The shock-absorbing system of a car is important for comfortable movement. It ensures a smooth ride and successfully absorbs uneven road surfaces. The quality of the suspension largely depends on the condition of the springs. The slightest wear of elements can cause a lot of trouble for the owner. Therefore, it is recommended to carry out timely diagnostics and replacement of old parts.

VAZ passenger cars are equipped with an independent double-wishbone suspension at the front, where springs play a key role. The famous “seven” also requires periodic maintenance of its moving parts. We will discuss further technical diagnostics and repair of the front suspension for the VAZ-2107 model.

Problems with front springs

The springs on the VAZ front suspension are located in the front part of the car on the sides of the engine compartment. Their main task is to “absorb” road imperfections. With prolonged use, parts inevitably wear out and require immediate intervention by a mechanic. Atypical behavior of the car indicates an imminent breakdown. If the car body sags significantly compared to the initial condition of the car, this is a sure sign of wear and tear. Trouble does not come alone, so as a result of body roll, accompanying troubles emerge:

- Drastic reduction in ground clearance

- Increased tire wear

- Rapid failure of other suspension elements

- The muffler and driveshaft periodically cling to the road surface

- The body sways intensely when moving

Worth reading:

- Self-replacement of the VAZ 2110 CV joint

- How to replace the steering rack of a VAZ 2115 yourself

- Using a rope or wire, pull the upper arm higher, thereby providing access to the front suspension spring.

Self-replacement of VAZ 2106 front suspension springs

- Use a pry bar to pry the lower end of the spring and remove it from the lower arm support cup.

Self-replacement of VAZ 2106 front suspension springs

Causes of failure of front suspension springs

The warranty period for standard suspension elements is 5 years. However, actual operating conditions are very different from ideal factory tests. The reason for this is the deplorable state of domestic roads and frequent transitions to different road surfaces.

Therefore, professional drivers advise changing components at least once every 3 years or after 30,000 km of travel.

Front suspension failure occurs for several main reasons:

- Late diagnosis and replacement of consumables

- Defective part

- Driving on poor quality roads

When identifying the first “symptoms” of the disease, it is better to eliminate the problem immediately. Constantly postponing repairs can lead to breakdown of other elements of the car, which will cost the car owner a significant amount of money.

Algorithm for replacing the front springs of a VAZ 2107

Prepare the simplest tool for the job; every car owner who at least sometimes repairs his iron horse should have it.

- A set of keys (you should have it in your trunk);

- jack;

- a brush with metal bristles;

- wheel wrench;

- hammer;

- wire hook;

- mount;

- insulating tape.

The sequence for replacing the front springs is as follows:

1. Remove the shock absorber from the desired side and remove the wheel.

Signs of spring replacement

There are 3 main signs that indicate problems with the front springs. The presence of any of them or a combination of several indicate one thing - not everything is in order with the car.

Rolling the car to one side

To check the car for the presence of this defect, it is enough to place the vehicle on a flat surface without additional cargo inside. The unnatural skew of the car instantly catches your eye. If the body “leans” heavily on the left or right side, the front springs on the VAZ 2107 need to be replaced. A similar situation concerns an excessive slope on the front or rear axle.

But you definitely shouldn’t blame them alone, and here’s why. The design features of the suspension of VAZ cars from the “kopek” to the “seven” include a landing part in the upper part of the spring (popularly it is nicknamed “glass”). It acts as a top stop. During long-term operation of the vehicle, the glass tends to “fall through”. Externally, the body tilts to one side. The cause of the problem can only be diagnosed by removing the rubber cushion and glass. Typically, the failure of the glass occurs on the front springs, and especially often on the left wheel.

Extraneous noise in the suspension

A breakdown can be signaled by extraneous sounds, the source of which is located in the suspension area. This may include an obvious rattling or clanging sound, or a subtle knocking or grinding noise. Noises occur when the car drives on uneven sections of the road. For example, when hitting a bump or a wheel falling into a hole.

If atypical sounds are detected, a complete diagnosis of the vehicle's suspension and steering should be carried out. The source of the noise may be a ball joint, tie rods, or worn rubber gaskets. If everything is fine with them, the reason lies in the malfunction of the springs.

Extraneous sounds often indicate a split in a certain location. But sometimes the part breaks exactly in two. Then the car body looks skewed to the “sore spot”.

Metal fatigue

Auto mechanics often say that metal is “tired.” What does it mean? Metal fatigue means the loss of its initial properties due to prolonged use. Over time, the element copes worse with its assigned responsibilities.

