Control over the operation of the vehicle, its components and assemblies is carried out by sensors. The devices transmit readings online to the electronic control unit for interpretation and response. If a discrepancy is detected by the latter, the “Check Engine” indicator appears on the dashboard. The driver makes a decision based on the data received.

List of sensors installed on Lada Vesta

- Controller (KSUD).

- Coolant temperature sensor (CTS).

- Knock sensor (DS).

- Parking sensor.

- Crankshaft position sensor (CPS).

- Camshaft position sensor (phase sensor).

- Absolute pressure sensor (ABP) and air temperature sensor (ATS).

- Parking sensor.

- Oxygen sensor (OS) or lambda probe.

- Fuel level sensor.

- Mass air flow sensor (MAF) or throttle valve.

- Vehicle speed sensor (VS).

- ABS sensor Lada Vesta.

- Oil pressure sensor.

- Shock sensor.

- Clutch and brake sensors.

How to check the knock sensor

The question of how to check the knock sensor (hereinafter DS) worries many car enthusiasts, in particular those who have encountered DS errors. There are actually two main testing methods - mechanical and using a multimeter. The choice of one method or another depends, among other things, on the type of sensor; they can be resonant or broadband. Accordingly, their verification algorithm will be different. For sensors, the value of changing resistance or voltage is measured using a multimeter. An additional check with an oscilloscope is also possible, allowing you to look in detail at the process of triggering the sensor.

KSUD

KSUD - engine control system controller (catalog number 21127141102062). This is the main sensor that receives data about the state of the technical equipment from the systems.

Installed in the engine compartment, on the left in the direction of travel of the car. Built into a plastic case along with power fuses.

Signs of inoperability:

- no data on the display when starting the engine;

- partial display of data;

- sound accompaniment during work.

The service life is unlimited according to the instruction manual. In practice, no more than 5 years, after which it needs to be replaced with a new one.

Voltage measurement

The most effective way to check the engine knock sensor is with a multimeter (another name is an electrical tester; it can be either electronic or mechanical). This check can be performed by removing the sensor from its seat or checking it directly on site, but dismantling it will be more convenient to work with. So, to check, you need to set the multimeter to measure direct voltage (DC) in the range of approximately 200 mV (or less). After this, connect the probes of the device to the electrical terminals of the sensor. Try to make good contact, since the quality of the test will depend on this, because some insensitive (cheap) multimeters may not recognize a slight change in voltage!

Next, you need to take a screwdriver (or other strong cylindrical object) and insert it into the central hole of the sensor, and then apply it to the fracture so that force is generated in the inner metal ring (do not overdo it, the sensor body is plastic and can crack! ). In this case, you need to pay attention to the readings of the multimeter. Without mechanical impact on the knock sensor, the voltage value from it will be zero. And as the force applied to it increases, the output voltage will also increase. It may vary for different sensors, but usually the value is from zero to 20 ... 30 mV with low or medium physical effort.

A similar procedure can be performed without removing the sensor from its mounting location. To do this, you need to disconnect its contacts (chip) and similarly connect the multimeter probes to them (also ensuring high-quality contact). Next, use some object to press on it or knock with a metal object not far from the place where it is installed. In this case, the voltage value on the multimeter should increase as the applied force increases. If, during such a test, the value of the output voltage does not change, most likely the sensor has failed and must be replaced (these components cannot be repaired). However, it makes sense to perform additional checks on it.

Also, the value of the output voltage from the knock sensor can be checked by placing it on some metal surface (or another, but so that it conducts sound waves well, that is, detonates) and hitting it with another metal object in close proximity to the sensor (observe when Be careful not to damage the device!). A working sensor should respond to this by changing the output voltage, which will be directly displayed on the multimeter screen.

You can similarly check the resonant (“old”) knock sensor. In general, the procedure is similar; you need to connect one probe to the output contact, and the second to its body (“ground”). After this, you need to hit the sensor body with a wrench or other heavy object. If the device is working properly, the output voltage value on the multimeter screen will change briefly. Otherwise, most likely the sensor has failed. However, it makes sense to additionally check its resistance, since the voltage drop can be very small, and some multimeters may simply not pick it up.

