Tightening torque for main and connecting rod bearings

Engine repair is considered the most difficult thing in a car, because no other part contains such a huge number of interconnected elements. On the one hand, this is very convenient, because if one of them breaks down, there is no need to change the entire assembly; it is enough to simply replace the failed part; on the other hand, the more component elements, the more complex the device and the more difficult it is for those who I'm not very experienced in car repairs. However, with a strong desire, anything is possible, especially if your zeal is supported by theoretical knowledge, for example, in determining the tightening torque of the main and connecting rod bearings. If for now this phrase is a set of incomprehensible words for you, be sure to read this article before getting into the engine.

When is it time to change the camshaft

Emergency intervention in the operation of the VAZ 2114 8 cl camshaft is necessary in the event of any obvious malfunctions. Signs may be different, for example, a knocking sound is heard when the engine is running or problems with the seals. You need to check what’s wrong in such a situation immediately, either yourself or at a service station.

If you determine that the problem is in the seals, then 10 minutes will be enough for you to make a replacement. The oil seals are located in easily accessible places and installing a new one does not require dismantling large systems and components. If you don’t know which one you need to replace, you can check this simply by looking at which one is already installed.

A more complex malfunction may occur if you hear a knocking sound in the engine. This malfunction may not progress, that is, the knocking does not increase, while the readings of all sensors are normal. Some drivers take this calmly; they are not bothered by this state of affairs and continue to use the vehicle without paying attention to it. But the solution is simple: if your engine knocks, it means that the axial play of the camshaft has increased. In this case, you can put a washer between the camshaft and the cover and there is a high probability that the knocking will stop. A fairly simple way out of this situation.

Some cars are equipped with camshaft position sensors, whose task is to signal in case of malfunction or malfunction of the system. But sometimes sensors fail and may need to be replaced. It is inexpensive and the price of such a sensor on the market does not exceed $10, and you can find out which one to buy from the car’s instructions. Installing such a sensor is simple, so there is no point in stopping there.

Sliding bearings, their types and role in the operation of internal combustion engines.

Main and connecting rod bearings are two types of plain bearings. They are produced using the same technology and differ from each other only in the inner diameter (for connecting rod liners this diameter is smaller).

The main task of the liners is to convert translational movements (up and down) into rotational ones and ensure uninterrupted operation of the crankshaft so that it does not wear out prematurely. It is for these purposes that the liners are installed under a strictly defined gap, in which a strictly specified oil pressure is maintained.

If this gap increases, the engine oil pressure in it becomes less, which means that the journals of the gas distribution mechanism, crankshaft, and other important components wear out much faster. Needless to say, too much pressure (reduced clearance) also does not bring anything positive, since it creates additional obstacles in the operation of the crankshaft; it may begin to jam. That is why it is so important to control this gap, which is impossible without using a torque wrench in repair work, knowledge of the necessary parameters that are prescribed by the manufacturer in the technical literature on engine repair, as well as observing the tightening torque of the main and connecting rod bearings. By the way, the tightening force (torque) of the connecting rod and main bearing cap bolts is different.

Please note that the given standards are relevant only when using new sets of parts, since the assembly/disassembly of a previously used unit due to its wear and tear cannot guarantee compliance with the required clearances. Alternatively, in this situation, when tightening the bolts, you can focus on the upper limit of the recommended torque, or you can use special repair bushings with four different sizes, differing from each other by 0.25 mm, provided that the crankshaft is ground until the minimum gap between rubbing elements will not be 0.025/0.05/0.075/0.1/0.125 (depending on the existing gap and the repair product used).

Examples of specific tightening torques for connecting rod and main bearing cap bolts for some VAZ family vehicles.

| Automobile model | Bed cover tightening torque, N*m (kgf.m.) | Tightening torque of connecting rod bearings, N*m (kgf.m.) |

| VAZ 2108 | 69,0–84,0 (6,9–8,4) | 44,0–54,0 (4,4–5,4) |

| VAZ 2106 | 68,31–84,38 (6,97–8,61) | 43,32–53,51 (4,42–5,4) |

| Lada Priora | 68,31-84,38 (6,97-8,61) | 43,3-53,5 (4,42-5,46) |

Replacement procedure

To replace the gasket, it is necessary, first of all, to completely dismantle the entire assembly, remove the seal that has become unusable and reassemble everything in the reverse order. At the final stage, it will be extremely important to tighten the bolts correctly.

The procedure is carried out in the same order for engines with both 16 and 8 valves. First of all, it will be necessary to disable the sensors that control the coolant temperature and oil pressure.

