1. Drain the engine coolant

2. Remove the ends of the high-voltage wires from the spark plugs.

3. Remove the cylinder head cover

4. Remove the camshaft pulley

Cap bolts are available with the camshaft installed, but require a socket wrench with a special head. The cylinder head can be removed along with the receiver and exhaust manifold. But if the head is removed for repairs, it is better to disassemble it first

5. Remove the thermostat housing from the cylinder head studs

6. Unscrew the nut and bolt of the upper fastening of the rear timing belt cover

7. Using a Togx E14 wrench, unscrew the 10 cylinder head bolts evenly in several steps.

8. Carefully move the rear timing belt cover to the side and remove the cylinder head.

9. Remove the cylinder head gasket and remove the two guide bushings from the seats.

1. We wash the cylinder head from dirt and deposits with kerosene or diesel fuel.

2. Using a medical syringe or blower, remove the remaining oil and coolant from the threaded holes in the cylinder block (for the cylinder head bolts.

3. We clean the mating surfaces of the cylinder head and cylinder block from the remains of the old gasket, and degrease the surfaces with a solvent.

Always use a new gasket when installing the cylinder head. Oil should not come into contact with the gasket surface.

4. Install the head guide bushings into the slots in the cylinder block.

5. We put the gasket on the cylinder block, while the guide bushings should fit into the corresponding holes in the gasket.

6. Install the head onto the cylinder block. By slightly moving the head from side to side, we make sure that the guide bushings fit into the corresponding holes in the head.

Reuse of cylinder head bolts is only permitted if their length does not exceed 135.5 mm.

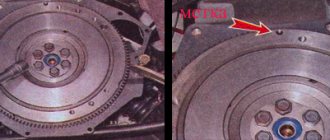

Bolt tightening sequence

8. Before screwing in, moisten the threaded part of the bolts in engine oil, then let the oil drain after about half an hour.

9. Install the bolts and washers into the head holes.

10. Using a torque wrench, tighten the head bolts (in the sequence shown in the photo) in four stages:

— tighten the bolts to a torque of 20 Nm (2 kg-m);

- tighten the screws to a torque of 69.4 - 85.7 Nm (7.1 - 8.7 kg);

— turn the bolts 90*;

— turn the bolts 90* again.

11. Further assembly is carried out in the reverse order of removal.

To perform the work, you will need a special template or a wide forging ruler, a set of flat feeler gauges - a device for lapping valves, and lapping paste.

1. Remove the cylinder head

2. We clean the block head from dirt and carbon deposits, rinse it from oil deposits, and remove carbon deposits from the walls of the combustion chambers with a wire brush.

3. Carefully inspect the cylinder head. There should be no cracks on them. The working surfaces of the camshaft bearings and the walls of the thrust holes must be free of scratches and traces of metal coating. The valve guides and seats must fit snugly against the cylinder head body, with no signs of displacement during valve timing. Valves and their seats must not have cracks or burns.

4. Check the flatness of the head.

This requires a special pattern, but if it is not there, the lower plane of the head attachment can be checked with reasonable accuracy using a wide blacksmith's ruler.

The template (ruler) is applied with its edge to the mating plane diagonally to the head.

Make sure that there is no gap between the edge of the template (ruler) and the plane of the head. The gap can be observed both in the central part of the plane and along its edges. Distance measurement is carried out along both diagonals using a set of flat probes.

The maximum permissible distance is 0.1 mm.

If the gap is greater than permissible, the head must be replaced.

5. Check the tightness of the block head. To do this, close the window for supplying coolant to the thermostat with a plug on the end surface of the head.

6. Turn the head upside down and fill the internal cavities for coolant with kerosene.

7. Make sure that kerosene does not leak from the block head.

If the kerosene level in any of the chambers drops, it means that one or both valves are leaking.

If a leak is detected, the cylinder head must be repaired or replaced.

Lada Granta valve grinding

1. Remove the valve stem seal

2. Remove the valve from the guide sleeve.

3. Apply lapping paste to the valve edge.

4. Install the valve into the block head and attach the valve grinder to the valve stem.

5. While pressing the valve against the seat, rotate it from side to side. After 10-15 movements, turn the valve 90 * and continue grinding.

6. Lapping is carried out until a uniform ring mark is formed on the valve plate.

7. Remove any remaining lapping paste from the valve and valve seat.

8. Grind the remaining tubes in the same way.

9. After grinding in, recheck the tightness of the valves

10. If the kerosene does not disappear, install new valve stem seals and valve in the reverse order of removal.

Experts consider the VAZ 11186 engine as a modernization of the 21114 engine, a minor modification of the 21083, or an improvement in the characteristics of the 11183 internal combustion engine. The first option is considered more correct, since the design of the 11186 and 21114 are absolutely identical, with the exception of the pistons. Engine 11186 is equipped with AvtoVAZ products, and the previous version of the internal combustion engine was equipped with pistons produced by Federal Mogul (USA), which developed it under a contract with the Volzhsky Automobile Plant.

Design Features

By default, the 11186 engine retains all the design features of the original 21114, from which it originated:

- volume 1.6 l;

- the block height is 2.3 mm greater than that of 2110;

- crankshaft with an increased crank radius by the same 2.3 mm (piston stroke 75.6 mm, respectively);

- ShPG, flywheel and crown from 2110.

In addition, a feature for the 11186 engine is the bending of the valves on the pistons when the timing belt drive breaks:

- the piston skirt is reduced here to make it lighter;

- It is physically impossible to make a deep hole for the valve inside the piston.

