1200 rub. for the photo report

We pay for photo reports on car repairs. Earnings from 10,000 rubles/month.

Write:

Some car enthusiasts are afraid that when the ABS light is on, it somehow affects the operation of the braking system as a whole. They urgently begin to scour the entire Internet in search of an answer to why the ABS light is on and what to do. But don’t panic so much, the brakes on your car should be in perfect order, only the anti-lock system will not work , which, in principle, is not critical, although in some emergency situations it helps a lot. To understand the system, I recommend reading about ABS.

How ABC works

The anti-lock braking system was developed when it became clear that when the wheels suddenly jam, the car loses stability and is difficult to control. Moreover, the quality of braking did not improve, and the car was pretty much carried off the road. Therefore, a system was developed that, by regulating the pressure in the brake system pipes, allows the wheels to turn slightly. This significantly improves vehicle dynamics, allowing the driver to control the vehicle more confidently. But despite its apparent simplicity, this is a rather complex process that requires the coordinated operation of many mechanisms included in the anti-lock braking system. If any of the components fails, a warning lamp lights up on the instrument panel.

You can often hear the question from drivers: “Why is the ABS sensor on?” It is important to know that when the warning light comes on, it does not necessarily indicate a faulty wheel sensor.

ABS turns on randomly, the light blinks or lights up periodically

One of the most difficult forms of breakdowns is the constant blinking of the ABS light. This means that the anti-lock braking system sensors send incorrect signals to the computer, which, in turn, issues other incorrect commands to the vehicle's systems and modules. In such cases, many people prefer to simply turn off the anti-lock system, since unpleasant incidents may occur. For example, turning on ABS at a speed of 90 kilometers per hour with light braking can damage the chassis of the car and contribute to a complete loss of control over control. It's better to do this:

- bring the car to a service center for diagnostics, find out the reason for the chaotic operation of the equipment;

- for domestic cars equipped with a primitive anti-blocking device, it is better to immediately disable the system;

- complex designs and on-board electronic systems of foreign cars will have to be reflashed for repair;

- on some machines it will be easier to find the problem and fix it than to disable the anti-lock;

- you need to keep in mind that this particular system is not always the cause of the ABS light coming on; the problems can be different;

- During the diagnostic process, it is better to check the entire on-board electrical system and equipment.

By paying a certain amount for a car inspection, you can get the right answers to important questions. Sometimes a light that comes on on the panel can develop into a full-fledged repair of important units and components of the car, so you will have to spend a lot. But in most cases, this problem is not so expensive to solve. The cost of repair work depends, of course, on the make and model of the car, and on the price of spare parts. If an ABS sensor for a domestic car costs from 600 rubles, then a Japanese SUV will cost more than 10,000 rubles to replace one such sensor. We suggest watching a video about solving a similar problem using computer diagnostics:

How ABC works on Lada Priora

Like most modern car systems, ABS is computer controlled. But in addition to the electronic control unit, it also includes several sensors and actuators. The entire system consists of several elements. 1

.

Electronic control unit (ECU). 2

.

Sensors on wheel hubs 4 pcs. 3

.

Brake fluid pressure valves in the system 4 pcs. 4

.

EVN (Electric Return Pump). 5

. Warning light on the instrument panel. Despite all its apparent simplicity, this is a rather complex, high-tech system. Each sensor transmits data on the rotation speed of the Priora wheel to the electronic control unit. Based on the data received, the control unit sends a signal to the brake system valve, which, when you press the brake pedal, releasing pressure, prevents the wheels from completely locking and starting an uncontrolled skid of the car.

Let's sum it up

Problems with ABS are not very pleasant incidents in any case. It is better to stay away from various problems and try to operate the car according to the requirements and advice of the manufacturer. But sometimes this turns out to be impossible, so it is necessary to have a good service in mind that can help in different situations. By contacting an official service center with this problem, you may become a victim of an overly scrupulous approach to diagnostics and incur huge repair costs.

However, sometimes the problem with the ABS sensor and the light on this system can be solved independently. Use the tips described above in the publication to understand all the features of a particular troubleshooting method. We warn you that it is impossible to completely disable ABS yourself. The on-board computer will either simply not allow the car to start, or will begin to behave inappropriately, producing new diagnostic system error codes each time. Have you encountered incorrect operation of ABS sensors and a constantly burning light?

The ABS system is an important element of the entire car design, without which safe movement is indispensable. According to statistics, the reason for a large number of road accidents is that drivers do not use the braking system correctly. In most cases, this problem occurs in winter, when the road surface is very slippery. Let's take a closer look at the components of the ABS system, and also give advice on what to do if the ABS light comes on.

