Despite the fact that the VAZ-2121 SUV was developed quite a long time ago, this car is still very popular. In 1994, the model was changed to VAZ-21213. Many people buy these cars because of their high cross-country ability, which can be the envy of some jeeps from famous brands. Others like reliability, unpretentiousness and high maintainability. A simple design and excellent off-road characteristics made this vehicle a vehicle for lovers of travel, hunting, fishing and tourism.

Niva cars 211213 are equipped with a 1.7 liter engine. It is carburetor, and is based on a VAZ-2106 engine. There is also a five-speed manual transmission and a proximity ignition system. The power system is equipped with a Solex 21073 carburetor for the Niva. Many novice car owners are intimidated by carburetors and everything connected with them. But a carburetor is not a death sentence. You just need to understand its basic structure, how to adjust it, and how to repair it.

Device

The Solex 21073 carburetor installed on the Niva 1.7 can be classified as an emulsion device.

The mechanism is designed to prepare a working fuel-air mixture. The device consists of two parts - the body and the cover. The device also consists of a float chamber with the ability to balance the level. There is an accelerator pump, an economizer, and an econostat. The design has two fuel chambers and diffusers. A flammable mixture is prepared in them. The lid has fittings through which gasoline is supplied to the carburetor, and excess fuel goes back into the tank. There are also studs in the lid. They are used to mount the air filter. The lid is also equipped with a needle valve for the float chamber, where the fuel level is directly regulated. The carburetor has a mechanical air damper. It allows you to start the engine “cold”. In this modification, the Solex 21073 carburetor on the Niva 21213 shows very high efficiency. When properly configured, the device is capable of providing very high technical performance for front-wheel drive vehicles.

Do-it-yourself Solex carburetor adjustment

The main purpose of carburetor tuning is to ensure stable engine operation throughout the entire speed range. A number of adjustment operations can only be performed by an experienced craftsman in specially created workshop conditions. However, you can make some settings yourself and achieve a very decent result.

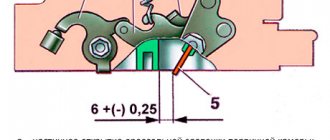

So, first, let's find out how the float chamber is adjusted in order to set the optimal fuel level. This procedure is usually performed after the needle valve has been replaced. To do this, remove the carburetor cover and then place it on a clean surface with the floats facing up. Using a caliper, measure the distance between the cover gasket and the furthest point of each float. If this distance is 34–35 mm, then everything is in order. Otherwise, the gap must be adjusted using the tongue and levers by bending them in one or the opposite direction.

It is necessary to install the support surface of the tongue so that it is located strictly perpendicular to the axis of the needle valve. No dents or dents are allowed. When replacing the cover, make sure that the floats do not come into contact with the walls of the float chamber when moving. If necessary, also bend the float arms.

How to adjust the starting system

There are several ways to correctly adjust the starting system of the Solex carburetor of the Niva 21213, but most often two main ones are used: by the size of the gap at the edges of the valves and by the crankshaft speed. The first method involves removing the device, and the second is used when the carburetor is installed on the car. Let's look at each of these options.

If you have removed the carburetor for repair work, then it makes sense to use the first method. In this case, the adjustment consists of setting the optimal gap between the lower edge of the throttle valve and the wall of the mixing chamber - its value should be 1.1 mm. Adjustment is carried out using a 7 mm wrench screw (or a slotted screwdriver). Before carrying out this operation, set the air damper lever to its extreme position, completely closing it - to do this, turn the lever all the way counterclockwise. Thus, you have cocked the starting device and brought it into working condition. The lever should be in a similar position when setting the gap between the lower edge of the air damper and the walls of the chamber. There is a screw in the diaphragm mechanism cover, by turning which you can set the gap to 3 mm, after first loosening the lock nut. At the same time, set the diaphragm rod in such a position that it comes into contact with the adjusting screw. If you followed the instructions and the adjustment was completed successfully, do not forget to secure the screw with a locknut. All measurements can be carried out using a special probe or wire of the appropriate diameter.

