A carburetor is an important element of a car's fuel system. Its main task is to prepare the air-fuel mixture and seamlessly transfer it to the engine combustion chamber. Solex 21073 is one of the best designs of an emulsion two-chamber carburetor. It consists of two main elements: a massive lower part and a lighter lid. Taking into account the increasing requirements for environmental safety and decisions of the European Union Commission, all manufactured cars must comply with Euro 2 and Euro 3 standards. The Solex carburetor allows you to fulfill these rules.

Device and principle of operation

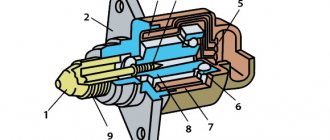

The basic principles of mixing fuel and air using a simplified scheme are demonstrated in the figure.

As the piston moves downward from top dead center, the intake valve opens, allowing the air-fuel mixture to be drawn in from the carburetor. At this moment, in the diffuser 6 of the mixing chamber 8, the fuel coming from the atomizer 4 through the nozzle 9, metering the fuel flow, is mixed with the air sucked in through the air damper 5. The flow of the air-fuel mixture is regulated by the throttle valve 7, connected to the gas pedal.

One of the main parts of the carburetor design is the float chamber 11. The operation of the engine depends on its correct setting. The fuel level in the float chamber is regulated by the position of floats 10 - there are two of them in Solex. When gasoline enters chamber 11 from fuel line 1, the floats float up and block the flow of fuel through needle valve 2. In this case, the air displaced from the float chamber leaves through technological hole 3.

Sprayer 4 is designed in such a way that its upper cut edge is slightly higher than the fuel level in the float chamber. As the air flow passes through the diffuser, gasoline is sucked in and further mixed with air. If there is too much fuel in the float chamber, it may leak out. If the mixture contains too much gasoline, it will lead to the following negative consequences:

- pouring candles;

- incomplete combustion of fuel;

- increased fuel consumption;

- reduction of engine thrust;

- increase in the volume of harmful emissions.

When the level of gasoline in the float chamber is low, it is difficult to suck it in. The air-fuel mixture contains an insufficient amount of gasoline, which leads to unstable engine operation and jerking when driving the car. For this reason, it is necessary to monitor the fuel level in the float chamber and the condition of the needle valve.

Troubleshooting

Car components do not last forever and sometimes the Solex 21073 carburetor installed on the Niva fails. Repairs must begin with diagnostics. It may be possible to get by with a simple adjustment. Thus, during operation, solid particles can enter the carburetor, causing clogging of the injectors. Low-quality gasoline leads to the formation of deposits on the walls of the device channels. This significantly reduces their cross-section. Failure of carburetor systems can be diagnosed by the following symptoms:

- Increased fuel consumption.

- Difficulty starting the engine. Reduced power and dynamic characteristics.

- Unstable minimum.

In this case, it is necessary to clean the Solex 21073 carburetor installed on the Niva. Adjustments made later will allow the device to function properly again.

Installing a carburetor on a Niva

Until 1994, the Niva 2121 was equipped with Ozone carburetors, which still operate successfully to this day. Assessing all the positive and negative aspects of existing designs, AvtoVAZ began installing Solex 21073 carburetors on the Niva. According to numerous car enthusiasts, this mechanism is more economical than Ozone. The engine is characterized by better performance, but it becomes more difficult to configure, more capricious to the quality of gasoline and oil vapors penetrating from the crankcase.

You can install or replace the carburetor yourself using standard tools. First, you need to dismantle the air filter, loosen the fuel line clamp and carefully remove it from the fitting, draining the gasoline in the fuel line into a prepared container. Then you should loosen the clamps and remove all pipes connecting to the carburetor:

- draining fuel into the fuel tank;

- carburetor heating unit;

- vacuum regulator of the ignition distributor;

- exhaust gas recirculation systems;

- suction of crankcase gases.

By removing all the electrical connectors, you can remove the throttle linkages and the choke control cable. Having disconnected all external communications from the carburetor, it is necessary to unscrew the nuts securing it to the intake manifold. Then you can carefully dismantle the mechanism. Installing a new carburetor is performed in the reverse order.