There are sensors that have output contacts (output chips). Checking them is carried out in the same way; to do this, you need to measure the value of the output voltage between its two contacts. Depending on the design of a particular engine, the sensor must be dismantled for this or can be checked directly on site.

Please note that after the shock, the increased output voltage must necessarily return to its original value. Some faulty knock sensors do increase the output voltage when they are triggered (struck on or near them), but the problem is that the voltage remains high once they are touched. The danger in this situation is that the ECU does not diagnose that the sensor is faulty and does not activate the Check Engine light. But in fact, in accordance with the information coming from the sensor, the control unit changes the ignition angle and the engine may operate in a mode that is not optimal for the car, that is, with late ignition. This can manifest itself in increased fuel consumption, loss of dynamic characteristics, problems when starting the engine (especially in cold weather) and other minor troubles. Such breakdowns can be caused by various reasons, and sometimes it is very difficult to understand that they are caused precisely by incorrect operation of the knock sensor.

DTOZH

Coolant temperature sensor (article 2190-1306010). Controls the temperature in the vehicle's cooling system. When a critical point is reached, it signals on the dashboard to notify the driver.

Related link:

Which trunk shock absorbers should I choose for the Lada Vesta?

Installed in the thermostat cover housing. Service life – 75-85 thousand km. Cannot be repaired.

Signs of inoperability:

- incorrect display of operating temperature;

- display inactive;

- unstable degree display.

The theory of engine vibration at idle speed of Lada Vesta and possible causes

The initial data for the control system (CS) of the power plant is the temperature and volume of air sucked through the intake manifold. It is impossible to adjust the thermal characteristic - the engine is naturally aspirated and takes a mixture of oxygen and nitrogen directly from the environment.

Theoretical aspects

The amount of air is regulated: the degree to which the gas pedal is pressed determines the opening angle of the throttle valve. Incorrect determination of the control system for the volume of the air mixture leads to the fact that the speed of the Lada Vesta floats at idle and while driving.

What causes the floating effect? The amount of gasoline sprayed into the manifold is calculated based on the volume of incoming air. When the computer perceives the latter incorrectly, the motor gains momentum. The degree of fuel injection remains the same, the mixture becomes leaner and the power plant begins to stall. The amount of oxygen and nitrogen mixture consumed is reduced, fuel consumption remains the same and is now sufficient - engine operation is stabilized. Then the cycle repeats.

Probable Causes

At this stage, it is clear that low-quality fuel can cause engine detonation, but not cause unstable idling. Untimely ignition of the fuel-air mixture can cause a negative effect. To eliminate the malfunction, a comprehensive inspection should be carried out:

- SU sensors.

- Regulator in the throttle assembly.

- Elements of the inlet assembly unit.

- Brake system units.

- Gasoline vapor recovery algorithm devices.

- Ignition systems.

DD

Knock sensor (part number 2346015900). Designed to record high-frequency vibrations of the cylinder block that occur during fuel combustion.

Located on the outer wall of the cylinder block. The service life is unlimited. Cannot be repaired.

Signs of inoperability:

- difficulty starting the engine;

- Unstable engine operation at idle speed.

Checking the knock sensor with an oscilloscope

There is another method for checking DD - using an oscilloscope. In this case, it is unlikely that it will be possible to check the functionality without dismantling it, since usually an oscilloscope is a stationary device and it does not always make sense to carry it to the garage. On the contrary, removing the knock sensor from the engine is not very difficult and takes a few minutes.

The check in this case is similar to those described above. To do this, you need to connect two oscilloscope probes to the corresponding terminals of the sensor (it is more convenient to check a broadband, two-terminal sensor). Next, after selecting the operating mode of the oscilloscope, you can use it to look at the amplitude shape of the signal emanating from the sensor being diagnosed. In quiet mode it will be a straight line. But if mechanical shocks are applied to the sensor (not very strong, so as not to damage it), then instead of a straight line, the device will show splashes. And the stronger the blow, the greater the amplitude.

Naturally, if the amplitude of the signal does not change during the striking process, it means that the sensor is most likely faulty. However, it is better to diagnose it further by measuring the output voltage and resistance. Also remember that the amplitude surge should be short-lived, after which the amplitude is reduced to zero (there will be a straight line on the oscilloscope screen).