As for the second method, used in the process of setting up the starting system, most knowledgeable car enthusiasts prefer it, since in this case adjusting the Solex carburetor on the Niva 2121 takes much less time. The procedure is as follows:

- First you need to provide free access to the carburetor, which requires removing the air filter.

- Pull the choke control cuff (choke) all the way and start the engine (assuming it has been warmed up in advance).

- Using a flathead screwdriver, force open the air damper 1/3.

- Next, by turning the screw located next to the throttle control lever, set the crankshaft speed to 3200 rpm.

- Now the air damper should be released, then loosen the lock nut of the starter adjustment screw and use a slotted screwdriver to turn the screw until the rotation speed decreases to 3000 rpm.

- Once you have tightened the locknut, you can consider setting up the starting system complete.

If you have a gas analyzer at your disposal, then all work on setting up the starting device can be carried out based on the recommended amount of carbon monoxide (CO) in the exhaust gases. In the case when the carbon monoxide content is 8% when the suction is pulled out all the way, nothing needs to be adjusted. If this value is less, then it is necessary to tighten the screw on the diaphragm mechanism cover. Conversely, if the percentage of CO in the exhaust is exceeded, this screw is unscrewed and repeated measurements are taken.

Operating principle

The Solex 21073 carburetor installed on the Niva is designed to prepare a mixture of fuel and air, as well as supply it to the combustion chambers of the engine. After starting the power unit, the driver closes the damper. This ensures that a rich mixture is supplied to the cylinders.

By adjusting the automatic system, air flow increases by turning the throttle. As the engine warms up, the choke is removed. The carburetor begins to operate in its main operating mode. Gasoline from the fuel tank is supplied to the float chamber using a diaphragm pump. The amount of fuel depends on the position of the needle valve. Next, liquid fuel enters the main jet through special channels located in the device body. Then - into the first mixing chamber. The second camera of the device will be activated when the engine begins to operate under high load - if the driver sharply presses the accelerator pedal. When the engine is idling, the solenoid valve is activated. Thanks to this, the motor can operate stably. Fuel consumption is reduced.

What kind of carburetor is installed on the Niva initially?

The Niva car is equipped with carburetors from the classic “Ozone”, which is not the best two-chamber unit with an idle economizer. The economizer is an autonomous system with a solenoid valve that automatically comes into operation when the ignition is turned on. When the speed increases above 1000, it is turned off, and the engine is maintained using an air damper.

The updated model received the French Solex design. The 1.7-liter engine required an increase in the amount of air-fuel mixture, and therefore Ozone was no longer used.

Float mechanism

The Solex 21073 carburetor, installed on the Niva, has a float chamber of two sections. They are located on both sides of the main cameras of the device. The system consists of two ebonite floats, which are mounted on a lever.

The latter swings on an axis pressed into the bosses of the device cover. There is a tongue on the bracket. The element presses the needle valve needle through a special ball. The float mechanism serves to adjust the level of fuel required for normal operation of the carburetor. The needle valve is a non-separable type. It is not being repaired. The valve body is mounted on a thread in the carburetor cap. The ball protects the needle from shock when the machine moves. If the chamber is empty (for example, if the driver is using LPG), then the floats will knock.

How to reduce fuel consumption on a VAZ 2121

moLife Blog Carburetor Pierburg 2E

Using a standard carburetor, the Niva consumes a large amount of fuel. Putting a Solex carburetor on the field does not mean that the problem is completely solved

It is important to monitor many other systems and the overall condition of the vehicle.

