Like all domestic cars, Lada Priora has its drawbacks. During the release of the model, a list of the most frequent breakdowns and weak points of this machine was formed. For Lada Priora, repairs of engine spare parts and electrical equipment are common occurrences. There are also problems with the suspension struts and interior plastic.

In case of serious breakdowns that are beyond your competence, you need to undergo diagnostics at a service station. But if you are sure that you are able to identify a certain, not too serious breakdown, you can cope on your own. Repairing the Priora on your own will help you follow the operating and repair instructions for the VAZ 2170.

Description of the design of the Lada Priora car

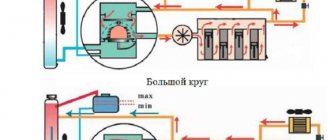

The Lada Priora car (VAZ-2170) is a model of AVTOVAZ LLC, which was designed to replace cars of the VAZ-2110 family. Its production began in the spring of 2007. Lada Priora is a five-seater passenger car with a front transverse engine, front-wheel drive and an all-metal welded body with a supporting structure. The car has many parts that are unified with the VAZ-2110 family, but even more are original, which allows us to talk about the car as a new model. Lada Priora meets modern requirements for passive safety. The front and rear bumpers are made of impact-resistant material to absorb impact energy during a collision. The B-pillars, roof and sills are reinforced. All doors are equipped with metal bars to improve resistance to side impacts. Modified front and rear suspensions with carefully selected characteristics of shock absorbers and anti-roll bars made it possible to obtain high levels of stability and controllability. The basic equipment of the car includes electric power steering, a driver's airbag, and electrically adjustable exterior mirrors. For greater convenience and safety, a set of options will appear on the Priora in the future: an airbag for the passenger, seat belt pretensioners, anti-lock brakes, air conditioning, fog lights, and electrically heated exterior rear-view mirrors. The car is equipped with a modernized four-cylinder, in-line, four-stroke, sixteen-valve VAZ-21126 engine with a displacement of 1.6 liters (power 98 hp) with distributed fuel injection and electronic control. All vehicles are equipped with a catalytic exhaust gas converter and two oxygen concentration sensors, which allows them to meet modern Euro-3 exhaust gas toxicity standards. Significant changes have taken place in the transmission. The gearbox now uses sealed bearings for the primary and secondary shafts and more efficient synchronizers. The clutch is reinforced and designed to transmit more torque, and the clutch drive uses a cable with automatic length adjustment, which eliminates the need to adjust the unit during operation.

Lada Priora operation and repair

We remove the lock to replace it, as well as when repairing the door (straightening, painting).

Comment

The door lock consists of an internal and external part. If the outer part is faulty, it can be replaced without removing the door trim.

Removal

1. Remove the door trim and remove the plastic film.

2. Disconnect the wiring block of the lock gear motor from the wiring harness block

3. Remove the gear motor wires from the clamp.

4. Using a slotted screwdriver, disconnect the plastic ends of the switch rods (cylinders) of lock 1 and the outer handle of lock 2 from the lock levers.

5. Using a TORX T40 key, unscrew the two screws securing the lock.

6. Remove the outer part of the lock.

7. Using a Phillips screwdriver, unscrew the three screws securing the inner door opening handle.

8. Using a Phillips screwdriver, unscrew the screw securing the inside of the lock to the door panel.

9. Remove the inner part of the lock assembly with the locking button rod and the gear motor from the door.

10. To remove the lock latch, mark its position on the B-pillar (with a marker or felt-tip pen).

11. Using a TORX T40 wrench, unscrew pin 1 of the lock and two screws from the fastener.

12. Remove the lock.

Comment

Shims can be installed under the retainer. They should be put in place during assembly.

Installation

Install the door lock in the reverse order.

Recommendation

It is convenient to put the plastic rod ends on the ball pins of the lock levers using sliding pliers.

We install the lock retainer following the marks made. If the door does not close well (for example, with a metallic knock or you have to slam the door hard to close), adjust the lock (see below).

Adjustment

Comment

The door lock is adjusted by changing the position of the latch on the pillar. When closing the door, the protruding part of the latch body should not touch the door and the elements of the outer part of the lock. The latch pin must fit into the slot on the outer part of the lock without touching the edges of the slot.

1. Loosen the tightening of the latch pin and two screws securing the latch (see above). By changing the position of the latch in the vertical plane, we achieve the optimal position of the latch pin in the lock slot.

2. The tightness of the door cover is adjusted by moving the latch in the horizontal plane.

3. If the latch touches the lock or door, accordingly increase or decrease the number of shims installed under the latch.

Recommendation

You can make additional shims yourself by cutting them out of sheet metal (preferably aluminum alloy).