ABC control unit on Priora

Structurally, on the Priora, the ABS ECU is mounted together with the EWH and valves that regulate the pressure into a single unit - the hydraulic unit.

It is located on the front left side member of the vehicle. The hydraulic unit is connected to the entire system by a common wiring harness. It includes pipes for supplying brake fluid to the working cylinders. An EWH is also installed here, increasing the pressure in the system. This unit does not understand handicraft conditions. Usually replaced entirely with a new one.

FakeHeader

Comments 12

That's it, guys, the problem is solved. There was condensation in the oil receiver, and this condensate froze. We drained the oil, removed the filler, warmed up the oil receiver, filled in oil, started the engine, heated the engine to 80 and drained the oil, then poured in new oil. Now everything seems to be fine.

Drain the oil, my sump and change the oil receiver, a friend did this on a viburnum and the machine came to life.

I don’t think it’s anything serious, maybe the oil is frozen. Another option is to check the wire that goes to the sensor with a tester; if the light does not light, it means there is an open circuit, this happens in cold weather

I had this happen with a couple of Kalinovodovs as well. Condensation. It appears if you go on short trips in winter. Then it freezes in the car along with the oil in severe frost. I warmed up the pan and changed the oil. I switched to 5v40 Mobile. Before this, the owner supposedly had zero .Thank God this didn’t happen again!

It is no secret that the engine is the main component of a car, for the normal functioning of which a number of conditions must be met. One of them is maintaining optimal engine oil pressure. Reducing this parameter can lead to a number of problems - increased wear on the engine, a decrease in its power, disruption of the functioning of some components, and so on. But more about everything.

Functions of motor oil

Let's remember what tasks are assigned to motor oil. There are several of them:

- Reducing friction between the main elements of the engine, as well as increasing their service life.

- Formation of the required pressure level in all systems and components equipped with a hydraulic drive.

- Effective heat removal from the piston system, bearings and other rubbing elements of the system.

- Reliable protection of all engine components from corrosion.

- Prevention of various deposits and the appearance of soot on the walls of the motor.

- Protection of the engine from the action of acids that may form during combustion of the air-fuel mixture.

- Elimination of any form of sediment in the main components (oil pipeline or engine crankcase).

Main reasons for lack of oil pressure

Before checking the oil pressure in the system, you must clearly understand the reasons for this phenomenon. There are several of them:

Reduced oil level in the power unit. To avoid this problem, you should check the oil level from time to time under the following basic conditions - the engine should be stopped and cool. If the level drops, it is necessary to top up using oil of the same type, brand and viscosity. After this, check the pressure again. Increased oil filter resistance. Often, novice car enthusiasts make a mistake in choosing this unit and install a filter of the wrong type (intended for a different model). In such a situation, the throughput of the newly installed filter may not correspond to normal engine operating parameters. Oil pump failure. A malfunction of this unit is a very common pressure issue. Its malfunction can be caused by simple contamination and the presence of significant deposits on the internal filter elements. To fix this problem, you may need to replace the pump. As a rule, car enthusiasts do this work with their own hands, without going to a service station. Increasing the gaps between the main elements of the power unit. The main reason is wear and tear. There are times when, even if all the problems listed above are eliminated, the pressure in the system remains at an extremely low level. In such a situation, disassembling the engine and checking the main clearances can help out.

In particular, special attention must be paid to the distances between the bearings and the connecting rod journals. Coolant or fuel getting into the engine oil. A similar problem can occur for a number of reasons - burnout of the cylinder head gasket, wear of the rings, failure of one of the cylinders, and so on.

In the event of such a malfunction, it is no longer possible to do without changing the oil and repairing the engine. The oil pressure sensor is broken. If after diagnostics (we will look at its essence below) it turns out that the oil pressure in the systems is normal, but the sensor still gives a signal to the contrary, then the only way out is to replace the sensor. The wiring has failed. In domestic cars, this reason is one of the most common. The emergency oil pressure light may light up due to damage to the switching conductors.

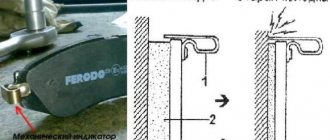

ABS sensor on the hub

The sensors that supply wheel speed data to the control unit are made on the principle of a Hall sensor. By the way, most rotation sensors use exactly this principle: changing the voltage on the semiconductor of the sensor, depending on the passage of a control point on the rotating disk near it. It is in correlation with the signals from the ABS sensors that the control unit manipulates the valves.

Failure of ABS 8.1 Priora SE. Error C0110.

A friend of mine has been bothered by a problem for a long time.

