Niva is an excellent domestic SUV that can compete with modern jeeps. VAZ 21214 received a durable body, a powerful power plant and a reliable suspension.

Like any car it has its drawbacks. These include the location of the generator - the unit is installed in the lower part of the body. When testing for strength in forest and mountainous areas, dirt, sand, and water get into it.

Another unpleasant point is that coolant constantly drips onto the unit. The problem can be solved by moving the generator upstairs.

It is worth carrying out such an upgrade if you often use your Niva on real off-road conditions. Under normal conditions, the location of the part does not matter.

After reading this article, you will learn:

- what is needed to move the generator upstairs;

- How does the process work for cars with and without power steering;

- Is it worth buying a new unit for VAZ 21214.

Even a novice car enthusiast can understand the diagrams and drawings in this article. Photographic materials will also help you understand the information. To carry out the work, it is worth preparing in advance a set of wrenches, torsion bars and other standard tools.

Transfer process for carburetor Niva

Study this drawing carefully. The author decided to make a bracket for moving the generator with his own hands. The part is made of metal, the thickness of which should be 4 mm, and the width and length should be 80 mm. To assemble the bracket, you will need parts from other domestic cars:

- belt 6РК1290;

- adjustment bar;

- crankshaft pulley from tens.

In this option, you will need an upper adjustment bar. The author of the drawing decided to borrow this element from the Volga. The upper adjustment bar must be cut in place, and then a new hole for fasteners must be drilled, its diameter should be 8.5 mm.

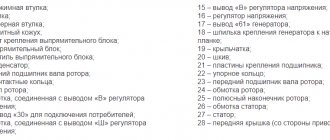

Generator - device, characteristics, operation check

Start the engine, let it run for a few minutes, then, pressing the gas pedal, bring the crankshaft speed to 3000 rpm. Turn on the high beam headlights, heated rear window, and heater fan.

Measure the voltage at the battery terminals, which should be above 13.2 V for generator 9412.3701 and 13.6 V for generator 371.3701.

If this is not the case, the voltage regulator with the brush assembly, the generator windings are faulty (open or shorted) or the contact rings of the field winding are oxidized.

The removed voltage regulator of the generator 9412.3701 can be checked by connecting a lamp (1–5 W, 12 V) between the brushes, and a power source to the “D” and “ground” terminals (DC only, “minus” to ground!) , initially with a voltage of 12 V, and then 15–16 V.

In the first case, the lamp should be on, in the second - not. If the lamp lights up in both cases, there is a breakdown in the regulator; if it doesn’t light up, there is a break or broken contact between the brushes and the regulator terminals. In both cases the regulator should be replaced. To check the generator regulator 371.3701, the current source should be connected to terminals “B” and “C” (“plus”) and “ground” (“minus”).

Also interesting: Removing and installing the Chevrolet Niva starter

To check the valves of the rectifier unit, disconnect the wires from the battery, generator and from the voltage regulator terminal(s).

Connect the “plus” of the battery through a lamp (1–5 W, 12 V) to terminal “B” of the generator 9412.3701 (to terminal “30” of the generator 371.3701), and the “minus” to its body.

If the lamp is on, then there is a short circuit in both the block of “positive” and the block of “negative” valves.

To check the short circuit in the “positive” valves, connect the “plus” of the battery through a lamp to the “B” terminal of the generator 9412.3701 (with the “30” terminal of the 371.3701 generator), and the “minus” - to the terminal of one of the phase windings of the stator. If the lamp is on, one or more positive valves are broken.

To check the short circuit in the “negative” valves, connect the “plus” of the battery through a lamp to the terminal of one of the phase windings of the stator, and the “minus” to the generator housing. If the lamp is on, one or more negative valves are broken or the stator windings are shorted to the generator housing.

To prevent short-circuiting of the windings, remove the generator from the car and, having disconnected the windings from the voltage regulator and rectifier unit, check their short circuit to ground with a lamp or ohmmeter. The generator valves can also be checked with an ohmmeter without connecting the battery and test lamp.

The short circuit of additional diodes can be checked by connecting the “plus” of the battery through a lamp to terminal “D” of the generator 9412.3701 (to terminal “61” of the generator 371.3701), and the “minus” - to the terminal of one of the phase windings of the stator (to one of the mounting bolts of the rectifier block ). If the lamp is on, one or more additional diodes are broken.