The following parameters affect fuel consumption:

| Cleanliness of filters. This applies not only to the fuel filter, but also to the air filter. If less oxygen gets into the carburetor, the Niva 2121 will begin to consume more fuel in order to maintain the speed at the desired level. The mixture will become richer and it will begin to pour. |

| Tire pressure. If the pressure is insufficient, then the engine has to do a lot of work to overcome such resistance. This leads to the fact that, while performing unnecessary work, the engine consumes a huge amount of fuel. But you should not overinflate your tires, as this will impair road grip. |

| Excess weight of the car. The effect is the same as with insufficient pressure. If you carry it in the trunk, the carburetor will fill the cylinders with more fuel. Niva 2121 is not designed for transporting goods. |

| Violation of aerodynamics. This applies to luggage racks and cargo installed on the roof of a car. An increase in air resistance causes the motor to consume more energy. The same applies to open windows when driving on the highway. |

| Aggressive driving style. It is known from driving school that a smooth increase in speed and smooth braking helps to save fuel. When driving at higher speeds, the carburetor consumes more gasoline. The VAZ 21213 Niva was designed taking into account driving at speeds no higher than 3000. If you do not exceed these limits, you can save a lot. |

| Driving in neutral gear. This is the biggest mistake many drivers make. When the speed drops below 1100 rpm, the autonomous idle system comes into play, which forces the engine to consume more fuel so that it does not stall, since the throttle is closed at this moment. When approaching intersections, you need to take your foot off the pedal and smoothly shift to lower gears. |

| Use of electronic devices. If you turn on a large number of different devices at a time when they are not needed, the load on the generator, the pulley of which is in mechanical connection with the crankshaft, increases. This leads to excessive consumption of gasoline. |

| Long engine warm-up. Many people take too long to warm up their car. It is most effective to apply warm-up while moving. When the motor has reached 50 degrees Celsius, you can start moving without putting a lot of load on the motor. The temperature will reach 90 degrees much faster, and, accordingly, more fuel will be saved. |

| Driving at maximum speed on the highway. If you go too fast, air resistance increases proportionally, which slows down your movement. The same principle applies here as when aerodynamic characteristics are violated. |

Author of the article: Yuri Veselov

Main dosing systems

The first and second chambers are equipped with diffusers. There is one large and one small element. Spray devices are also made together with small diffusers. The latter are connected through channels to the emulsion wells, and they communicate through one channel with the float chamber. To ensure that gasoline flows in certain portions, the main fuel jets are located below in the emulsion wells. These same wells have special tubes. Each of them is equipped with an air jet at the top. Air is supplied to them from the neck of the device.

Which is better - Niva carburetor or injector: technical characteristics, tips and recommendations

“Niva” is perhaps the most famous Soviet and Russian SUV. This car was first introduced back in the 70s of the last century. Niva is still produced to this day. At the moment, all new Nivas already come with injection engines. But on the aftermarket there are many carburetor options. Which Niva is better - an injector or a carburetor? Let's try to figure it out.

Technical characteristics of the carburetor version

To find out which Niva is better - carburetor or injection, first you need to consider the technical characteristics of both models. So, let's start in order. Initially, the engine for the Niva was taken from the classic Zhiguli. This is the same engine, but with an increased volume of the combustion chamber. The first for a Soviet SUV was the 2121 engine with a displacement of 1580 cubic centimeters. This engine developed a power of 80 horsepower. With it, the car accelerated to hundreds in 21 seconds. At the same time, according to the passport data, the consumption was 13.1 liters, but in reality it was even more.

Operating principle of the main dosing chamber

Under the influence of vacuum that occurs in the engine cylinders, air is drawn through the filter. Next, oxygen is supplied to the first chamber. It passes through diffusers. Due to the fact that the air flow speed has increased, an even greater vacuum is created in the nozzle area.

Under its action, the fuel rises from the emulsion well from the atomizer. At the same time, air passes through the air nozzle into the emulsion tube and is then mixed with fuel. As a result, an emulsion is formed, which is sucked at high speed into the carburetor channels, where it connects with the air flow. The installed Solex 21073 carburetor on the Niva operates on this principle. Its design may vary depending on the modification. But the principle of operation of the systems is approximately the same for all devices.

