Clutch problems can cause serious trouble for owners of cars with a manual transmission. The VAZ 2107 is no exception. However, most faults can be quite easily fixed with your own hands.

- Clutch slave cylinder VAZ 2107

RCS device - Location of the RCS

- Symptoms of a malfunction of the control center

- Main malfunctions of the RCS

- Repair kit for RCS

- Dismantling of the RCS

Video: repair of the VAZ 2107 clutch slave cylinder

How to replace the clutch slave cylinder on a Lada 2107 without the help of specialists?

Nobody wants to experience discomfort while driving, especially if it is associated with problems in driving. Owners of domestic “classics” have to devote more time and effort to the condition of their car, because they are used to doing everything with their own hands. We can say with complete confidence that if a car owner has already mastered the process of wheel alignment adjustment , then he can also repair the hydraulic drive of the transmission clutch, just study the technology.

General information

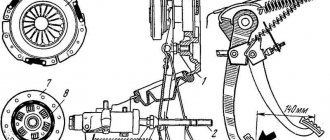

In order for the replacement of the VAZ 2107 clutch slave cylinder to be justified, it is good to know its purpose and the first signs of a malfunction. The torque transmission system on classic VAZ models is driven by a hydraulic drive, the main task of which is to transmit force when pressing the clutch control pedal.

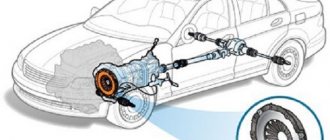

In turn, the hydraulic drive consists of two cylinders: the main and the working. When the pedal is applied, pressure is created in the main center, as a result of which the brake fluid is pumped through the valve into the working cylinder (WC). The latter activates the rod, which squeezes the fork, thereby selecting gears.

Traditionally, the control center is located on the gearbox housing and secured with two bolts, so it can only be reached from under the bottom of the car. The operation of both cylinders depends on the presence of brake fluid, so you need to monitor its level, especially since this is not difficult to do - the container is located in the engine compartment.

When is it necessary to replace a faulty clutch slave cylinder on a VAZ 2107: signs and causes

In most cases, clutch control problems are associated with loss of tightness, when the pedal loses its elasticity when pressed. However, this fact is not so bad, but the inability to engage the gear is already serious.

If we put together the signs indicating the need to replace the clutch slave cylinder on a VAZ 2107, we get the list:

- A drop in the level of brake fluid in the reservoir, which indicates a loss of tightness of the hose or brake fluid. The breakdown is also determined by the spots under the car.

- Periodic “failures” of the pedal or its soft movement indicate air entering the system. Failure may be the result of a worn cuff or cracks in the working cylinder body.

- A gradual loss of pedal stiffness and difficult gear shifting indicate a broken RC spring. In this case, the fluid level remains unchanged, and adjusting the pedal does not produce any results.

Liquid leakage from the master cylinder is signaled by similar signs, so during inspection you need to pay attention to its condition.

Work on top of the car

So, a start has been made, the goal is to remove the gearbox to replace the clutch. On VAZ 2106 and similar cars this is done quite quickly, it is only important to follow a certain sequence:

- Inside the car, remove the gear shift knob. It is attached using plastic latches. Sometimes difficulties arise with dismantling, and it gets to the point where the latches break off. The price of a new set of fastenings is no more than one hundred rubles, and you can purchase it even after repairs have been carried out. Therefore, do not be afraid if you suddenly break the plastic antennae.

- Go to the engine compartment, unscrew the four nuts that secure the exhaust pipe to the manifold. The fact is that the exhaust pipe will interfere with the removal of the box, but it is enough to move it a little to the side.

- Disconnect the battery and remove it from the car.

- Unscrew the two top bolts of the starter, disconnect the power wires for the windings and the solenoid relay from it.

- Disconnect the ground wire that goes to the gearbox.

How to change the Lada slave cylinder yourself?

To work you will need the following set of tools:

- Pliers.

- Open-end wrench “17”.

- Head "13".