You need to pay attention to the shape of the signal from the sensor

However, even if the knock sensor worked and produced some kind of signal, its shape must be carefully examined on an oscilloscope. Ideally, it should be in the shape of a thick needle with one sharp, pronounced end, and the front (sides) of the splash should be smooth, without jagged edges. If the picture is like this, then the sensor is in perfect order. If the pulse has several peaks, and its front has jagged edges, then it is better to replace such a sensor. The fact is that, most likely, the piezoelectric element in it is already very old and it produces an incorrect signal. After all, this sensitive part of the sensor gradually fails over time and under the influence of vibration and high temperatures.

Thus, diagnostics of a knock sensor with an oscilloscope is the most reliable and complete, giving the most detailed picture of the technical condition of the device.

DPKV

Crankshaft position sensor (article 8200701972-B). Online, the ECU sends data on crankshaft speed and tilt angle.

Installed in the tide hole of the oil pump cover. Resource – 80-90 thousand km. Cannot be repaired.

Signs of inoperability:

- the engine does not start for a long time.

Lada Vesta 1.8 21179 Detonation on any fuel

Welcome to ChipTuner Forum.

Theme Options

0.3-0.4V, when the gas is released it drops to 0.2, under load it increases to 0.6. Not really hoping for results, I recently changed my DD to Kaluga, with the AT index. And there is a result. At XX voltage on DD

1.5V, when releasing the gas it drops slightly to 1.3-1.4V, under load on average 1.7-1.8V with peaks above 2V. At the same time, at low speeds, detonation is now not audible at all, in any way. Victory? On the one hand, yes, but... the car stopped moving. I'm looking at what's happening there now. And the following happens. With uniform movement, everything is fine, the rebounds on the cylinders are 0, but if you accelerate even a little or even a small slide will appear - a rebound of 6-9-12 degrees. In the gas to the floor mode, it always hangs at a maximum of 12 degrees across all cylinders. In some modes, the real SOP is established generally after TDC (

2000 rpm). In the region of 3-4 thousand, ringing is also heard - there is not enough angle adjustment range. Below are my thoughts on further search for a solution to the problem: What causes detonation in general: 1. Bad fuel? In a city with over a million people, all network gas stations have donkey gasoline instead of 95. It could be, of course, but other cars somehow drive on this, so it seems unlikely. 2. Raised corners of the UZ in the firmware? The rebound makes the angles not at all early, but in some modes there is still a ringing sound, that is, it seems that the adjustment of the OZ is working adequately, or not? 3. Is there soot in the KS as thick as a finger? Of course, I didn’t climb into the cylinders with an endoscope, but for the last 1.5 years I have been using gasoline with detergent additives, and periodically I add Techron to the tank again to clean the CS. The option is possible, but seems unlikely. 4. Lean mixture? So the ECU would see this through the lambda. Its graph looks quite lively, and even in power modes (when lambda regulation is disabled) the situation should have improved, but no, detonation still occurs. How else can you check for a lean mixture? 5. ? In general, I have run out of options and, to be honest, I am at a dead end, so I will be happy to listen to your thoughts. I apologize for such an unreadable sheet, I wanted to describe the situation in as much detail as possible.

Source

Phase sensor

Camshaft position sensor (part number A2C90920400). Informs the electronic engine control unit when the piston reaches top and bottom dead centers during the compression stroke.

Installed on the engine, below the valve covers. Resource – 90-100 thousand km. Cannot be repaired.

Signs of inoperability:

- The ECU goes into emergency mode;

- The engine is unstable at idle speed.

Motor Controller

The controller is responsible for all processes necessary for the operation of the engine and is the main device in the car. Without this block, the operation of the car engine will be impossible, as well as if it breaks down.

Signs of malfunction:

Failure of the unit will lead to a complete stop of the engine and will not allow the internal functions of the car to operate.

DBP and DTV

Absolute pressure sensor and air temperature sensor (article 21150382821003). Informs the ECU about the amount of air consumed in order to adjust the enrichment of the combustible mixture in the combustion chamber.

Installed on the air pipe manifold. Resource – 90-100 thousand km. Cannot be repaired.

Signs of inoperability:

- the engine is unstable at idle speed;

- passive acceleration dynamics.

The owners named two reasons for the “jerking” of the LADA Vesta SW Cross when starting off

The clutch and sensors remain the weak points of the improving Vesta.