The ABS started to turn off. At the same time, an error was displayed. He, like most other car enthusiasts, “solved the problem” by resetting the error. Which, as you know, does not actually solve the problem. How to fix the error. The problem arose spontaneously and not that often. Recently, it began to occur more often, until the system stopped working completely, and the error stopped being reset. More precisely, it began to appear immediately after the reset. I didn’t really get into these systems, I didn’t study them, so I took their word for it. The owner and the one who sent him the error claimed that the problem was in the brain, in the ABS unit itself. I persuaded my friend to pick out the ABS block. We can't do anything worse if it doesn't work. In the end, they picked it without me. They write on the forums that the problem is common, acid from the battery gets onto the wiring harnesses, and kind of corrodes them. And so they dug everything out and found no problems. Everything is clean and dry. They say they checked everything, everything rang, all the fuses. Everything is fine. And even for some time the problem went away, as much as two weeks. When she appeared again, I finally persuaded my friend to take a look. We chose the time, got ready, sorted it out. Looking ahead, I will say that they even checked the wrong fuses. I advise everyone to always read the instructions. Of course, I understand, we are Russians, we open the instructions when we have already broken everything. Well, this is exactly the case, everything broke. But, having listened to their friend and believed him, they did a lot of extra work. Everybody lies. © Dr. House.

It was decided, since this was the case, since everything had been checked, to remove all the corrugations, disassemble all the harnesses and go through all the wiring. I decided to start with the ABS connector.

And so, the following error pops up.

The decoding here is not correct. The scanner, it helps, but it does not find the breakdown itself, the diagnostician finds the breakdown. If you open the ABS repair manual, you can see the following explanation.

And further in the manual there are the following recommendations: “If fault code C0110 is detected, check the supply voltage at contact 2 of the harness block to the hydraulic unit”

. We do a simple measurement, the voltage comes. Well, that means, from time to time, you have to look for something, somewhere. The first thing I decided to do was disassemble the block itself and check the terminals. They were going to remove the block itself anyway. They unscrewed it, pulled the block out into the light of day, and disassembled it. All terminals are intact and in excellent condition. Well, then let's call from the plus to the fuses, from the fuses to the block. And this is where it turns out that they were checking the wrong fuses. Let us remember the words of Dr. House. It turns out they were sure that the fuses on the ABS were the same pair as in the relay and fuse box.

Look at the lower left corner of the diagram.

These fuses are located in the main fuse block.

This is where the cause of all the troubles is immediately revealed. There are simply terrible traces of oxidation. I pulled out the fuse and powder began to fall off it.

To see the scale of the work.

All I had to do was rip open the fuse box.

I disassembled the fuse connector, filled it with VDeshka, scraped everything out, cleaned it, blew it out with compressed air. I reassembled all the connectors. I must say that everything is not very easy to understand, and even less easy to remove the terminals from the chip. GM stamps are clearly visible on the chips in the fuse block. After I assembled the connectors and inserted the fuses, everything was covered with lithol from below. The old grandfather's way. So that dirt and moisture do not get there. We collected everything, corrected the error and went for a test drive. Everything works, no error appears. Now we need to travel and have a look. I hope the problem has been overcome. Maybe this post will help someone. Read the instructions, don’t trust anyone, check everything yourself.

Source

Electronics

This is a failure of components associated with electronics:

• breaks in the electrical wiring harness; • failure of rotation speed sensors; • break or short circuit of the control valve activation coil; • failure of the return pump electric motor; • valve activation relay failure; • program failure, or failure of the ABS control unit.

ABS FAULTS IN THE FIELD OF HYDROMECHANICS

In this case, the most typical failures are leakage of oil seals in various connections and assemblies. Deterioration of working surfaces on disks, and as a result, a change in the distance between the sensor and the readable surface. System valves jamming. Clogging of hydraulic drive pipes and breakdown of the working part of the return pump.

DETERMINING ABS MALFUNCTION

The serviceability of the ABS system in the Priora, like in any car, is a very important issue. It is very convenient that the slightest malfunction in its operation will immediately be reflected on the dashboard. The ABS warning light will come on or it will not go out after the required time after turning on the ignition.

There's no need to think twice about it. You urgently need to go for computer diagnostics to a decent service station. Modern Priora ABS ECUs have access to a diagnostic connector. They are perfectly diagnosed by both portable portable scanners and stationary motor testers. Since all ABS electronics are very closely connected with the mechanical part, most breakdowns in this area can be determined by an experienced diagnostician by scanning the ECU. For example, the operating valve is jammed in one of the directions. What happens: the coil, figuratively speaking, tries to influence him, but he doesn’t move. The computer, noticing a load violation in the circuit, will immediately give a signal. The “ABS sensor” will light up. When connected, the technician will see the direction that needs to be looked at and quickly fix the problem.

