Standard Chevrolet Niva fault codes can be seen in two ways. Thanks to the well-thought-out layout of the diagnostic system, breakdowns are displayed on the on-board computer through the tidy display. It is possible to connect a third-party scanner. In the first option, diagnostics are performed independently and the sequence of actions is relevant for cars from 2004 to 2015. There is an insidious minus here. On-board systems cannot show the exact location of the fault, which greatly complicates the repair procedure.

The second method involves connecting a special diagnostic scanner. The external device displays the exact location of the fault, and even the specific unit where the breakdown occurred. Not every master has special diagnosticians. To perform the procedure, you will need to contact a specialist.

How to Troubleshoot or Reset Trouble Code P0444

Some suggested steps to troubleshoot and fix error code P0444:

Diagnosis and problem solving

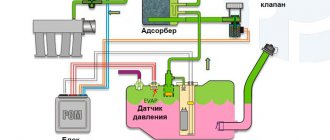

Without going into details of the operation of all electronics, we note that the functioning of all vehicle systems is “monitored” by an electronic control unit (ECU).

It receives information from numerous sensors. Like any computer, the ECU requires software called firmware. This firmware is capable of analyzing indicators received from sensors, comparing them with normal parameters, identifying errors and storing these errors in memory.

Carrying out self-diagnosis

In the Chevrolet Niva, as in some other cars of the VAZ family, some parameters can be displayed on the VDO dashboard. It is often called an integrated on-board computer.

Testing is started by first pressing the daily mileage reset button and simultaneously turning the ignition key.

All instrument needles begin to move, which indicates the beginning of the testing process. Pressing the same button once will cause the firmware version to appear on the display, and pressing it again will give us a reading called an error code.

Panel codes should not be confused with ECU codes, which are diagnosed by external devices.

| Error code | Decoding |

| 1 | Processor faults |

| 2 | No signal from the fuel level sensor |

| 4 | Increased voltage of the on-board network (exceeds 16 V) |

| 8 | Reduced voltage on-board network |

| 12 | Control indicator malfunction |

| 13 | No signal LAMDA probe |

| 14 | Increased coolant temperature |

| 5 | Reduced coolant temperature |

| 19 | Error from HF sensor |

| 21-22 | Error with TPS |

| 24 | Error from speed sensor |

| 27 — 28 | Incorrect CO potentiometer parameters |

| 23 — 25 | Error from intake air temperature sensor |

| 33 — 34 | Error from the MAF sensor |

| 35 | Error from sensor XX |

| 41 | Error from phase sensor |

| 42 | Ignition system malfunction |

| 43 | Error from knock sensor |

| 44 — 45 | Rich/lean fuel mixture |

| 49 | Loss of vacuum |

| 51 — 52 | ROM/RAM errors |

| 53 | No signal from CO potentiometer |

| 54 | No signal from the octane corrector |

| 55 | Load on the power unit |

The operation of the on-board computer cannot be called flawless, since many errors arise as a result of software failure. You have to reset the errors by holding down the daily mileage reset button in testing mode. This diagnostic method is not entirely convenient for the reason that the error code can be the result of the sum of two codes at the same time (10=8+2).

Where to start checking?

No matter how many years your beloved VAZ serves faithfully, sooner or later negative processes begin inside it: the car stalls, periodically does not obey its owner, and it may even seem that it is trying to do harm in every possible way. Of course, you can accept the situation and wait until the car completely stalls. Or, as an option, ask service station workers for help.

In this case, another solution is possible: try to solve the issue with your own hands. For example, the check engine light is on. Outwardly, everything seems quite simple: the system signals a malfunction of a specific sensor. All that remains is to make a replacement, and the car is ready for use again. However, everything is not so simple. It often happens that the sensor does not light up, but the car still does not move. In this case, diagnosis should be carried out by a professional.

The easiest way to carry out diagnostics is with the help of a special tester DST-2M, which is available in the arsenal of almost every service station worker. If you want to constantly repair the car yourself, you can purchase a sensor for your own use. If repair work is planned to be carried out occasionally, it is better to refrain from purchasing.

Typically, diagnosis includes:

Based on the data obtained, you can understand what exactly the problem is and what methods should be used to solve it. The VAZ 21314 injector is quite durable, but without proper care it will definitely fail.

Diagnostics with a scanner

The information in this section is quite extensive, since there are many types of scanners.

The basic principle of their operation is that all data, including errors, is transmitted from the ECU to a special diagnostic connector, which in a Chevrolet Niva is located on the driver's side under the steering wheel.

The scanner's job is to read and decode these messages.

Note that there are dealer scanners, that is, those that are designed for a given car. For Chevrolet Niva this is BC State.

It is inserted into the panel instead of the signaling device, and the information loop is prepared from the factory.

