The last few days I have been busy fixing engine problems that arose after a long-distance trip of about 1200 km to Moscow.

The symptoms of the malfunction were as follows:

— The malfunction clearly manifested itself while stopping at a traffic light. — The car began to jerk while driving, very strong jerks. — The Check Engine light came on and while driving it began to flash. — The engine idle speed floated between 700 and 500. — The car body began to vibrate very strongly at idle and at low speeds during acceleration. — The traction disappeared and the car began to pick up speed very slowly when accelerating. — When you press the gas pedal, the engine speed quickly rises, but there is no acceleration. — At high speeds and speeds above 80 km/h, the malfunction ceased to manifest itself clearly, but there could be a powerful short-term unexpected jerk. — When reverse gear is engaged, there are significant jerks when driving. — Engine troubles during operation. — There was additional noise from the exhaust pipe (a loud clicking sound). — Gasoline consumption has increased from 8.3 to 11 liters according to the on-board computer.

What's the first thing that comes to mind?

— Problems with oil. — Problems with candles. — Clogged injectors.

What did you do right away?

— Checked the oil. The oil was at a minimum, but not critical. Topped up in the wind and frost. — I ordered spark plugs via Wi-Fi and replaced them immediately. It got better, but the problems did not disappear. — I thought about cleaning the injectors, but decided to replace them.

I ordered a new set of injectors, but I was not sure that replacing the injectors would go away the problems. While the injectors come with Exists, I need to somehow drive, and I began to study further on the Internet.

Symptoms on all forums indicate a malfunction of the following components: - Spark plugs. - Coils. - Injectors. - High voltage wires. — Engine mountings (vibration). - Catalyst.

I was ready to replace everything except the catalyst, because a new one costs about 68,000 rubles, and they usually don’t change it, but install a flame arrester for significantly less money, something like 12,000 rubles.

What interested me most about my malfunction was the drop in engine power with jerks and the vibration in the body, which was a consequence of these jerks.

It turned out that the blinking Check Engine and the “triple” of the engine indicate that one of the engine cylinders is not working due to a “misfire”. I don’t have an ODB II cord, and therefore there is no way to read the error code, and engine diagnostics with this cord from the officials costs the same as the ODB II cord itself with software for connecting to a computer (1200 rubles).

It seemed to me that the engine might be “troubling” because the injector for injecting air mixtures is not working or the coil with the spark plug simply does not ignite it. When I saw on numerous forums a description of the obvious symptoms of “Loss of engine thrust” with a faulty coil “Dielectric breakdown”, it immediately became clear that most likely life was being poisoned by a broken coil. Plus, I looked again at the photo of my old spark plugs from the article about replacing engine spark plugs. It turned out that three spark plugs are dry, and one has a slightly damp inner insulator, and there are many oil spots on the outer ceramic insulator. Oil spots on the outer insulator of the spark plug indicate that the spark is hitting anywhere, and the efficiency of igniting the fuel mixture in a given cylinder is reduced. I am attaching a photo of the old candles again.

As a result, it turns out that on some cylinder the spark plug simply does not work correctly and because of this there are misfires and all other symptoms.

In the morning I pulled out all the coils and examined them again. It turned out that the second coil was very badly punctured and charred in the area of the rubber tip. As a temporary solution, you could wrap the breakdown with fum tape or heat shrink to fix the problem in order to get there normally or wait until a new coil arrives. A solution with fum tape and heat shrink will not be enough for a long time, and it is better not to do it yourself, but to replace the coil with a new one, because this element is considered not suitable for repair.

INTERRUPTIONS IN ENGINE OPERATION

Malfunctions of the Lada Kalina car and their elimination 02.02.201108.02.2016 During interruptions, the engine idles unevenly, does not develop sufficient power, and consumes gasoline increased.

Interruptions, as a rule, are explained by a malfunction of the electric fuel pump nozzles, spark plugs or one of the cylinders, or air leaks into one of the cylinders.

You need to find the problem and, if possible, eliminate it.

1. Start the engine and let it idle. Go to the exhaust pipe and listen to the sound of the exhaust. You can bring your hand to the cut of the exhaust pipe - this way the interruptions are felt better.

The sound should be even, “soft”, of the same tone.

Popping noises from the exhaust pipe at regular intervals indicate that one cylinder is not working due to a failed spark plug, lack of spark, injector failure, strong air leaks into one cylinder, or a significant decrease in compression in it.

Popping noises occur at irregular intervals due to dirty injector nozzles, severe wear or dirty spark plugs.

If popping noises occur at irregular intervals, you can try to replace the entire set of spark plugs yourself, regardless of mileage and appearance, but it is better to do this after contacting a car service center to diagnose and repair the engine management system. 2. If the popping sounds are regular, stop the engine and open the hood. Check the condition of the ignition system wires.