- before dismantling the thermostat, drain all the coolant;

- unscrew the housing protecting the air filter;

- the carburetor is left in place;

- disconnect the exhaust pipe at the muffler, on the side of the exhaust manifold.

After all this, you will need to remove the drive gear from the camshaft. Before this, the piston located in the first cylinder must be moved to top dead center (TDC).

Only after this is it possible to remove the casing and the drive belt itself, loosen the bolts securing the gear and remove it completely.

Now comes the turn of the electrical cables. In order to remove the block with the ignition wires, you will need to press the latch. The central high-voltage loop is switched off in the same way.

Next, you need to remove the fuel hose coming out of the pump - here you will need to disassemble the clamps holding it. Then the traction of both the air and throttle valve drives from the carburetor is disconnected.

You should also de-energize the solenoid valve - to do this, just disconnect all the wires leading to it. After this, remove the hose from the vacuum booster. The sleeves that supply heat to the interior are completely removed.

engine assembly for VAZ 2108, VAZ 2109, VAZ 21099

1. Clean carbon deposits along the edges of the cylinder block beds. Clean the oil grooves in the beds from deposits.

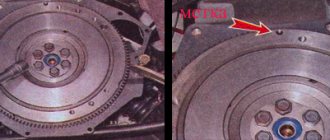

2. Install the main bearing shells in the cylinder block bed in accordance with the marks made when disassembling the engine. Attention: middle liner 1 without groove. When installing the liners, their locking lugs must fit into the grooves of the beds. Lubricate the bearings with engine oil.

Step-by-step scheme of work

The procedure and torque for tightening the cylinder head of a VAZ 2109 with various types of engines was initially established at the manufacturer’s factory and written in full and step by step in the book. According to the diagram, the procedure for pulling the cylinder head of a VAZ 2109 should be done with 2 central bolts.

How to properly tighten the cylinder head of a VAZ 2109:

- First, the screws are twisted with a mandatory force of 2 kg/cm, which is measured in Newtons. The next step is to tighten the screws with an important torque of 7.5 to 8.5 kg/cm. Subsequently, the screws are tightened 90 degrees.

- Next, after the previously completed work, it is necessary to make one more turn of each individual bolt by 90 degrees.

VAZ 2108 | Gap between connecting rod bearing shells and crankshaft | Lada Samara

4 – scale for calibrated wire

The gap between the liners and the crankshaft journal can be checked by calculation (by measuring the parts) or with a calibrated plastic wire.

The nominal installation gap between the liners and necks is 0.036–0.086 mm. If the gap is no more than the maximum permissible for wear of 0.1 mm, then these liners can be installed without changing the diameter of the connecting rod journals.

If the gap is greater than the maximum permissible for wear of 0.1 mm, the bearing bushings should be replaced with repair ones (table. Sets of bearing shells of repair sizes and repair dimensions of the crankshaft journals) and grind the connecting rod journals according to the data on the repair dimensions of the crankshaft (see subsection 4.8.5.3).

If there are deep marks on the working surface of the liners or they are too worn, the liners should be replaced with new ones. It is recommended to replace the connecting rod bearing shells at the same time as replacing the piston rings. This will avoid repeated repairs, and most importantly, it will improve the operating conditions of the crankshaft connecting rod journals and significantly increase their service life. Main bearing shells are usually replaced after a significant mileage of a car whose engine has previously undergone one or two routine repairs. The liners are replaced without any adjustment operations and only in pairs; replacing one liner from a pair is unacceptable. When installing the liners, you need to ensure that the locking protrusions at the joints fit tightly into the corresponding grooves of the cylinder block, main bearing caps, connecting rods and their caps. After replacing the connecting rod or main bearing shells, the vehicle speed should not exceed 60 km/h within 1000 km.

Step-by-step scheme of work

The procedure and torque for tightening the cylinder head of a VAZ 2109 with various types of engines was initially established at the manufacturer’s factory and written in full and step by step in the book. According to the diagram, the procedure for pulling the cylinder head of a VAZ 2109 should be done with 2 central bolts.

How to properly tighten the cylinder head of a VAZ 2109:

- First, the screws are twisted with a mandatory force of 2 kg/cm, which is measured in Newtons. The next step is to tighten the screws with an important torque of 7.5 to 8.5 kg/cm. Subsequently, the screws are tightened 90 degrees.

