algorithm for replacing rear brake discs is as simple as the front ones. The process is similar. Its main stages:

- it is necessary to remove the wheel to gain access directly to the part - the car is raised on a jack or lift;

- the caliper is removed along with the pads - you can place it side by side or hang it on a spring;

- use an open-end wrench to unscrew two nuts;

- a new disk is installed.

Assembling the caliper, installing the pads - everything is done in the reverse order. It is necessary to ensure that the thickness of the brake disc corresponds to that specified by the manufacturer. If you have difficulty removing the pads, you need to press in the cylinder with a screwdriver. If difficulties arise with unscrewing threaded connections, you need to use WD-40.

Serviceable brake discs affect the driving comfort, vehicle speed and safety. It is necessary to carry out timely inspection and repair of the main components of the brake system.

What you need to switch to disc brakes

The standard kit for converting from drum brakes to disc brakes includes:

- 2 brake discs;

- 2 brake calipers (when purchasing used spare parts, it is advisable to immediately inspect the working area of the piston for scoring (there should not be any); before installation, the caliper must be serviced by replacing the boot and lubricating the areas under the guides);

- 2 brake hoses, as well as brackets and fasteners for their fixation;

- fittings, sealing copper washers, bypass bolts;

- 2 brake shields, which may have places for mounting calipers. If these are not provided, a plan washer is needed. Installing the anchor plate may require longer caliper bolts. If it is not possible to purchase an element, the plan washer will have to be sharpened according to an individual drawing;

- parking brake mechanism (the design of the components depends on the type of brake system you choose);

- The handbrake cable is overwhelmingly not suitable, so it also needs to be replaced.