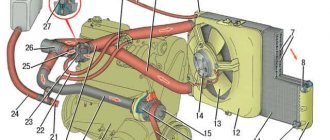

The car engine 21126 is a four-stroke four-cylinder engine installed on a VAZ 2170 car. Fuel injection is distributed, the camshaft is located at the top. The VAZ 21126 engine is equipped with a liquid cooling system, closed type, coolant circulation is forced. The lubrication system is combined (spraying and under pressure).

To change gears, the Lada Priora is equipped with a five-speed gearbox.

The 126 engine has the following technical characteristics:

- Cylinders with a volume of 1.6 liters.

- The compression ratio is 11.

- Rated power is 98 horsepower.

- Priora engine 16 valves.

- Fuel is supplied by electronically controlled distributed injection.

- The sixteen valve engine weighs 115 kg.

Factors affecting the service life of the VAZ 2170

According to the manufacturer, the ICE 21126 with sixteen valves has a stable operation duration of 200 thousand kilometers. After a certain mileage it is necessary to carry out major repairs. Taking good care of the VAZ 2170, proper maintenance (MOT) and timely replacement of damaged components and parts will lead to a long service life of the vehicle.

Reasons affecting the service life of the power unit:

- Engine overheating. Elevated temperatures of a running engine negatively affect the overall service life of the motor. Maintaining the operating temperature of the power unit elements at a constant level significantly extends its operating time.

- Fuel. The vehicle's owner's manual contains detailed information about the recommended brand of gasoline. Filling the 16-valve Priora engine with fuel must be of proven quality.

- Machine oils. Which oil is best to fill, its brand and how much lubricant is needed is indicated in the accompanying documentation for the car. The 126 sixteen valve engine accepts semi-synthetic and synthetic motor oils most well. A complete oil change should be carried out annually or after a mileage of 15 thousand kilometers.

The optimal operating engine temperature is 90 - 95 °C. The rules allow the power unit to operate at temperatures reaching up to one hundred degrees, provided that the radiator fan is running. The engine temperature is considered low if it is below +90°C. In cold weather, it takes more time to warm up the engine to the desired mark on the device.

When servicing your VAZ 2107 car, the car owner can change the oil with his own hands. To do this, you need to know how to drain used lubricating fluid, what kind of oil to pour into the Priora and how much engine oil to pour into the neck.

Ways to solve the problem

Since the collision of pistons with valves has quite serious negative consequences, many car enthusiasts are interested in whether it is possible to influence this situation.

There are several methods that allow you to convert a valve-bending motor into a “plug-inless” one.

The simplest of them is installing pistons with grooves. By the way, on some VAZ engines this is how the problem with “sticking” is solved.

On the bottom of such pistons there are special recesses for valve plates. Due to this, the latter in the open position do not come into contact with the pistons installed at TDC.

But not all engines can be modernized in this way, for the reason that it is not always possible to find pistons with factory-made grooves to replace the “original” ones.

The second method is to independently make grooves on the piston. This method is suitable for those who have not found replacement “non-stick” pistons. But this method has a significant drawback - it is very difficult to make identical recesses on all pistons. As a result, an imbalance in the weight of the pistons may occur, which will affect the service life of the crankshaft. Also, grooves of different sizes can cause different compression in the cylinders, and this problem cannot be eliminated.

The third method is to increase the height of the combustion chamber. This is done by installing 2-3 gaskets under the head of the block. This method has a negative side - an increase in the volume of the combustion chamber, which entails a drop in compression, and as a result - a decrease in power and an increase in fuel consumption.

Source

Are the valves bending?

In Lada Priora cars, even in a 16-valve 126 power unit, valves can often bend. The reasons causing this defect lie in non-compliance with operating rules, in case of violation of the regulations for replacing the following components and parts:

- rollers;

- timing belt;

- water pump.

If one of the listed components breaks down, the pistons, exerting mechanical stress on the valves, can bend them. The design features of the engine are the reasons why the engine can bend valves. Deformation of the valves necessitates a major overhaul of the Priora engine.

To avoid this defect, the car owner needs to timely check the timing elements. Of particular importance is the belt, which is subject to thorough inspection after 50 thousand kilometers. When checking, the following faults are excluded:

The rollers and timing pump 126 must also be inspected, because The motor bends the valves even when they malfunction.

Signs of wear on the belt and other timing components are vibrations and an unpleasant grinding noise in the engine compartment. In this case, it is necessary to urgently repair or replace the broken elements to avoid deformation of the engine valves.

Priora engine tuning

To improve the power performance of the Priora power unit, they resort to the following modifications:

- The receiver is installed.