Photo: LADA Vesta SW Cross, source Auto The network is replete with complaints from owners of LADA Vesta SW Cross with manual transmission about “jerking” when starting off, which begins at low mileage. Motorists on Drive2 cited two main reasons for the problem.

Poor grip

“The mileage is 30 thousand, you start off like in a PAZ. It's shaking darkly. There is an idea to change the clutch. I bought a Lancer a year earlier, everything is fine, and the mileage is 85 thousand,” complained the owner of a 2022 LADA Vesta SW Cross with a 1.8 liter engine and a 6-speed manual transmission.

There are many complaints on the Internet about the quality of the clutch used by AvtoVAZ when assembling 1.8-liter “manual” versions of cars. “Vestovody” about, “I changed it at 20 thousand”, “We changed it at 18.5 thousand km under warranty for a reinforced version of Valeo. It’s great now,” “I started shaking at 15 thousand, I installed a disk from Sachs, now it’s beautiful.”

In addition, motorists note that the clutch warranty is valid for just 30 thousand km, and therefore there is no point in delaying a visit to the dealer - there is a high chance that they will replace it for free. AvtoVAZ admitted this mistake and now it is much easier to contact dealers. It is also recommended to adapt the “box” every 10 thousand km for prevention, or even pay attention to the LADA Vesta with a CVT.

Knock and absolute pressure sensors

However, the reason for “shaking when cold” in the LADA Vesta SW Cross and 1.8-liter sedans may not only be the clutch:

“Check the knock sensor. Vesta 1.8 MT, shook at 7 thousand km. When starting off, it felt like the engine would jump out from under the hood,” “The clutch was changed at 16 thousand, but after 3 thousand everything happened again. Three times over 3-5 thousand kilometers they made adaptation at OD. After replacing the absolute pressure sensor and the knock sensor, my grandmother whispered. Now it’s 65 thousand, everything is fine,” Fr.

Most likely, the problem lies in the knock and absolute pressure sensor. So far the developers have not recognized the problem at the official level.

Photo: interior of LADA Vesta SW Cross 1.8 MT, source drivenn On the topic:

Toyota Land Cruiser 300 will become cheaper: The Japanese are preparing a version for India

A cheaper Kruzak may also appear in Russia. It’s interesting that owners of 1.6-liter West cars with manual transmission were less affected by the “twitching” problem. The car “shakes” less often, and “treatment” is easier and more effective. Moreover, clutch analogues in this case are of higher quality and the choice is wider.

First of all, owners of LADA Vesta SW Cross, if such problems arise, are recommended to contact the official service, without fear of “tales from the Internet” about the indifference of dealers.

I decided to change the knock sensor as a test because detonation occurred at some speeds, and incomprehensibly, at medium speeds much more often. I heard about two detonation hits. I stopped by the service station, which is near the house, almost 300m away. I took the sensor from the 10, I didn’t know if it would fit or not, but the service store is across the wall, so I think I’ll take it back if anything happens. We removed the sensor, matched the markings, and installed it. At the same time, I decided to ask the mechanic to listen to an incomprehensible rustling sound on the right side of the engine. The stethoscope pointed to a rustling sound in the area of the pulley where the crankshaft is. The master says that this noise may or may not be coming from the timing mechanism. I tell him, let’s open the timing case, let’s see what’s there, they opened it. Everything seems to be normal, but everything is covered in red dust! It's like rust from somewhere. I think eh, it wasn’t a day off tomorrow, the service center is nearby, let’s change the timing belt kit, maybe this rustling will go away. I went to the store, there is no timing kit for Vesta and the sellers don’t know what kind it is. I tell the master how to remove the belt and rollers, go to the store and show it, maybe it will fit from another Lada model. And so it happened, I came from Priora, the issue price was 1800 rubles without fanfare. They replaced everything, the rustling didn’t go away, eh. The assumption is that this sound is made by the oil pump, but we haven’t gotten there yet. I left the service station and haven’t heard detonation even once, but the car seemed to have lost a little traction, but oh well, I’ll go and have a look. The story didn't end there. That same evening, after the service, I went to the Camp store and bought a clutch, because these clicks when shifting from 1st to 2nd gear were annoying, in fact, I call them clicks, but in fact it is the sound of a dangling clutch disc. And when warming up at idle, the knocking of the same disk also occurred. I bought a Triall clutch for RUB 6,000. I arrived at work the next day, opened the box and there wasn’t even a release lever, but they told me in the store it’s hydraulic and you have this clutch, but I forgot to check if it was included in the store. Let's move on. I went to a service station near work. Everything is agreed, the work is 7500, I have the clutch, ok. They started to disassemble it and immediately said that I had a normal release lever, not a hydraulic one. As a result, my clutch did not fit, but came from a grant with a release kit for 3500, everything was assembled. The old clutch was as good as new, but the entire driven disc rattled if it was installed on the shaft and rocked from side to side. In short, the clutch was changed, the car began to shift and start, and there was practically no noise left from the clutch, with the exception of a small, barely audible rattling at idle. And the stabilizer struts were bought a month ago, I thought the small knocks in the suspension would go away after replacement, but they didn’t. ))) but the old ones are of course a little worn out. The total cost for all costs is 17,000 rubles, approximately including washing. Good luck on the roads to everyone. Write comments, I will try to answer.

