In general, my mass air flow sensor began to die, the voltage at the ignition is 1.035V - and this is a dying state, and this in general is a reading of as much as 1.2 liters of air! ideally it should be 0.996v. As everyone understands, a mass air flow sensor is nothing more than a normal resistance that changes depending on the heating, the incoming air flow blows on the sensor, thereby reducing the resistance and increasing the voltage on the sensor, the more air -> the colder the sensor -> the less resistance -> the more voltage = and by voltage we determine how much air the engine has consumed, we spray fuel there in a ratio of 1: 14.7. Over time, the sensor, I call it “burning out”, loses resistance, then our ingenuity comes to us, what can we do? 1. put a tuning resistor on the 4th and 5th wires and compensate for the lost resistance. (never tested, but in theory it should work) 2. Force your brains to think about a higher voltage and a smaller amount of air. (everyone remembers what the wise men told us - we need to install the mass air flow sensor the same as before (I’ll explain below)). At first I wanted to go along the first path, but I didn’t want to mess with the wires, so we go along the second. We will adjust the voltage values to the amount of air. We take the wonderful program “Max air flow sensor corrector v.1.0”, open our firmware for it and look at the voltage values = amount of air

Now remember those sages, and all because different mass air flow sensors have different meanings for the incoming air, we will return to the sages later, but for now to our sheep.

Now let's turn to typical parameters, for example I have January 7.2

Please note that at idle speed XX 800 the engine should breathe only 8 kg of oxygen, which, coupled with my sensor, showed 11 or even 12 kg, naturally it also gave 13 kg of gasoline, and there was only 8 kg of air => here you go and a rich mixture, excessive fuel consumption and engine shaking.

This means that in the DMRV program I open the firmware and look in the third column for the value that our engine consumes at idle, let’s take the figure 11.7 kg/h and adjust the 4th column so that according to the parameters it would be 8.3 kg/h

After saving the firmware, upload it to your brain))))

Now at idle I have 8 kg of air at 3000 XX - 26 kg/h of air (remember the standard parameters), the engine has stopped shaking. Consumption has decreased slightly.

Ps back to the sages, if you find the same mass air flow sensor as you had, just open the firmware, select your new mass air flow sensor, save, upload.

Z.Y. There is a Bosch sensor, it showed well over 1.035. It was never washed (they just changed it to a new one) This sensor lay for several months near the grain crusher, when the crusher is working, vibration is felt near it, after several months of “massage” it began to show normal readings! Now we need to repeat this experiment) now the reading is 1.01. Can anyone repeat it? With “vibration cleaning” of the mass air flow sensor.

The mass air flow sensor is one of the most expensive measuring instruments in the VAZ 2114. The main reason for its failure is contamination of the sensitive contacts. With the right skill, they can be cleaned, thereby bringing the sensor back to life and depriving yourself of the need to spend 2.5-3 thousand rubles on purchasing a new device.

From this article you will learn how to clean the mass air flow sensor, what products are best to use for this and what tools are needed to clean the mass air flow sensor of a VAZ 2114.

A sensor that requires mandatory systematic cleaning

WHEN SHOULD YOU CLEAN THE SENSOR?

How quickly the mass air flow sensor becomes clogged directly depends on the degree of contamination of the air filter on which it is located. If the filter is not clogged, then it effectively cleans the air of all dust particles and the air flow sensor does not come into contact with small mechanical impurities, however, if the air filter is worn out or simply of poor quality, the sensor will become dirty very quickly.

Cleaning the air flow sensor is performed in the following cases:

- The fourteenth is very blunt during acceleration, any twitching, jerking or dips in speed indicate that something is wrong with the sensor;

- The engine idles intermittently or, conversely, the engine speed rises excessively at idle;

- Fuel consumption has increased (VAZ-2114 owners often write that if the sensor is dirty, gasoline consumption can increase from 9-10 to 15 liters);

- The engine refuses to start.

Flushing the mass air flow sensor on a VAZ 2114 solves any of these problems, unless, of course, the sensor is the only cause.

Flushing the air flow sensor on a VAZ 2114

CHECKING THE FUNCTIONAL STATE OF THE DMRV

To determine that this particular unit is faulty and the mass air flow sensor needs to be washed and repaired, you need to check the mass air flow sensor with a multimeter.