Several extreme turns on both sides of the part fall into the risk zone, since they bear the main load. At the moment of compression, the rings are pressed tightly and hit each other. After some time, mining areas appear at the contact points of the rings. There is a transformation of the round rod, which gradually takes on a flattened shape.

A spring with a defect does not fully respond to road unevenness, and the suspension gently “sags.” If such a malfunction is detected, it is recommended to replace the part with a new one.

↑ Sequence of tightening nuts and axles in rubber-metal joints

To prevent improper distribution of forces in rubber-metal joints, tightening the nuts and lever axles must be done in the following order:

- Place the car on a level surface and place the wheels parallel to the axis of the car;

- load the car with a load of 3136 N (320 kgf);

- under these conditions, use a torque wrench to tighten the nuts securing the axles of the upper and then the lower arms and the nuts securing the axle of the lower arm to the cross member.

Check and adjust the front wheel alignment angles.

What to look for when choosing

When choosing a new consumable, you should pay attention to key characteristics. Knowing the basic parameters will allow you to find the optimal part that suits your specific needs.

Length

The ride height depends on the length. Typically, the manufacturer mentions the recommended clearance value in the technical documentation of the model. In rare cases, the spring lengths of the rear and front axles may differ. But it is advisable not to deviate from the technical parameters from the manufacturer. These parameters are determined by precise technical calculations.

You can deviate from the recommendations in two cases:

- “pumping” the car for the sake of visual customization

- modernization of the chassis for transporting heavy loads

Rigidity

The degree of rigidity determines the behavior of the car on the road and distributes the load across the remaining suspension elements. Soft springs are suitable for comfortable, smooth rides, while hard springs cope well with high loads. Therefore, the choice of rigidity largely depends on the purpose of using the machine.

Among owners of VAZ cars (including the Seven), there is a common problem with purchasing new consumables for their “swallow”. In a single set from one manufacturer, sometimes there are elements with different degrees of rigidity. Unfortunately, it is impossible to know about this in advance, and the body defect appears during use.

To resolve the issue, car owners resort to one of two methods. The first option involves purchasing another pair, usually foreign-made. The second method involves installing spacers.

A spacer is a rubber lining that is placed under the seating area of the “glass”. This method will significantly save the budget of the owner of the Lada.

The degree of spring stiffness depends on several indicators:

- The thickness of the rod section. A simple law applies here: the thicker the rod, the higher the level of rigidity. However, there are models with different ring diameters, and therefore the rule applies only to classic straight models.

- Total diameter of turns. Increasing the width of the rings leads to increased softness.

- Number of turns. The higher the number of revolutions of the rod, the lower the rigidity of the part.

Turning parameters

The main characteristics include two indicators: the number of turns and the thickness of the section. They determine the final degree of rigidity of the part.

It is not uncommon to find original springs with different ring diameters. Externally, they have an oval shape: wide in the middle with a gradual decrease towards the edges. The different diameters of the rings are also made of metal of different thicknesses. For massive turns, a thick rod is used, and the small rings on the sides are made of thin material. This design feature gives it versatility: it dampens small vibrations and large shocks equally well.

But the main “disease” of these models is hidden in the extreme turns. Due to the small thickness of the metal, the side parts of the part are very fragile, and therefore often break on uneven roads. This is the price of comfort: for a soft ride you have to pay for frequent repairs.

An alternative to factory springs is products from third-party manufacturers. A non-original product is made from a rod with a constant cross-section. This negatively affects ride comfort due to high rigidity. But non-original consumables are distinguished by their reliability and durability.

Types

The springs of the shock-absorbing system are conventionally divided into 5 categories, which can be presented in table form:

| Variety | Characteristic |

| Standard | They come as standard equipment for the car from the manufacturer. Designed for driving on city highways and rough terrain. |

| Reinforced | Capable of withstanding heavy loads. Used for transporting heavy loads. |

| Extended | Modification to increase the vehicle's ground clearance. |

| Shortened | They have the opposite effect - reducing the vehicle's ground clearance. At the same time, controllability indicators increase significantly. |

| Variable hardness | A universal option for traveling on various road surfaces. |

Finding the optimal solution depends on the intended use of the vehicle and the manufacturer's recommendations.