The insulation of high-voltage wires should not be damaged, and the wire tips should not be oxidized. If there is damage to the wires, replace the faulty wire.

USEFUL ADVICE The simplest and at the same time effective way to check high-voltage wires is to check in the dark. Place the car in a dark place, start the engine and open the hood. Inspect the high-voltage wires. If the insulation of the wires is damaged, you will see a characteristic blue-violet sparkle (“northern lights”). In this case, the high-voltage wires must be replaced. 3. Remove the ends of the high-voltage wires.

When removing high voltage wires, never pull on the wire. When removing, pull directly on the tip, turning it from side to side.

4. Turn out the spark plugs with a spark plug wrench.

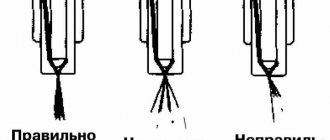

5. Carefully inspect the candles and compare their appearance with the photographs below. The gap between the spark plug electrodes should be 1.0-1.13 mm. If the candle is black and wet, you can throw it away.

6. If all the spark plugs look good, reinstall them and connect the high-voltage wires. Cylinder operating order: 1-3-4-2; The cylinders are numbered (1, 2, 3, 4) from the engine crankshaft pulley.

7 Take a spare spark plug. Secure it to the engine in any way.

WARNING Do not fix the spark plug on the oil filler neck, oil dipstick, fuel pump, or fuel hoses.

Reliable contact of the body or threaded part of the spark plug with the “ground” is optional, but desirable.

Connect the high-voltage wire from cylinder 1 to the spare spark plug.

Start the engine. If engine interruptions do not worsen, replace the spark plug in cylinder 1 with a good one.

Attach the high voltage wire and start the engine. If the interruptions intensify, repeat procedure step 7 sequentially with all cylinders to identify the faulty spark plug.

USEFUL TIPS If the diagnosis reveals a malfunction of the 3rd cylinder, remove the hose connecting the vacuum brake booster to the engine, turn it off securely and start the engine. If engine interruptions stop, diagnostics and replacement of the vacuum brake booster is required. If engine trouble continues, try spraying a liquid like WD-40 on the outside of the hose. If engine interruptions stop even for a short period of time, try replacing the hose; there may be a rupture in it.

If, as a result of the measures taken, interruptions in engine operation are not eliminated, contact a car service to diagnose the ignition system on a stand or diagnose the engine - measure the compression.

Normal compression is more than 1.1 MPa (11 kgf/cm2), a difference of more than 0.1 MPa (1 kgf/cm2) in one cylinder indicates the need for engine repair.

The check blinks and the car jerks

The last few days I have been busy fixing engine problems that arose after a long-distance trip of about 1200 km to Moscow.

The symptoms of the malfunction were as follows:

— The malfunction clearly manifested itself while stopping at a traffic light. — The car began to jerk while driving, very strong jerks. — The Check Engine light came on and while driving it began to flash. — The engine idle speed floated between 700 and 500. — The car body began to vibrate very strongly at idle and at low speeds during acceleration. — The traction disappeared and the car began to pick up speed very slowly when accelerating. — When you press the gas pedal, the engine speed quickly rises, but there is no acceleration. — At high speeds and speeds above 80 km/h, the malfunction ceased to manifest itself clearly, but there could be a powerful short-term unexpected jerk. — When reverse gear is engaged, there are significant jerks when driving. — Engine troubles during operation. — There was additional noise from the exhaust pipe (a loud clicking sound). — Gasoline consumption has increased from 8.3 to 11 liters according to the on-board computer.

What's the first thing that comes to mind?

— Problems with oil. — Problems with candles. — Clogged injectors.

What did you do right away?

— Checked the oil. The oil was at a minimum, but not critical. Topped up in the wind and frost. — I ordered spark plugs via Wi-Fi and replaced them immediately. It got better, but the problems did not disappear. — I thought about cleaning the injectors, but decided to replace them.

I ordered a new set of injectors, but I was not sure that replacing the injectors would go away the problems. While the injectors come with Exists, I need to somehow drive, and I began to study further on the Internet.

Symptoms on all forums indicate a malfunction of the following components: - Spark plugs. - Coils. - Injectors. - High voltage wires. — Engine mountings (vibration). - Catalyst.

I was ready to replace everything except the catalyst, because a new one costs about 68,000 rubles, and they usually don’t change it, but install a flame arrester for significantly less money, something like 12,000 rubles.

What interested me most about my malfunction was the drop in engine power with jerks and the vibration in the body, which was a consequence of these jerks.

It turned out that the blinking Check Engine and the “triple” of the engine indicate that one of the engine cylinders is not working due to a “misfire”. I don’t have an ODB II cord, and therefore there is no way to read the error code, and engine diagnostics with this cord from the officials costs the same as the ODB II cord itself with software for connecting to a computer (1200 rubles).