Methods for tuning the Ozone carburetor for a VAZ classic.

1. We take out and throw out the spring from the vacuum drive of the throttle valve of the primary chamber. The method is already known and described by many. The improvement in dynamics is significant, fuel consumption practically does not increase: a maximum of 0.5 liters per hundred. 2. You can try to convert the secondary chamber throttle valve drive into a mechanical one. This is done very simply: we take a small piece of wire (You can take the same spring that was in the vacuum drive of the secondary chamber), straighten it, and bend it into a ring on one side. We put this same ring under the nut securing the throttle valve drive levers of the secondary chamber. Moreover, you need to slip it so that the protrusion on one drive lever is between this piece of wire and the second drive lever (as in “Weber”). Then you need to tighten the nut tightly. We get another improvement in dynamics, especially noticeable at high speeds; fuel consumption per hundred remains virtually unchanged. You may soon forget what overclocking failures are. 3. We take out the standard small diffuser of the primary chamber (inserted from above into the large diffuser above the throttle valve), marked 3.5. We put there a small diffuser marked 4.5, exactly the same as in the secondary chamber of the classic carburetor. If necessary, replace the standard (“30”) accelerator pump nozzle with a large (“40″) one (like the “Weber” 2101-03). Dynamics, especially at low speeds, improves. 4. Increase the jets (you must know what you are doing!). Primary chamber: install GTZh-125, GVZh-150. We do not touch the secondary camera yet. Dynamics and power have increased. We increase, neglecting recommendations for saving gasoline and environmentalists: we put GTZh-162, GVZh-190 in the secondary chamber! The largest jets ever produced and installed only on the Weber in the six (the diameter of the secondary chamber diffuser in the Ozone is similar to that in the Weber). Fuel consumption increases; a non-killed engine can be turned above 6000 rpm. increase!... In the primary chamber we put GTZh-130 for an engine with a volume of 1500 and GTZh-135 for an engine of 1600. It no longer makes sense to install jets - when you sharply press the gas pedal, the carburetor begins to “overflow” and “chokes” - the dynamics are worse, the power drops , consumption is higher. In the secondary, the same GTZh-162, GVZh-190 remain. Fuel consumption. The point is that if you have installed such a set of jets, then during normal city driving there is no need to press the pedal to the floor everywhere and always. Accordingly, gasoline consumption can be easily maintained at 10.5-11 l/100 km. At XX, gasoline consumption will remain the same all the time - we didn’t regulate it! . But if somewhere we need quick acceleration, our enlarged jets will help us a lot

An important circumstance when tuning a carburetor for a VAZ “classic”. The bottom line is that jets must be selected individually for each engine.

An average description is presented here, but a lot still depends on the condition and size of the engine, each specific carburetor and the jets themselves. Every detail makes a difference to the overall scheme! Installing a “Solex” in comparison with an “Ozone” will give better dynamics, but with a “Weber” or “Ozone” the car still drives easier, without failures, and there is also a minimum financial investment. And the biggest difference is reliability. A way to increase the amount of air entering the carburetor is “pseudocharging”. The heated air supply hose is replaced with a longer one. They take him to the radiator. Attach it close to the fan, so that air from the fan enters the hose in a direct flow. A slight increase in dynamics (cons: only warm air, a very “dirty” method - all the dirt not stopped by the filter flies into the cylinders - reduced service life).

Idle system

The device is equipped with an idle system. It is designed to allow the engine to operate at low speeds. At this moment, the vacuum in the diffusers is very small. Fuel cannot enter the main metering system. At idle speed of the engine, fuel is supplied under the throttle valve of the first chamber of the carburetor. There the vacuum is strong enough to form a stable combustible mixture.