A break in the main valves is determined by a sharp decrease in the output current (voltage drop under load). However, it can also be caused by an open or shorted circuit in the generator windings.

A break in the additional valves can be determined by the low voltage at plug “D” of generator 9412.3701 or plug “61” of generator 371.

3701 (below 14 V) at low and medium generator rotor speeds.

The serviceability of each diode (main or additional) can only be determined with a removed rectifier unit using an ohmmeter or a test lamp. If the rectifier unit fails, it is recommended to replace it as an assembly.

It is possible to replace individual valves, but the main valves will require repressing them in the holder - an operation that requires care and skill.

Read news about the new Niva

- Niva generator transfer bracket drawing

- Niva Chevrolet front hub repair

- Niva Chevrolet where is the starter relay located?

- Do-it-yourself Niva suspension lift. How to lift the front and rear suspension of a Niva car?

- Generator Niva 2121, 21213, 21214: which one is installed, replacement

- Generator Niva 2121, 21213, 21214: which one is installed, replacement

- Generator Niva 2121, 21213, 21214: which one is installed, replacement

- Generator Niva 2121, 21213, 21214: which one is installed, replacement

Fastening drawing

The drawing suggests moving the generator to the place of the hydraulic booster. To do this, you need to make a bracket and install it next to the power steering. You need to select washers for the bracket ears in advance.

This option uses a belt with a size of 1220 mm. It is important that the angle of its wedge must be exactly 40 degrees. An excellent solution would be to buy a belt with ZIL 157. The return hose has a center length of 1115 millimeters, and the high-pressure pressure hoses are 1450 mm.

Check all dimensions carefully, remember the saying: measure 7 times, cut once, there is no need for mistakes here. There is no standard hole for these hoses in the right casing, so you will have to take it and cut it yourself.

The bracket itself for moving the device upstairs is made according to this drawing:

Click to enlarge

Guide to removing and connecting the generator

To remove the unit, you need to prepare a set of tools: keys “10” and “19”, ratchets with heads, a hammer and a small extension.

The process consists of the following steps:

- First of all, remove the negative terminal from the battery.

- Next, you need to remove the engine protection and the right mudguard.

- Then, using a hammer, carefully knock out the mounting bolt and remove it.

- At the next stage, you need to disconnect all the wires going to the generator: the plug and the wires secured with a nut.

- Then the fastening on which the belt tensioner is located is unscrewed.

- By removing the belt, the assembly can be dismantled through the hole that was formed after removing the protection.

- After replacement or repair, install the unit in reverse order.

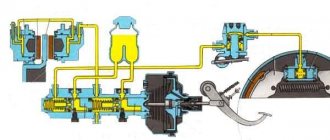

The generator is connected according to the diagram.

Price issue

The VAZ 21214 generator has good repairability, which allows you to significantly save money if worn or broken parts are replaced in a timely manner.

If you change the complete unit, the cost of replacement will be as follows:

- generator 21214 – 3125 rub.;

- lower mount – 133 RUR;

- fastening bolt - 53 rub.;

- tension bar - 55 rub.;

- relay RS-527 – 57 rub.

How to move the generator on NIV upstairs (VAZ 21214M with power steering)

Show Control Panel

- Published: Sep 11, 2017

- The video was created on the topic of how to move the generator to the top of a fuel-injected VAZ (LADA) 21214M 2012 car with power steering. The bracket used was a “modified” one. It is installed without any modifications or adjustments (tested on yourself) and is attached to 8 (!) mounting points - 4 on the side of the front cover of the internal combustion engine and 4 on the left side (in the direction of travel) to the standard places of the block. The problem with the radiator pipe was solved by cutting the pipe from the radiator side by 2 cm. And another important point that was missed in the video is the grounding of the genes. The bracket is painted, so you can’t just “hang a lot” on it; you need to choose a place where the wire will be in reliable contact with the body of the genes (otherwise the car will not start)

What is behind the cancellation of the transfer of the Lada 4×4 assembly to the main conveyor

Quite recently, in one of the articles (“AvtoVAZ” and GM: JV or confrontation?) we mentioned that the Lada 4×4, which many VAZ employees still call exclusively “the old Niva,” is changing its “place of registration.” From the 62nd building, the production of the ex-Niva was supposed to be transferred to the third line of the main conveyor.