I've been reading Pikabu for a long time. And I often see very useful advice in the comments, including on car repairs. For example, we recently found a problem with a poorly functioning gearbox (automatic) and as a result the problem was a non-working reverse light. This is my problem that I can’t solve. What we have is a 2018 Lada Vesta car with engine 21129. Mileage is 40,000. Somewhere at mileage 15,000 I noticed detonation at engine speeds of 1800-2300 rpm, as a rule, detonation appears in hot weather, and sometimes at a speed of 120-130 km /h. But as a rule, it appears after a long period of standing in traffic jams. It was done - 1 changed several LUKOIL, BP, Rosneft gas stations. Gasoline only 95 - 95 Ultimate 2- replacement of the knock sensor 3- reflash of the engine 4- replacement of Champion brand spark plugs This did not solve the problem

A car under warranty is not worth contacting many services and they say that as long as there is no error (the check is not lit), there is no point in doing anything. I read somewhere that one of the reasons could be a bad mass - I’ll check it soon. Dear Pikabushniki, please advise what could be the reason. Witty advice - buy yourself a normal car, change the gasket between the steering wheel and the seat, and please don’t offer anything similar. Tried it didn't work

No duplicates found

In fact, if you look at it, it can: 1. Mixture. Its preparation is calculated as the ratio of the amount of air passing during cycle 2. Lambda. It also affects the mixture 3. The balancing of the pulleys is disturbed (which is very unsuitable for your problems) 4. The flywheel causes detonation (again, then it would manifest itself at very different engine speeds) 5. The generator. More precisely, a relay regulator. This is exactly what can greatly influence the engine load and you will feel detonation. 6. Drive shafts

There was once a client with such parsley. As a result, he ended up with spark plugs plus wires. But still less, but supported, although the mileage was about 100.

You can guess anything, check the compression just in case

By the way. And the reason then is the lousy cooling in traffic jams and at speed. Everything fits together. Change the antifreeze.

And winter is coming, and if there is antifreeze from the factory, then it could be any crap like Felix antifreeze, we saw this new on Kalina.

Which doesn't say anything about its heat transfer properties. My neighbor has been drinking for three years now and nothing has frozen, even though he sometimes sleeps in the snow.

Could it be that the cooling fan is triggering too high? I moved from 102 to 98 with the help of BC, although I switched it on the Grant 8 valve.

Check the gap in the spark plugs

Same problem. Vesta 1.8 18 year old everything listed above has been done. The problem hasn't gone away

One nuance - Press further "gas" and detonation disappears.

Diagnostics does not show any errors.

There is no detonation in first gear in any mode.

Not with the air conditioning on either. Apparently the computer is correcting something.

A year has passed and the problem has not been resolved. One more remedy helped a little. Possibly a placebo effect. They are called absorber rings. Look for a video on YouTube

There are no errors other than low voltage on board. But there is no receipt. But low onboard voltage does not affect detonation

maybe DMRV? try driving without it

There is a theory that the DTV sensor is poorly located (but this is not certain). And it is transferred to the resonator. There are ready-made kits:

Everything is normal, detonation is allowed in this speed range.