- Exhaust pattern: 4-2-1.

- Throttle valve: 54 -56 mm.

- Sports camshaft.

- Modification of the cylinder head (cylinder head) by sawing.

- Lightweight valves.

- 440cc type injectors.

In addition to the considered method of transforming the power unit to increase dynamic performance, there are several more ways to tune a car of this model.

The first VAZ 2110 cars were produced with an 8-valve engine with a volume of 1.5 liters, and later with a 1.6 liter engine. On such units, when the timing belt breaks, the valves do not bend. This is explained by their absence in the piston. In the tenth generation, VAZ 2112 cars appeared with a 16-valve engine and a volume of 1.5 liters. With the release of this model, many car owners began to encounter problems with valve bending on the Priora. The design of the new motor has changed. Due to the 16-valve head, the power of this unit increased from 76 hp. up to 92 hp However, the big problem with such a motor is 21126 valve bending on the Priora. As a result, the car needs major repairs.

The reason why the valves in the Lada Priora were bent is the absence of special piston grooves in the 1.5 engine with 16 valves. Because of this, when the belt breaks, the pistons hit the valves, which bend them. Somewhat later, 16-valve 1.6-liter engines began to be installed on Priora. The design of these engines is practically no different from the previous ones with a volume of 1.5 liters. The main difference is that the new engine has recessed pistons. If the timing belt breaks, the pistons do not meet the valves, and the engine does not bend the valves on the Priora.

The modern engine from AvtoVAZ is presented in the form of a 16-valve unit, which differs from previous analogues in its reliability and safety; bent valves are not typical for it. However, the erroneous opinion of most car enthusiasts is due to the fact that on the updated Priora the engine bends the valves in rare cases. This is explained by the fact that this car is equipped with a 16-valve 1.6-liter engine. Practice has shown that when the timing belt breaks on a Lada, the pistons bend the valve when they meet. Repairing an engine of this type is more expensive than its “12” counterparts. The likelihood of a belt breaking on a Priora is low, since it is almost twice as wide as on “12” engines. When using a defective belt, the question “does the valve bend on a Priora?” will continue to arise.

Valves for motor

Comparing Priora and Kalina engines, auto mechanics claim that owners of a second car face a similar problem. Therefore, it is recommended to regularly monitor the condition of the timing belt. Some car enthusiasts are concerned about whether the valves bend if there is a large layer of carbon on the pistons. Similar breakdowns occur in such motors. Therefore, owners of any type of vehicle should regularly monitor the condition of the timing belt, checking it for cracks, chips, threads and peeling. These signs indicate that the timing belt needs to be changed immediately. Otherwise, the question “does the engine bend the valves on a Priora?” will not be resolved.

Belt care

To avoid any reasons that could lead to a broken timing belt in the Priora, the designers advise taking care of this unit, because you can only avoid a belt break and all further troubles if you constantly care for and monitor your car. The most important thing you need to know is the mileage of the Priora.

The manufacturer guarantees that the timing belt service life is approximately 200 thousand km, and only after reaching this mileage does it need to be changed. But experience shows that trouble can occur much earlier, and this can be explained by the fact that each individual engine can be equipped with belts from a different manufacturer. In one case there may be a belt made in China, and in another, for example, a Polish one.

For this reason, you need to listen to the sound of the engine literally when you reach a mileage of 100 thousand kilometers. If you suddenly hear extraneous sounds: a suspicious “rustling” sound, you must immediately contact the service for diagnostics. If service workers offer to replace the timing belt, then you should not be greedy, since a malfunction can lead to extremely undesirable consequences.

I would like to note the fact that timing belt breaks on a 16-valve Priora occur more often than on an eight-valve engine. This is explained by the fact that in the head of a 16-valve engine, the valves extend a little further than in an 8-valve engine, and at the same time the risk of the piston meeting the valve increases. Of course, you can replace the 16-valve head with an 8-valve one and forget about the trouble, but then the car owner will lose about 20 “horses”.

Whatever the reason for such a nuisance as a broken timing belt in a Priora, the car owner should always know that basic equipment care, timely replacement of gas distribution mechanism consumables and common sense will always ensure that your car will always remain functional in any situation. After all, the pleasure of driving well-functioning equipment is an invaluable payment for taking care of your car.