The manufacturer's manual contains a description of the components and parameters of the internal combustion engine, which are most often compared with the characteristics of the 11183 engine, which has the most similar markings. The main differences between these power drives from the same manufacturer are:

- torque is 15 Nm more;

- power 87 l. With. instead of 82 l. With.;

- motor 11186 has been produced since 2011, and its predecessor 11183 since 2004;

- instead of serial pistons from 2110 weighing 350 g, a lightweight version 21116 weighing 240 g is used;

- connecting rod length increased from 121 mm to 133.32 mm;

- the piston skirt has a graphite coating, the metal in the area of the first ring is anodized;

- combustion chamber 30 cm 3 instead of 26 cm 3;

- compression ratio increased from 9.6 to 10.5;

- The cylinder head gasket is all-metal, its thickness has been reduced from 1.2 mm to 0.43 mm;

- the cylinder head is 1.2 mm higher to compensate for the enlarged combustion chamber;

- the diameter of the bolts was reduced from M12 to M10 to reduce cylinder deformations during tightening;

- the flow channels in the cylinder head have been increased in diameter, nozzles have been installed to cool the piston heads;

- the working chamfer under the valves is maintained longer due to the strengthening of the aluminum alloy using a special technology;

- since the holes in the pistons are not enough to ensure the safety of the valves, a high-strength timing belt from the Gates manufacturer is used;

- the camshaft V-belt received an automatic tensioner, which had not previously been used in VAZ engines;

- the piston system is protected externally from overheating by a cooling jacket integrated into the cylinder block;

- the length of the receiver channels has been increased, the characteristics of the internal combustion engine are close to those of a 16 valve engine;

- the catalytic collector has a flattened block, which made it possible to separate the ducts and get rid of power losses and turbulence;

- the generator is mounted on a bracket, so its drive belt is not overtightened, like 11183, and lasts longer;

- The cabin heat exchanger and expansion tank are included in the thermostat in parallel, the operating error has decreased to 2 degrees instead of 5 degrees.

This is interesting: Removing the heater fan Lada Granta

Why do you need a cylinder head gasket?

The gasket installed between the cylinder block and the cylinder head can be made of various materials: aluminum, copper, paronite and others. Regardless of the material, it performs one function - it ensures tightness between adjacent elements.

The cylinder head gasket operates under difficult conditions, both temperature and chemical. The engine temperature, depending on the time of year and operating mode, is constantly changing. In winter, when parked, it can drop to minus values, and in summer it can rise above several hundred degrees Celsius. In addition to constant temperature changes, the cylinder head gasket is affected by aggressive liquids - antifreeze and engine oil.

Due to severe operating conditions, the cylinder head gasket may fail, and most often it will break down. In such a situation, there is only one way to solve the problem - a complete replacement of the cylinder head gasket.

Instructions for tightening cylinder head bolts

As mentioned above, we use exclusively a torque wrench to tighten the cylinder head. It is impossible to tighten the cylinder head with the required force with open-end or ring wrenches, even if you use additional tools, a crowbar or a pipe.

How to properly tighten the cylinder head bolts?

The dynamometer located near the handle shows how much force was applied when tightening, and this requirement must be met accurately. A slight deviation from the requirements is allowed, about 0.5 kg/m.

After you take the torque wrench, remember the second requirement - the order in which the cylinder head bolts (nuts) are tightened. The order is a certain scheme that must be strictly followed.

The central nuts (bolts) are tightened first, and then we gradually move to the edge of the cylinder head.

There are several head tightening patterns, and all of them are correct. The main thing is to follow the “iron” rule: tighten the bolts (nuts) in pairs from the center to the edges. And don’t try to tighten it completely right away, as this can warp the head. Tighten in three stages: first tighten the bolts (nuts) slightly, then tighten them strongly, and then finally tighten them firmly. For the first tightening, set the key dynamometer to 3 kg/m, then more. The intermediate puff should be “sounded” by a characteristic crackling sound. This sound means that the nut (bolt) is tightened correctly. Experienced mechanics recommend tightening bolts (nuts diagonally).

After this, finally tighten the cylinder head, and the engine can be operated. The torque wrench is set to the maximum position required by the repair manual for the vehicle.

Important! After the clicks, during final tightening, you cannot pull the bolts (nuts) any further! This will lead to thread failure

Cylinder head and valve mechanism (eng.) (disassembly, repair, replacement of cylinder head gasket)

After tightening the cylinder head, let it settle. In order not to waste time, you can still screw on the manifold and other equipment removed during disassembly, tighten the chain, etc. After waiting 30-40 minutes, take a test puff.

The fact is that the gasket, which is placed between the cylinder head and the engine block itself, tends to “shrink,” that is, fill the irregularities and grooves that are on the surfaces of the cylinder head and the block, although they are not noticeable to the naked eye. If you ignore the control tightening, then in the near future the gasket will “squeeze through”, and the engine repair will have to be repeated.

And further! After a short run on the repaired engine (no more than 100 km), you should tighten the bolts (cylinder head nuts) again; this must be done, because “when it’s hot,” that is, when it warms up, the gasket may “shrink” again.

That's all the instructions that will help the car enthusiast independently tighten the car's cylinder head. The main thing is not to confuse the tightening sequence and avoid jerking when operating the torque wrench.

If you follow our advice, tightening your car's cylinder head will be quick, save you money (you won't have to go to a service station) and ensure long and reliable operation of your car's engine.

Something else useful for you:

Advantages and disadvantages

The main advantage of the motor is the fact that the manufacturer has already managed to increase the power to 64.2 kW. In addition, it is possible to boost the motor without loss of service life. That is, the owner will not have to make major repairs more often than scheduled.

The disadvantages of ICE 11186 are:

- “meeting” of the piston with the valve in the event of a break in the timing belt drive;

- periodic valve adjustment;

- non-repairable ignition unit.

The advantages of the engine in comparison with the existing versions of the internal combustion engine of the AvtoVAZ manufacturer at the time of its creation are:

- do-it-yourself overhaul after the piston group has reached the end of its service life at least 3 times using different repair kits;

- increased volumes of combustion chambers;

- built-in piston cooling system;

- the hinged one is secured with brackets and has automatic tensioners;

- modernization of the cylinder head and crankshaft;

- piston and crankshaft relief;

- use of parts from existing engines.

Therefore, during repairs and tuning there are no problems with spare parts and components. Maintenance is cheaper than foreign-made engines.

Which is better: 8 or 16 valve engine system?

The engine type should be selected taking into account the operating conditions of the vehicle.

Comparisons should be made based on the way the car is used, driving style, and the availability of funds for repairs. From the point of view of repairability, engines with 8 valves are considered the best. Their main advantage is the quick start of the engine and low fuel consumption. Such units are most often purchased for driving around the city. Moreover, the main reason why the choice falls on these engines is that if the timing belt breaks, the valve system does not fail. This is ensured by the presence of cavities in the engine structure, where the valves fly off in an emergency situation associated with a rupture of the timing belt. The 8-valve Granta cannot boast of low noise levels in the cabin from a running engine. Perhaps these are all the disadvantages.