It seemed to me that the engine might be “troubling” because the injector for injecting air mixtures is not working or the coil with the spark plug simply does not ignite it. When I saw on numerous forums a description of the obvious symptoms of “Loss of engine thrust” with a faulty coil “Dielectric breakdown”, it immediately became clear that most likely life was being poisoned by a broken coil. Plus, I looked again at the photo of my old spark plugs from the article about replacing engine spark plugs. It turned out that three spark plugs are dry, and one has a slightly damp inner insulator, and there are many oil spots on the outer ceramic insulator. Oil spots on the outer insulator of the spark plug indicate that the spark is hitting anywhere, and the efficiency of igniting the fuel mixture in a given cylinder is reduced. I am attaching a photo of the old candles again.

As a result, it turns out that on some cylinder the spark plug simply does not work correctly and because of this there are misfires and all other symptoms.

In the morning I pulled out all the coils and examined them again. It turned out that the second coil was very badly punctured and charred in the area of the rubber tip. As a temporary solution, you could wrap the breakdown with fum tape or heat shrink to fix the problem in order to get there normally or wait until a new coil arrives. A solution with fum tape and heat shrink will not be enough for a long time, and it is better not to do it yourself, but to replace the coil with a new one, because this element is considered not suitable for repair.

It’s better not to drive with damaged coils for a long time, because unburned gasoline ends up in the exhaust manifold and burns out in the catalyst, which ultimately leads to breakdown of the catalyst and oxygen sensors, which costs quite a lot of money if you repair it normally and not knock out the catalyst with the installation of sensor decoys so that the Check Engine does not light up.

The vibration in the body was associated with a faulty ignition system due to a broken coil, because the engine began to jump under the hood. This symptom may indirectly indicate a torn engine mount; I plan to check it in the near future.

After replacing the ignition coil, the car drives dynamically, without jerking or vibration in the body.

Diagnostic process

Instrument panel with which you can perform diagnostics

So, diagnostic operations using the dashboard are not complicated and almost every Kalina car owner is able to cope with this on their own. Following the step-by-step instructions described below, you can carry out diagnostics on any generation of VAZ 1117-1119.

Now let's move directly to the process of performing diagnostic operations:

- We reset the daily mileage indicator. For this purpose, there is a special button on the instrument cluster. Using the daily mileage button we reset the indicator

- Do not release the button and turn to position I. Insert the key into the ignition and turn to position 1

- If everything is done correctly, then all the arrows on the instrument cluster will begin to move from the initial position (zero indicators) to the final ones. Instrument arrows move from the beginning to the final control point

- Using the button on the wiper switch handle, we switch the information screen.

- First of all, the tachometer and sensors are checked for functionality.

- In the second case, the software version will be displayed on the screen. Often, as practice shows, this is version 3.0 or 3.2. The instrument panel screen shows the software version (in this case UEr 3.0)

- In the third case, error codes that are present in the ECU will appear. Errors received during the diagnostic process. There are 8 and 4 errors in photo 6.

- Now let's decipher the errors that can pop up on the dashboard screen:

Decoding instrument panel readings

2

— the on-board network voltage exceeds the norm;3

- An error has been detected in the fuel level sensor.

Occurs if there is an open circuit in the sensor within 20 seconds. 4

- an error has occurred in the coolant temperature sensor.

Appears if an open circuit is detected within 30 seconds. 5

- an error has been detected in the outside temperature sensor in the car.

If there are no sensor readings within 20 seconds, “-C” appears); 6

- detected;

7

— emergency oil pressure;

8

- error or malfunction of the brake system;

9

- low battery charge;

E

— determination of an error in a data packet stored in EEPROM.

Now all that remains is to compare all the errors that popped up on the screen with those listed above.

Running self-diagnosis, reading error codes, erasing errors (check engine)

Hello, tell me how to reset the error: Before starting the engine, I disconnected the air flow sensor (the connector on the air filter cover), and then I forgot to connect it and started the engine, after which it shows an error on my panel - the Engine System Malfunction Warning Light (orange) came on. . I turned the sensor back on, but the icon did not go out. How can I reset this error? Thanks in advance for your answer

Try this: To check 1. Turn on the ignition (without starting the engine), count for 3 seconds. 2. Quickly (within 5 seconds) press the gas pedal all the way 5 times 3. Immediately after the last press (release the pedal completely), count 7 seconds. 4.Press the pedal all the way and hold it until the CHECK (MI indicator) starts flashing. 5.Release the pedal and read the codes

four series of 10 flashes code 0000 - no problems detected if, for example, code 0102 - looks like this: 10 flashes // 1 flash // 10 flash // 2 flash. // — pause after reading the last error, everything repeats in a circle until you turn off the ignition.