The standard kit for the VAZ 2107 is original parts from a “penny”. But to improve aerodynamic performance, car owners resort to tricks. Often, instead of standard elements, spare parts from the “four” are chosen, which have a positive effect on handling. True, to install them in the “seven” you need to remove the outermost turn.

Installing new front suspension springs

1. Take a new product and fix a new gasket (spacer) on it, this is where electrical tape comes in handy. Make sure the gasket is positioned correctly. The wide part should touch the spring part, and the narrow part should touch the body.

2. Use a spudger and push it through the special hole at the bottom of the arm. After this, fix the spring with a spatula (for now only on the bottom side).

3. Take a jack and place it under the lower control arm. Now lift the device slightly to load the spring. At this moment, use a spatula to guide the spring so that it takes place on the screw part of the cup.

4. Now continue increasing the load and throw the stabilizer bar over the stud. Check again that the spring is installed correctly.

5. Reinstall everything in reverse order. If the replacement is carried out on an overpass or a special pit, then the nuts securing the lower arm to the axle can only be tightened when the car is loaded.

Replacing the front suspension springs will not cause you any difficulties. The main thing is to adhere to the given algorithm and be careful at each stage.

After completing the work, check that all nuts are tightened well. Have a good trip and of course no breakdowns.

Replacement of the front suspension springs is carried out in the following cases: when the integrity of the springs is compromised, in case of mechanical damage or cracks, as well as in case of significant subsidence.

Main types and ratings of suspension springs

How to choose the best springs for the VAZ 2107 presented on the domestic market? It is impossible to give a definite answer to the question, since each driver eventually finds “his” company, whose products he is ready to trust. A list of 14 well-known companies that have long proven themselves to be the best will help you understand the huge number of brands.

LESJOFORS

The real flagship of the industry comes from Europe. The company has been producing spare parts for car suspensions for many years. The company has a developed network of branches with representation in four European countries.

Lesjofos springs are cast from special steel with a high carbon content. A special protective coating is applied to the surface of the part and then painted. The products are distinguished by their long service life, confirmed by numerous tests. There are over 3 thousand items on the market under a well-known brand. The main disadvantage of the product is the “biting” price tag.

KILEN

At the end of the last century, the company came under the wing of “lesjofos”, and today it is a “daughter” of the giant. Accordingly, the sub-brand’s products have twice the service life compared to the original parts from the Volga plant. Car owners praise the product for its high quality combined with an adequate price.

LEMFORDER

The company is a well-known supplier of original products for many premium cars. Therefore, the price of the product is not the lowest. But in return, the buyer receives unsurpassed quality, supported by countless positive reviews.

CS GERMANY

German company producing components. The products are in the middle price category. Drivers respect the brand for the optimal ratio of cost and quality of the goods offered.

KONI

The company's products are distinguished by a large margin of safety and are widely represented on the market. The price of components is in the “above average” category. The main feature of the springs is the ability to dynamically adjust the stiffness level.

BOGE

The manufacturer produces various parts for car suspension. The manufactured products belong to the “premium” category. The cost of boge products fully corresponds to the class of the company. Manufacturing defects occur rarely; reviews from car owners are mostly positive.

EIBACH

is one of the key players in the automotive market. Its products practically do not lose their initial properties over time and are popularly considered “immortal”. The only thing that spoils the overall impression is the cost of parts from the eminent flagship of the industry, which is many times superior to its competitors.

SS20

The key feature of the manufacturer is a painstaking approach to manufacturing technology. The factory carefully selects pairs with equal hardness. Therefore, when purchasing, you can be sure that the kit is guaranteed to have similar parameters. Production technologies are based on cold and hot winding methods.

K&F

belongs to the leading manufacturers of spare parts for cars and trucks. In addition to supplying new parts, the company actively operates in the secondary market. The rich product range includes over a thousand items. Springs from a famous brand are famous for their quality, but they cost a lot of money.

TEVEMA

Polish manufacturer of shock-absorbing springs operating in the European and Asian regions. The insane demand for the company's products is dictated by the low cost of parts, which are several times cheaper than original components.

SIRIUS

The company produces products in the budget segment. A wide selection of components received positive feedback from car owners. It is especially worth noting the possibility of producing parts according to an individual sketch.

FOBOS

The company does not have enough stars in the sky, but the price tag for the products is appropriate. A small range of products with mediocre quality. Car owners note that the first defects “pop up” after just a year of active use.

ASOMI

The company is famous for its own production technologies, which are kept in the strictest confidence. "Asomi" offers high-quality products at reasonable prices.