Error 0562 – low voltage on board network

The error is entered under the following conditions:

The error is entered into the ECU memory on the first drive cycle.

The cause of the error may be poor contact in the ignition system fuse block or a severely discharged battery.

1. Check the tension of the generator belt; if the belt is loose, tighten it.

2. Turn off the ignition, connect the diagnostic tool, turn on the ignition, start the engine. We are trying to reproduce the conditions under which the error occurred. The engine runs at idle. All consumers are disabled. Using the scanner, we determine the voltage of the on-board network. The voltage should be 12 - 14.7V.

3. If this is the case, increase the engine speed to 2000 and monitor the voltage using the scanner. The voltage should be 12 - 14.7V. If the voltage is not in this range, repair the generator. If in range, check the correct connection and integrity of the ignition system wiring harness.

4. If, according to point No. 3, the voltage is not in this range, check the voltage at the battery terminals. The voltage should be 12 - 14.7V.

5. If this is the case, replace the controller..

6. If this is not the case, repair the generator.

the last thing is the battery when charging

If you are sure that there is detonation, then you need a diagnostician to drive around with a (normal) scanner. Look at the UOP first.

Just kill it. Maybe it's not the engine that's degenerating, but the suspension that's knocking, or the airbag?

Remove the logs and look, maybe the intake temperature is high.

if on a hot engine the temperature read by the scanner from the engine control unit is not 80-90 degrees, but, for example, 40-60, then it’s lying.

Can you look at the error codes with a scanner? And see if the gears/belts are on the markings? Although, of course, it may be that the gasoline is stupid and you don’t get it at any gas station, from one oil refinery there.

Lambda probe

Oxygen concentration sensor (part number 226A41771RF). Separates the gas flow in the exhaust manifold and informs the ECU about the gas concentration.

Installed on the outer wall of the exhaust manifold. Resource over 100,000 km. Cannot be repaired. Signs of inoperability:

- error indication on the dashboard.

Detailed description and location of sensors

Installed in the engine compartment, on the left in the direction of travel of the car. Built into a plastic case along with power fuses.

- no data on the display when starting the engine;

- partial display of data;

- sound accompaniment during work.

The service life is unlimited according to the instruction manual. In practice, no more than 5 years, after which it needs to be replaced with a new one.

Coolant temperature sensor (article 2190-1306010). Controls the temperature in the vehicle's cooling system. When a critical point is reached, it signals on the dashboard to notify the driver.

Installed in the thermostat cover housing. Service life – 75-85 thousand km. Cannot be repaired.

- incorrect display of operating temperature;

- display inactive;

- unstable degree display.

Knock sensor (part number 2346015900). Designed to record high-frequency vibrations of the cylinder block that occur during fuel combustion.

Located on the outer wall of the cylinder block. The service life is unlimited. Cannot be repaired.

- difficulty starting the engine;

- Unstable engine operation at idle speed.

Crankshaft position sensor (article 8200701972-B). Online, the ECU sends data on crankshaft speed and tilt angle.

Installed in the tide hole of the oil pump cover. Resource – 80-90 thousand km. Cannot be repaired.

- the engine does not start for a long time.

Mass air flow sensor

Mass air flow sensor (article 8450020039). Installed behind the air filter housing. Reads the amount of air consumed by the engine while driving.

Related link:

License plate illumination on a Lada Vesta car.

Resource over 100,000 km. Cannot be repaired.

Signs of inoperability:

- error indication on the dashboard.

Absolute pressure and air temperature sensor

DBP and DTV are designed to determine the pressure in the intake receiver and its temperature. Directly participates in the formation of the fuel mixture by measuring air parameters and transmitting them to the controller.

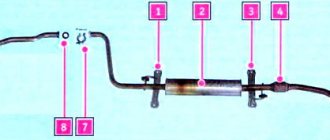

LADA VESTA. AIR PRESSURE AND TEMPERATURE SENSOR (DDTV) OF ENGINE 21129 WITH M86 EURO-5 CONTROLLER

The air pressure and temperature sensor (APTS) is installed on the intake module (Fig. 1.1-02). The DDTV includes an absolute pressure sensor in the intake manifold (MAP) and an intake air temperature sensor (IAT).