We erase the errors that we received during check 0. Before performing step 1, the ignition must be turned off for at least 10 seconds 1. Turn on the ignition (without starting the engine), count 3 seconds. 2. Quickly (within 5 seconds) press the gas pedal all the way 5 times 3. Immediately after the last press (release the pedal completely), count 7 seconds. 4. Press the gas pedal all the way and keep it pressed until the “check” blinks in four series of 10 flashes

If the check engine light comes on on the dashboard of a Lada Kalina with an 8-valve engine, this is a fairly common occurrence. The reasons for the appearance of such an alarm signal are different, and there are many of them and most owners have already become familiar with them. Many car owners are interested in the question of how to reset a check.

In our material we will try to determine the main factors affecting the activation of this lamp. To identify the causes, you can use the diagnostic service of the service center. It is also possible to determine the influencing factor in independent mode. And how to reset a check.

Troubleshooting methods

Now that all the causes have been identified, we can begin to consider troubleshooting. But, before we begin, it is worth noting that a car enthusiast needs to have an idea of the design features of the engine if he wants to fix the problem himself. Otherwise, go directly to a car service center, in order to avoid other problems that, due to lack of experience, car enthusiasts usually create for themselves.

Sensors

Often, the reason why the check light on Kalina may come on is the failure of one of the sensors. Possible ones that are worth checking right away include: mass air flow sensor, idle speed control, crankshaft position sensor, oxygen sensor and coolant temperature sensor.

But, there is a simpler and more effective way to determine the malfunction of a particular sensor, namely connecting to the electronic engine control unit. Here you can look at the errors and, by deciphering them, determine where the problem is.

Throttle

A clogged throttle valve can often cause the check engine light to come on because not enough air is supplied to the power unit. The solution to the problem is cleaning. This process can be carried out using carburetor cleaning fluid or VD-40 fluid.

The part is removed from the car and cleaned, after which it is installed in place. It is also recommended to check the throttle position sensor, which may have failed.

Injectors

One of the common reasons for the “check” icon to appear on the dashboard is a malfunction of one or more injectors that do not spray the fuel mixture properly. So, it is worth dismantling all the elements and checking them using a special stand.

If there is none, then you can use the traditional method by pouring flushing fluid into the fuel supply pipes and activating the injectors using the battery. This way it will be clear which injector is not working well. But, experienced auto mechanics recommend cleaning and checking the nozzles on a stand, since the effectiveness of the procedure is higher.

Fuel pump and filter

Another cause of the malfunction may be a malfunction of the gasoline pump or its filter. Lack of power or contamination of the filter elements leads to the fact that an insufficient amount of fuel will enter the power unit to form an air-fuel mixture.

The malfunction can be cured by checking the functionality of the gasoline pump, as well as by replacing the filter inside the gasoline pump. It is also worth looking at the fuel filter, which could become clogged when pouring low-quality gasoline.

Air filter

A clogged air filter can cause insufficient air in the combustion chambers. So, to check this element, it must be dismantled, which is done quite simply. By inspecting the filter element, you can find out how dirty it is and whether the product needs to be replaced. So, after replacement, the check signal from the dashboard may disappear.

Spark plugs and high voltage wires

Wiring is also often the reason why the check icon lights up on the panel. This happens when the spark plug is inoperative or there is a breakdown in one of the high-voltage wires.

It is recommended to check spark plugs on a special spark plug stand. But, if there is none, then you can use the generally accepted “old-fashioned” methods. But high-voltage wires are checked using a conventional multimeter, where the resistance along each wire should be about 5 ohms. If a broken part is found, it must be replaced.

Petrol

But, in addition to the above reasons, the problem may lie on the surface. Thus, ordinary low-quality gasoline can cause the “Check Engine” icon to appear on the car’s dashboard. To eliminate the breakdown, it is necessary to drain the low-quality fuel and flush the fuel supply system. But, if you drive for a long time on such fuel, the batteries may fail, which should also be checked when flushing.

What does the Check Engine icon mean on Kalina?

When the check light is on on Kalina 1, the engine is first tested. Perhaps this is where the problem lies and urgent emergency maintenance will need to be performed. In situations where the engine is normal, but there is a signal, you need to check the quality of the fuel.

Important! If the check light comes on after refueling in a new place, it is enough to check the quality of the fuel. When it is low, the warning system lights up, the solution is simple - fill it with good fuel.

The check engine icon looks the same in different cars

If the check light on Kalina 8 valves comes on, the reasons can be sought in the fuel supply system. Even minimal failures, failure of the tank cap or catalyst lead to serious malfunctions over time. It is easy to identify such problems; the main thing is to regularly carry out visual inspections.

The signal indicator is located on the instrument panel in the area of the revolution counter. It looks like a rectangle, inside of which there is a corresponding inscription. If the simplest tests do not help determine the cause, routine diagnostics are needed.

Important! If the blinking goes away on its own, then the problem has gone away too.