Main reasons

Car owners of Lada Priora 21126 are interested in knowing the reasons why the valves on their car bend. Auto mechanics claim that on all modern models of this car, as a result of a broken timing belt, the valve motor bends. The first engines for front-wheel drive VAZ 2110, unlike similar units for rear-wheel drive, had a volume of 1.5 liters. Somewhat later, similar designs with a volume of 1.6 liters appeared. with 8 valves and one camshaft. Some car enthusiasts do not know whether the valves on such engines bend. This process does not occur due to the first elements not meeting the pistons at the dead center. After evolution, new 16-valve units with two camshafts appeared. This made it possible to increase power from 76 hp. up to 92 hp, while the engine size has not changed.

Experts say that such units are also unreliable, since when the timing belt breaks, valves and pistons meet even at a dead center, and as a result, the engine bends the second elements on the Priora. Such repairs are expensive. In addition to replacing the valve, sometimes the pistons also have to be replaced.

AvtoVAZ designers, having modified the 16-valve engine, installed it for the first time on the new VAZ 2112. The engine received the abbreviation 124. The distinctive features of the new unit from previous analogues are the presence of an updated piston group. They received “grooves” or so-called “notches”, with the help of which reliable protection is created against timing belt breakage. The VAZ 2112 with this engine is considered a reliable and powerful vehicle.

Features of recessed pistons

The 10th family of cars was discontinued due to the presence of many technical flaws. The updated family has gone through major changes that affected environmental issues and increased engine power. It should be noted that all 16-valve engines are currently installed not only on Priora, but also on other VAZ models, including Kalina and Granta. However, the engine bends the valves on every such car.

The exception to the fact that if the timing belt breaks, these parts will not meet the pistons are the first eight-valve engines. Modern production of domestic cars does not provide for the use of these units. New eight-valve counterparts with increased power also bend the valves.

Since 2011, Priora had 8 valve engines marked 21114, which did not bend the valves. In recent years, the valves on all produced Lada Priora have been bent, since they have engines with 8 valves marked 21116.

https://www.youtube.com/watch?v=J6t92yeqsZY

Cautions and Consequences

Valve bending on a Priora is mainly due to the piston meeting the first parts. If the timing belt breaks, the car owner cannot avoid expensive repairs. In such a situation, auto mechanics recommend:

- regularly check the condition of the belt,

- determine the presence of chips and cracks on the belt,

- check if there are any threads on the belt.

Many experts recommend installing a 124 piston group on the Lada Priora. But before this you need to think carefully, since installation will require dismantling the old piston group.

| № | Dismantling |

| 1 | Remove the engine from the car |

| 2 | Take it apart |

| 3 | Drain and replace oil |

| 4 | Remove the crankshaft |

| 5 | Remove pistons |

| 6 | Remove connecting rods |

In this case, you will also need to buy a new, lighter piston group. From an official dealer it will cost no more than 2-5 dollars. Some auto mechanics recommend buying a car of another brand, the price of which is practically no different from the cost of the Priora. It could be a KIA RIO or a Chevrolet Aveo. This problem can be solved using an optimized cooling system for the block and cylinder head.

Frequent timing belt breakage is associated with the use of low-quality automotive parts, including the idler pulley. To prevent such a breakdown, Priora car owners install the lower gear on the crankshaft, belt and rollers from the VAZ-2112 on their cars. In this case, the pump and gears on the camshaft do not change. Washers 5 mm thick are placed under the rollers. The presence of a large number of manufacturers of these parts allows you to choose high-quality and reliable products for cars.

To avoid bending the valves on the Lada, it is recommended to change the timing belt and rollers every 25-30 thousand km. If there are short connecting rods and other pistons, repairing the Priora will cost a large amount.

Replacement timing

The Priora timing mechanism is a complex structure, which has two camshafts, 16 valves, tension and idler rollers. And the toothed belt also rotates the coolant pump blades. Recommendations from the Lada Priora manufacturer indicate that the timing belt needs to be changed after a mileage of 200 thousand km. It is difficult to say whether there are cars with such mileage without rotation of rubber products in the timing drive.

The duration of such rotation depends on many factors:

- Quality of material and workmanship of the part.

- Operating conditions of the machine.

- Technical condition of the engine.

- Grease or other technical fluid gets into the belt rotation zone.

Taking these factors into account, experts recommend stopping at a mileage of approximately 50–60 thousand km, in some cases even less. If we talk about such a reduction in the recommended period of operation of rubber goods on Priora, then the following circumstances can be noted. The movement of a car in urban conditions is accompanied by frequent stops and then starting. The belt teeth experience jerking, which weakens them. The smooth operation of the engine on the highway has a minimum of such jerks, so the drive will work longer.

The ingress of engine lubricant, coolant or other foreign particles will also greatly reduce service life. If you notice a lubricant leak in the area of the camshaft or crankshaft seals, the leak is immediately repaired. It is imperative to change rubber goods when purchasing a used car, since the mileage on this car is unknown. And the condition of the pulleys on the crankshaft and camshafts also reduces the service life of timing drive rubber parts.