Yesterday AvtoVAZ issued a press release, from which it follows that the above-mentioned transfer is temporarily cancelled. Let's try to explain what is behind this and why it is important for the GM-AvtoVAZ joint venture.

The 62nd building is almost the same age as the VAZ itself; it was commissioned in 1976 for the production of the first generation Niva.

Assembly of Lada 4x4 in the 62nd building of AvtoVAZAt that time, the equipment of the 62nd building was quite progressive and, which was uncharacteristic for the domestic automobile industry, compact. In fact, all the main operations were concentrated in one workshop - body welding, painting and assembly. Moreover, the painting complex was made two-story!

Painting complex Lada 4x4

Alas, today the Niva production line is hopelessly outdated; there is no economic sense in upgrading it to a different model; it would be much cheaper to take everything to a landfill and reinstall the conveyors. The 62nd building continues to function only because there is demand for the old Niva, and at least until 2022 it will remain in production.

There is no point in upgrading existing equipment also because the plant has more modern unused capacity. We are talking about the so-called third line of the main conveyor. Previously, modifications of the VAZ-2110 were assembled on it, but in 2014 the line was modernized for the production of Lada Vesta. We installed a new assembly conveyor and improved the painting complex. Now this branch looks even more modern than the one where cars are assembled on the French BO platform. Now Priora is going there.

However, in mid-2015, the management of AvtoVAZ made an odious decision to release Vesta in Izhevsk. This actually exposed the third line of the conveyor, because the production of Priora is gradually being phased out. For the entire 2015, the plant produced 28,507 Prioras, despite the fact that the line is designed for 220,000 cars.

Underutilization of a modern conveyor means direct losses. At least in terms of the load factor per worker: in fact, the same number of workers is capable of assembling ten times as many cars. A painting complex that does not operate at full capacity, but regularly requires maintenance, also does not increase the efficiency of line use. And in general, it’s a shame: the quality of car manufacturing on the third line is now very high, and it’s simply stupid not to use these opportunities.

It was precisely this consideration that guided Bo Andersson when he decided to load the third line of the conveyor with models from “external” production - from OPP (long-wheelbase Niva) and VIS-Auto (pickups based on Granta and the same long-wheelbase Niva). But Andersson did not take into account the economics of this project: the transfer itself from OPP and from VIS-Auto would have cost more than the preferences received from loading the third line. And so it happened: the OPP was partially dismantled for scrap metal, the long-wheelbase Niva was “registered” on the main assembly line, but the production volume of this model was so small that the entire economic effect went into deep “minus”. But they didn’t get to the VIS-Auto models at all: Andersson left the plant.

And now, under the new president of AvtoVAZ OJSC, information has appeared about transferring the assembly of the old Niva to the third line. What would happen to the 62nd Corps was not formulated even at the level of rumors. It was simply ordered to prepare a transfer to the summer, from June 23.

The old Niva with its 35,000 per year, of course, will help for the third line, and the quality of the car would inevitably improve. But even with the implementation of this idea, the efficiency of the new line will be approximately one third. At the same time, moving the old Niva itself is also costly, as is dismantling the equipment of the 62nd building.

All this would be justified only under one condition: the 62nd Corps began to be prepared for a new project. Moreover, one that cannot be launched on the same third branch. So the upcoming (though it is not clear when) Niva-3, also known as Lada 4x4 New Generation, falls out of the discussion; it is designed for assembly on the underutilized conveyor belt under discussion.

Only... Chevrolet Niva-2 could act as a new project for the 62nd building! Yes, yes, the same one that was discussed in our recent article. Moreover, it does not really matter whose forces would organize the production of this model - the GM-AvtoVAZ joint venture or, under certain conditions, AvtoVAZ itself.

Strictly speaking, the question of organizing the production of the Chevrolet Niva-2 rests on two problems: no money and no space. This is exactly the place we are talking about now. GM-AvtoVAZ has the biggest “ambush” - with the placement of a welding complex purchased in South Korea. After the construction of buildings in the Togliatti SEZ was stopped, the joint venture began to consider the option proposed by AvtoVAZ to load the capacity of pilot production that had not been completely liquidated (presses and painting were preserved there). Moreover, an agreement has already been concluded with the VAZ press production for the production of large-sized stampings and front parts. The molds are made, they just need to be “re-attached” to the AvtoVAZ presses. And such work has already begun. But, as you know, a few days ago AvtoVAZ unilaterally refused to cooperate with the joint venture to place welding on its territory. This happened exactly when it became known that the joint venture had found money to continue the Chevrolet Niva-2 project. This was announced at the recent St. Petersburg Economic Forum: Sberbank will finance it. True, the joint venture itself learned about this from the media: the governor of the Samara region Nikolai Merkushkin and the president of Sberbank German Gref decided everything for them. But this is so, in particular, not affecting the overall intrigue.