Failure of the fuel tank, failure of the neutralizer

When the check engine light comes on, the owner of a Lada Kalina with an 8-valve engine first of all aims to find faults directly in the engine. However, the reason can sometimes “lurk” elsewhere. The glow of the symbol is caused by a loss of tightness in the fuel circuit. Even a loose tank cap can cause this situation.

Depressurization of the system involves the penetration of an additional portion of air into the circuit. In this case, a symptom such as an increase in fuel consumption appears, and the correct functioning of the engine itself is also disrupted.

When the owner of a Lada Kalina does not detect any extraneous sounds in the engine or other deviations in its operation, but the lamp on the dashboard still continues to glow, then the first step is to make sure that the gas tank cap is tight. Quite often there are situations in which drivers, in a frantic rush, forget to check that the cap is correctly and securely seated after refueling.

If after such a check the lamp on the dashboard “refuses” to go out, then you need to continue searching for other reasons. What to do when the catalyst “announces” its malfunction? This important component of the exhaust system serves to neutralize the flow of exhaust gases. It is no secret that a huge number of substances harmful to the surrounding atmosphere accumulate in the exhaust system during engine operation. Due to the presence and functioning of the neutralizer, the level of their emissions is reduced significantly.

Among the main signs of a breakdown of the catalyst in Lada Kalina, 2 experts highlight the factor of reduced engine power. This also manifests itself in worsening dynamics.

As already noted, a common reason for the neutralizer to become unusable is the breakdown of the lambda probe in the Lada Kalina 2. Also, worn-out spark plugs can significantly shorten the “life” of the exhaust circuit element considered here.

As a result of the influence of these factors, a significant decrease in the effect of gas neutralization is observed. Oxides accumulate inside the component, which over time leads to overheating and the risk of catalyst destruction. Operating a car with such a breakdown is undesirable, since incorrect operation of the engine will not allow the unit to develop the declared characteristics. Over time, a neutralizer that has become unusable can cause damage to the power plant, so timely replacement of this component is a more rational and cheaper measure compared to engine overhaul. To replace it, you will need to contact a service center, since it is unlikely that you will be able to carry out the repair procedure yourself.

Let us remind you that the keys to a long service life of the neutralizer are:

- timely replacement of spark plugs;

- use of high-quality fuel;

- correct operation of the lambda probe.

Another factor if the check light is on is the failure of the sensor responsible for the mass flow of air sucked into the intake manifold. This malfunction is characterized by a decrease in the engine power level and the failure of the unit to start smoothly when cold.

Why can the mass air flow sensor fail? One of the reasons for this annoying situation is the untimely replacement of the filter element in the air intake circuit. The motor itself is unlikely to suffer from a faulty state of the sensor, other than the indicated loss of power parameter. However, the owner will refuel more, due to the increase in consumption provoked by this fact. The price of the mass air flow sensor is not exorbitant, so it is not advisable to delay replacement. The repair procedure itself is not difficult to perform. This can also be done at the service center during scheduled maintenance.

Distributor

Due to damage to this element, the spark does not reach the spark plug or arrives late. This happens due to wear of the bushing, bearings and shaft. As a result, a gap appears between the contacts, causing cycles to be skipped.

Troubling appears when it is cold, but disappears almost completely after warming up. This also occurs due to thermal expansion as the gaps become smaller.

New Lada: Lada Largus 2022 – present, I Restyling station wagon: reviews from owners, leave a review on LADA New Largus Cross 2022 – present, I Restyling station wagon on Autospot

Engine diagnostics

Before you start tinkering with the hardware, it’s worth turning to the car’s software and understanding whether the reason may lie in the failure of one of the power unit’s sensors or in a so-called software failure.

Getting access to the car's software is quite simple. To do this, the motorist will need some equipment and materials. First, you should find out which engine control unit is installed on the vehicle.

To do this, you need to look at the service documentation or decipher the body number. The second option is not available to everyone, and therefore it is worth following the path of the slightest resistance. Electronic engine control units marked 11186-1411020-12 can be installed on the Lada Kalina 2 power unit.

Diagnostics Lada Kalina 2.

Depending on which ECU is installed on the car, it is worth choosing software for diagnosing and repairing software. Also, in the process you cannot do without a USB data cable, which is called OBD II. Well, to perform direct diagnostics and guide the process - a laptop computer or tablet.

Let's proceed directly to the process of diagnostics and troubleshooting. We install the appropriate program on the tablet, which will not only allow it to synchronize with the ECU, but will also make it possible to carry out full diagnostics. After installing the software, connect the cable to the tablet and control unit.

By analyzing the data obtained, you can understand what the condition of the equipment is and whether there are problems. Typically, diagnostics show failed sensors that need to be replaced. After replacement, it is worth clearing the accumulated errors and trying to see if the engine operation has changed. If this does not happen and the cause remains, then you should go directly to looking for the causes in the hardware.