As for the Lada Granta car with a 16-valve engine system, it is best suited for driving over long distances. With such engines you can develop a decent speed, which is a plus compared to the 8-valve option. Also, the noise from the engine will not interfere when driving at high speeds. As for the disadvantages, to increase driving speed, such engines use a lightweight piston system. This means that the piston of a 16-valve system is shorter than that of 8-valve cars. Simply put, it lacks the space needed to keep the piston from making contact with the valve if the timing belt breaks. The Granta with air conditioning is the same.

Thus, the following conclusions can be drawn:

- Choosing a car valve system is an individual decision for each car enthusiast.

- If you monitor the condition of the car's working components, you can avoid major repairs, the cost of which is comparable to buying a new engine, and at the same time safely drive a 16-valve engine.

- In all other cases, it is recommended to purchase a car with 8 valves. Reviews of the Lada with this configuration can be obtained from owners of domestic cars.

How to adjust valves on a VAZ-21099

The frequency of such a procedure depends solely on how much your car needs it. The fact is that there are a huge number of domestically produced cars that do not require valve adjustment even after 100 thousand kilometers. But as soon as you hear a knock coming from under the valve cover, which appears mainly on a well-warmed-up engine, or the car engine refuses to start at all, there is a high probability that the reason lies precisely in the incorrectly set gap between the valve tappets and washers .

And now we bring to your attention the entire list of tools necessary to adjust the valves on the Lada Granta on your own:

- socket head (diameter 10) with ratchet or wrench;

- tweezers (needed to remove old washers);

- probes from 0.05 to 1 mm;

- adjustment device (suitable the same as for the VAZ-2108);

- shims (these must be purchased after the current gap has been measured).

By the way, on a Lada Granta engine with 8 valves, experts strongly recommend adjusting them after it has run 25 thousand kilometers. First of all, this action is necessary to significantly increase the efficiency of the engine.

Lada Granta valve: main faults

Even taking into account the fact that the internal combustion engine of the Lada Granta 21116 is not the most complex unit structurally, certain problems associated with certain engine malfunctions may still arise during operation.

Main malfunctions and methods for their elimination:

- The occurrence of knocks and noises. The problem is misaligned valve clearances or defects in the pistons, connecting rods or crankshaft main bearings. The problem is eliminated by adjusting the gaps by repairing or replacing damaged parts;

- The occurrence of floating idle speed. The problem is related to a failure in the electronic throttle control system “E-gas”, namely the failure of its sensors. The malfunction is determined by testing the system and replacing the sensors;

Common mistakes when tightening the head

Please note that mistakes made during installation of the cylinder head can lead to damage to the head itself and the cylinder block. Also, after the start of operation of the internal combustion engine, serious malfunctions may appear that can quickly damage the engine. In some cases, the power unit may suffer so much that it requires major repairs or replacement of such a motor with a contract engine. In the list of various errors that lead to undesirable consequences, it is worth highlighting separately: overtightening the bolts, getting engine oil into the holes for installing fastening bolts, working with unsuitable or worn attachments on a torque wrench, violating the order of bolt tightening, using bolts that do not fit size.

Quite often, the hole for the mounting bolt in the cylinder block becomes clogged with dirt, rust, etc. Attempts to clean the hole do not always yield positive results. As a result, it can be very difficult to tighten the bolts with the proper torque. For this reason, the bolt threads are lubricated with oil. In this case, it is forbidden to pour oil into the hole itself to improve lubrication. Such actions can lead to the fact that the threaded well simply collapses after tightening the bolt. In such a situation, the cylinder block will need to be repaired or even replaced.

An attempt to tighten the cylinder head without using a torque wrench can also cause problems. In this case, the tightening torque is often exceeded. The consequences can be very different, but often the head bolts break, after which it becomes necessary to disassemble the engine again to remove debris and repair the cylinder block.

Bolts for tightening the cylinder head usually have a hex head, less often they are made in the form of a square. If the nozzle is worn out, then there is a risk of it turning during tightening. As a result, the edges of the bolt head “lick off”. In such a situation, the damaged fastener is difficult to tighten or unscrew for replacement. Regarding the selection of bolts, it is necessary to additionally take into account some features. In many repair manuals you can find information that bolts can be reused. As practice shows, it is optimal to replace fasteners with new ones after each cylinder head removal.

The fact is that after tightening the bolt becomes a little longer, that is, it stretches out

For this reason, you should pay attention to the maximum permissible bolt length, which should be specified in the instruction manual. If there are no new bolts, then before installation it is necessary to measure the existing fasteners

In the case when the bolt turns out to be slightly longer than the maximum permissible value, then it stops at the bottom of the hole in the cylinder block. The result is either a broken bolt or a split in the cylinder block itself.

Finally, we will add that it is possible that working fluids from one system enter another (for example, antifreeze gets into the oil channels). Malfunctions of this kind are quite serious, since disruptions in the normal operation of the lubrication or cooling system lead to overheating of the internal combustion engine, accelerated wear of rubbing parts, engine jamming, etc.

How to independently determine that the cylinder head gasket has burned out. Recommendations for pulling the cylinder head after replacement. Which gasket is better to choose?

Main and connecting rod bearings: purpose, design and operating features of plain bearings. How to tighten liners correctly, tightening torque.

Why and when does the cylinder head need to be ground? How to check the mating plane of the block head with your own hands. Milling and grinding of cylinder head.

Purpose of the cylinder head of an internal combustion engine. Materials and manufacturing method, features of fastening the head to the cylinder block, components of the cylinder head.

Do-it-yourself removal of the engine cylinder head in a garage: preparation and removal of the cylinder head. How to remove the head if it is stuck. Useful tips.

Purpose of the cylinder block in the design of the internal combustion engine. Varieties, materials and manufacturing methods. Advantages and disadvantages of blocks made of cast iron and aluminum.

What cars was it used in?

Created in 2011, the 11186 engine is used as a power drive for several models of the auto manufacturer AvtoVAZ:

- Lada Kalina II – station wagon, sedan;

- Lada Granta (Lux and Norma equipment) – liftback, sedan;

- Lada Priora – sedan, station wagon, hatchback;

- Lada Largus – minivan, station wagon, van;

- Lada Vesta - station wagon;

- Lada XRay is a compact crossover/high hatchback.

Improved engine characteristics allow it to be used on any front-wheel drive car in the event of a swap rather than engine tuning.