A multimeter, also known as a tester, is an electronic device that can be purchased at any auto store at a price of 400-600 rubles for the simplest models (their functionality will be quite enough for us). It is not inexpensive and will be useful in the garage many times - you can use it to check any sensors and electronic systems of the car.

The serviceability of the mass flow sensor is checked as follows:

- We switch the tester to voltmeter mode and set the upper limit of sensitivity to 2 Volts;

- We connect the multimeter probes to the yellow and green wires (they are located in the sensor connection socket);

- We activate the ignition (there is no need to start the engine) and look at the tester reading.

If the tester testifies that the voltage between the yellow and green contacts fluctuates in the range from 0.0099 to 0.02, then everything is fine with the unit.

If the device is dying due to wear or contamination of sensitive parts, the tester will show a maximum voltage of 0.03 V, in which case it is necessary to clean the mass air flow sensor on the VAZ 2114.

In the case when the multimeter readings are much higher than the upper voltage limit, in the range of 0.045-0.5 V, or significantly less than the minimum - 0.09-0.095 V, the probability that flushing the mass flow sensor will give a result is approximately 50%.

Checking the mass flow sensor with a multimeter is not a dogma, there are other methods

There is another simple method to check the functionality of this unit, which can be used if you do not have a multimeter. Just remove the mass air flow sensor and close the air duct valve, start the fourteenth and run it at 2 thousand rpm. If you feel that in the absence of a sensor the car behaves much better on the road, this is the problem.

Symptoms of malfunction

There are several signs by which you can determine a malfunction of the mass air flow sensor:

- The check engine light comes on on the instrument panel;

- Fuel consumption increases noticeably;

- The car loses dynamics and power, failures occur when trying to increase engine speed;

- Difficulties arise when starting on a hot engine.

But what exactly causes these symptoms? The causes of sensor malfunction are as follows.

- The connector has lost contact.

- The air filter, grilles or sensor temperature detectors are dirty.

- Mechanical damage to sensor elements has occurred.

When the first signs of a malfunction occur, you should definitely check the mass air flow sensor, and then, depending on the situation, clean or replace the device.

Examination

Now let's talk about how to check our sensor. Today, two main methods of checking the mass air flow sensor are used.

- The engine is tested in operation with the mass air flow sensor disconnected. Simply turn off the power from the regulator and start the motor. When the mass air flow sensor is not present during startup, the electronic control unit turns on the power unit in emergency mode. The speed is adjusted to 1500 rpm. After disconnecting the sensor, drive a few kilometers and evaluate the dynamics and power. If the engine is running normally, then the sensor is the cause of the symptoms.

- The second method will require the use of a car tester or voltmeter. After starting the ignition, do not start the engine. The voltage threshold is set on the tester to 2V. The positive probe connects to the yellow wire on the sensor connector, and the black probe connects to the green wire. Next, refer to the table.

Index

Air flow sensor condition

The sensor is functioning normally

Not ideal, but still acceptable voltage readings

Maximum permissible values that indicate imminent sensor failure

The air flow sensor has failed and needs to be replaced

WHAT IS IT BETTER TO WASH THE MAF?

The reason why the mass air flow sensor fails is contamination of its sensitive element, which is a wire or a platinum resistor (depending on the type of device).

Platinum sensing elements can be easily damaged if not properly cleaned. If this happens, the device can simply be thrown into a landfill, since it will be impossible to recover them.

When choosing how to clean the air flow sensor, never use the following liquids:

- Products containing acetone;

- Ketone-containing products and any other artificial solvents;

- Liquids containing sulfur ethers.

Also, do not try to clean the mass air flow sensor on the VAZ 2114 using cotton ear buds or a toothbrush - any mechanical contact with the sensitive element of the device is unacceptable.

In essence, you have to choose a liquid for flushing the mass air flow sensor from three options:

- Regular medical alcohol without any impurities;

- Carburetor cleaner without acetone;

- WD-40.

WD-40

Ideally, it is best to use WD-40 and medical alcohol at the same time (diluted with distilled water in a ratio of 5 to 1): first, WD-40 is applied to the sensitive contacts, after which it is washed off with alcohol.

Detailed repair instructions

In practice, with the help of cleaning, the functionality of most sensors can be restored. At the same time, the car owner saves money. If, when checking the mass air flow sensor, it turns out that the voltage readings do not correspond to the norm, then you need to dismantle the device and wash it.