Universal scanners should be connected to the diagnostic connector. The most popular scanners today are models that allow you to transmit information via Bluetooth.

To do this, you need to install the appropriate application on your smartphone, for example, OpenDiag, and connect it to the scanner.

The program interface allows you not only to read the parameters, but also to manage some of them. You can also reset all errors from your smartphone. There are scanners with their own display. All error information in the form of codes is displayed on this display.

Replacing brushes or the generator itself

Current collection brushes wear out most often, so here is a description of how to do this job:

- Remove the negative terminal from the battery and disconnect the wires leading from the generator casing.

- Remove the protective cap from the terminals of the positive terminal of the wires. Unscrew the nut that secures the block to the generator block.

- Disconnect the spring clips and remove the black plastic cover.

- Unscrew the voltage regulator mountings with a Phillips screwdriver. Take it out along with the brushes.

- Disconnect the wires from it. Remove the assembly together with the fastening bar, take off the belt.

- Release the generator from the bracket by unscrewing all the mounting bolts.

The further plan of action depends on what you will change. If the brushes are very worn, they need to be replaced. If the current collectors are visually intact, then the reason may be in other parts of the generator. In most cases, car enthusiasts simply change it entirely.

Chevrolet Niva error codes

Errors transmitted through the diagnostic connector are displayed on an external device as a four-digit code. There are special tables that allow you to decipher these codes.

| Code | Explanation |

| P0102 | Low signal level of the mass air flow sensor (MAF). |

| P0103 | High signal level of the mass air flow sensor (MAF). |

| P0112 | low signal level of the intake manifold temperature sensor (ITM). |

| P0113 | High signal level of the intake manifold temperature sensor (IMT). |

| P0116 | The signal from the coolant temperature sensor (TTOZH) is out of the permissible range. |

| P0117 | Low signal level of the coolant temperature sensor (DTOZH). |

| P0118 | High signal level of the coolant temperature sensor (DTOZH). |

| P0122 | Low signal level of the throttle position sensor (TPS). |

| P0123 | High signal level of the throttle position sensor (TPS). |

| P0130 | Incorrect signal from oxygen sensor No. 1 to the converter. |

| P0131 | Low level signal from oxygen sensor No. 1 to the converter. |

| P0132 | High level signal from oxygen sensor No. 1 to the converter. |

| P0133 | Slow response to enrichment or depletion of oxygen sensor No. 1 to the converter. |

| P0134 | Lack of signal (open circuit) of oxygen sensor No. 1 to the converter. |

| P0135 | Malfunction of the oxygen sensor heater circuit No. 1 to the converter. |

| P0136 | Short circuit to ground in the N9 oxygen sensor circuit 2. |

| P0137 | Low level signal from oxygen sensor No. 2 after the converter. |

| P0138 | High level signal from oxygen sensor No. 2 after the converter. |

| P0140 | Lack of signal (open circuit) of oxygen sensor No. 2 after the converter. |

| P0141 | Malfunction of the heater circuit of the oxygen sensor No. 2 after the converter. |

| P0171 | The fuel supply system (fuel-air mixture) is too lean. |

| P0172 | The fuel system (air/fuel mixture) is too rich. |

| P0201 | Open circuit for controlling the injector of the 1st cylinder. |

| P0202 | Open circuit in the 2nd cylinder injector control circuit. |

| P0203 | Open circuit in the 3rd cylinder injector control circuit. |

| P0204 | Open circuit in the 4th cylinder injector control circuit. |

| P0261 | Short circuit to ground in the 1st cylinder injector control circuit. |

| P0262 | Short circuit to the source of the on-board network of the injector control circuit of the 1st cylinder. |

| P0264 | Short circuit to ground in the 2nd cylinder injector control circuit. |

| P0265 | Short circuit to the source of the on-board network of the injector control circuit of the 2nd cylinder. |

| P0267 | Short circuit to ground in the 3rd cylinder injector control circuit. |

| P0268 | Short circuit to the source of the on-board network of the injector control circuit of the 3rd cylinder. |

| P0270 | Short circuit to ground in the 4th cylinder injector control circuit. |

| P0271 | Short circuit to the source of the on-board network of the injector control circuit of the 4th cylinder. |

| P0300 | Random/multiple misfires detected. |

| P0301 | Misfire detected in cylinder N91. |

| P0302 | Misfire detected in cylinder N9 2. |

| P0303 | Misfire detected in cylinder N9 3. |

| P0304 | Misfire detected in cylinder N9 4. |

| P0327 | Low signal level of the knock sensor (DS). |

| P0328 | High signal level of the knock sensor (DS). |

| P0335 | There is no signal from the crankshaft position sensor (CPS). |

| P0336 | The crankshaft position sensor (CPS) signal is outside the permissible limits. |