Replacing the device

Sooner or later, everything falls into disrepair, and the coolant sensor in the Lada Kalina also faces the same fate.

If any problem does occur, the device cannot be repaired; it is simply replaced. But don’t worry about this, this procedure is not complicated, it can be done independently, or you can turn to professionals for help.

If you are sure that the problem is still in the coolant sensor, proceed with replacement

. First you need to drain the coolant, then remove the air filter. Next, the plastic clip opens and the sensor harness connector is separated. After this, the element can be easily removed from the thermostat housing. Installing a new device occurs the other way around: the element is first screwed into place where it should be, and only then fixed with all the clamps. The latest thing is to replace the antifreeze.

Naturally, when performing actions, you must follow all safety rules and be careful not to harm your property or yourself. As you can see, the procedure is actually not complicated.

, but if after this, malfunctions are observed in the operation of the car, and the engine in particular, it is worth contacting a service station and completely checking other systems.

The engine stalls when hot: causes and common faults

Let's start with the main features. Often, a cold engine starts quite normally, but then begins to stall after partial warming up or completely reaching operating temperatures. In this case, tripping can occur both at idle and under load (while driving).

You should start by checking the control system (ECM) and the engine power system. It is recommended to immediately carry out computer diagnostics and check the condition of the injector and injectors.

In any case, incorrect readings or malfunctions of sensors (lambda probe, temperature sensor, mass air flow sensor, etc.) and actuators can cause a hot engine to fail. Based on incorrect readings, the ECU may well over-enrich the working fuel-air mixture and flood the spark plugs.

Next you need to move on to the spark plugs. At the initial stage, you should remove the spark plug high-voltage wires and unscrew the spark plugs from the BC. Next, a visual inspection of their contacts and insulators is carried out. Normally, candles should be dry, grayish in color, without a heavy layer of soot.

If the spark plug is wet and/or oily, then it is quite obvious that too much engine oil is entering the combustion chamber or the fuel is not being burned in the cylinder. In any case, a wet spark plug does not allow the cylinder to operate normally. Let us add that often both causes are often present simultaneously or are a consequence of each other.

If all the spark plugs are wet, you should check the oil level in the internal combustion engine. When the level is elevated (often as a result of overflow), the oil pressure in the lubrication system after the engine warms up exceeds the norm, excess lubricant penetrates the combustion chamber and contaminates the spark plugs. The result is a weak spark.

You also need to check the crankcase ventilation system. For example, the breather hose may become kinked, contamination may occur, etc. The main thing is that problems with this system also lead to pressure rising and excess oil entering the cylinders. If the hot vibration disappears after pumping out excess oil and cleaning the crankcase ventilation system, we can talk about a successful solution to the problem.

If this does not help, the spark plugs themselves will require increased attention. It is likely that even if the spark plugs have recently been changed, they will turn out to be incorrectly selected for the engine in terms of heat rating and will be “cold”; also, the spark plugs may simply fail or the product will be defective. To check, you need a kit that is known to be working (it is better if the spark plugs were removed from another car). If the engine does not start in these sections after warming up, then the spark plugs need to be replaced.

If it turns out that the dry spark plug in the cylinder has become wet, then it is worth checking the high-voltage ignition wire of a particular cylinder. The wire needs to be replaced with a working one. Also note that the problem may not be in the wires. For example, on carburetor internal combustion engines, a common cause of ignition problems is the distributor (ignition distributor).

On injection engines, failures can result from breakdowns of the ignition coils. In the case of a distributor, the device must be disassembled, dried, cleaned the contacts and made the necessary adjustments. If we are talking about an engine with an injector, you can swap the ignition coils and wires. This method allows you to quickly identify a faulty coil.

Check light is on, video diagnosis) — Lada Kalina Hatchback, 1.6 l., 2010 on DRIVE2

Please help, the check light comes on, full description:

There is a viburnum on a cable with a 1.6 16kl engine. From Priora with Bosch M7.9.7+ controller.

Initially, the car began to have trouble starting in cold weather and the check light came on.

At that time it was still under warranty, I went to the PSSS, they diagnosed one of the injectors as dirty, I did not agree with them, I always filled in good gasoline.

In general, after discussions, we carried out another diagnostic and found the ECU filled with antifreeze, they changed it and the problem went away. But a few days later the check light came on again, there was no longer a guarantee, I went to the diagnostician and they counted errors:

0300 Random or multiple misfires detected 0301 Cylinder 1 misfire detected

0302 Misfire detected in cylinder 2

The errors were cleared, I was advised to change the spark plugs, it turned out the officials screwed in 3 different types of spark plugs

candles that were replaced by the officials

I installed NGK BCPR6E -11, changed the oil, all filters, the mesh in the fuel pump, it was quite clean

fuel pump mesh

and everything worked perfectly, everything was clean in the gas tank too)

gas tank

I didn’t drive the car for a couple of days, and the problem repeated itself, the check light came on, you can see everything in the video. If you warm up the car, it can work perfectly without a check.