Air is supplied through the main jet and the emulsion well of the first chamber. The fuel will then flow to the idle fuel jet. After this, it is mixed with air supplied from the XX air jet. Oxygen is supplied to this element through a special channel. This operating scheme allows the engine to ensure a smooth transition from load to idle and prevents fuel from leaking out of the float chamber.

Setting up a new carburetor

Before adjustment, you need to install jets suitable for the engine size. Too small will cause a loss of power and increase fuel consumption. The float chamber does not need to be adjusted; this was done at the factory. Next, the carburetor itself is adjusted:

- Start the engine and warm up to operating temperature.

- Turn the quantity screw until the engine speed drops to 800 rpm.

- Unscrew the quality screw until the crankshaft speed increases to the maximum.

- Now set the quantity again to 800 rpm.

- Unscrew the quality screw gradually until the engine begins to tremble a little (this means that CO2 emissions will be minimal).

Troubleshooting

Car components do not last forever, and sometimes the installed Solex 21073 carburetor on the Niva fails. Repairing it must begin with diagnostics. It may be possible to get by with a simple adjustment. So, during operation, solid particles can enter the carburetor, which ultimately causes clogging of the jets. Low-quality gasoline leads to the formation of deposits on the walls of the channels in the device. This significantly reduces their cross section. Failure of carburetor systems can be diagnosed by the following symptoms:

- Increased fuel consumption.

- Difficulties in starting the engine. Reduced power and dynamic performance.

- Unstable operation at idle.

In this case, it is necessary to clean the installed Solex 21073 carburetor on the Niva. The adjustments that will be made after this will allow the device to work as it should again.

The meaning of replacing a standard unit

The factory equipment of Niva 21213 is a famous headache for owners. It is not bad, but many parts are strongly recommended for replacement. Their combination significantly reduces the possible potential of a domestic SUV. As for the carburetor, it is replaced for the following reasons:

- Installing a couple of parts. Two carbs are installed by those owners who do not have enough power. This arrangement is quite rare, because the same effect can be achieved by tuning or installing a more advanced carburetor.

- The second reason for changing the unit is to reduce the normally high fuel consumption. Rare use of an all-terrain vehicle for its intended purpose and city driving provoke excessive fuel consumption without using all the capabilities of the vehicle.

How to restore carburetor operation?

For repairs, most often you have to remove the device from the engine. First, remove the air filter. Then the fuel lines, air pipes, wires and cables are removed. then unscrew the fastening nuts.

It is best to disassemble the carburetor on a table or other convenient surface. The parts should be laid out in some order. This will help you not lose them. The process of adjusting the needle valve is performed using a special template. To wash the device, you must use special liquids. Replacement jets can be purchased at any auto stores. Often, disassembling and flushing the carburetor helps solve a lot of problems.

Installation in reverse order

Installing a carburetor mechanism on a Niva takes much longer than removing it. This is because the reverse process is more complex in terms of connecting hoses and fuel lines.

The procedure for installing Ozone on a VAZ 2121 is as follows:

The device is threaded onto four studs to the intake manifold.

The corresponding nuts are screwed onto these studs to give the carburetor stability and the required position.

The throttle control rod snaps into place.

The choke cable is screwed into place.

Next, you will need to connect all the hoses in strict order: first the fuel pipe, then the return line, after which you can connect the remaining hoses in any order.

The fuel filter box is screwed to the carburetor body.

After this, the box is attached to the engine compartment frame.

Adjustment

If the installed Solex 21073 carburetor on the Niva fails, repairs and adjustments help bring the device back to life. The settings allow you to restore optimal modes in which the motor will operate as efficiently as possible. Fuel consumption is at an average level. First of all, start the engine and warm it up a little. Next, you need to remove the fuel hose and the device cover. It is recommended to remove the latter with extreme caution so as not to damage the float. Next, using a measuring tool, measure the distance in each of the carburetor chambers. Measure from the mating surfaces to the edge of the fuel. This size should be approximately 24 mm. If this distance is less or more, then it is adjusted by bending the float. Then you need to start and warm up the engine again. When the level adjustments are successfully completed, you can proceed to adjusting the idle speed.