Equipment location and dismantling

The standard fuel mixer is installed on the exhaust manifold platform using four studs in the engine compartment. It is recommended to carry out prophylaxis in the removed state. The design contains many small parts and mechanisms that require cleaning and diagnostics. Of course, if the breakdown is obvious and insignificant, then there is no need to dismantle the equipment at all. The final decision is made by the repairman. After all, this directly proportionally affects the final cost of the work.

To remove the carburetor from its standard seat, you must:

- Unscrew the air filter cover on the right side of the engine, remove the cleaner itself and its housing part. Having previously unscrewed the four nuts to “8”. Some motorists independently modify the mechanism to accommodate long “10” bolts for ease of fixation;

- disconnect the crankcase exhaust pipes, vacuum hose, fuel supply pipe, return channel. Since there are gasoline residues in the pipes, you need to get a rag to remove the consequences of the leak.

Note to the driver: it is strictly forbidden to carry out repair work on a “hot” engine, as there is a high probability of ignition. Ignoring these recommendations leads to undesirable consequences. Woe - craftsmen often get burned.

When the body part of the “mixer” is completely freed from third-party mechanisms, it is necessary to release the fastening bolts of the top cover using a Phillips-head screwdriver. Just five;

This completes the dismantling of the upper half of the cover. To carry out a full diagnosis/repair, it is necessary to unscrew the second - lower part. The landing platform is mounted on four studs with nuts.

When removing the carburetor from its original place, you need to be extremely careful. The manifold outlet is open and a foreign object may get inside that should not be there. This can lead to the inoperability of the entire unit.

Instructions for adjusting the carburetor

Solex is a fairly reliable device, but it is advisable to carry out the necessary adjustments every six months of vehicle operation in order to optimize engine performance and save gasoline. These include: adjusting the quality of the fuel mixture, its level in the float chamber and the number of idle speeds.

Before carrying out any calibration work or troubleshooting, it is advisable to clean the carburetor of dust, oil and other contaminants. It is more convenient to do this with the air filter removed.

When adjusting the Solex carburetor installed on the Niva, you need to put the gearshift knob in the neutral position, start the engine and let it run for about five minutes. This will allow the fuel pump to fill the chamber. Then you should remove the fuel hose from the carburetor, after turning off the ignition. To prevent the gasoline remaining in the fuel line from leaking onto the engine, prepare in advance a container into which it can be drained. After this, dismantle the choke control cable and remove the screws securing the carburetor cover to its body. When removing the cover, you need to be extremely careful not to damage the gasket and fastenings of the floats.

Having gained access to the float chamber, it is necessary to measure the fuel level. It is convenient to do this with a caliper with a depth gauge. The distance from the edge of the chamber to the edge of the fuel should be 24-25 millimeters. If these values do not correspond, you should bend the tongue on the float axis in the desired direction, put the cap in place, start the engine, and then repeat the procedure of removing the cap and measuring the fuel level.

The idle speed setting is carried out on a warm engine. First, use a flat-head screwdriver to tighten the mixture quality screw located on the base of the carburetor until it stops. It has a left-hand thread, so it should be screwed counterclockwise. Then you need to unscrew it five turns and start the engine. Having removed the choke (air damper), we make minimum but stable engine speeds by rotating the fuel supply amount screw. Then, slowly turning the quality screw, you need to achieve unstable operation of the motor, and after that, unscrew the quality screw one and a half turns. This is enough to restore stable operation. You can set the recommended rpm (850-900) using the quantity screw.

Replacement in every detail

Having selected the Solex carburetor jets by numbers, you can begin to replace them; unlike boring, it is quite possible to carry out this operation yourself at home. By the way, the reason is not always an incorrectly selected element; very often during operation, these parts wear out and become clogged, which leads to a change in the diameter and composition of the mixture with all the ensuing consequences. In addition, car owners in this way increase the power of their “iron horse” or, conversely, reduce gasoline consumption. In general, replacing jets is quite suitable in the category of vehicle tuning.

To remove the Solex jets, you will have to dismantle the engine and, of course, disassemble it. Before removing the power unit, be sure to disconnect the negative cable from the battery, and then remove the air filter housing. Prepare a clean rag and a solvent, such as white spirit, in advance to clean the surface of the motor from dirt. Now you need to find the place where the drive cable is attached to the air damper and slightly loosen the screw securing these parts. Do the same with the bolt securing the cable sheath. An open-end wrench is perfect for this purpose. After disconnecting the cable from the carburetor, remove the crankcase gas supply hose from the pipe.