This is interesting: Unloading and loading refrigerant from the Lada Largus air conditioner

Video “What to do if the gasket between the cylinders burns out”

This video shows the burnout of the gasket between the cylinders of a Lada Kalina with an 8 cl power plant. This material will also be necessary for those who have a problem with the cylinder block gasket. It shows many of the steps and techniques required not only to install a new gasket, but also to maintain this unit in working order. Remember that, first of all, in order for this unit to serve you for a longer time, it is necessary to comply with and carry out on time all service measures specified by the manufacturer.

Maintenance

In accordance with the manufacturer's regulations, engine 11186 must be serviced in the following order:

| Oil consumption | maximum 1 l/1000 km |

| Engine oil for 11186 | 5W-30 and 10W-30 |

| Engine oil volume | 3.5 l |

| Operating temperature | 95° |

| Motor life | stated 150,000 km |

| Adjustment of valves | washers between camshaft cams and tappets |

| Cooling system | forced, antifreeze/antifreeze |

| Coolant quantity | 7.8 l |

| water pump | polymer impeller |

| Candles for 11186 | BPR6ES, A17DVRM |

| Gap between spark plug electrodes | 1.1 mm |

| Timing belt | 163 teeth, pitch 8 mm, belt width 26.7 mm |

| Cylinder operating order | 1-3-4-2 |

| Air filter | Nitto, Knecht, Fram, WIX, Hengst |

| Oil filter | catalog number 90915-10001 |

| Flywheel | from 2110, steel crown placed on a cast iron body |

| Flywheel mounting bolts | MT box – M10x1.25 mm, length 26 mm, groove 11 mm |

| Valve stem seals | code 90913-02090 light inlet |

| Compression | 13 bar |

| XX speed | 650 – 750 min -1 |

| Tightening force of threaded connections | spark plug – 18 Nm |

| Maintenance object | Time (year) or mileage (1000 km), |

which comes first

This is exactly the frequency of maintenance that the ICE 11186 device is designed for.

Reviews

| № | Positive |

| 1. | Alexander: in two years of using the car I have never changed anything. I carry out prevention systematically, as prescribed by the instructions. I believe that a moderate driving style, high-quality oil, and original parts can work wonders. |

| 2. | Kirill: at 65,000 km I tightened one rod because it started to click when it was “cold”. I haven't changed anything until now. Everything is original installed. |

| 3. | Vasily: I replaced the timing belt in a year and a half. I thought it would be difficult, but it turned out to be the opposite. I recommend that motorists carry out preventive maintenance on their own. |

| 4. | Gennady: adjusting the valve clearances on Grant is not easy, but I was able to do it myself, without outside help. Instructions and video tutorials on the Internet are always at hand. |

| 5. | Ignat: after a year of using the car, the valves began to knock. At the service station the technician said that there was no need to change it, they limited themselves to tightening it. I still ride, no complaints. |

| 6. | Vladislav: for three years of using the car, I installed all the spare parts myself and did not contact the service center. Which is what I recommend to other Grantmakers. There were no major breakdowns, they were so insignificant. Fuel and oil filters don't count. |

| Negative | |

| 1. | Victor: My timing belt fell off within the first year after purchase, which turned out to be unexpected. I installed the new one myself, the process is not complicated. |

| 2. | Ivan: at 45,000 the valves began to knock, so I took it to the service station. The master said that the second and third valves were defective. Replaced with new ones. Buy Lada Granta in 16 cl. |

| 3. |

Malfunctions: causes, elimination

Like all internal combustion engines with mechanical adjustment of valve clearances, the 11186 engine requires periodic adjustment of this characteristic. In addition, during operation, characteristic “diseases” of this particular version of the power drive were identified:

| Timing belt | 3/50 |

| battery | 1/20 |

| Valve clearances | 2/20 |

| Crankcase ventilation | 2/20 |

| Belts that drive attachments | 2/20 |

| Fuel line and tank cap | 2/40 |

| Motor oil | 1/10 |

| Oil filter) | 1/10 |

| Air filter) | 1 – 2/40 |

| Fuel filter) | 4/40 |

| Heating/Cooling Fittings and Hoses | 2/40 |

| coolant | 2/40 |

| Oxygen sensor | 100 |

| Spark plug | 1 – 2/20 |

| Exhaust manifold | 1 |

| Bend valves | broken timing belt | periodic wear monitoring |

| Ignition system interruptions | failure of the corresponding block | replacing the ignition module |

| Increased oil consumption | development of main liners |

stuck piston rings

When repairing piston and crankshaft engines, it is recommended to use original components from the AvtoVAZ manufacturer. Because only he uses special technologies for strengthening structural materials. From third-party companies, the metal may be “raw”; the resource of such consumables cannot be analyzed.

Diagnosis of malfunction of the gas distribution mechanism

The process of diagnostics and identification of the source of failure is quite complex. Sometimes, without digital equipment, it is impossible to conduct a full inspection and assess the general technical condition of components and assemblies.

- Always go by ear. Feel the motor running. If you hear extraneous, previously uncharacteristic sounds, knocking on “cold” or “hot” - most likely the reason is in the timing belt;

- Pay attention to the level of fuel consumption, acceleration dynamics, and the informativeness of the accelerator pedal. Passivity, poor “responsiveness” are factors indicating a possible breakdown;

Tuning

Initially, the manufacturer builds additional potential into its engines in order to make any changes in future versions. However, the 11186 engine can be upgraded on its own. The following type of tuning is considered standard:

- camshaft - replacement of a standard part with a Nuzhdin 10.93 or Dynamics 108 camshaft;

- cylinder block - boring to 86 - 88 mm (pistons and connecting rods of appropriate sizes will be required);

- intake manifold - zero resistance filter, damper with a diameter of 54 mm, grinding of the internal surfaces of the channels;

- catcollector - replacement with a spider having a 4:2:1 scheme;

- Timing - installation of T-shaped lightweight valves;

- Cylinder head – head milling.

Tuning that adds 30% of power is considered safe (“resource-producing”) for the engine. That is, for 87 hp. With. it will be 29 liters. s., which results in about 115 hp. With. Further tuning becomes dangerous, since the service life will decrease in arithmetic progression. This method is used by athletes, but not by ordinary car enthusiasts.

