Correctly tensioning the timing belt on production vehicles is a simple procedure, but it requires certain special knowledge.

The algorithm of actions may vary slightly depending on the model of the power unit, and not on the make of the car. There are differences in the procedure for replacing and tensioning the belt on 8-valve and 16-valve engines. Read on to find out how to tighten the timing belt on both types of car hearts.

Four-cylinder eight-valve power units are more often found on:

- VAZ-2108 - 2115;

- VAZ-2110 - 2111.

Sixteen-valve engines are mainly used:

- On VAZ-2112;

- Lada Priora;

- Lada Kalina;

- Lada Largus;

- Lada Granta;

- Lada news.

A number of cars of the Samara 2 family were also equipped with 16-valve engines. In addition, such engines were also installed on models 2110-2111.

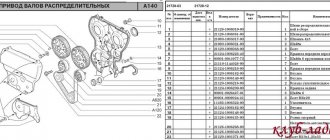

Timing belt location

The belt is hidden under a cover from dirt and other debris. This cover is made of plastic and can be easily removed by unscrewing the fastening bolts. Having removed the cover, the entire timing mechanism will appear before your eyes (except for the pistons, their connecting rods, valves, etc., they are located in the cylinder block). Below we have posted a photo where the belt is clearly visible (indicated by a red arrow), and we indicated the camshaft pulley with a blue arrow, the pump with a green arrow, and the tension roller (which regulates the tension of the belt) with a yellow arrow. Remember the details listed.

Step-by-step tensioning of the timing belt VAZ 2114

The other day I noticed that the timing belt started clicking. I immediately went into the garage and removed the top half of my sawed-off drive cover. Indeed, the belt turned out to be very loose. Inspection showed that the tension roller had moved.

The belt is clearly loose

The fact is that during the previous adjustment of the belt tension, the pin began to rotate along with the roller nut. Having read horror stories about the fragility of the stud, I decided not to touch it, and, having adjusted the tension, I was afraid to tighten the nut too much. I clearly tightened it weakly, and this is the result. It's good that the belt teeth didn't jump. I realized that it is undesirable to touch this unit again, and in order not to unnecessarily rotate the nut, and with it the stud, I need a reliable way to check and adjust the tension.

The method proposed in many manuals for checking belt tension by twisting it 90 degrees with a force of 2 kgf does not provide for measuring this force. It is very difficult to evaluate it subjectively. As a result, the belt is either loose and slams, threatening to jump, or it is overtightened and howls like a shot down Messerschmitt in Soviet films.

When replacement is required

The timing belt is responsible for the operation of the gas distribution mechanism.

Try in every possible way to avoid breaking the belt while driving, otherwise this may negatively affect the condition of the engine and the cost of its repair.

The most dangerous is the contact, the “meeting” between two main elements - the piston and the valve. In this case, the unit becomes deformed, requiring expensive restoration of the car.

There are several main criteria that indicate the need to replace the unit.

| Sign of wear | Peculiarities |

| Natural wear and tear | Each element has a certain resource, a margin of safety, above which it can “jump” only in rare exceptions. For timing belts on nines it is 50-60 thousand kilometers |

| Visual signs of wear | If you examine the condition of the strap, if there are any malfunctions, this will manifest itself in the form of defects, cracks, and peeling along the edges. All this suggests that you cannot continue to operate the car with such a strap; replacement is required. |

| Oil or coolant on the surface | Another sign that the strap is outdated and needs to be replaced. At the same time, do not forget to check for leaks in their cooling system and oil channels |

| Retighten the strap | When the service life has not yet come to an end, the strap may still become loose. To eliminate this, it is tensioned. But over time, the tension reaches its limit, the strap becomes overtightened and is no longer able to return to the desired position. For replacement and only |

| Tooth wear | If there are problems with the teeth, when moving, the belt simply begins to slip while the crankshaft rotates. Here you will have to change the gears and the belt itself |

Crack on the strap

How to determine that the belt twisting force is 2 kgf?

I remembered that I read somewhere a long time ago that you can tighten the belt with a household dynamometer using a special key. I bought a key on the market for 50 rubles, but it turned out to be impossible to work with it. I had to bend it into an “G” shape, screw the sector in place and make recesses for the dynamometer hook. The length of the arm from the key pins to the point of application of the torque force is 80 mm.

Special key for adjusting the timing belt tension. The distance from the pins to the groove for the dynamometer hook is 80 mm. As it turned out later, the key can be used without an additional sector

And then everything is simple. We put the x17 key on the driven gear nut and, lightly tapping it with your hand, select the slack in the drive belt branch. Next, we insert a special key into the holes of the roller axis, engage the key rod with a dynamometer and create a force of 2.5...3.0 kgf. Holding the special wrench by the sector, tighten the roller nut. The main thing here is not to overdo it and not tighten the nut with a torque of more than 4.2 kgcm, otherwise the stud may bend and the belt will subsequently slip.