An aerosol carburetor cleaner that does not contain acetone, pure medical alcohol, a penetrating lubricant such as WD-40, and distilled water are suitable for this purpose.

It should be remembered that you cannot use a toothbrush or cotton swabs for cleaning, since mechanical contact with the sensitive elements of the sensor can cause serious harm. Alcohol must be diluted with water in a ratio of 5 to 1. In addition to the listed means, in some cases you may need a 10-20 cc syringe with a needle.

Removal and cleaning of the mass air flow sensor must be carried out in the following order:

- First, disconnect the block with the power wires. To do this, you need to press the release button, which is located at the bottom of the device. Unscrew the screws securing the unit to the air filter housing.

- Unscrew the connecting elements of the protective casing, screws, and remove the sensor itself.

- The most sensitive parts of the device are the temperature sensor wire and contacts. They need to be washed with extreme caution.

When using aerosol cans (carburetor cleaner, WD-40), it is necessary to control the jet pressure. It is unacceptable to use too much pressure, so you need to hold the canister tube at a distance of 5-10 centimeters. You can also rinse these elements with a syringe. For this, an aqueous solution of alcohol is used.

Thus, if the air flow sensor partially loses its functionality, you should not rush to purchase a new device. It is advisable to spend 15-20 minutes dismantling and cleaning the old device. This will restore its functions and help save money.

Source

CLEAN THE SENSOR STEP BY STAGE

Having decided how to wash the mass air flow sensor, you can proceed directly to the procedure itself.

In addition to the cleaning liquid, you will need a regular syringe with a 10-20 cc needle, a screwdriver and a 10 cc wrench to remove the sensor.

- We dismantle the device: remove the block connected to the sensor with power wires (on its lower part there is a locking button that must be pressed, after which the block can simply be pulled out) and using a 10mm wrench, unscrew the two screws that secure the sensor to the air filter housing;

- In the place where the block with wires is connected to the sensor, there are two screws connecting the parts of its protective casing; they must be unscrewed with a Phillips screwdriver, after which you can disassemble the casing and pull out the mass air flow sensor itself;

- We wash all sensitive elements of the sensor (temperature sensor wire, contacts) with cleaning liquid. If it is VD-40 or a carburetor cleaner, which are supplied from a can, carefully monitor the jet pressure on the elements of the device; it should not be too strong (the optimal distance of the can nozzle from the structure is 5-10 centimeters);

- Apply WD-40 for the first time, let it dry for 30-40 seconds and reapply (2-3 times is usually enough);

- Next, use a syringe to rinse the sensitive elements and sensor contacts with a mixture of medical alcohol and distilled water.

This completes the procedure. Knowing how to clean the mass air flow sensor on a VAZ 2114, all the work can be done in 15-20 minutes. All that remains is to install the device in place and check its functionality.

This technique can also be used on the VAZ 2114 and VAZ 2115.

The price of a mass air flow sensor (MAF) stands out among other car spare parts and is about 2000 rubles. If the diagnostics revealed an error in the mass air flow sensor, then do not rush to change it, try to restore the mass air flow sensor yourself .

First you will need to remove the pipe from the mass flow sensor (instructions). Next, you need to remove the mass air flow sensor from the pipe, otherwise it will not be possible to perform high-quality cleaning. To remove the sensor, you will need a set of sprocket wrenches. Unscrew the screws and pull the sensor out of the pipe.

You can often find that the inside of the sensor itself is covered with an oil coating; our task is to make everything perfectly clean.

To clean the air flow sensor from this deposit, a carburetor cleaner is suitable. On the inside of the film there are 2-3 sensors, which are small wires that are attached using a special resin. We carefully spray this sensitive element so as not to damage it. We wait a while for the product to dry. We repeat this procedure several times, depending on the contamination of the air flow sensor. To speed up drying, you can use a compressor/can of compressed air, but the point is not in high pressure, but in blowing for drying. Flushing the air flow sensor can also be done using other means, for example, alcohol. In addition to the sensor, it is worth paying attention to both the mesh of the pipe and its inner surface. If necessary, clean the air flow sensor pipe from dirt, debris and dust. This the MAF repair . We perform the assembly in reverse order and change the air filter.