Thus, the 11186 motor has one significant drawback - it bends the valves. The manufacturer partially corrects the situation through high-life timing belts from Gates. In other respects, the internal combustion engine was superior to its existing counterparts at that time, with the exception of the 21114 engine, which was taken as the basis.

Tools:

- 5 mm hex key

- Ratchet wrench

- Extension

- 8 mm head

- 10 mm head

- 13 mm head

- Torx head E14

- 15 mm straight box spanner

- 17 mm straight box spanner

- Curved box spanner 8 mm

- Torque wrench

- Driver for socket attachment

- 17mm wrench attachment

- Medium flat screwdriver

- Medium Phillips screwdriver

- Screw jack

- Wheel key

- Special wrench for turning the tension roller (or circlip remover)

- A key for fixing the camshaft pulley (or an extension for the end attachment on the wrench)

- Knife (or scraper)

- Funnel

- Universal puller (if necessary)

- Calipers

- Valve adjustment tool

- Tweezers

- Micrometer

Parts and consumables:

- Shoe - 2 pcs.

- Technical capacity

- Coolant

- Head gasket

- Head bolts (if necessary)

- Engine oil

- Shims (if necessary)

- Rags

Notes:

If a leak of engine oil or coolant is detected at the junction of the cylinder head with the cylinder block, remove the head and replace its gasket. A leak can also occur due to warping of the block head due to overheating. The cylinder head gasket of the VAZ 11183 engine is made of metal asbestos sheet, and on the VAZ 21116 and VAZ 11186 engines it is metal. The procedure for replacing the cylinder head gasket on a Lada Granta car on all three engines is the same and is shown using the example of a VAZ 11183 engine. Replacing the cylinder head gasket of a VAZ 21126 engine is described separately.

The cylinder head gasket is a one-time use product, so the gasket must be replaced each time the cylinder head is removed.

1. Set the piston of the 1st cylinder to the TDC position of the compression stroke, then leave the front timing cover removed.

What is a torque wrench used for?

A certain tightening torque on the mating parts is necessary for uniform contact of the planes. In addition, if a gasket is installed along the contour, the uneven force of the bolted connections can destroy it.

A torque wrench allows you to tighten bolts with an accuracy of hundredths of a millimeter. In addition, it is often necessary to perform torque tightening of the bearing seat with high precision.

The manufacturer calculates torque values based on the type of material and design features of the unit. When building a car at a factory, all fasteners are tightened according to specifications: as a rule, this work is performed by assembly robots.

Consequences of retightening the cylinder head bolts

If the threaded connections of the block head are tightened with a force exceeding the nominal force, then the tensile force that acts on the bolt or stud will begin to destroy the threads in the block or pull out the body of the fastener. The so-called yield point occurs, when with a further increase in the tightening force, the pressing force begins to decrease. Result: rapid burnout of the gasket at the point of worst compression.

If the threads in the holes of the block are severely damaged, then they will no longer be able to provide the necessary pressure on the head at the correct tightening torque. It will need to be restored, and this is an additional cost. Experienced motor repairmen in practice feel the maximum tightening force that a threaded connection can withstand. They will never allow defects from overtightening bolts or nuts.

What happens if you don’t tighten the cylinder head bolts enough?

If the head is fastened with minimal force, this will lead to weak pressing of it to the surface of the cylinder block. Microscopic gaps form between the gasket and the adjacent planes of the block and head, which will certainly lead to burning of the sealing material.

Review of the engine of the VAZ car Lada Granta Liftback

The VAZ-21116 engine of the Lada Granta Liftback car has a displacement of 1.6 liters, eight-valve, based on the VAZ-2111 engine. It has a cylinder block increased in height by 2.3 mm and an original crankshaft.

The cylinder diameter remains the same - 82 mm, the piston stroke is increased to 75.6 mm, in contrast to 71 mm for the base engine. Oil nozzles are installed in the main bearing supports.

Fig. 12. Cross section of the VAZ-21116 engine of the Lada Granta with a volume of 1.6 liters.

1 — oil pan drain plug; 2 — engine oil pan 3 crankshaft; 4 oil filter; 5 - catalytic manifold; 6 — coolant pump; 7 - piston; 8 — oxygen concentration sensor; 9 — laying of the intake pipeline and exhaust manifold; 10 — inlet pipeline; 11 — nozzle; 12 — diagnostic fitting of the fuel rail; 13 receiver; 14 — bracket for fastening the tip of the cable sheath; 15 — cylinder head cover; 16 — camshaft bearing housing; 17 - camshaft; 18 — crankcase ventilation system hose; 19 — valve pusher; 20 — cylinder head; 21 bolts securing the head to the cylinder block; 22 - valve; 23 - candle; 24 — cylinder head gasket; 25 — upper compression ring; 26 — lower compression ring; 27 — oil scraper ring; 28 — piston pin; 29 — fitting for installing the oil level indicator; 30 — connecting rod; 31 flywheel; 32 cylinder block; 33 oil pan gasket; 34 — oil level indicator; 35 - oil intake

The cylinder head of the Lada Granta Liftback VAZ-2190 engine contains one camshaft, eight valves and eight valve tappets with adjusting washers. The camshaft supports are made in the head.

Two camshaft bearing housings are bolted to the upper plane of the head. The gas distribution mechanism is closed on top with a cap with an oil filler neck.

A camshaft position sensor is installed in the cylinder head plug, and a pin is installed at the rear end of the shaft for the sensor to detect the shaft position.

The camshaft and coolant pump are driven by a toothed belt from a toothed pulley mounted on the engine crankshaft. The tension of the belt and the direction of its movement along the pulleys is carried out by a tension roller.

Removing and installing the cylinder head of the VAZ-21116 engine of the Lada Granta Liftback

Work on removing the cylinder head of the Lada Granta:

— Drain the coolant from the engine.

— Remove the tips of the high-voltage wires from the spark plugs.

— Remove the cylinder head cover.

— Remove the camshaft pulley.

— The cylinder head bolts are accessible with the camshaft installed, but a socket wrench with a special head is required.

— The cylinder head of the Lada Granta VAZ-2190 can be removed as an assembly with a receiver and exhaust manifold. But if the head is removed to repair it, then it is better to first disassemble it.

— Removing the thermostat housing from the cylinder head studs.

— Unscrew the nut and bolt of the upper fastening of the rear timing belt cover.