Rice. 1.1-02. Location of DDTV in the engine compartment of cars of the LADA VESTA family: 1 - DDTV

The output signal of the DBP connected to the controller is a DC voltage in the range of 0.15. 4.6 V, the value of which depends on the pressure in the intake manifold. Using this signal, the controller calculates the amount of air sucked into the intake manifold per cycle.

DS

Vehicle speed sensor (article 8450006894). Measures the actual speed of movement and transmits data to the electronic engine control unit.

Installed at the top, on the clutch housing cover. Resource over 100,000 km. Cannot be repaired. Signs of inoperability:

- no speedometer readings.

DDM

Oil pressure sensor (article 8200671275). Installed behind the cylinder head. When the minimum level is reached, the contacts close and an error signal is transmitted to the dashboard.

Resource over 100,000 km. Cannot be repaired. Signs of inoperability:

- error alarm on the car dashboard.

How to replace the sensor

Replacing the mechanism yourself is not difficult. It is located between the second and third cylinders; you need to open the hood and provide yourself with unhindered access. It is important that the engine is turned off at this time. As soon as the DD is detected, it is necessary to disconnect the plug going to the sensor wires.

If the mechanism is broadband, then to complete all the work you will need a key set to “13”. In the case of a resonant device, you should arm yourself with a key set to “22”. You just need to unscrew the nuts from the stud with a “13” wrench or the piezoelectric sensor itself with a “22” wrench. It is also necessary to clean the contacts with sandpaper to remove all dirt and oxidation. This procedure should not be neglected, because the quality of the transmitted signal depends on the state of the contacts.

Oxidation and various types of plaque interfere with the transmission of a high-quality signal. As a consequence, this leads to a decrease in the level and accuracy of the impulse, which will leave its mark on the operation of the car. After which it is necessary to install a new mechanism and reassemble in the reverse order.

Review of Manufacturer Prices

| Name | Price in rubles |

| Controller (KSUD) | From 1200 |

| Coolant temperature sensor (DTOZH) | From 450 |

| Knock sensor (DS) | From 450 |

| Crankshaft position sensor (CPS) | From 450 |

| Camshaft position sensor (phase sensor) | From 650 |

| Absolute pressure sensor (ABP) and air temperature sensor (ATS) | From 500 |

| Oxygen sensor (absorber) | From 350 |

| Mass air flow sensor (MAF) | From 350 |

| Vehicle speed sensor (VS) | From 350 |

| Oil pressure sensor | From 350 |

| Clutch and brake sensors | From 350 |

| *prices are as of April 15, 2019 | |

Conclusion

Use the specified list of sensor part numbers when purchasing spare parts or new components. Despite the simplicity of the design, install the equipment in certified workshops, where they provide a quality guarantee for the work performed. If any difficulties arise, please contact the managers of the official representative offices of the car brand for advice.

Problems with brakes in Lada Vesta, Xray and Largus turned out to be more widespread

AvtoVAZ sent a letter to dealers with information that problems with the vacuum brake booster were found on 10,655 Lada Largus, Xray, Vesta cars.

Just today the corresponding news appeared on the Rosstandart website, according to which problems were found in more cars.

According to the agency, a defect in the brake booster check valve can be detected on 12,192 vehicles of the above models, which were sold from September 2019 to the present.

“The reason for the recall of vehicles is to check the functionality of the check valve of the vacuum brake booster,” Rosstandart said in a statement.

Traditionally, a list of VIN codes of potentially defective cars has been published, so you can find out for yourself whether your car is subject to a recall campaign. Also, in the near future, authorized representatives of AvtoVAZ and Lada will inform the owners of Vesta, Xray and Largus about the need to visit the service.

Earlier, Skoda announced a recall campaign in Russia: the Superb model requires flashing of the on-board network control unit.