Removing jets from Solex

To disconnect the fuel hose from the fitting, in addition to a wrench, you will also need a Phillips screwdriver. First, loosen the fastening clamp, then remove the hose and use an M8 bolt to plug the hole in the latter. It is necessary to remove the vacuum regulator hose. The wire terminal is also disconnected from the solenoid valve terminal. We take a flat-head screwdriver and use it to press out the end of the throttle linkage, and then remove it. Now it is possible to remove the return spring.

To remove the carburetor you need to prepare a spanner and open-end wrench set to “13”. The first to unscrew are 3 nuts, through which the part is attached to the inlet pipeline, and the second is the fastening nut. Take this opportunity to inspect the carburetor gasket; perhaps it could use replacement. If the unit will be removed for a long time, be sure to plug the inlet pipe with a rag. To replace the jets in the carburetor, it remains to remove the cover from it. Take a flathead screwdriver and unscrew these parts. First we remove the fuel jets, then the air jets. In the rings of the last parts you will find emulsion tubes; to pull them out, you should pry them off with a file.

Replacing the carburetor gasket

The main fuel element of the secondary chamber is designated by the letter “A”, and the primary one by “B”. Then we proceed to removing the air jets, marked “B” and “D” for the secondary and primary chambers, respectively.

Replacement should not be done blindly. Visually assess the condition of the jets. The presence of marks, scratches and irregularities on their inner surface is unacceptable, since these defects reduce throughput. Contamination of parts with resins also has a negative impact. Before installing new jets, it is advisable to check them on a special stand, so you can see how well the specified throughput of the elements corresponds to real indicators.

Installation of new Solex parts

If you have already started disassembling the carburetor, then it would be a good idea to study the condition of its other parts; perhaps replacing the jets is not the only need for this unit. We unscrew the accelerator pump screw and remove the latter along with the valve and o-rings. Then we remove the rings and diffusers of both chambers from their original location. To remove the channel from the accelerator pump, you need to unscrew the fixing screw.

Next, remove the fuel nozzle along with the housing and take it out. You can dismantle the diaphragm after you open its cover and remove the spring. Having unscrewed the bolted connections, we disconnect the carburetor body and the throttle valve. Now you have access to the thermal insulation element and cardboard spacers. Remove the cover along with the adjusting screw, then remove the latter with the sealing ring. All parts with defects must be replaced; the remaining parts are thoroughly washed in a special product. We blow out the jets and other holes with compressed air. Reassemble in reverse order.

Basic Solex malfunctions and methods for eliminating them

Before looking for problems with the device, you need to make sure that the ignition system is working flawlessly and is adjusted correctly. You also need to check whether the timing belt is functioning correctly, since malfunctions in the operation of this mechanism can also cause malfunctions in the carburetor.

Table 1. Classification of possible carburetor malfunctions and methods for eliminating them.

| Malfunctions | Causes |

Elimination methods

A little history

A new carburetor was needed when the front-wheel drive VAZ project was being developed. The transverse arrangement of the engine did not make it possible to install the old OZONE carburetor, which was used for the “classic”. But the development of the French company Solex, after a little “finishing with a file,” went off without a hitch.

The design of Solex carburetors made it possible to install them on engines of different types and power, slightly changing some parameters. So, the most common was the Solex model 21083, which was installed on a 1.5 liter engine. VAZ 2108, 2109. For “classics” with a 1.45-1.6 liter engine. modification 21053 was developed, structurally similar to Solex 21073, designed for the VAZ 21213 Niva with a powerful 1.7 liter engine. And even for Moskvich with a 1.5 liter engine. Solex 21041 was installed, and for 1.8 liters. – modification 21041-10, suitable for both Volga and UAZ.

Advantages and disadvantages of tuning

The Solex carburetor is assembled from standard parts and assemblies from various manufacturers and is not subject to individual adjustment. But the cast body, made of aluminum alloy, diffusers, damper jets, as well as fasteners have unprocessed burrs, protrusions, and roughness. The task of tuning is to remove all obstacles to the movement of the air-fuel mixture by grinding, polishing channels and parts with which the fuel flow comes into contact, as well as modifying diffusers and adjusting jets in accordance with the individual requirements of the car enthusiast.