| P0337 | Short circuit to ground in the crankshaft position sensor (CPS) circuit. |

| P0338 | Open circuit of the crankshaft position sensor (CPS). |

| P0340 | Malfunction of the camshaft position sensor (CPS) circuit. |

| P0342 | Low signal level of the camshaft position sensor (DPRV). |

| P0343 | High signal level of the camshaft position sensor (CPS). |

| P0422 | The efficiency of the neutralizer is below the permissible threshold. |

| P0441 | Incorrect air flow through the valve. |

| P0443 | The canister purge valve control circuit is faulty. |

| P0480 | Cooling fan N91 relay control circuit malfunction. |

| P0481 | Cooling fan N9 2 relay control circuit malfunction. |

| P0500 | Incorrect vehicle speed sensor signal. |

| P0503 | Intermittent signal from the vehicle speed sensor. |

| P0506 | Low idle speed (idle speed control blocked). |

| P0507 | High idle speed (idle speed control blocked). |

| P0560 | The on-board network voltage is below the system operability threshold. |

| P0562 | Reduced voltage of the on-board network. |

| P0563 | Increased voltage of the on-board network. |

| P0601 | Controller ROM checksum error. |

| P0603 | Error writing/reading external RAM of the controller. |

| P0604 | Error writing/reading internal RAM of the controller. |

| P0615 | Open starter relay control circuit. |

| P0616 | Short circuit to ground in the starter relay control circuit. |

| P0617 | Short circuit to the on-board supply source of the starter relay control circuit. |

| P1135 | Malfunction of the oxygen sensor heater circuit No. 1 to the converter. |

| P1140 | The signal from the mass air flow sensor (MAF) is incorrect; the measured load parameter differs from the calculated one. |

| P1141 | Malfunction of the heater circuit of the oxygen sensor No. 2 after the converter. |

| P1386 | The test pulse or controller knock channel integrator is out of tolerance. |

| P1410 | Short circuit to the on-board power source of the canister purge valve control circuit. |

| P1425 | Short circuit to ground in the canister purge valve control circuit. |

| P1426 | Open circuit for controlling the canister purge valve. |

| P1501 | Short circuit to ground in the electric fuel pump relay control circuit. |

| P1502 | Short circuit to the on-board supply source of the electric fuel pump relay control circuit. |

| P1509 | Overload of the idle air regulator (IAC) control circuit. |

| P1513 | Short circuit to ground in the idle air regulator (IAC) control circuit. |

| P1514 | Short circuit to the on-board power source (or open circuit) of the idle air regulator (IAC) control circuit. |

| P1541 | Open circuit in the electric fuel pump relay control circuit. |

| P1570 | There is no response from the car anti-theft system (ATS) or the circuit is open. |

| P1602 | Loss of on-board power supply voltage in the controller. |

| P1606 | Incorrect rough road sensor signal. |

| P1616 | Low level of rough road sensor signal. |

| P1617 | High level of rough road sensor signal. |

| P1640 | Error writing/reading internal flash RAM (EEPROM) of the controller. |

| P1689 | Incorrect code values in the controller fault memory. |

SELF-DIAGNOSTICS OF THE KALINA/PRIORA INSTRUMENT COMBINATION

- With the ignition off, press the “Reset” button (reset daily mileage). While holding the button, turn on the ignition.

- The instrument panel will go into self-diagnosis mode, all segment positions will light up on the display, all indicators will light up, and the arrows will travel the full path.

- Using the control button on the right steering column switch, we switch between modes (self-diagnosis, firmware version, error codes).

- To reset errors, you need to be in error mode and press and hold the “Reset” button for more than 3s.

- The diagnostic mode exits automatically after inactivity for 20-30 seconds.

Decoding error codes in the dashboard:

- 2-increased voltage of the on-board network;

- 3-fuel level sensor error (if a break in the sensor circuit is detected within 20s);

- 4-error of the coolant temperature sensor (if an open circuit of the sensor is detected within 20s);

- 5-outside temperature sensor error (if there are no sensor readings within 20s, indication on the LCD is “-C”);

- 6-engine overheating (the criterion for triggering the acoustic alarm has been met);

- 7-emergency oil pressure (the criterion for triggering the acoustic alarm is met);

- 8-defect of the brake system (the criterion for triggering the acoustic alarm is met);

- The 9-battery is discharged (the criterion for triggering the acoustic alarm is met);

- E-determination of an error in a data packet stored in EEPROM.

Computer diagnostics

The most complete diagnosis is possible with a computer or laptop. In order to use this method, you must purchase an adapter. This adapter performs two functions at once. It is an adapter from a K-line port to a USB port or to a COM port. It also acts as a decoder, which allows you to transmit signals from the ECU to the PC. You will also need to install the appropriate software on your laptop. There are a lot of free versions on the Internet. There are universal programs, as well as programs written for a specific car. After connecting to the computer, you will need to turn on the ignition and launch the program. The connection will happen automatically.