— Evenly, in several stages, unscrew the 10 bolts securing the cylinder head.

— Pulling the rear timing belt cover slightly to the side, remove the cylinder head.

— Remove the cylinder head gasket and remove the two guide bushings from their seats.

Work on installing the cylinder head of the Lada Granta VAZ-2190:

— We wash the cylinder head from dirt and deposits with kerosene or diesel fuel.

— Remove any remaining oil and coolant from the threaded holes of the cylinder block (under the cylinder head bolts).

— We clean the mating surfaces of the head and cylinder block from the remnants of the old gasket, degrease the surfaces with a solvent.

— When installing the cylinder head, always use a new gasket. Oil should not come into contact with the surface of the gasket.

— Install the head guide bushings into the seats of the cylinder block.

— Place the gasket on the cylinder block, and the guide bushings should fit into the corresponding holes in the gasket.

— Install the head on the cylinder block. By slightly moving the head from side to side, we ensure that the guide bushings fit into the corresponding holes in the head.

Work order

Before tightening, you will have to get to the block head. This can be done no earlier than after disassembling a good half of the engine.

First, open the connectors, the connecting wires leading to the antifreeze temperature sensors and the oil level control sensors. Once done, drain the coolant

It is necessary to dwell on this important point separately. Be careful - the composition mentioned above is quite toxic, so it is better to work with gloves

To collect coolant, prepare a container with a volume of at least 9 liters.

To drain the fluid, open the distribution tank, and then unscrew the plug located directly on the cylinder block. When the leak stops, move the container to the radiator - there is a separate drain here. After removing all the antifreeze, screw on the caps.

- remove the thermostat, and behind it the air filter;

- disconnect the exhaust pipe from the manifold;

- Remove the protective housing and the belt from the VAZ camshaft;

- The throttle valve drive cables must be separated from the carburetor;

- remove all cables leading to the cylinder head, as well as tubes, hoses, etc. (be sure to loosen the clamps that secure them, otherwise you won’t be able to move them to the side).

You now have direct access to the head. Unscrew all the bolts holding it, and, using the help of a partner, remove the cylinder head. After this, tear off the old gasket.

Carefully clean the rear surface of the VAZ 8-valve engine block from dirt and adhered fragments of the sealing element material. Sand it with fine sandpaper - you should be left with a completely smooth, matte base.

At the same time, check all valves and seals.

Be sure to remove any oil or debris from the bolt holes. Lubrication helps reduce the friction force, which in this case is fraught with many troubles, and foreign fragments will not allow reliable fastening.

All that remains is to install a new gasket and reinstall the VAZ-2114 cylinder head. This is where the time comes to talk about what tightening torque is required.

Other section materials

| Technical description |

| Vehicle specifications |

| Vehicle registration details |

| Location of controls and instruments |

| Car keys |

| Ignition switch (lock) |

| Front and rear doors |

| Hood |

| trunk lid |

| Fuel filler plug |

| Seats |

| Rear view mirrors |

| Interior lighting |

| Instrument cluster |

| Granta steering wheel adjustment knob |

| Steering column switches |

| Granta headlight beam direction control unit |

| Granta heating and ventilation system control unit |

| Safety precautions during maintenance and repair of Granta |

| Location of the main components and assemblies of Granta |

| Vehicle check |

| Maintenance schedule |

| Checking the condition of wheels and tires |

| Replacing windshield wiper blades |

| Checking the fluid level in the windshield washer reservoir |

| Checking the engine oil level |

| Changing the engine oil and oil filter |

| Checking the level and topping up Granta coolant |

| Coolant replacement |

| Checking the condition and replacing Granta spark plugs |

| Removing the Granta air filter replacement element |

| Replacing the fuel filter |

| Adjusting thermal clearances in the valve drive of the Lada gas distribution mechanism |

| Checking the condition and replacing the generator drive belt |

| Checking the condition and replacing the Lada timing belt |

| Checking the condition of the exhaust system |

| Checking the gearbox oil level |

| Changing the gearbox oil |

| Checking the fluid level in the hydraulic brake reservoir |

| Bleeding the hydraulic brakes Granta (VAZ-11183, |

| Checking the condition of the chassis and transmission |

| Checking the steering condition |

| Checking the condition of the brake system |

| Adjusting the parking brake |

| Replacing the heating and ventilation system filter |

| Adjusting the direction of headlight beams |

| The crankshaft does not turn with the starter |

| Loud noise when the starter is running |

| The crankshaft is turned by the starter, but the engine does not start |

| The engine is running erratically |

Removing and disassembling the cylinder head

We remove the cylinder head to repair or replace it, replace the head gasket, when dismantling the ShPG, as well as when completely disassembling the engine. We carry out the work on an overpass or inspection ditch. Drain the liquid from the engine cooling system (see “Replacing the coolant”). You can remove the cylinder head in two ways: assembled with the intake pipe, fuel rail and exhaust gas manifold, or by first dismantling these parts. We show the second method of removing the cylinder head. We dismantle the inlet pipe (see “Removing the inlet pipe”) and the catalytic collector (see “Removing the catalytic collector”). We disconnect the tips of the high-voltage wires from the spark plugs (see “Checking the condition and replacing the spark plugs”). Remove the cylinder head cover (see “Adjusting thermal clearances in the timing valve drive”). Remove the rear timing cover (see “Replacing the camshaft oil seal”). Disconnect the wiring harness connectors from the coolant temperature sensors (see “Removing the coolant temperature sensor”) and the low oil pressure indicator (see “Replacing the low oil pressure indicator sensor”).

What force and tightening torque should be for the Grant wheel nuts?

The values for the tightening torque of the wheel nuts for this car are indicated above. And the tightening torque of the wheel bolts on the Lada Grant is 105-120 Hm. For cars with a liftback body this value is 70-90 Nm.

Is there a difference in the tightening torque of the front and rear wheels?

The front and rear wheels of the vehicle should be tightened with the same force. This rule also applies to each of the wheel bolts. For them, the tightening torque of the Grant wheels should not be different.

How to tighten Granta wheels to the required torque

To tighten the Granta wheels to the required torque, you will need a torque wrench. It should only be used with a test tightening. At the beginning of the process, you will need a regular spray bottle.

Torque wrench

Before the procedure, the car is placed on a flat, hard surface. To prevent involuntary movement, it must be secured with a hand brake. After installing the wheels, the bolts must be inserted into the mounting holes.