If their teeth are worn, they will speed up belt failure. How long after to change the timing belt on a Priora is up to the owner, he knows the operating conditions of the car. Experts recommend focusing on 50–60 thousand kilometers. If the car has not been driven for a long time, it is also better to replace the belt. With “age,” the material ages, begins to crack, and can quickly fail.

Some innovations

Upgraded 16-valve engine

The recently released sedans and hatchbacks of the Priora family are equipped as standard with a modernized engine - a 90-horsepower engine with 8 valves and lightweight connecting rod and piston groups. This power unit was developed at the AvtoVAZ scientific and technical center. To master it, the manufacturer needed to modernize the production lines of main parts and engine assembly. Metallurgical production has undergone modernization of the cylinder block casting line.

To reduce the overall weight by 39% compared to the main version, it was necessary to optimize the cooling system of the cylinder head and block. The engine received a new camshaft drive, including an automatic tensioner, piston cooling nozzles, and a metal cylinder head gasket. Reducing mechanical losses made it possible to increase the motor power from 59.5 kW to 64 kW, that is, up to 90 hp. At the same time, the maximum torque increased from 120 Nm to 140 Nm. This resulted in reduced vibration and noise levels. Specific fuel consumption also decreased, which led to an increase in engine life to 200 thousand km. The environmental friendliness of the engine has also increased. Carbon dioxide emissions have been reduced from 175 g/km to 165 g/km.

AvtoVAZ produced more than 700 cars with new engines. The recommended retail price for the Lada Priora in the “Standard” sedan configuration is 8 thousand. e., and the hatchback - 8,500 thousand. e. The domestic manufacturer plans to soon use new engines on Lada Granta and Lada Kalina.

The engine is the basis of any car - without it there is no movement and Drive! The engine on the Priora comes in 2 modifications: 21126 and 21127, the second is essentially a modified 126 engine, which has been installed on Lada Priora since 2013. after restyling the Lada Priora car model.

126 engines (16 valves) are high-torque after 1000 rpm, and up to 4000 - this is the maximum torque, after 4 thousand the torque decays. The 127 engine, due to the distributed air intake, pulls well from below, damping out at about the same rate as its brother. If the running-in was carried out properly, then the engine life will be close to 200 thousand km. Overhaul of the engine of a Priora car, like the entire AvtoVAZ range, is subject to the garage - there is nothing supernatural about it. The price of spare parts is more expensive than tenths, but cheaper than foreign ones. Engine power of 98 and 106 hp allows you to feel confident on the road - well, certainly not a vegetable. I consider the main 2 disadvantages of the engine to be the unit: pump roller, timing belt. If one of these spare parts fails, the valve bends. 2 minus - camshaft plugs: when these rubber bands dry out at low temperatures, they are squeezed out along with the oil. If you don’t see this in time, there will be trouble! The fact that hydraulic compensators knock when cold is considered the norm - you can close your eyes to this, there will be no harm.

In the vast majority of cases, Lada Priora cars are equipped with a 16-valve engine (the 8-valve engine was “inherited” from the “ten” and was not warmly received by car enthusiasts).

The first 16 valve engine received number 126, the second – 127. The characteristics of the Priora engine No. 126 turned out to be so good and optimal that the car with this engine was sold most often. Repair of the Priora engine with 16 valves is not carried out so often, but you will have to look into it at least once every six months - in order to make sure with your own eyes that everything is in order with it. In addition, you need to keep an eye on the timing belt - if you miss this unit, you can get into big money. Read the article to the end, and we will tell you about these 2 units.

The cause of a broken timing belt and failure of the intake and exhaust valves may be:

- Incorrect installation of the tension and support rollers (or their poor quality, defective, fake...).

- Poor quality timing belt.

- Scores and defects on the camshaft drive pulleys, water pump , crankshaft and support washer.

- The hydraulic pusher is jammed (if the oil quality is poor or its level is insufficient).

- Poor quality of plumbing and repair work.

- Engine overheating.

- A surrogate fuel that leads to carbon deposits on the exhaust valves.

Signs of the need for internal combustion engine repair

The reasons why the operation of the engine is disrupted are arranged in a small list, starting with refusal to start and ending with floating idle speed (this problem was removed on the 127 “engine”). Not all breakdowns end in capital damage - sometimes it’s enough to add oil, sometimes it’s enough to adjust the ECU settings.

Compression reduction

A decrease in cylinder compression below 16 atmospheres is a bad sign. Such a high limit corresponds to a compression ratio of 11.