Cleaning

Quite often you can avoid replacing the mass air flow sensor by simply cleaning this engine element.

You should do the cleaning yourself in this way:

- Remove the pipe from the mass air flow sensor;

- Now remove the sensor from the pipe. Otherwise, high-quality washing will not work;

- To remove the sensor, arm yourself with sprocket keys in advance. Finding such kits is not a problem;

- Unscrew all the fasteners, remove the sensor from the pipe and assess its external condition;

- Often there are traces of oil deposits on the sensor. The purpose of cleaning is to make the device as good as new;

- Carburetor cleaner is often used to clean the air flow sensor;

- Inside the film there are sensors, which are small wires attached to a special resin. These elements must be carefully sprayed with cleaner so as not to damage the devices;

- Wait a while for the surfaces to dry. To speed up the process, use a can of compressed air;

- It is not uncommon to use alcohol instead of carburetor cleaner, which also works quite effectively;

- Proper cleaning of the mass air flow sensor involves treating the pipes from accumulated debris, dirt and dust;

- Having carefully processed all the components of the removed mass air flow sensor, wait until it dries, and then reassemble it. Cleaning is complete.

Spray cleaning

Statistics show that in about 80% of cases, simple cleaning can return the mass air flow sensor to its previous functionality.

Price issue

80% is not 100. Therefore, sometimes you have to change the sensor. And to replace it, you need to buy it.

There are three price categories for air mass flow sensors:

- Cheap. These are predominantly Chinese products, the price of which is up to 1000 rubles. It is strongly not recommended to purchase such regulators;

- Average. These include sensors from AvtoVAZ, domestic and some foreign analogues. These cost from 1500 to 2500 rubles;

- Expensive. High-quality, reliable, imported air flow sensors, the price of which can reach 5.5 thousand rubles. It’s hard to say how rational it is to buy them. But they will definitely last a long time.

When choosing a new mass air flow sensor, focus not only on the price, but also on the manufacturer. Today, the most popular devices are from Siemens and Bosch. Average in price, excellent in quality.

When should you clean the sensor?

How quickly the mass air flow sensor becomes clogged directly depends on the degree of contamination of the air filter on which it is located. If the filter is not clogged, then it effectively cleans the air of all dust particles and the air flow sensor does not come into contact with small mechanical impurities, however, if the air filter is worn out or simply of poor quality, the sensor will become dirty very quickly.

Cleaning the air flow sensor is performed in the following cases:

- The fourteenth is very blunt during acceleration, any twitching, jerking or dips in speed indicate that something is wrong with the sensor;

- The engine idles intermittently or, conversely, the engine speed rises excessively at idle;

- Fuel consumption has increased (VAZ-2114 owners often write that if the sensor is dirty, gasoline consumption can increase from 9-10 to 15 liters);

- The engine refuses to start.

Flushing the mass air flow sensor on a VAZ 2114 solves any of these problems, unless, of course, the sensor is the only cause.

Checking the functional state of the mass air flow sensor

To determine that this particular unit is faulty and the mass air flow sensor needs to be washed and repaired, you need to check the mass air flow sensor with a multimeter.

A multimeter, also known as a tester, is an electronic device that can be purchased at any auto store at a price of 400-600 rubles for the simplest models (their functionality will be quite enough for us). It is not inexpensive and will be useful in the garage many times - you can use it to check any sensors and electronic systems of the car.

The serviceability of the mass flow sensor is checked as follows:

- We switch the tester to voltmeter mode and set the upper limit of sensitivity to 2 Volts;

- We connect the multimeter probes to the yellow and green wires (they are located in the sensor connection socket);

- We activate the ignition (there is no need to start the engine) and look at the tester reading.

If the tester testifies that the voltage between the yellow and green contacts fluctuates in the range from 0.0099 to 0.02, then everything is fine with the unit.

If the device is dying due to wear or contamination of sensitive parts, the tester will show a maximum voltage of 0.03 V, in which case it is necessary to clean the mass air flow sensor on the VAZ 2114.

In the case when the multimeter readings are much higher than the upper voltage limit, in the range of 0.045-0.5 V, or significantly less than the minimum - 0.09-0.095 V, the probability that flushing the mass flow sensor will give a result is approximately 50%.