Some tips and tricks

When carrying out various types of preventative work on the carburetor, you should always observe the markings of the fuel and air nozzles. For the former it is 112, for the latter 150. If the positions do not match, the owner will immediately feel a decrease in acceleration dynamics and an increase in fuel consumption, which are not justified in any way. A narrowing of the throughput channel leads to a lean mixture; it, as well as enrichment, also negatively affects the performance of the machine as a whole.

This concludes the discussion of the topic. Despite the complexity of the mechanism's design, it can be repaired on your own. If you are still in doubt, read the recommendations again and successfully complete the repair. Now you know exactly what to do if your car stalls at idle.

Solex carburetor: modifications

The basic design of these devices was developed by engineers from the French company Soleks.

The Dimitrovgrad plant later received a production license, and all other modifications were made by specialists here. The popular Solex 21073 was developed at DAAZ. Reviews about it are only positive. The mechanism is easy to customize and is highly reliable. DAAZ-2108 is designed to work with a 1.3-liter engine for VAZ 2108 and 2109. Solex 21083 was modified for 1.5-liter power units. The same mechanisms were equipped with models from the first batches of the VAZ 2110 with a microprocessor-based ignition system. On classic VAZ models, Solex 21053-1107010 was installed. VAZ Niva models were equipped with the Solex mechanism 21073-1107010. Now it has been replaced by an injector.

Carburetor repair for dips and jerks

Carburetor repair may be necessary if the engine idles unstable, and adjusting the quantity and quality screws does not always help. Often the reason lies in over-enrichment of the mixture, which may be a consequence of incorrect adjustment of the float system or malfunctions in the vacuum economizer system for power modes. In the latter case, a torn diaphragm may need to be replaced or the economizer valve through which fuel is leaking may need to be repaired.

Model 2121 may cause jerking, swaying or dips when moving. In this case, there may be several reasons for their occurrence, which may require carburetor repair to eliminate them. Dips that appear when the throttle valve is slowly opened are often associated with clogging of the idle jet. Here it is necessary to adjust the fuel level and check the level of clogging in the main fuel jets.

If the car gives a deep failure when trying to open the first or second throttle chambers, then in addition to clogged nozzles, the reason may be poor installation of small diffusers in the corresponding sockets.

When the Niva 21213 gives slight twitches at low and medium speeds and accelerates sluggishly, it may be due to poor fuel dosage on the shut-off valve side due to its wear. In this case, repairs are needed in terms of replacing the shut-off valve with a shut-off needle made of metal with a valve that has this needle made of a different material.

Cars of the 2121 series sometimes give failures when any sudden opening of the throttle valves, which then disappear within 5 seconds when the engine is running at the same pace. Often such problems are associated with a malfunction of the accelerator pump, which leads to a lack of or an incorrect drop in gasoline flows. A similar situation can result from a diaphragm rupture, a rubber O-ring on the sprayer holder being destroyed, or the lower part of the valve being destroyed.

The engine in the VAZ-21213 Niva is equipped with a Solex family carburetor. Many Niva owners complain about the capriciousness of this device. The manufacturer claims that Solex is correctly adjusted at the factory, but this statement is not always true. Problems with the engine power system unit arise not only due to its incorrect configuration, but also due to the negligence of the car owner himself.

- Reasons for the high fuel consumption of the carburetor VAZ 2107

Ignoring recommendations on the frequency of replacing air and fuel filters leads to the fact that the most important mechanism in the engine power system refuses to work correctly. The goal to which all carburetor adjustment processes come down is to ensure stable operation of the power unit over the entire speed range. Adjusting the Solex carburetor on the VAZ 21213 Niva is an essential condition for trouble-free operation of the engine.

Device

The Solex 21073 carburetor is an emulsion type. Its modifications were initially installed on motors with contactless ignition. The device is distinguished by the presence of two chambers equipped with throttle valves, as well as dosing systems. The device also has transition systems for the first and second cameras. There is an idle system, but only for the first chamber.