Reviews

| № | Positive |

| 1. | Dmitrievich (drive2.ru): in three years of operation of the car, I have never changed the sensors. |

| 2. | Semyon (prom.ua): at a mileage of 65,000 km, I replaced the mass air flow sensor, I have already driven 100,000 km, there are no problems. |

| 3. | Sergey (drom.ru): 80,000 km on the speedometer, replaced the temperature sensor, no complaints about the quality of the car. |

| 4. | Konstantin (rozetka.ua): I recently replaced the DDT, bought the original one, the price was 350 rubles. I installed an additional alarm and shock sensor. |

| 5. | Vladimir (Auto.ru): I’m happy with the car, there are no special comments, the equipment is working normally. |

| 6. | Nikolay (Auto.Mail.ru): in two and a half years of using the equipment, I replaced the oil pressure sensor once. The car is under warranty, the dealer service is free. |

| 7. | Kirill (drive2.ru): The ABS sensor failed at 90,000 km, replaced it with a new one. I bought it at the company store. |

| 8. | Sergey (drive2.ru): I can’t say anything special about the sensors, they work in normal mode. |

| Negative | |

| 9. | Vladimirovich (prom.ua): I additionally installed a parking sensor, I missed it so much in the “Standard” configuration. Also replaced the idle speed sensor. |

| 10. | Alexander (Bibika.ru): the temperature sensor often fails; I don’t know what causes this. |

| 11. | Valentin (drive2.ru): the speedometer does not display information correctly on the dashboard, the dealer recommended replacing it under warranty. |

| 12. | Semyon (Avtodispatcher.ru): I installed the tire pressure sensor myself; it is not supplied as standard. |

Related link:

Features of headlight adjustment on Lada Vesta

Why does the new Lada Vesta accelerate poorly?

Owners of the new Lada Vesta may be unpleasantly surprised by its inexpressive dynamics - the car is frankly “stupid” during acceleration, even with a manual transmission. What is the reason for this, does it need to be treated? I'll tell you based on my own experience.

This article will focus on the Lada Vesta in the “Comfort” configuration, manual transmission, 1.6 liter engine.

The reasons for the sluggish acceleration of the new Vesta “from the bottom” are as follows:

1. On a new car, the engine has not yet “rolled out”. It gains full strength somewhere around 10-15 thousand kilometers. There's nothing you can do about it, you just need to be patient and not overload it unnecessarily, at least for the first 2000 kilometers - they are designated by the factory as a break-in period. During this period, I tried not to spin the engine above 3000 rpm.

2. After the first 2000 kilometers were covered, I began to periodically give higher revolutions and found out that at 3500-5000 rpm the thrust is quite normal. As practice has shown, the “top” engine is more convenient than the “low” one - in the city there is enough dynamics to keep in the flow (but no more), but if you need to overtake someone on the highway, we switch to a lower gear and get really brisk acceleration. With a low-end engine, overtaking is more difficult.

3. The West gearbox has more “stretched” gears than many foreign cars of comparable class. That is why the dynamics of the car are not so impressive. But there is also a positive point - the car is more economical than the same Logan or Almera.

4. Vesta’s weight is also greater than that of its competitors - the sedan weighs 1230 kg. Logan weighs 1106 kg, Almera - 1170 kg, Kia Rio - 1160 kg. That is, the difference approximately corresponds to the weight of the additional passenger. Naturally, this affects the acceleration dynamics.

5. Standard ECU firmware for Euro5 “strangles” the engine at low speeds. So that there is no desire to inject more fuel into the engine than it can burn and not pollute the environment with “low-quality” exhaust gases. Looks like they overdid it. However, this feature is characteristic of all modern cars without exception.

Another noticed feature (not only of Vesta!) is that in hot weather the car’s dynamics are worse than in cool weather. It's not even a matter of the air conditioner being on. The reason is that hot air is more rarefied than cold air. Accordingly, the oxygen content per unit volume is less. Oxygen is an oxidizing agent that causes the mixture to burn in the cylinders. To maintain dynamic performance in hot weather, the engine requires more air, but the throughput of the intake tract is limited, which can cause “oxygen starvation.” In response to this, the ECU reduces the amount of fuel injected. When driving slowly at low speeds, this effect is practically unnoticeable, but if you try to accelerate sharply, the reduction in traction will be very noticeable. Personally, I got my fill of this in July on the roads of the Krasnodar Territory in 33-degree heat, overtaking trucks.

Let's sum it up

When buying a Vesta, you should be aware that this is not a racing car or a city “lighter”. This is a car for calm travel from point A to point B.

The 1.6 engine in the new Vesta may indeed seem “dull”, but as it runs in it gains strength. The main thing is to maintain a sense of proportion and not overload the first few thousand kilometers with long driving at too low and too high speeds.