4. After completing the adjustment, tighten the fastening screws and the lock lock pin.

Technical characteristics of the Lada Priora car

| COMMON DATA | |

| Characteristics | Options |

| Body type | Sedan |

| Number of seats | 5 |

| Number of doors | 4 |

| Curb weight, kg | 1088 |

| Total weight, kg | 1578 |

| Minimum ground clearance (under the exhaust system), mm | 135 |

| Permissible total weight of the towed trailer, kg, equipped with brakes, not equipped with brakes | 800 500 |

| Trunk volume, l | 430 |

| Maximum speed, km/h | 183 |

| Acceleration time to 100 km/h, s | 11,5 |

| Fuel consumption, l/100 km urban cycle 9.8 extra-urban cycle 5.6 mixed cycle | 9,8 5,6 7,2 |

| Minimum (overall) turning radius, m | 5,8 |

| Fuel tank capacity, l | 43 |

| ENGINE | |

| Characteristics | Options |

| Model | 21126 |

| Type | Gasoline, in-line, four-stroke, four-cylinder, sixteen-valve |

| Location | Front, transverse |

| Supply system | Multiport fuel injection |

| Cylinder diameter and piston stroke, mm | 82,0?75,6 |

| Working volume, cm3 | 1597 |

| Rated power at crankshaft rotation speed, min-1, kW (hp) | 72 (98) at 5,600 |

| Maximum torque at crankshaft speed, min-1, Nm | 145 at 4000 |

| Fuel Gasoline | "Premium-95" or "Premium Euro-95" |

| Ignition system | Electronic, part of the engine management system |

| Toxicity standards | Euro-3 |

| TRANSMISSION | |

| Characteristics | Options |

| Clutch | Single disc, dry, with diaphragm pressure spring |

| Clutch release drive | Cable, with automatic adjustment of cable length |

| Transmission | Mechanical, five-speed, with synchronizers in all forward gears |

| main gear | Cylindrical, structurally made in one block with the gearbox. Differential - bevel, two-satellite |

| Gearbox gear ratios: 1st gear 2nd gear 3rd gear 4th gear 5th gear reverse gear | 3,64 1,95 1,36 0,94 0,78 3,50 |

| Final drive ratio | 3,7 |

| Drive wheels | Shafts with constant velocity joints |

| CHASSIS | |

| Characteristics | Options |

| Front suspension | Independent, MacPherson type, with telescopic shock absorbers, coil springs, wishbones, longitudinal braces and anti-roll bar |

| Rear suspension | Semi-independent, with coil springs, telescopic hydraulic shock absorbers and trailing arms connected by a U-shaped transverse beam and a torsion-type anti-roll bar built into it |

| Tires | Radial, low profile, tubeless |

| Tire size | 175/65R14 82Н 185/60R14 82Н |

| Wheels | Disc, light alloy (spare wheel - steel) |

| Wheel size | 5.0J-14H2 5.5J-14H2 6.0J-14H2 |

| Wheel offset, mm | 35 |

| STEERING | |

| Characteristics | Options |

| Steering gear | Gear - rack and pinion with electric booster |

| Steering gear | Two rods with rubber-metal joints (on the steering mechanism side) and ball joints (on the swing arm side) |

| BRAKE SYSTEM | |

| Characteristics | Options |

| Service brake system | Hydraulic, dual-circuit - diagonal, with a vacuum booster and brake force regulator in the rear wheel brake drive |

| Front wheel brake | Ventilated disc with single-piston floating caliper and automatic disc-to-pad clearance adjustment |

| Rear wheel brake | Drum-type, with self-aligning shoes and automatic adjustment of the gap between the shoes and the drum |

| Parking brake | Manual, with cable drive to the brake pads of the rear wheels |

| ELECTRICAL EQUIPMENT | |

| Characteristics | Options |

| Electrical diagram | Single-wire, negative terminals of power sources and consumers are connected to the “ground” (body and power unit) of the car |

| Rated voltage, V | 12 |

| Accumulator battery | Starter 6ST-55A, capacity 55 Ah |

| Generator | AC, three-phase, with built-in rectifier unit and electronic voltage regulator |

| Maximum current supplied by the generator, A | 80 |

| Starter | With permanent magnet excitation, electromagnetic traction relay and freewheel |

Sometimes the Priora electrician fails

Electrical equipment often suffers from breakdowns:

- electric power steering;

- wiper drive;

- headlight lamps.

At the first stages of Lada Priora sales, problems arose with a new function - electric power steering. This was a trial step for AvtoVAZ, and it is logical that there were some disruptions. Jerks were observed when the steering wheel rotated, as well as jamming and stiff movement. The electrical diagram provided in the owner's manual helps to trace the steering drive circuit and identify faults. Sometimes the problem was solved by simply cleaning the contacts and strengthening the wiring. But often the breakdowns were much more serious, and only the service station workers could solve them.

Over time, the plant developed optimal assembly technology. Therefore, problems with the amplifier occur much less frequently. If the drive performance deteriorates, open the “Electrical equipment” section of the VAZ operating manual. We check the entire drive circuit for continuity and short circuit, and also clean the contacts.

On already “middle-aged” Priors, problems with the ignition coil can be traced. Also, over time, malfunctions in the operation of the windshield wiper drive occur, and headlight bulbs burn out. You can repair these parts yourself, following the instructions in the manual.

The standard battery on the Priora is not entirely successful. There are often complaints that the battery lasts for a year or a year and a half. Normal service life is up to three years. The battery on the Lada is a non-separable type, so you only have to replace it.