The mechanism consists of two halves. The lower one is more massive - and the upper one. This half is the body of the device itself, and the upper part is the cover for the carburetor. At the bottom of each chamber there are rotary-type dampers with a mechanical drive. At the top of the first chamber of the carburetor there is a damper for air supply. It is necessary to start a still unheated power unit. This part is activated by a cable that goes into the cabin and is connected to a lever responsible for the suction and to the starting vacuum system.

Float mechanism

The Solex 21073 carburetor, installed on the Niva, has a float chamber of two sections. They are located on both sides of the main cameras of the device. The system consists of two ebonite floats, which are mounted on a lever.

The latter swings on an axis pressed into the bosses of the device cover. There is a tongue on the bracket. The element presses the needle valve needle through a special ball. The float mechanism serves to adjust the level of fuel required for normal operation of the carburetor. The needle valve is a non-separable type. It is not being repaired. The valve body is mounted on a thread in the carburetor cap. The ball protects the needle from shock when the machine moves. If the chamber is empty (for example, if the driver is using LPG), then the floats will knock.

Operating principle

Solex 21073 works as follows. Gasoline will enter the float chamber using the inlet fitting - the fuel also passes through the filter mesh, where it is cleaned, and goes through the needle valve. The chamber with the float is two-sectional, and the sections are connected to each other. They will contain the same amount of gasoline. This design makes it possible to significantly reduce the effect of body tilt on the fuel level in this chamber.

This ensures more stable engine operation. As the chamber fills, the float, pressing part of the needle valve, blocks the access of fuel to the chamber. This maintains a constant level of gasoline in the mechanism. Next, from the float chamber, gasoline flows through the jets into the mixing wells. Air enters these same wells through special holes in the emulsion tubes or air jets. Next, gasoline and air are mixed in them. As a result, a fuel mixture is formed. It will get into the small as well as large diffusers of the device. This is the main dosing chamber. Depending on the operating mode of the engine, certain mechanisms and systems can be started in the carburetor. When the owner tries to start the engine “cold” in order to enrich the fuel mixture, the starting device comes into play. The driver starts it from the passenger compartment - this is a choke.

When the handle is pulled out to its maximum, the air damper of the first chamber is completely closed. At the same time, the throttle valve in the first chamber opens to the distance of the starting gap. It is adjusted using the adjusting screw on the Solex carburetor. Adjusting the gap will allow you to adjust the idle speed.

How to choose jets for Solex?

With proper selection of jets for the Solex carburetor, the engine will operate smoothly and stably even under frequent loads. At the same time, you will also be able to save up to 35% of gasoline in city mode. First of all, you should decide on the main element, and then you can move on to the air element. Moreover, engine size is of great importance when selecting. If it is large, then it is better to use secondary jets of small cross-section. The diameter of parts with calibration holes in the first and second chambers may differ slightly.

You can easily find special tables that indicate the optimal ratio of fuel and air jet indices for Solex, and also predict the resulting mixture and even the behavior of the car. For example, if you take a fuel cell of high productivity, and an air cell, on the contrary, of low efficiency, then there will be an over-enriched mixture that will not ignite. A table will help you in the selection, which indicates the optimal diameter of all jets depending on the type of engine and brand of carburetor.

Jet index ratio table

It is very important to decide on the type and size of jets for Solex, but you also need to buy them. At this stage, you need to know what information is hidden by the numbers printed on the top of the elements

It is not uncommon when two designations are applied to the surface of a part, and a certain parameter is hidden in each of them. For example, the numbers “21” and “23” correspond to the outer diameter of the dosing element. By seeing the designation “95” or “97.5” on the main fuel jets, you can judge the performance, since this designation characterizes the throughput of the element. Air elements also indicate their capacity, but this value is usually between “125” and “155”.

Some people are sure that there is no need to rush to select new jets, and you can increase the throughput of a part by boring out its diameter. However, this operation should be performed only on high-precision equipment. In garage conditions, you cannot change the diameter of the jets using a drill or drill, as this will only ruin them. Therefore, if a part does not fit according to some criteria, you should purchase a new element that meets the requirements.

Starting system

This mechanism is a special cavity that connects to the intake manifold. The device also has a diaphragm and a rod that is connected to the air damper. After the engine is started, a vacuum occurs in the intake manifold. It acts on the diaphragm rod, thereby opening the air damper. If the choke handle is returned to its normal position, this will reduce the starting clearances.