Before adjustment, it is necessary to select the slack of the pulling belt branch

The force on the dynamometer should be 2.5…3.0 kgf

Having removed the dynamometer and holding the key by the sector, tighten the roller nut

If you don't have a torque wrench, you can use the same dynamometer to control the force. I did just that, only I had to put a pipe on the key, otherwise the dynamometer scale was missing. There are no photos of this action, because there were not enough hands to hold the key with the pipe, the dynamometer and the camera.

I checked the quality of tension with the engine running: when revving, the radial runout of the pulling branch of the belt was 10...12 mm, which corresponds to the norm.

Yes, I forgot: before adjusting, I turned the loosened pin with pliers and a rag wrapped around the thread by almost 2 turns and tightened it; It's holding up for now.

see also

Whistle on a cold engine

- 19 0 25k

Belt conditioner

- 18 2 24k

How to eliminate a whistling alternator belt

- 248 1 224k

Hinged belt

- 0 0 42k

If the alternator belt breaks on the road

- 108 0 94k

How to tension the alternator belt

Many car owners are interested in the question: how to tighten the alternator belt ? After all, the battery charge level and the voltage in the car’s electrical network depend on this. Also, the condition of the belt itself, as well as the condition of the crankshaft bearings and the generator shaft, depend on how the generator belt is tensioned Next, we will analyze in detail how to properly tension the alternator belt with a specific example.

Which timing belt is better to choose for VAZ 2114 8 valves

The material used to manufacture modern timing belts is dense metal rubber. The reliability, wear resistance and service life of the product directly depend on its quality. If it is necessary to replace it, the car owner is faced with a difficult question: which belt to choose, which manufacturer and brand to give preference to.

The situation is complicated by the presence of a large number of counterfeits of well-known brands on the market. Due to high-quality imitation of appearance, including packaging, inscriptions, holograms, it is almost impossible to distinguish them from original products.

For example, some manufacturers, such as Gates, increase the service life of belts by increasing the resistance of materials to significant temperature changes, exposure to technical fluids, and oil.

This happens due to the use of nitrile instead of neoprion. Unscrupulous manufacturers use simpler and cheaper materials.

If you buy an outwardly identical fake, you may end up with premature failure of the belt, roller, pump, and be undeservedly disappointed in the brand.

To avoid such a risk, it is better to buy from official services and trusted suppliers.

According to test results, belts from domestic manufacturers perform no worse than foreign ones, for example BRT. Given the affordable price, this is a big plus.

Imported ones - Contitech and Lemforder - have good quality. Slightly more expensive and stronger than Dayco. Also Roulunds and Bosch, but much more expensive..

What determines the durability of a timing belt?

The gas distribution system is very sensitive to the synchronization of phases with the strokes of the pistons. The belt plays a key role in this process.

There are a number of factors that reduce the life of the belt and other timing parts:

- Excessive tension. Leads to rapid stretching of the belt, increased wear of the roller, misalignment of the stud, timing drive bearings, and pump.

- Insufficient tension. Even slight slippage accelerates belt wear and causes engine malfunction.

- When replacing the belt, the tension roller is left with the old one. This may be justified if the timing belt is damaged prematurely or if oil, antifreeze or other liquid has entered. In other cases, this is due to the risk of failure of the worn-out roller when the belt is working and the need for their emergency replacement.

- Intensive use of cars in urban mode or in regions with hot climates. High temperatures lead to premature drying and cracking of the belt. The recommended mileage interval between replacements, under such conditions, is reduced to 30 thousand km.

- Quality of belt and roller material. Counterfeits have a shorter lifespan than the originals.

- Timing casing seal failure. The ingress of dust, dirt, moisture, and oil shortens the service life of not only the belt, but also other parts of the gas distribution mechanism.

- Repair errors. Sometimes, due to improper installation or adjustment, the belt rubs against some parts of the engine compartment. This leads to rapid wear and failure.

Any deviations in the properties of the PMG belt from the norm negatively affect the operation of the engine. Therefore, periodic condition monitoring, timely scheduled replacements of all required parts - belt, roller and pump - will help minimize many problems with the engine.

Recommendations

Excessive belt tension causes increased wear on the water pump bearings and tension pulley. If the belt tension is weak, the valve timing may be disrupted due to the belt jumping over the teeth on the camshaft pulley. In addition, improper adjustment leads to increased belt wear.

Rotate the crankshaft only by the bolt securing the pulley to it (do not turn the crankshaft by the camshaft pulley).

The tension roller is turned with a special key. If it is not available, you can use a screwdriver and two suitable pins ∅ 4 mm (for example, drills) that fit tightly into the holes of the roller.

Correctly tensioning the timing belt on production vehicles is a simple procedure, but it requires certain special knowledge.

The algorithm of actions may vary slightly depending on the model of the power unit, and not on the make of the car. There are differences in the procedure for replacing and tensioning the belt on 8-valve and 16-valve engines. Read on to find out how to tighten the timing belt on both types of car hearts.

Four-cylinder eight-valve power units are more often found on:

Sixteen-valve engines are mainly used:

A number of cars of the Samara 2 family were also equipped with 16-valve engines. In addition, such engines were also installed on models 2110-2111.