Check Engine

When the ignition is turned on, the indicator should light up, so the ECM checks the serviceability of the lamp and control circuit. After starting the engine, the indicator should go out if the controller memory does not contain the conditions for turning it on.

To protect against random, short-term errors that may be caused by loss of contact in electrical connectors or unstable engine operation, the warning light turns on after a certain period of time after detecting a malfunction in the ECM. During this period, the on-board diagnostic system checks for a malfunction.

Chevrolet Niva error codes: decoding and description of meanings

The popular Russian-made model is very widespread in the CIS countries due to its optimal cost and increased cross-country ability, which is critically important in the conditions of domestic operation. Motorists buy cars for off-road travel and small towns, where the quality of roads leaves much to be desired.

The disadvantages of the car include weak wiring - when the load increases to the design limit, on-board electronic systems often fail, which causes software failures. Chevy Niva error codes appear on the dashboard display or are detected using special equipment, but the common thing is that they all indicate a malfunction of a specific component.

On which cars is this problem most common?

The problem with code P0138 can occur on different machines, but there are always statistics on which brands this error occurs more often. Here is a list of some of them:

- Chevrolet (Chevrolet Aveo, Captiva, Cruz, Lacetti, Rezzo, Epica)

- Chrysler (Chrysler Voyager, Pacifica, Sebring, 300c)

- Citroen (Citroen C5)

- Daewoo (Daewoo Matiz, Nexia)

- Dodge (Dodge Dakota, Caravan, Neon, Ram, Stratus)

- Ford (Ford Mondeo, Focus, Explorer, Escape)

- Honda (Honda Accord, Odyssey, SRV, Civic)

- Hover

- Hyundai (Hyundai Accent, Getz, Santa Fe, Tucson)

- Infiniti

- Jeep (Jeep Wrangler, Grand Cherokee)

- Kia (Kia Rio, Sorento, Sportage)

- Lexus (Lexus rx350)

- Lifan (Lifan Breeze, Solano)

- Mazda (Mazda 3, Mazda 6, Mazda cx7)

- Mercedes

- Mitsubishi (Mitsubishi Outlander, Lancer)

- Nissan (Nissan Almera, Qashqai, Murano, Patrol, Pathfinder, Primera, Teana, X-Trail)

- Opel (Opel Antara, Astra, Corsa)

- Peugeot (Peugeot 206, 308, 407)

- Pontiac (Pontiac Vibe)

- Renault (Renault Duster, Logan, Sandero, Fluence)

- Saab

- Skoda (Skoda Octavia)

- Ssangyong

- Subaru

- Suzuki (Suzuki Grand Vitara)

- Toyota (Toyota Avensis, Venza, Camry, Prado, Prius, Rav4, Highlander)

- Volkswagen

- VAZ

- Gazelle Next

- TagAZ

With fault code P0138, you can sometimes encounter other errors. The most common are: P0038, P0108, P0113, P0118, P0123, P0132, P0134, P0136, P0137, P0139, P0140, P0141, P0158, P0170, P0172, P0325, P0340, P0351, P0447, P050 1, P0606, P1167, P2096 , P2253.

Chevrolet Niva error diagnosis

The most reliable way to identify what is wrong with a car is to diagnose electrical appliances and equipment. The procedure allows you to accurately identify breakdowns and quickly repair your car.

There are two ways to detect a problem in a car.

Self-diagnosis VAZ 2123

Engine error codes (P0000)

Note!

Chevrolet Niva on-board computer errors found in this way reflect the most accurate state of affairs at the current time.

Why is error 8 associated with brake system problems?

Some car enthusiasts misinterpret error message 8, believing that they need to check the brake system. This is due to the fact that on VAZ cars this fault number indicates insufficient brake fluid level.

The Chevrolet Niva's on-board computer uses different designations, so you should not interpret them in the same way as in the VAZ. If you doubt the condition of the brake system, you can check it during the repair process. First of all, pay attention to the brake fluid level, and then check the pads.

Sources used:

- https://vaz-russia.com/chevrolet-niva-vaz-2123/kody-oshibok-niva-shevrole.html

- https://xn--80aal0a.xn--80asehdb/do-my-self/repair/repair-lada-niva-chevrolet/5746-rasshifrovka-kodov-oshibok-chevrolet-niva-lada.html

- https://nivachevrole.ru/varia/error-codes/

- https://expertniva.ru/elektrooborudovanie/kodi-osibok.html

- https://ladaprofi.ru/shevrole-niva/kak-ispravit-oshibku-nomer-8-na-shevrole-niva.html