TECHNORESSOR

An economical option for those who are broke. The company produces spare parts for cars and trucks. Springs gradually lose their initial properties. An excellent solution for economical drivers.

When it's time to replace

There are several signs by which you can determine that it is time to replace the springs. These signs are:

If you find a problem with the springs on a VAZ 2107, then you should replace them without delay. This will extend the life of other suspension elements and save money. It is recommended to replace devices in pairs, since replacing only one element will cause the body to skew, which will negatively affect driving. In some cases, spacers help when the springs have sagged but are not deformed. Experts believe that you should not get carried away with spacers, since the physical properties of a car with spacers are many times worse. As a result of such modifications, the suspension does not function correctly, which affects many factors: from control to comfort. Therefore, if necessary, it is better to replace the springs, both rear and front. We will learn how this is done on a VAZ 2107 from this material.

Spring Upgrade

The process of upgrading springs involves changing the length of the part on your own. To do this, the element is shortened or replaced with a longer sample.

Shortened springs

Drivers resort to reducing the size of a part in order to improve the characteristics of their iron comrade. Trimming the springs gives the car some advantages:

- Lowering the body position

- Better steering response

- Reduced roll when entering a turn

Many manufacturers offer a ready-made solution in the form of special versions of short springs. However, it is worth remembering that after tuning the ground clearance will decrease significantly. Such a “seven” will not be able to drive on uneven roads.

You can lower the “seven” yourself. To do this, you need to cut 2 turns from each spring using a grinder.

It is not recommended to cut off more rings, because the body will touch the ground.

Video: cutting springs on a classic

The video shows working with a VAZ 2106, but the technological process for the “Seven” is completely identical.

Link to video:

Also check out

- How to replace the support bearing of a VAZ 2110 without wheel alignment

- Installation of new front struts on Lada Priora cars

- How to replace a VAZ 2110 timing belt and tension roller at home

- Remove the suspension spring, remove the spring gasket from the upper support cup. After this, you can replace the front suspension spring.

Self-replacement of VAZ 2106 front suspension springs

To do this, do the following:

- Use electrical tape to secure the gasket to the spring and install the part in place.

Self-replacement of VAZ 2106 front suspension springs

- Place the blade in the hole for the shock absorber, supporting the spring with it, and fix the lower coil. There is a screw surface on the lower arm that indicates the correct position of the spring. Installation should achieve this position

Self-replacement of VAZ 2106 front suspension springs

Self-replacement of VAZ 2106 front suspension springs

- Having installed the lower coil in the correct position, jack up the lever and load the spring. Using a mounting spudger, seat the spring onto the screw surface.

Self-replacement of VAZ 2106 front suspension springs

- Increase the load on the spring, install the stabilizer bar between the two studs that secure the bracket.

Self-replacement of VAZ 2106 front suspension springs

Self-replacement of VAZ 2106 front suspension springs

20

- Reassemble everything in reverse order.

After this, the replacement of the VAZ 2106 suspension springs can be considered complete.

You can check it out:

- Installation of new front struts on Lada Priora cars

Spacers for springs

Even the most innovative springs gradually exhaust their service life. And the owner is faced with a choice: replace the part with a new one or extend the life of the element with the help of a spacer.

The spacer for the VAZ 2107 has several varieties:

- Interturn (attached between the rings)

- Butt (between the spring and the cup)

- Suspension spacer

An interturn spacer is suitable for spring repair. You can buy it at a VAZ car parts store. Installation is performed in the following sequence:

- Raise the wheel with a jack

- Unclench the required coils of the spring with crowbars

- Soak the spacer with soapy water

- Insert the spacer with a screwdriver and secure it

- Remove the jack from under the wheel

- Repeat all steps on the other wheel

Video: operating procedure

You can view the video material at the link:

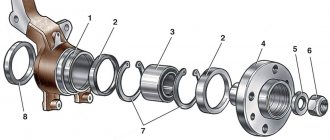

↑ Spring compression with device 67.7828.9504

1 — suspension spring; 2 — screw of the device; 3 - support plate.

- Insert screw 2 of tool 67.7828.9504 into the hole in the upper support of the suspension spring.

- Then place the support plate 3 on the spring coil 1 and on the screw 2 from below and secure it to the spring with a clamp.

- Screw the nut onto the screw from below so that the nut retainer fits into the socket of plate 3.

- By turning screw 2 with a wrench, compress the suspension spring until the suspension arms are completely unloaded.