The gap parameters depend on the geometric characteristics of the lever and are not adjustable in any way. As for the throttle valve of the second chamber, when the choke is pulled out, it is in a locked state.

Scheme and principle of operation

The types and modifications of carburetors for a given car can be very different, but the principle of operation remains the same.

When starting the engine cold, the driver closes the choke to limit the flow of air and increase the amount of gasoline. This makes it easier to start and brings the speed necessary for stable operation.

Carburetor 21073 DaAZ device and principle of operation: diagram of the design and operation of the carburetor I - first chamber; II - second chamber; 1 — accelerator pump drive lever; 2 — adjusting screw of the starting device: 3 — diaphragm of the starting device; 4 — air channel of the starting device; 5 - solenoid shut-off valve; 6 — idle fuel jet; 7 — main air jet of the first chamber; 8 — idle air jet; 9 — air damper; 10 — sprayer of the main dosing system of the first chamber; 11 — accelerator pump nozzle; 12 — nozzle of the main dosing system of the second chamber: 13 — econostat nozzle: 14 — main air jet of the second chamber; 15 — air jet of the transition system of the second chamber; 16 — channel for balancing the float chamber; 17 - float chamber; 18 — needle valve; 19 — calibrated hole for fuel bypass into the tank; 20 — carburetor fuel filter; 21 — fuel supply fitting; 22 — power mode economizer diaphragm; 23 - fuel jet of the power mode economizer; 24 — ball valve of the power mode economizer; 25 - float; 26 — econostat fuel jet with tube; 27 — fuel nozzle of the transition system of the second chamber with a tube; 28 — emulsion tube of the second chamber: 29 — main fuel jet of the second chamber; 30 - outlet of the transition system of the second chamber; 31, 33 — throttle valves: 32 — slit of the transition system of the first chamber; 34 — outlet of the idle system; 35 — carburetor heating block; 30 - adjusting screw for the composition {quality} of the idle mixture; 37 — engine crankcase ventilation fitting; 38 - fitting for supplying vacuum to the vacuum ignition regulator; 39 — vacuum selection fittings for the recirculation system; 40 — main fuel jet of the first chamber; 41 — emulsion tube of the first chamber; 42 - ball valve of the accelerator pump; 43 — accelerator pump diaphragm.

During the warm-up process, air intake is increased to reduce speed and eliminate interruptions. Thus, the air damper opens completely and the amount of gasoline is reduced. Other methods of warming up are not provided for by the design.

Gasoline is supplied through the fuel filter to the float chamber, and then to the main metering system of the mixing chamber. The scheme for pumping air and mixing it with gasoline in the diffuser occurs due to the vacuum that occurs during the operation of the valve mechanism and pistons, compressing and pushing out the working mixture.

The second chamber system is designed to increase air flow to the nozzle when the engine is running under heavy load, when the speed is high.

To ensure that the engine runs stably at idle, and at low speeds to prevent it from stalling and eliminate interruptions, an idle system is provided. And to maintain the level of fuel used in the Solex 21073 carburetor, there is a whole scheme for the operation of the float system. Let's consider the operation of each system separately.

Idle system

This unit is necessary in order to supply the combustion chambers with a combustible mixture at the lowest speeds. Thanks to this system, the power unit will not stall when there is no load. Fuel will enter the system through the main jet into the first chamber. Through the XX jet, where it is then mixed with oxygen, the fuel enters the system through the air valve. This mechanism allows you to ensure stable engine operation at idle speed without load.

Next, the combustible mixture will enter the first chamber through a special channel located under the throttle valve. The fuel mechanism leading to the XX exhaust port is closed with a quality screw. This is an adjusting screw that can be used to adjust and change the characteristics of the carburetor. The operation of the engine in idle mode on the Solex 21073 mechanism is also adjusted with this element. Due to it, the gap value of the throttle valve of the first chamber in XX mode is determined.

How to restore carburetor operation?

For repairs, most often you have to remove the device from the engine. First, remove the air filter. Then the fuel lines, air pipes, wires and cables are removed. then unscrew the fastening nuts.