GM-AvtoVAZ now has only one option for locating a new plant: on its own territory. More precisely, not on our own, but leased from the same AvtoVAZ. We are talking about the T30 building, with an area of approximately 8 thousand square meters. meters. But a new plant requires a minimum of 18 thousand square meters. meters - 12 for welding and 6 for logistics. How they will place everything there is unclear.

Here we remember that the 62nd Corps was preparing for liberation. And about the fact that they wanted to do welding at the OPP. And suddenly: the joint venture finds money for the project, and AvtoVAZ breaks the preliminary agreements. You don’t need to have a higher education in philosophy to figure out the previously rumored rumor: AvtoVAZ had its own plans for the Chevrolet Niva-2 project and skillfully took advantage of the time pressure in which the joint venture found itself. We are not saying that AvtoVAZ wanted to directly snatch this model from the joint venture, of course not. Everything could have been more elegant - increasing AvtoVAZ’s share in the joint venture to a controlling share, jointly fine-tuning ShNiva-2 to the point of being able to use VAZ units, etc. But in the end, this would still lead to AvtoVAZ’s total control over the project.

And now it won’t. And all that remains is to sabotage the efforts of the joint venture, within the legal framework, of course, without violating the Law on Joint Stock Companies.

It's laughable, but if this version is true, then it turns out that Merkushkin unwittingly worked for the Americans by participating in the search for funding for GM-AvtoVAZ (it is appropriate to stipulate here that this is exclusively the author’s opinion, so that it does not become the subject of proceedings in Roskomnadzor). But AvtoVAZ still has so much leverage over GM-AvtoVAZ that even resolving the financial issue does not guarantee the Chevrolet Niva-2 a quick and successful production line.

Article: 21214-3701650, additional articles: 21214370165000

Order code: 007433

- Buy with this product

- show more

- Passenger cars / VAZ / VAZ-21311 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2131-73/generator_s_armaturoiy-252/#part65704″>Lower generator bracketElectrical equipment / Generator with fittings

- There are no reviews for this product yet.

The series of articles 'Crystal VAZs or typical breakdowns of domestic cars' introduces car enthusiasts to typical faults that arise when operating AvtoVAZ cars. This article is dedicated to the favorite of hunters and fishermen - “Niva”.

Hello, dear readers of the blog about the adventures of the Pale Goblin =))

On one of my last rides, my standard generator failed after drinking a fair amount of water with mud and sand. And finding myself in the forest at night and without a generator, I realized that I needed to move it upstairs like the right field guides. ))

Basic malfunctions and ways to eliminate them

Checking the health of the unit is done using a multimeter. After the engine is started, the voltage at the battery terminals should be 13.6 V. If the value is higher or lower, this indicates a break or short circuit of the windings, oxidation of the slip rings, a malfunction in the brush assembly, or voltage regulator.

The generator unit may not work well due to weak belt tension or its breakage. In this case, you need to adjust the tension or replace the belt. Faulty voltage regulator, needs to be replaced. If a breakdown, short circuit, or damage to the rotor windings is detected, it should be replaced. If there is a break or short circuit in the stator windings, it requires replacement. If the diodes are damaged, the rectifier unit is replaced.

Should I install a more powerful current generation unit?

We have already described above why the unit wears out quickly. An excellent solution is to install a new generator. Another common reason is the installation of off-site equipment that consumes a lot of electricity. The current strength of a standard unit is not always enough, so you should think about installing a more powerful generator.

The model depends on the year of manufacture of the car and engine. For example, the first Nivas with a 1.6 power plant have a device with a remote regulator, which was used in the “classics”. In more modern machines the regulator is already built-in.

If you want to buy an aftermarket unit, it would be wise to get a 2003 model year Chevrolet. The selection must be made according to the catalog numbers and parameters that are present in this table:

If you can modify the mounts yourself, then the list of available generators can expand significantly. Craftsmen even install devices from foreign cars.