FEATURES OF ABS PRIOR DIAGNOSTICS

Some scanners that read faults recorded in the ECU produce only alphanumeric codes, so for particularly meticulous car enthusiasts it makes sense to have on hand the decoding of these codes for the VAZ Priora: C0035 - malfunction of the left front sensor; C0040 – the same for the front right; C0045 – rear left malfunction; C0050 – the same for the right rear; C0060 – failure of the left front exhaust valve; C0065 – front left intake valve failure; C0070 – malfunction of the front right exhaust valve; C0075 – malfunction of the front right intake valve; C0080 – rear left exhaust; C0085 – rear left inlet; C0090 – rear right exhaust; C0095 – rear right intake valve; C0110 – return pump circuit malfunction; C0121 – failure in the relay circuit for turning on the supply voltage of the valves; C0161 – malfunction in the brake light circuit; C0245 – incorrect reading of rotation speed; C0550 - ECU malfunction; C0800 - voltage mismatch in the ABS network. This list allows you to find a fault, even if a simple scanner for a Priora produces only codes, and find out why the “ABS sensor came on.” Still, it is worth remembering that it will be more pleasant for the technician to hear the correct wording - the anti-lock system malfunction lamp is on.

Anti-lock braking system malfunctions

All Priora ABS malfunctions can be divided into two categories. Malfunctions of the electronic part and malfunctions in the field of fluid mechanics. That's how they should be considered.

Electronic failures

This is a failure of electronics-related components:

- breaks in the electrical wiring harness;

- failure of rotation speed sensors;

- break or short circuit of the control valve activation coil;

- failure of the return pump electric motor;

- valve activation relay failure;

- program failure, or failure of the ABS control unit.

Looking for a reason

You should start troubleshooting with the fuse. If this element burns out, the ABS does not work. Note that you should not always go into the fuse box, since the behavior of the system itself can give a “hint” regarding the serviceability of the fuse. For example, if the ABS light on the instrument panel comes on only under certain conditions, but after turning off the power to the ignition switch and restarting the engine, the problem disappears, then the problem is clearly not in the fuse. It should only be checked if the warning light is constantly on.

The sensors are located in a place that cannot be called well protected. Therefore, dirt sticking to it will easily cause a malfunction, causing the system to shut down.

Sensors may simply break during the process of repairing and servicing the chassis. Careless work and the use of impact tools during disassembly often cause internal damage to the sensors. Since they cannot be repaired, the damaged element will have to be replaced to restore ABS functionality.

The system can also shut down in an emergency due to the setting elements of the sensors. They are installed on the hub, and during operation they can also become covered with dirt, which will disrupt the functioning of the sensors. Inaccurate maintenance of the chassis can also lead to damage and destruction of the control elements, which will affect the performance of the ABS.

More often than not, the problem occurs due to wiring. Oxidation of contacts, chafing or interruption of wires coming from sensors - this leads to disruption of the system and the activation of a warning light. Sometimes, during the process of servicing the chassis, the wiring is disconnected from the sensors, and then they forget to connect it back. Therefore, when looking for the cause, inspect the wires for damage, their terminals, and only then pay attention to the sensors.

Malfunctions due to all of the above elements of the system are considered easy, since they are easy to fix and inexpensive. It's worse if the problem is caused by the control unit. In this case, you need to either reflash this element or replace it.

The anti-lock braking system fails due to damage to the components and assemblies near which the sensors are located. ABS is disabled if the wheel bearing is severely worn. Because of this, the hub has a lot of play, which leads to disruption of the ABS sensors, and this is the reason for the emergency shutdown.

Those who first switched from carburetor old cars to a brand new middle-class car are first scared when the ABS light comes on. For those who don’t know what ABS is, it’s clear that it’s an anti-locking system, but not everyone knows what it specifically does. Now we will describe everything in detail.

Why did the ABC light come on?

Video: The ABS light is on on the instrument panel. The brake lights do not go off.

As already noted, breakdowns occur in the electronic component, which includes sensors installed on the wheel hubs and the control unit. The mechanical component does not cause problems.

The “culprits” for the ABS warning light coming on:

Why the ABS fails can be easily identified by checking the listed components if the car is equipped with an on-board computer with a display on which error codes are displayed. This will significantly narrow down your search, since you can find out from the code which sensor is acting up.

In a car without an on-board computer display, to determine the malfunction, you will have to look for a scanner and connect it to the diagnostic connector to determine what caused the failure.

Note that identifying the error code will make the search easier, since diagnostics will not provide accurate information; it will indicate where to look for the fault. Therefore, you can even do without scanning.