They must be screwed clockwise. The work should be done crosswise. You need to start tightening the bolt by hand. Next, tighten with a wheel wrench with sufficient force.

Tightening is carried out gradually. In this case, it is necessary to control the reliability of twisting by rocking the wheel. When the wheel is already tightened sufficiently, you should finally tighten it with a torque wrench to the required torque.

When using the tool, you must follow the rules:

- A torque wrench is used for control tightening. It should not be used as a regular spray gun.

- The key must be selected so that its maximum force is slightly greater than necessary.

- Before broaching, make sure that the exact tightening torque is known. It needs to be set on the instrument.

- Use a wrench to check the tightness of all bolts in a circle.

Proper use of a torque wrench and precise setting of the torque eliminates under-tightening or over-tightening of wheel elements.

Junsun recorder for Android with GPS and Sim card

More details

Restorer-polish for plastic, rubber and leather

More details

German autobuffers Power Guard. Increase ground clearance, reduce wear.

More details

Radar detector + Recorder for 2 cameras + GPS

More details

Sun protection frame blinds with magnetic fastenings

More details

AvtoShark Store

wheel bolt tightening grant tightening torque rear wheel hub nut tightening torque

Performing the operation without a torque wrench

Since the force is precisely indicated on all of these vehicles, it is impossible to do without a torque wrench when seating the cylinder head. But on some cars it is quite possible to do without it and use ordinary wrenches and an extension socket to tighten it.

Let us immediately note that performing work without special equipment. The tool is allowed only on “old” engines (Moskvich, VAZ of the first models).

A feature of tightening the cylinder head without a torque wrench is the need to “feel” the force applied. Otherwise, the general method of work is the same as using special equipment. tool:

- We tighten all the bolts by hand;

- We do the 1st approach, applying medium force (we try to pull all the bolts with the same force, smoothly and without jerking). Be sure to follow the tightening order;

- We carry out the second approach, increasing the force (in order to more accurately “feel” the force, the key with an increased shoulder should be pulled “toward” rather than pushed “away”);

- We do the third approach with high force (turn until the bolt stops).

One of the options for tightening without a torque wrench is to double tighten the fasteners after completing the 2nd approach.

Since not everyone can “feel” the applied force without the skills, it is better not to use the method without a torque wrench, because the consequences of improperly tightening the cylinder head are quite serious and can lead to very serious damage.

Therefore, before engine repairs involving removing the cylinder head, you should stock up on a special tool, especially since it will not be superfluous and there will always be a use for it.

Tightening the cylinder head

Tightening torques of the main threaded connections of components and assemblies of LADA 2190 vehicles

| Name of fastener | Tightening torque, N m (kgf m) |

| Bottom bolt securing the right suspension mount bracket to the engine | from 60 to 73 (from 6.0 to 7.3) |

| Upper bolt securing the right suspension mount bracket to the engine | from 36 to 43 (from 3.6 to 4.3) |

| Nut of the stud securing the rear suspension support to the body | from 33 to 51 (from 3.3 to 5.1) |

| M12 bolt securing the rear suspension bracket to the power unit | from 58 to 92 (from 5.8 to 9.2) |

| Bolt M10 securing the rear suspension bracket to the power unit | from 33 to 52 (from 3.3 to 5.2) |

| Nut of the stud securing the left suspension support bracket to the gearbox | from 21 to 32 (from 2.1 to 3.2) |

| Left engine mount stud nut | from 33 to 51 (from 3.3 to 5.1) |

| Nut of the stud securing the intake pipe and exhaust manifold | from 21 to 25 (from 2.1 to 2.5) |

| Water pump mounting bolt | from 7 to 8 (from 0.7 to 0.8) |

| Muffler exhaust pipe fastening nut | from 22 to 26 (from 2.2 to 2.6) |

| Nut securing the flange of the additional muffler | from 22 to 26 (from 2.2 to 2.6) |

| Nut securing the clutch housing to the engine block | from 55 to 87 (from 5.5 to 8.7) |

| Bolt securing the clutch housing to the engine block (80mm) | from 55 to 87 (from 5.5 to 8.7) |

| Bolt securing the clutch housing to the engine block (60 mm) | from 55 to 87 (from 5.5 to 8.7) |

| Nut securing the gearbox housing to the clutch housing | from 16 to 25 (from 1.6 to 2.5) |

| Bolt securing the gearbox housing to the clutch housing (90 mm) | from 16 to 25 (from 1.6 to 2.5) |

| Bolt securing the gearbox housing to the clutch housing (85 mm) | from 16 to 25 (from 1.6 to 2.5) |

| Nut securing the upper suspension mount to the body | from 20 to 24 (from 2.0 to 2.4) |

| Bolts (50 and 70 mm) securing the brace bracket to the body | from 58 to 70 (from 5.8 to 7.0) |

| Self-locking nut for fastening the telescopic strut rod to the upper support | from 68 to 81 (from 6.8 to 8.1) |

| Nut of the eccentric bolt securing the telescopic strut to the steering knuckle | from 79 to 96 (from 7.9 to 9.6) |

| Nut of the bolt securing the telescopic strut to the steering knuckle | from 79 to 96 (from 7.9 to 9.6) |

| Nut of the bolt securing the front suspension arm to the body | from 79 to 96 (from 7.9 to 9.6) |

| Nut of the bolt securing the stabilizer bar to the front suspension arm | from 43 to 52 (from 4.3 to 5.2) |

| Self-locking nut for fastening the stabilizer bar to the body | from 13 to 16 (from 1.3 to 1.6) |

| Self-locking nut for fastening the brace to the bracket | from 163 to 176 (from 16.3 to 17.6) |

| Rear suspension arm bolt nut | from 68 to 82 (from 6.8 to 8.2) |

| Nut of a bolt of fastening of a bracket of fastening of levers | from 28 to 34 (from 2.8 to 3.4) |

| Nut of a bolt of fastening of the lower end of the shock-absorber of a back suspension bracket | from 70 to 80 (from 7.0 to 8.0) |

| Nut securing the upper end of the rear suspension shock absorber | from 31 to 37 (from 3.1 to 3.7) |

| Steering housing mounting bolt nut | from 15 to 18 (from 1.5 to 1.8) |

| Steering shaft bracket mounting bolt nut | from 15 to 19 (from 1.5 to 1.9) |

| Steering linkage clamp bolt | from 39 to 47 (from 3.9 to 4.7) |

| Wheel bolt | from 76 to 92 (from 7.6 to 9.2) |

To do this, you need to find the book you are interested in and click on the “Buy” button. The price of the book is indicated on the button.