It is more comfortable to carry out the repair process on an inspection pit or overpass. If this is not possible, the front part of the machine must be jacked up and placed on supports, having previously secured the rear wheels with shoes. Further work is carried out on the following transitions:

- Loosen the nut of the hose tip in the RC plug using a 17-mm open-end wrench.

- Using pliers, disconnect the tension spring.

- Unbend and remove the cotter pin at the end of the pusher using pliers.

- Using a 13mm socket, unscrew the two bolts securing the cylinder to the gearbox housing.

- Disconnect the bracket that was secured with bolts.

- Having removed the pusher from the fork, take the RC in your hand and, using a 17mm wrench, completely unscrew the tip nut and remove the hose.

- Replace the clutch slave cylinder on a VAZ 2107, and immediately tighten the hose tip to avoid loss of brake fluid.

- Attach the new part in reverse order.

A certain part of car enthusiasts prefer to drain the old brake fluid before surgery, believing that this will allow them to get rid of dirt in the system. Be that as it may, you will have to bleed and adjust the clutch in any case.

How to bleed the clutch control system?

For the quality of transmission operation, the absence of air in the system is important, which is why bleeding is done. The procedure is similar to bleeding the brakes. An assistant is needed to complete the work:

- Fill the reservoir on the master cylinder with brake fluid.

- Place a rubber hose of the appropriate diameter onto the fitting. Place the other end of the hose in a container with some liquid.

- Ask an assistant to press the pedal 5-6 times and hold it in the pressed position.

- Using a “10” wrench, unscrew the fitting half a turn and release air bubbles, then tighten the fitting and repeat the procedure until the air in the liquid completely disappears.

Replacement

The cost of this type of work in a car service starts from 550 rubles. But for most car enthusiasts, this operation is not so difficult to perform on their own.

- new GVC;

- brake fluid;

- set of wrenches with extension;

- syringe or rubber bulb.

- Pump out the fluid from the hydraulic drive reservoir using a syringe or rubber bulb.

- Remove the expansion tank and move it to the side so that it does not interfere with work.

- Unscrew the tube with a 13mm wrench. Move it a little.

- Loosen the clamp and disconnect the rubber hose that goes from the tank to the cylinder.

- Unscrew the two nuts with a 13mm socket wrench and an extension.

- Remove the master cylinder from the studs.

- Replace the GCS with a new one.

- Reassemble everything in reverse order.

Bleeding the clutch

The replacement has been made, but you should not hit the road without bleeding the clutch system. The process is similar to bleeding the brakes and is carried out in the following sequence:

- Brake fluid is poured into the reservoir.

- A hose is put on the master cylinder fitting, the other end is lowered into a bottle filled with liquid. This will show how air leaves the system during the pumping process.

- The operation requires an assistant. One sits in the car and presses the clutch pedal 5-6 times on command, after which he leaves it pressed. The second one opens the fitting until the release of air stops. This is done several times until all air is removed from the clutch system.

- Tighten the fitting and add fluid to the reservoir.

Conclusion

After replacing the clutch master cylinder and bleeding the entire system, you can safely hit the road without fear that the clutch will fail and the car will lose control because of it.

How to repair the working cylinder of a classic “seven” clutch?

In certain cases, car enthusiasts prefer to independently purchase not only repair kit , but also spare parts for cylinder restoration on their own. This option allows you to save some money if you follow the following points:

- Clamp the part in a vice and unscrew the plug at the back.

- Remove the rubber cap.

- Remove the retaining ring from the plug side.

- Extract the internal elements of a node.

- Using a 10mm wrench, unscrew the bleeder fitting.

In order for the replacement of a repaired clutch slave cylinder on a VAZ 2107 to be of high quality, you need to:

- Inspect the condition of the spring and replace it if necessary.

- Replace all rubber seals.

- Inspect the node mirror.

- Clean the fitting.

Before assembly, all parts should be lubricated with brake fluid. You cannot use gasoline or diesel fuel, because the rubber will lose its quality. Change the gasket under the plug only if there are leaks. Having assembled and installed the unit, we finish the process by bleeding the system.