It is best to disassemble the carburetor on a table or other convenient surface. The parts should be laid out in some order. This will help you not lose them. The process of adjusting the needle valve is performed using a special template. To wash the device, you must use special liquids. Replacement jets can be purchased at any auto stores. Often, disassembling and flushing the carburetor helps solve a lot of problems.

Setting the level in the float chamber

So, we looked at the Solex device. Adjusting the carburetor will help set the optimal mode when the engine will operate as efficiently as possible and at the same time fuel consumption will not be too high. First you need to start and warm up the engine a little. Then remove the fuel hose and carburetor cover. Then disconnect the suction cable and twist the cover off the device.

It must be removed as smoothly and carefully as possible so as not to damage the float. Then use a ruler or caliper to measure the distance in each chamber. You need to measure from the mating surfaces to the edge of the gasoline. This size should be about 24 mm. If it is larger or smaller, then the parameter is adjusted by bending the float. Then the device is reassembled, the engine is started and it is warmed up.

His Majesty diffuser

As you can see, the diffuser occupies not the last place in this hierarchy, and here’s why. The main problem with Solex DAAZ 21083 is that the standard mixture is too lean. The engineers deliberately took this step in order to strangle the engine in favor of efficiency, depriving it of its dynamic potential. But even without resorting to complex and subtle calculations, it is clear that first of all it is necessary to eliminate aerodynamic errors, which are full of any DAAZ carburetor.

After the diffusers are brought into human form, the filling of the cylinder with the working mixture is significantly improved, and as a result, the output from the engine, even after such an insignificant alteration at first glance, is visible even to the eye. Now it makes sense to think about increasing the filling of the combustion chamber. Standard diffusers on 21083 have diameters of 21x23 mm of the primary and secondary chambers, respectively. Usually the dimensions are adjusted to 24 mm, so the motor will not be pinched at least by air.

Now you can increase the diameters of the fuel jets. “Can” does not mean necessary, and if fuel economy is more important, then the jets are best left alone. Even after replacing them with jets of increased diameter, the car will not turn into a Maserati, but fuel consumption will definitely increase. If this doesn’t scare you, then change the standard jets to 107.5 and 115, and the air jets to 155 and 135 in the primary and secondary chambers, respectively. If you are not satisfied with the result, you can always install the standard jets in place.

Idle adjustment

Many car owners, namely beginners, most often buy old cars and do not know how to adjust the carburetor correctly. The result is power loss, high fuel consumption, floating speed and other problems. After the level adjustment is successfully completed, the idle speed is adjusted. Before doing this, it is recommended to turn off the engine. To work, you will need a flat blade screwdriver and time. There is a hole on the base of the mechanism. It contains a screw responsible for the quality of the mixture. It is screwed in until it stops. However, you should not be too zealous.

Then, from the extreme position, the screw is unscrewed five turns. Next, the engine is started without choke. Unscrew the quality screw - carburetor 21073 will regulate the engine speed. Then the element is screwed in again. It is necessary to rotate until the operation of the power unit becomes as stable as possible. Rotate the screw slowly. When the engine becomes quieter, turn it out no more than one turn. As a result, the idle speed will be about 900. But if the engine stalls, they are slightly increased.

Results

Of course, it is clear that there is no limit to improvements. Sometimes they can even go to excess: drilling, for example, a throttle valve, polishing an MD, soldering epulsion tubes on a carburetor. But, as they say, what is in excess is unhealthy. But such a procedure, fascinating in its own way, like selecting the types of jets for a Solex 21073 carburetor, for example, is something quite necessary for the correct setup of the unit and its complete compatibility with the engine compartment. As a result, you get an economical car that responds well to gas.

Features of servicing DAAZ-21073 devices

All possible disruptions in the operation of the device directly depend on the quality and frequency of service. Despite the design differences between the VAZ DAAZ-21073 and the DAAZ-4178 carburetor on the UAZ, their maintenance is not much different. The technically required work includes:

- external cleaning;

- washing the float chamber strainer;

- cleaning the float chamber;

- cleaning jets;

- adjustment of the float device;

- adjustment of the starting device;

- stabilization of the XX system.

Washing the external and internal parts of the carburetor unit is carried out using kerosene, white spirit or preparations in aerosol cans. The aerosol composition is injected into the chambers and jets while the engine is running. The cleaned apparatus is blown with compressed air.