For residents of Ukraine in hryvnias, and for all other countries - dollars.

After clicking on the “BUY” button, a payment window will open where you can select a payment system with which you can pay for the selected book using any bank card (Visa, MasterCard, MIR, etc.)

When you click on the “Pay by bank card” button, the Portmone payment system will open, which is the easiest way to make a payment.

- Yandex (payment from any bank cards, Yandex Money account, QIWI Wallet, terminals, etc.);

- Portmone (payment from any bank cards, Portmone account);

- PayPal (payment from any bank cards, PayPal account);

- WebMoney (payment from any bank cards, payment from WebMoney wallets).

Engine Lada Granta (VAZ 2190)

Lada Granta engines are gasoline, four-stroke, four-cylinder in-line with overhead camshaft and liquid cooling.

The information is relevant for models 2011, 2012, 2013, 2014, 2015, 2016.

| Basic data for monitoring, adjustment and maintenance | |

| Engine cylinder operating order | 1-3-4-2 |

| Minimum crankshaft rotation speed at idle, min-1 | 840 |

| Pressure in the engine lubrication system at an oil temperature of 85 'C and at a crankshaft speed of 5400 rpm, kPa (kgf/cm2) | 441,3-637,4 (4,5 — 6,5) |

| Minimum pressure in the engine lubrication system at idle speed, kPa (kgf/cm2) | 196,2 (2,0) |

| Oil volume in the engine lubrication system, l | 3,5 |

| Engine oil group according to API. not less | S.J. SL, SM |

| Engine oil viscosity grade according to SAE: | |

| -15 *С - above +45 *С | 20W50 |

| -20 *С — +45 *С | 15W40 |

| -25 *С — +35 *С | 10W40 |

| -25 *С — +25 *С | 10W30 |

| -30 *С — +35 *С | 5W40 |

| — 30 *С — + 25 *С | 5W30 |

| below -35 *С – +30 *С | 0W40 |

| below -35 *С – +25 *С | 0W30 |

| Applicable oil filter | 2108-1012005; 2108-1012005-07; 2108-1012005-08 |

Payment via Yandex Cashier

After selecting payment via Yandex, the Yandex Cashier payment system will launch, where you need to select a convenient payment method (bank card, QIWI, Yandex Money account, etc.)

After specifying payment details and confirming payment, payment for the goods will occur.

If you have a bank card in a currency other than the ruble, then the money will be debited from the card at the rate of the Central Bank of Russia at the time of the purchase.

This payment method is optimal for residents of Russia, Kazakhstan and Belarus.

Payment via Portmone

After selecting payment through Portmone, the payment system will launch, where you need to select the payment method: bank card or Portmone account.

The price in the Portmone payment system is converted into dollars at the exchange rate of the Central Bank of the country where you are located.

If you have a bank card in a currency other than the dollar, then the money will be debited from the card at the rate of the Central Bank of your country at the time of the purchase.

After specifying payment details and confirming payment, payment for the goods will occur.

Payment via PayPal

After selecting payment via PayPal, the PayPal payment system will launch, where you need to select the payment method: bank card or PayPal account.

If you already have a PayPal account, then you need to log into it and make a payment.

If you do not have a PayPal account and you want to pay using a bank card via PayPal, you need to click on the “Create an Account” button - shown with an arrow in the picture.

PayPal will then prompt you to select your country and provide your credit card information.

After specifying the information required to make the payment, you must click on the “Pay Now” button.

How does the part change?

To dismantle the old boot and install a new one, you will need an inspection hole or a lift. Obviously, such devices are not always available at home, so most often you have to use a jack.

Before starting the procedure, of course, you need to purchase a new boot. There is nothing better than the original part, but many modern manufacturers offer quite passable analogues. They often come with matching clamps.

You also need to stock up on the following ingredients and tools:

Payment via WebMoney

After selecting payment via WebMoney, the payment system will launch, where you need to select the payment method: bank card or WebMoney wallet.

If you already have a WebMoney wallet, then you need to log into it and make a payment.

If you do not have a WebMoney wallet and you want to pay in another way, you need to select any of the methods that WebMoney offers and make the payment

After specifying payment details and confirming payment, payment for the goods will occur.

Downloading a book

After successfully completing the payment (by any method) and returning to the KrutilVertel store from the payment system website, you will be taken to the successful payment page:

On this page you need to indicate your e-mail, where access to download the book will be sent.

If you are already registered on our website, then simply follow the link to your personal account.

The book you purchased will be in your personal account, from where you can always download it.

Please note that after making the payment, you need to return back from the payment system website to the KrutilVertel website.

If for some reason you did not return back to the site and closed the payment system tab with a message about the successful completion of the payment, please let us know - we will send you a letter indicating access to download the book.

Comments

TOP materials of the week

TOP products in the store

Your review of the Lada XRAY sound insulation

Lada.Online

Lada (“Lada”) is a brand of cars produced by JSC AVTOVAZ. Previously, it was used only for export cars, and for the domestic market, cars were produced under the Zhiguli brand. In 2004, the management of AVTOVAZ announced the transition to the Latin alphabet for the official spelling of the names of all cars produced by the plant: Lada - instead of "VAZ" and "Lada".

Lada.Online is the largest Russian-language automotive resource with a daily audience of thousands, which is dedicated primarily to cars of this brand, the domestic automotive industry and the automotive world in general.

This site is not the official LADA website.

© 2022 Lada.Online. Copying of material is permitted only with a link to the source.

Problems when paying with bank cards

Sometimes difficulties may arise when paying with Visa/MasterCard bank cards. The most common of them:

- There is a restriction on the card for paying for online purchases

- A plastic card is not intended for making payments online.

- The plastic card is not activated for making payments online.

- There are not enough funds on the plastic card.

In order to solve these problems, you need to call or write to the technical support of the bank where you are served. Bank specialists will help you resolve them and make payments.

That's basically it. The entire process of paying for a book in PDF format on car repair on our website takes 1-2 minutes.