Source

Popular models and manufacturers

When choosing a non-original clutch slave cylinder, products from the following manufacturers are most often used:

- Sachs. The German company is a leading manufacturer of clutch cylinders for most automobile brands of foreign and domestic manufacturers. The popularity is due to the high quality of products and the use of innovative developments.

- Lukas. The largest manufacturer of auto parts, whose products meet all international quality standards. It produces brake cylinders for most automobile brands and repair kits for them.

- Fenox. Specializing in the production of clutch and brake cylinders for more than 25 years. Supplies products to most automakers.

- TRW. The company owns the Lukas brand and supplies brake system components, in particular brake cylinders, for all the world's largest automakers. The products are distinguished by their quality and extreme reliability.

- LUK. Official partner of major automakers in terms of designing new developments and systems. Supplies clutch cylinders to assembly lines of most of the world's major automakers.

This is interesting: Intake manifold gasket - how to replace it?

Replacing the clutch slave cylinder VAZ 2107

On cars, in addition to the master and slave brake cylinders, there are also clutch cylinders. Many do not even know the purpose of these devices, as a result of which the failure of one of the mechanisms forces the car owner to visit the nearest service station and pay decent money for minor repairs. In this material we will pay attention to such a device as the VAZ 2107 clutch slave cylinder, what it is, where it is located and why it breaks.

Tips and tricks

As the main advice when choosing this unit, you should mention the quality of materials when purchasing. The purchased parts must have the manufacturer's markings and series and batch numbers. Many enterprises have their own information resources where you can check the originality of a part by simply checking the batch numbers and the specific part.

Warning! Otherwise, the counterfeit unit has unstable quality and may fail at any time.

Also, in the process of replacing the VAZ 2104 clutch slave cylinder, it is necessary to strictly follow the sequence of actions and accurately calculate the tightening torque of the hoses and pipes from the fluid tank to the main part in order to avoid cracking of the rubber and plastic parts of the body.

Also, once every few thousand kilometers, it is necessary to carry out an inspection of the entire assembly, since the vast majority of cars of these models have significant mileage, the likelihood of unexpected breakdowns is quite high.

Device location

To find the clutch slave cylinder on a VAZ classic, you need to look for it directly in the area where the gearbox is located. The device is attached with two bolts to the gearbox housing.

The mechanism can only be seen from below or in the very depths of the engine compartment on the driver’s side. Repair work related to dismantling and replacing the clutch slave cylinder can be carried out “from under the hood,” but it is much more convenient from an inspection hole or on an overpass. The video below shows the location of this unit. What function does this product perform and is it possible to do without it? We'll find out more about this later.

Features of operation

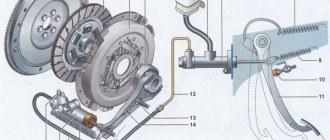

The operating principle is very simple. Below is a diagram where the slave cylinder is indicated by a green arrow.

According to this diagram, we can say that the RCS performs an important function, or rather, it activates the fork, which is connected to the clutch drum. The main element of the RCS, or rather the piston, is activated by the resulting fluid pressure coming from the main cylinder through the hose when the clutch pedal is pressed. The brake fluid pushes the piston, which in turn drives the fork, which acts on the drum, pushing the disc away from the flywheel. Many people wonder why brake fluid is used in the system? The reason is that brake fluid is incompressible, which is why it is used in such important systems as brakes and clutches.

When to replace the RCS

During the use of the unit, which happens very often, the product tends to fail. The main causes of breakdowns are chafing and wear of the cuffs, the appearance of cracks in them, which entails the leakage of liquid. Significant loss of fluid will cause the clutch system to malfunction. It is possible to repair a DCS that has become unusable, but it is easier and more efficient to replace it with a new one.