- Next, after the previously completed work, it is necessary to make one more turn of each individual bolt by 90 degrees.

see also

“Peter - AT” INN 780703320484 OGRNIP 313784720500453

Design nuances

The 21179 engine bears little resemblance to the basic version 21127, as both the design and appearance have changed:

- phasing of intake valves within ±30 degrees;

- hollow camshafts with cams using powder metallurgy;

- vortex air supply into the combustion chamber;

- cylinder cooling system (jacket);

- improved configuration and cylinder head gasket volumes;

- ShPG Federal Mogul;

- Korean pump;

- inclined drilling of oil channels in the crankshaft journals;

- polymer cylinder head cover and solid aluminum pan;

- flywheel for clutch 215 mm, which is recommended by the manufacturer.

Motor gaskets

ShPG from Federal Mogul

GC1–6

The crankshaft has an increased crank radius.

The working volume of the cylinders has increased due to the larger piston stroke. The crankshaft has an increased crank radius. The working volume of the cylinders has increased due to the larger piston stroke. Adjusting the phases required upgrading the lubrication system. Main bearings with an oil distribution groove of variable cross-section are installed to reduce oil consumption. For the first time, a foreign-made oil pump appeared on a VAZ engine - the South Korean GMB. The productivity of domestic pumps is 34–38 l/min at an engine speed of 6000 rpm, and GMB produces 54–60 liters. The pump body is aluminum, not cast iron. The cross-section of the oil intake is, of course, increased. The aluminum engine sump has a flange to mate with the clutch housing, which increases the rigidity of the power unit. The oil sump volume is 4.4 liters versus 3.2 liters for the 1.6 engine.

The water pump is also Korean, with high-quality bearings and seals that guarantee reliability. It is better than the serial VAZ ones: among other things, higher performance. The plastic intake module is made by the Tolyatti company Motor-Super. The gas-dynamic characteristics of the intake tract are optimized for the new engine. The developed fins of the module made it possible to reduce noise. The engine control system does not work with mass air flow readings, but calculates parameters through temperature and pressure. Therefore, the intake module has a slot for the corresponding sensor.

Birth pangs

The VAZ-21179 engine did not appear out of nowhere. The entire previous history of its emergence is a series of active design work and periods of oblivion. It all started in the early 2000s with plans to create a new model at VAZ, belonging to class “C” - the “Silhouette” project. A heavier car required a more powerful engine.

The existing 16-valve 1.6-liter engines were not suitable for this purpose. It should be said that in the line of VAZ engines there was a power unit with a volume of 1.8 liters. We are talking about unit 2130, which was installed on all-wheel drive vehicles: the five-door Niva and the Nadezhda minivan.

However, it was designed exclusively for “tractor” traction and had a power of only 85 horsepower. Therefore, they began to develop a new engine for the Silhouette project. Then management plans changed, and the developments were archived.

In 2008, they returned to the previous idea again, but they decided not to attempt a completely new unit, but to limit themselves to a deep modernization of the old 1.6-liter due to a lack of funding. One of the planned innovative solutions was the use of a variable valve timing system.

Since VAZ engineers had no experience in this area, it was decided to enter into a contract with the English concern Ricardo, which has the necessary competencies, to carry out calculation and research work. Also, at one time, thanks to cooperation with Porsche, a rather successful engine for the V8 was created, which became the prototype for all subsequent front-wheel drive models.

Work was stopped several times, then resumed again, as VAZ, like the entire Russian economy, was going through difficult times. And suddenly, completely unexpectedly, in March 2016, a new VAZ engine with the index 21179 was put into mass production.

Can't we stand on the price?

The cylinder block (BC) is the most labor-intensive part, requiring a significant amount of metal-cutting, mainly automatic equipment. Its replacement or modernization requires huge financial investments. Therefore, when designing the engine, an emphasis was placed on the maximum use of serial parts in the design, primarily such labor-intensive parts as the BC.

What would it mean, for example, to replace a cast iron block with an aluminum one? This would entail a revision of the entire technological chain: instead of existing foundry lines, it would be necessary to purchase expensive injection molding machines. How will this affect the cost, and therefore the selling price? After all, aluminum is more expensive than cast iron.

Application

At first, only front-wheel drive Lada Xray crossovers were equipped with the VAZ-21179 engine, then they began to install it on the Lada Vesta sedan. The popularity of the internal combustion engine continues to grow along with its demand - we have already mentioned AvtoVAZ’s plans to equip the all-wheel drive Lada Niva with this engine. It is possible that the expected all-wheel drive version of the Lada XRay will receive this engine corresponding to the “crossover” class, which will be quite appropriate for Largus, Kalina and Granta.

As the developers of the VAZ-21179 say, in this engine they combined many of their technical ideas, but not all of them. So, the prospects are the brightest, the VAZ-21238 is on the way - the same VAZ-21179, but with two phase shifters, which will seriously change the characteristics of the engine, and for the better.