Can anyone advise me to check or see what?

Thanks in advance to everyone who responded!

## the problem has been solved, more details here: www.drive2.ru/l/660985/

Mileage: 45000 km

Finding the cause of the malfunction

The engine starts to stall when the fuel pump malfunctions and does not pump in the required amount of fuel, or when it does not burn completely. The substrate of the first case is not only the fuel pump itself, but also the conductive system. And the second reason may be related to problems with the ignition system, spark plug carbon, or improper operation of the engine valves.

If the fuel system is not working properly

, the feeling that the engine is stalling will develop a minute after the start, and then will only increase. If there is a narrowing of the pipeline, or there is no power to the fuel pump, such problems are not uncommon. You can check this after exposing the relay: start the engine, check the functionality of the pump and relay. In this case, the on-board computer will not show errors.

If there is a problem in the valve apparatus itself, in the spark plugs or in the ignition system, it will also manifest itself. Namely: the engine will start normally, but a moment later it will start to stall. Similarly, the power unit fault light should light up, because standard sensors perceive an excess (or lack) of fuel.

When such interruptions in the fuel supply occur, twitching develops, because the amount of gases produced in different engine operating cycles varies.

CHECK ENGINE

—

Check Engine Check - There's nothing fun or enjoyable about those two words. There is also not much logic that can be derived from this phrase, at least not logic that we understand. What does “Check Engine” mean? Is it something more or less specific? No is not. That's because the Check Engine Light means there's something wrong with our engine, and we can't know 100% what it is under the hood that caused that proverbial light to come on. In general and most common cases, Check Engine means that you will have to communicate with car service workers; in the worst case, if your car is far from young, Check Engine may even mean an upcoming major repair.

How to rebuild a Lada engine

Serious malfunctions, of course, are very difficult to fix on your own, without special equipment, but every driver should know the basics. So, how to rebuild an engine?

Remove the motor and dismantle its components in the following sequence:

- water pump;

- generator;

- carburetor;

- starter;

- gasoline pump;

- collectors;

- ignition system breaker;

- camshaft drive;

- valve cover;

- flywheel;

- clutch device;

- pulley;

- cylinder head.

Now clean the parts and carefully inspect them for damage. If you notice any defective ones, replace them with new ones. It is advisable not to use used parts, even if they are in reasonable condition.

Repairing the cylinder head. Here you should change the seals and put the valves in order. We carry out installation in reverse order

When replacing spark plugs, it is important not to forget to check the safety valve, since a short circuit may also blow the fuse

Is the engine acting up? Check the spark plugs!

So, what should we do if we set off on a long journey, but suddenly, unable to withstand a severe test of strength, the car stalled midway? The situation is not pleasant. But don’t give up, it’s time to get down to business. The problem may lie in the following.

- Most likely, you filled your car with gasoline of not the best quality. It's possible that debris somehow got into the motor. Just in case, it’s still worth cleaning the fuel lines and the tank itself, drying it and filling it with normal fuel that you are sure of. By measuring the pressure in the fuel rail, you will know whether there is a problem here or whether you need to look further.

- Damage to the fuel pump. It is easier to identify this problem: if the ignition is still turned on, then if there is a defect, the fuel pump makes a characteristic sound, indicating a malfunction. Remove the pump from the gas tank and check the outlet pressure in the tank using the power supply method. The pressure coefficient should not be less than 2 atmospheres.

- Ignition system failure: spark plugs do not produce a spark. To fix the breakdown, you just need to replace the spark plugs with new ones; it won’t take much time.

- Throttle assembly defective. This unit is the most important part that performs a significant part of the engine’s work. When it deteriorates, air and fuel mix, which leads to engine stupor.

- Injector failure. This is the most rarely encountered problem.

- It is necessary to adjust the timing valves if for some reason there is a violation of the clearances.

- The gas pedal needs repair.

- The motor has not yet been run in, so it malfunctions. The solution to the problem is simple: you need to be patient and break it in, driving 6000-7000 km. But it is worth remembering that the speed cannot be raised above 3000, otherwise serious repairs will be required after break-in.

This sensor monitors oil pressure

Check the fuel filler cap

Many drivers, in most cases, when the “check engine” indication appears, will think about serious problems in the car’s engine, but will not even think to check the tightness of the fuel system, which may be compromised due to a defect or an insufficiently tightened fuel tank cap. This is a very common reason for the appearance of the “Check” engine icon.

Reason for the error: Leakage of the fuel system due to the passage of air through the filler cap of the fuel tank will increase the vehicle's fuel consumption, to which the vehicle's diagnostic system will generate an engine error by turning on the "Check engine" indication on the vehicle's instrument panel.