The engine is turned off. To set up, you will need a flathead screwdriver and a little time. There is a hole on the base of the device in which there is a screw that regulates the quality of the fuel mixture. It is twisted all the way. Then from the extreme position the same screw is unscrewed by about five turns. Then the engine is started. There is no need to use a suction. If you unscrew the “quality” screw, then the carburetor will change the engine speed. Then it is twisted again. It is required to rotate until the operation of the motor is stable and stable. When the engine starts to run smoothly, then the element is unscrewed no more than one turn. As a result, the idle speed will be set at 900. If the engine starts to stall, it is better to slightly increase the idle speed.

Reviews about installing other carburetors on Niva 21213

| Carburetor owner and model | Review of the carburetor |

| “Carburetor model Pekar K172” Author of review: Ssan40 | I bought a Pekar K172 about a month ago, by the way, it’s a copy of DAAZ. So, at first I was happy with the unit, there were no problems. Only the music didn’t play for long, and after about three weeks the problems started. Let me note that I didn’t do the tuning myself, I have a trusted technician who will adjust the carburetor and rebuild the gearbox. He did everything quickly and conscientiously. But again, while I was driving within the city, everything was fine, no flooded spark plugs or problems with adjustment, as soon as I got on the highway, the spark plugs were flooded. By the way, I have an Audi 80 b2 with a 1.8 ds engine. I had to stop after every 20 km to clean the spark plugs. While driving I almost went crazy. And what’s most interesting is that before Pekar there was a Solex, this carb needed replacement for a long time. I went to a specialist for debugging literally every month, maybe once every two months. And so, it seems like I bought a new carb, installed it, and then this happens. In short, I exchanged one piece of garbage for another, and even paid for it, and that’s not even counting the lost nerve cells. As it turned out, the new carb is even worse than the old one, and that one, by the way, served for more than one year. And yes, then I finally debugged it, did everything myself. But, as it turned out, even here I didn’t have to rejoice for long, everything was fine in the city, when I got on the highway, it started again, the spark plugs were flooded again and stops, plus idling was added to this. I decided to go to a specialist again, if he couldn’t debug the unit, it turns out that four and a half thousand went down the drain. |

| “Carburetor model baker 21073” Author of review: DimaPisarev | In short, I bought a new Pekar 21073 for my Niva, engine 1700. What can I say, in my opinion, the money was simply thrown away. I went to the carburetor guy, he looked at it, tinkered with it and said that he couldn’t debug it properly, that is, set it up. In the city the car drives fine, just a lot of fiddling with the choke. And yes, he said that I need to change the jets. |

| Carburetor model: Solex Reviewed by: Alexander Priporov | You could say that I am a true carburetor collector. I also installed sports ones when I was boosting 2108. There were problems with everyone. What can I say, I haven’t seen normal carburetors, at least, well, just so that everything would be fine, there were no such ones in my memory. Of course, I have an opinion on literally all carbs that are in demand in our country. So, if we talk specifically about Solex, the first thing that comes to mind is the word “simplicity”. You won't find a simpler carb. Repair is simple, as is setup. I will also note that repairing this unit is also cheaper than if you take carbs from other manufacturers. Buying a diaphragm is simple and inexpensive. The main thing is not to forget about cleaning, this carburetor needs to be cleaned about once every six months or so. By the way, I realized one thing for myself: if you want to install a single-chamber one, then be prepared to enlarge the first chamber of the nozzle, while closing the second one. Yes, here Solex is comparable to Weber, but if we talk specifically about versatility, then Solex is beyond competition. Such a large selection of jets opens up many possibilities for customizing the carburetor; you can get a unit with literally any necessary characteristics. |