- Take out the axis of the upper arm and disconnect it from the body.

- Disconnect the lower control arm axle from the cross member and remove the suspension assembly from the vehicle.

- Remove the spring, smoothly unloading it, remove the device and repeat the operations for the other suspension unit.

- Remove the engine splash guard and stabilizer bar.

NOTE! When removing suspension components, it is necessary to note the number and location of the adjusting washers between the axis of the lower arm and the cross member, as well as the adjusting plates between the cross member and the body side members, so that when installing the units, put these washers and plates in their original place.

About the choice of springs

As mentioned above, the choice of springs should be based on the purpose of the vehicle. Those who drive fast install hard springs, and those who love comfort install soft ones. There is another situation in which replacement is indispensable: the springs may get tired. It's simple: over the years, the elasticity of any spring decreases. If this happens with the rear springs of the "seven", then the rear of the car begins to sag greatly, and the wheels, falling into a particularly deep hole, begin to touch the fender liners with a characteristic grinding sound. After this, the driver is simply obliged to install new hard springs. Which ones to choose?

VAZ springs

If the springs wear out, the best option would be to install a set of standard rear springs for the VAZ 2107. If for some reason it was not possible to purchase “original” springs, there is a second option: springs from the VAZ 2104. They are slightly stiffer than the “original” springs, and drivers who prefer aggressive driving style, you will probably notice an improvement in the car's handling. Also, springs from the “four” are installed by those who decided to transfer their “seven” to gas fuel. Gas cylinders are heavy, therefore the rear springs must be stiffer and their free travel must be shorter. Finally, there is a third option: springs from a VAZ 2101. Today, it is not always possible to purchase new springs from a “kopek”, since the “kopek” has long been discontinued. But if you still managed to get such springs, the suspension of the “seven” will become softer after installing them.

About springs from foreign cars

It is not recommended to install rear springs from foreign cars on the VAZ 2107. The fact is that the parameters of these springs do not even come close to the standard VAZ springs. Springs on foreign cars are designed for a different car weight, a different body type, different shock absorbers, etc.

If the driver decides to install them, he will have to seriously modify the 7's suspension and will almost certainly have to change the rear shock absorbers, which will lead to additional costs. But even such measures do not guarantee normal operation of the suspension. Therefore, drivers who are tuning their “sevens” prefer not to mess with springs from foreign cars, getting along just fine with the VAZ springs mentioned above.

Replacing rear springs

Replacing the rear springs of a VAZ 2107 is much easier than replacing the front ones. For this you will need:

The replacement procedure is as follows:

- unscrew the pressure regulator rod in the rear brake circuit;

- unscrew the rear pipe tee fastening;

- unscrew the lower shock absorber mount;

- jack up the car and release the shock absorber and spring;

- remove the spring along with the gaskets;

- check the condition of the gaskets, replace if necessary;

- install the spring with spacers and assemble the suspension parts in the reverse order of disassembly.

Video on replacing rear springs

Monday, September 4, 2022

Replacement of front springs of VAZ-2107. Is there an effect?

And the length from tip to tip is 37.2 cm.

- Keys and heads for 13, 22

- Central spring puller and ball joint remover (preferably)

- Crowbar or large screwdriver, hammer, wire brush

- WD-shka or other “liquid key”

We load the suspension and remove the stabilizer cushion bracket, take out the cushion - we will also replace it with a new one.

Now loosen the nut securing the lower ball joint pin to the steering knuckle and tear off the pin. We discussed how to do this in the previous article.

It is worth keeping in mind that the puller can burst and the spring “shoot” or jump off the plate, so you need to work with it carefully!

Now we move the end of the stabilizer up behind the mounting pin, fix the upper arm with the hub assembly with a wire or rope behind the bump stop so as not to damage the brake hose.

We unscrew the nut securing the lower support, remove the finger from the fist and lower the lever down, carefully remove the spring and rubber spacer.

Now let's inspect it for damage. As we can see, there are traces of corrosion and interturn wear. It is better to replace such a spring, as there is a risk of its breakage.

Now, using a puller, we tighten the new spring and place the cups approximately under the second turn.

We put a new rubber spacer on the spring and fix it with tape or tape so that the end of the rod rests against the recess on the spacer. We carefully place the spring between the levers, orient the lower end of the rod so that it, like the spacer, rests against the recess on the metal cup of the lever.

Also, we put a new cushion on the stabilizer and install it on the lever.