In order not to wait until the pressure in the clutch pedal disappears, you need to periodically inspect the unit. If there is a leak in the fuel fluid, it is necessary to immediately carry out the appropriate repairs on the VAZ 2107. Before carrying out repairs, you need to make sure that this particular element is faulty, since the main circulation system may also fail. The main signs of failure of the RCS are:

- decrease in the level of fuel fluid in the tank;

- visible brake fluid leaks from the device body or from under the rubber boot;

- “failures” of the clutch pedal, which can be periodic or constant;

- difficulty changing gears.

But most often the malfunction is determined by detecting a brake fluid leak.

Features of replacing the RCS

Replacing the VAZ 2107 clutch slave cylinder begins with the need to remove all fluid from the reservoir. Further actions are carried out in order:

- First you need to loosen the fastening nut that connects the hose to the cylinder. There is no need to unscrew the nut completely, just loosen it at this stage.

- Using pliers, you need to remove the tension spring.

- After this, you should unclench the cotter pin and remove it from the tip of the pusher.

- Using a key set to “12”, you need to unscrew the two bolts that secure the product to the gearbox housing.

- After unscrewing the bolts, you can disconnect the bracket from the cylinder, which is intended to secure the spring.

- Holding the working cylinder body, you should dismantle it. During dismantling, pay attention to the pusher, which is located in the fork.

- After disconnecting the product from the crankcase, you can continue unscrewing the nut connecting the hose to the device. After unscrewing the nut, brake fluid will begin to flow out of the hose, so you should prepare a special container in advance.

Work under the car

This is perhaps the most difficult part of the entire repair, since there are many more steps to be taken here. So make yourself comfortable and proceed to the following operations:

- Unscrew the last (lower) nut securing the starter and remove it. This nut is the nastiest, since it is difficult to get to it using simple wrenches; you will need to use a socket, a ratchet and a cardan. True, it was possible to work with an ordinary open-end wrench installed in the end.

- Unscrew the suspension bearing mount.

- Disconnect the cardan and rear axle flange. Hold the bolt head from turning with a 12mm open end wrench.

- Apply sharp blows to the driveshaft to dislodge it from the rubber coupling on the transmission shaft. Move the cardan to the side.

- Unscrew the mounting of the pillow, install a support under the gearbox.

- Remove the slave cylinder from the clutch fork. Be careful not to lose the bar underneath and the spring.

- Remove the speedometer cable.

- That's all, now all that remains is to unscrew the four bolts that secure the box to the engine block.

Remove the gearbox carefully, try to move it as far as possible from the engine block. The fact is that you can damage the VAZ 2106 clutch drive disc. And this is quite easy to do.

If we take nines and newer VAZs as an example, then the clutch drive discs on them are more reliable and durable. It is advisable to set the gearshift lever to the position corresponding to the third speed.

The design and principle of operation of the VAZ 2107 clutch

The VAZ 2107 is equipped with a single-plate dry clutch with a hydraulic drive. The drive design includes:

- tank with a stopper and built-in liquid stabilizer;

- suspended pedal with pusher;

- master and slave cylinders;

- metal pipeline;

- hose connecting the pipeline and the working cylinder.

When the pedal is pressed, the force is transmitted through the pusher to the piston of the clutch master cylinder (MCC). The main fluid circulation pump is filled with brake fluid coming from the hydraulic drive reservoir. The piston pushes out the working fluid, and it flows under pressure through a pipeline and a rubber hose into the clutch slave cylinder (CSC). In the RCS, the pressure increases and the fluid pushes the rod out of the device, which, in turn, actuates the clutch fork. The fork, in turn, moves the release bearing, disengaging the pressure and driven discs.

Clutch slave cylinder VAZ 2107

The RCS is the final link of the clutch hydraulic drive. Its more frequent failure compared to other components of the mechanism is associated with increased loads resulting from high fluid pressure.

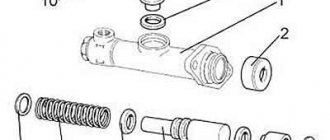

RCS device

The working cylinder of the VAZ 2107 consists of:

- housings;

- piston;

- rod (pusher);

- springs;

- protective cap (case);

- two cuffs (o-rings);

- valve for bleeding air;

- retaining ring with washer.