What needs to be done: If, when the “Check” indication appears, your car has not lost power, and there are no audible signs of engine damage (engine knocking, humming, creaking, etc.), then first check the gas tank for leaks. Your gas cap may be cracked or not tightened enough. If the cap was not tightened enough, then after tightening it all the way, continue driving the car for a while to see if the engine error disappears. To prevent a check engine light from appearing for this reason, check your fuel filler cap regularly. Remember that the cover must be replaced with a new one periodically!

Peculiarities

As a rule, stable activation of the check sensor occurs suddenly. During normal operation of all units controlled by this system, the indicator lights up briefly when the engine starts, and then goes out. Prolonged illumination indicates certain problems that are quite difficult to identify on your own. Why the check light is on on Kalina 8 and 16 valves is best to find out from specialists at a service station. This is especially true if the presented DIY troubleshooting methods did not produce results.

Hello, dear car enthusiasts! Probably many of you, while driving your car, have been spoiled a lot by the Check Engine light that lights up, then goes out, or even burns (without any obvious reason) with an “eternal flame.”

What's wrong? Even many auto gurus cannot give an exact answer to the question why the injector light is on. Let's try to dig into the structural principle of the malfunction.

The electronic control unit (ECU) of your car controls the engine through a system of sensors. If the injector light comes on, this means that one or more sensor parameters have failed, to which the ECU reacts accordingly.

Let's consider the functions assigned to the injector sensors. Knowing what the sensors are responsible for, it is somewhat easier to judge the behavior of your car and draw conclusions: either fix the problem yourself, or contact a car service for diagnostics.

The injector light is on: what the sensors say

Crankshaft sensor - determines the speed of its rotation, position, and, consequently, the location of the pistons in the cylinder. The sensor operates based on electromagnetic induction.

If the injector is on because the crankshaft sensor is triggered, the consequences, if ignored, may be as follows: engine idling will be unstable, and if the sensor fails, the engine may stall and will not start at all.

The injector light is on due to data from the phase sensor, which is responsible for monitoring the gas distribution control in each engine cylinder. In this case, the ECU switches from phase injection to backup - the so-called pair-parallel mode.

The operating principle of the sensor is based on the Hall effect; the sensor is located on the front of the block on the input manifold side. Typical signs of a malfunction are increased fuel consumption and hesitant engine starting.

Andreyaleksandr › blog › 53. why does the viburnum engine troit? or a berry with a twist.

Good day to all!

Cases of superimposition of one fault on another are not uncommon. So this time Kalina with a bouquet.

Actually, it all started with a complaint about periodic tripping of the engine. It may triple, it may not. A common thing for a VAZ 8-valve. Don't believe me? Open the Kalinoforum, there is an extensive topic on this issue, some in the forest, some for firewood. And they really have already managed to break the wood.

I tried to run an efficiency test, but it gave me something absurd.

But the ignition test gave the first clue: the spark burning time in cylinders 1 and 4 is noticeably different from cylinders 2 and 3 and there are no damped oscillations, which indicates a coil malfunction.

We replace it with a new one - the oscillograms take the correct form, the coil works.

Then the shape of the DPKV signal attracted attention, and the oscillogram of the pressure sensor in the cylinder clearly shows that the DPKV master disk is not in place.

And the OZ jumps abnormally

The phases are still in place

The Px script also swears at the UOZ

The DPKV master disk dangles in a figure eight pattern. And the reason turned out to be simple

Probably during repair work during installation, the pulley came off the key and was tightened that way. The key and protrusion on the timing gear were pressed into the pulley. Naturally, the master disk was not in place, which is why there were problems with the OZ. Plus a faulty coil - all this together caused tripling. Replace the pulley with a new one

The effectiveness test now passes.

Defective parts have been replaced.

The first part of the “Marlezon ballet” is finished. Actually, we could stop there, because the malfunction with which the car arrived has been fixed and the owner is satisfied with how the car works. But what caught my attention was the fuel trim factor.

And they say that the mixture is orderly, practically stoichiometric. Go ahead. Soot free exhaust pipe

And the ECU says rich mixture... Spark plugs

Rich mixture again? Okay, let's say the fuel pressure is too high. But no

But the sensor is too expensive, and the owner has already spent a lot on the coil and pulley, and in addition to the scanner, I have something to check the mass air flow sensor. Further pictures did not fit into the post, so I will tell you in words. The air flow sensor is alive and well and will live just as long. The oxygen sensor is also in working order and works better than new.

Well done TPS, signal picture. And the correction clamps the fuel supply as if the mixture is rich, although in fact it is normal... Miracles. The firmware remains. But this was already beyond the renovation budget. The car left, but if it comes back again there will definitely be a sequel. After all, I’m curious what the highlight is