If the compression decreases (or vice versa increases), then the “engine” will have to be rebuilt.

Knocks in the engine

Engine knocks can come from several points. These could be hydraulic compressors, timing belt rollers or pins. The knocking noise could also be caused by low oil level. The answer to the question will be given by a thorough detailed inspection of all parts of the unit and checking the oil level.

Blue smoke from the exhaust pipe

The blue smoke that comes from the exhaust pipe appears when oil enters the combustion chamber. It can leak either from the valves or from under the piston. The result is the same: the oil is eaten up and blue smoke pours out of the chimney. Once the leak is located, half the problem will already be solved.

Troit motor

Sometimes in the cold the engine may stall - don’t be alarmed by this, because it may simply be one of the spark plugs that fails. In this case, we advise you to simply restart the engine and it will stop running.

How much does it cost to overhaul a Priora engine - average price

Self-repair of a Priora engine with 16 valves costs an average of 16-20 thousand rubles. The cost depends on the severity of the breakdown and may be lower or higher than this average range. Repairing a Priora engine can be entrusted to the wrong hands, but then you will have to pay for the work - sometimes the cost of repairs reaches as much as 40 thousand rubles.

This is an unreasonably inflated figure, because, as practice shows, you can rebuild the engine on a Priora, working at a moderate pace, in just three days - and three days of work is definitely not worth that kind of money. Don’t be afraid of not being able to cope - your Lada is easy to repair, and using the advice and “tutorials”, you will conquer even such a task that is impossible at first glance.

Let's move on to the cylinder block

We remove the pallet. Rotating the crankshaft as it is convenient for us, unscrew two bolts on each connecting rod cap. We use a TORX E10 head for this.

We take out the pistons along with the connecting rods. To do this, use the wooden handle of a hammer to press the connecting rod from below and lightly tap it to knock it up. We remove the old liners and buy new ones of the same size according to the markings on them. Here is another stone in AvtoVAZ’s garden, the owner has never climbed into the car from the interior or into the engine, but three pistons were of group “B” and one was “C”. It turns out that at the factory they re-sharpened one cylinder a little and simply put an enlarged piston there, no words. There are no options, we take group “C”, don’t sharpen the engine because of this. We will not touch the main liners either.

We buy a new piston group that does not bend the valves, connecting rods and connecting rod bearings.

Eliminating longitudinal play of the crankshaft

It was noticed on this motor. To eliminate it, replace the thrust half-rings. Standard and repair sizes are available. We take the first repair size, if they are too tight we sand them down a little. We unscrew the middle main bearing and gently push it with a screwdriver and move the half rings. The mark on it is in the form of three serifs, shown below.

When the half ring comes out a little, turn the crankshaft, it will push it out. There are two types of half rings: white at the front and yellow at the rear; the grooves on them should point towards the crankshaft cheeks.

We install them as we removed the new half rings; if they go in with great effort, you can grind them a little on a small abrasive stone, but not from the side of the grooves. Checking the play. We tighten the main bearing with a torque of 8 kgf*m.

Assembling the piston

There is an arrow stamped on the top of the piston; it should be directed towards the front of the engine. And there are marks on the connecting rod that should look the same way. Don't get confused!

We insert one retaining ring into the groove on the piston. We insert the connecting rod into the piston and, having lubricated the connecting rod and the piston pin with oil, insert it into place. Insert the second retaining ring. Although this operation seems simple, it will take some pains. We inspect the assembled structure; all retaining rings must be clearly in their grooves, otherwise a ring that has jumped out while the engine is running can cause a lot of trouble.

After assembly, you need to break off the connecting rod bearing cap, since the connecting rod is made in one piece. It's like that on our cars. First, unscrew the bolts. We insert the connecting rod into the cleats at the level of the mark shown in the figure with the black arrow and lightly clamp it, then break it off with a slight movement of the hand. The first time is very scary. We put the cover in place and tighten the bolts so as not to mix it up in the future.

Checking the thermal gap in the piston rings

We lay out each set of rings for each cylinder. In the future we will not change their places. In turn, we insert each ring into its own cylinder and push it a little with the piston approximately to the middle.

We measure the gap with feeler gauges.

Nominal clearance: 0.25 - 0.45 mm.

The maximum clearance for all is 1 mm. But this already smacks of waste.

Installing new rings

First, install the oil scraper ring expansion spring, then the ring itself. The oil scraper ring lock should face the opposite direction of the spring lock. Then we install the lower compression ring and finally the upper compression ring. The inscription “TOP” must be stamped on the rings; it must face up. The rings in the piston grooves must rotate easily.