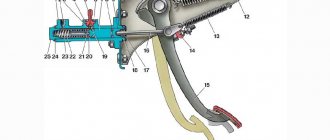

Location of the RCS

Unlike the main circulation center, which is located in the interior of the VAZ 2107, the working cylinder is located on the clutch housing body and is screwed to the bottom of the “bell” with two bolts. You can only get to it from below, after first removing the engine protection (if any). Therefore, all work is carried out on an inspection pit or overpass.

Symptoms of a malfunction of the control center

Failure of the RCS is accompanied by the following symptoms:

- unusually soft clutch pedal travel;

- periodic or constant failure of the clutch pedal;

- a sharp decrease in the level of working fluid in the tank;

- the appearance of traces of liquid under the car in the area of the gearbox;

- Difficulties when changing gears, accompanied by a crunching (grinding) noise in the gearbox.

These symptoms may also be the result of other malfunctions (the entire clutch mechanism, main clutch, gearbox, etc.). Therefore, before starting work on replacing or repairing the RCS, you need to make sure that it is he who is “to blame”. To do this, it should be carefully examined. If traces of working fluid are found on the cylinder body, on its rod or hose, you can begin dismantling the control center.

Main malfunctions of the RCS

The main part of the RCS is made of durable steel, so it is completely replaced only in case of serious mechanical damage. In other cases, you can limit yourself to repairs. Most often, the cylinder fails due to wear of the piston o-rings, protective boot, malfunction of the air release valve and damage to the hose connecting the cylinder and the pipeline.

Repair kit for RCS

Any failed part can be purchased separately. However, when replacing cuffs, it is more advisable to buy a repair kit, which includes three rubber seals and a protective cover. For classic VAZ models, repair kits are produced under the following catalog numbers:

The cost of such a set is about 50 rubles.

Complete disassembly with gearbox removal

The work must be done on a lift or in a pit. First of all, remove the battery

We continue disassembly by removing the rod from the gear shift lever. Then you will have to use a screwdriver to unscrew the screws securing the cover that covers the hole in the car body. This completes the manipulations inside the car dealership. What needs to be done next:

- Remove the exhaust pipe (exhaust system) and resonators;

- Then remove the starter from the flywheel housing and move it to the side;

- Disconnect the cardan from the rear axle and gearbox.

To be able to remove the box, remove the cross member of the rear engine mount and the speedometer drive cable. You also need to disconnect the hydraulic drive cylinder from the gearbox and move it to the side.

Next, you will need to remove the bolts that hold the clutch housing cover in place (key 10) and proceed to dismantling the box, and since it weighs a lot, it is worth putting a good support under it.

Read, it may come in handy: How to independently restore the effectiveness of the handbrake

After this, use a socket wrench to unscrew the bolts from the flywheel housing. Now, in order to remove the box, you will have to carefully move it back, slowly removing the primary shaft from the hub of the clutch driven disc. This must be done carefully so as not to drop the box and injure yourself. That's it, the box is removed.

Video about disassembling the clutch using the example of a VAZ 2106, suitable for the “Seven”, a small difference only in the interior

Clutch slave cylinder repair

To repair the control center, it must be removed from the vehicle. For this you will need:

- round nose pliers or pliers;

- wrenches 13 and 17;

- container for draining liquid;

- clean dry rag.

Dismantling of the RCS

Dismantling of the RCS is carried out in the following order:

- We install the car on an inspection hole or overpass.

- From the inspection hole, using a 17mm wrench, unscrew the tip of the connection between the hydraulic drive hose and the working cylinder.

Disassembly and replacement of faulty parts of the control center

To disassemble and repair the cylinder you will need:

- wrench 8;

- slotted screwdriver;

- clean dry cloth;

- some brake fluid.

The working cylinder is disassembled in the following sequence:

- We clamp the cylinder in a vice.

- Using an 8-mm open-end wrench, unscrew the air bleed valve and inspect it for damage. If a malfunction is suspected, we purchase a new valve and prepare it for installation.

Before replacing the piston cuffs and protective cover, the metal parts of the cylinder must be cleaned of dirt, dust, and traces of moisture using brake fluid and a clean rag. New seals and a cover are installed during the assembly of the RCS. First, the front cuff is put on the piston, then the rear one. In this case, the back cuff is fixed with a washer. The protective cover is installed together with the pusher. Assembling the device and installing it is done in the reverse order.

Video: repair of the VAZ 2107 clutch slave cylinder

Bleeding the hydraulic clutch

After any work related to depressurization of the clutch mechanism, as well as when replacing the fluid, the hydraulic drive must be pumped. For this you will need:

- brake fluid (0.3 l);

- rubber hose;

- key to 8;

- a vessel for collecting liquid (a 0.5 liter plastic bottle is suitable).

In addition, you will need an assistant for pumping. The procedure is as follows:

- After installing the control center and connecting the hose to it, fill the hydraulic drive reservoir with liquid to a level corresponding to the lower edge of the neck.

- We put one end of a pre-prepared hose onto the valve fitting to bleed air, and lower the other end into a container to collect liquid.

Setting the clutch drive

After bleeding, it is recommended to adjust the clutch drive. For this you will need:

- a caliper or (as a last resort) a ruler;

- wrenches 8, 10, 13, 17;

- round nose pliers or pliers.

The procedure for setting the clutch on carburetor and injection VAZ 2107 models is different. In the first case, the clutch pedal free play setting is adjusted, in the second - the amplitude of movement of the working cylinder rod.

For carburetor VAZ 2107, the drive is configured as follows:

- We measure the amplitude of free play (play) of the clutch pedal using a caliper. It should be 0.5–2.0 mm.

- If the amplitude goes beyond the specified limits, use a 10mm wrench to unscrew the locknut on the travel stop pin and, turning the stop in one direction or another, set the required backlash.

For injection VAZ 2107, the drive adjustment is carried out in the following order:

- We install the car on an inspection hole or overpass.

- Using pliers from below, remove the tension spring from the clutch fork.

- We determine the backlash of the working cylinder pusher by pressing the clutch fork all the way back. It should be 4–5 mm.

- If the play does not fall within the specified interval, use a 17 wrench to hold the rod adjustment nut, and use a 13 wrench to unscrew the fixing nut.

Why it stalls - reasons and their elimination

The clutch usually slips due to the following:

- There is no gap between the pressure bearing and the fifth basket;

- the clutch drive is not adjusted;

- oil gets on the discs;

Depending on the cause of this problem, the repair progress is determined. If the problem is with the diaphragm spring, it will have to be replaced with another one. When the friction linings wear out, the driven disk is replaced. When repairing/removing linings, the gaskets are checked. If they are in poor condition, they are also replaced with new ones. If oil gets on the driven disc, you will need to treat it with kerosene and clean it with fine sandpaper.

Disc oiling

Grease may get on any side of the flywheel and pressure plate due to an increased oil level in the gearbox housing or a leak in the rear crankshaft bearing. To solve the problem, diagnostics are performed and the cause of the leak is eliminated - the seals are replaced, then the spare parts are cleaned.

Read, it may come in handy: How to choose brake pads

The free stroke according to technical conditions is 30-35 mm, the full stroke is 140 mm. Any deviation from the norm is associated with a malfunction of the transmission and requires adjustment work. The parameter is checked using a ruler. To do this, determine the distance from the pedal to the center of the platform. The adjustment is made on a pit or lift using open-end wrenches 13 by 17 mm and 17 by 19 mm. We clean the adjusting rod and nuts with a brush and treat them with WD-40. Next, the lock nut is loosened, and by rotating the adjusting nut we change the gap. If the free play needs to be reduced, we lengthen the thrust; if it is increased, we shorten it. After completing the work, tighten the locknut.

Damaged release clutch