Testing with a multimeter is not a dogma, there are other methods

There is another simple method to check the functionality of this unit, which can be used if you do not have a multimeter. Just remove the mass air flow sensor and close the air duct valve, start the fourteenth and run it at 2 thousand rpm. If you feel that in the absence of a sensor the car behaves much better on the road, the problem is in it.

Testing and diagnostic methods

Shutdown

Pulling out the sensor is fairly easy.

It is located in the air filter. Article on the topic: Do-it-yourself installation of rear disc brakes on a VAZ 2114

This method involves starting the motor with the sensor removed - we need to disconnect its connector. When turned off, the controller starts emergency mode, and new portions of the mixture are calculated based on the position of the damper. We need to drive a little, the speed should be above 1500 rpm. If the car behaves more dynamically without a mass air flow sensor, then the diagnosis is complete - it’s time to change the consumable.

Checking with a multimeter

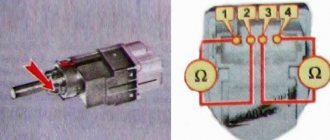

This test requires that you have skills in using a multimeter (tester). The method is suitable for almost all VAZ models, including 2110. We need to take a multimeter and set it to a mode that measures constant voltage, which is usually designated DCV or only V. To work with the mass air flow sensor, you need to understand its pinout, it is as follows:

- Yellow, closest to the windshield, supplies current to the signal input;

- Green indicates ground;

- The pink or red-black wire comes from the main relay;

- The white-gray wire is responsible for the voltage output.

The location of the wires and their sequence.

Depending on the model, the colors may be different, but the location does not change. Here you will have to deal with a specific model. But once you find the input signal wiring (closer to the windshield) and grounding, you can do it without instructions. The wiring is clear, now you need to turn on the ignition without starting the engine. The tester sets a limit of 2 Volts. The black probe of the tester is connected to the green ground wire of the air flow sensor, and the red one is connected to the yellow one. The measurement takes place between two terminals. The probes must be inserted carefully; an additional needle is not required, since the probes can be freely inserted along the wires without damaging the insulation.

We look at the tester display. If the consumable is new, then there we will see a voltage indicator of 1.01. Over time, the indicator increases as the resistors wear out (the resistance drops). The larger the number, the greater the wear of the sensitive element:

- In good condition, the indicator will be 1.01… 1.02;

- With “normal” - 1.02... 1.03;

- The sensor will soon stop working – 1.03… 1.04;

- The dying state of the flow meter is accompanied by an indicator of 1.04… 1.05;

- Replacement of the unit is required when the reading is 1.05 or higher.

Testing the mass flow sensor.

The dipstick must be inserted carefully. Diagnostics can also be carried out without a multimeter. Instead, you can use the on-board computer. To do this, you need to go to the “voltage from the mass flow sensor” section; we are interested in the “U MAF” indicator.

Visual inspection

Here we need to carefully examine the surface of the corrugation and consumables. To check the condition, we need to loosen the air intake clamp at the outlet of the mass air flow sensor, and then pull it off. If you see traces of grease or condensation on the surface, then most likely they have damaged the unit. Sometimes the sensor can be “reanimated” by removing all the dirt. It ends up in the consumables due to rare changes of the air filter. If liquid appears on the sensitive element, this is a 90% failure. Lubricating oil enters due to a clogged oil separator or due to an increased level in the crankcase.

Article on the topic: Replacing rear shock absorbers on a VAZ 2110 with your own hands (video)

Drops of oil on the sensor are a sure sign that it has failed.

If the above-described elements are detected, the diagnosis can be completed. If the surface is clean, move on. Remove the consumable from the air filter. It is held in place only by 2 screws, which are unscrewed with the 10th key. Looking at the photo, we see that there is an o-ring on the front of the mass flow sensor. It is installed for sealing - unfiltered air cannot leak through the inlet.

If this ring (in the photo it is green, but your color may be different) has slipped or remains in the filter housing, then a layer of dust can be found on the consumable mesh. Such a defect is enough to cause the sensitive element to fail. You need to assemble the unit according to the following scheme: check the reliability of the sealing skirt, put on the rubber ring, place the sensor in the air filter housing.

What is the best way to flush the air flow sensor?

The reason why the mass air flow sensor fails is contamination of its sensitive element, which is a wire or a platinum resistor (depending on the type of device).

Platinum sensing elements can be easily damaged if not properly cleaned. If this happens, the device can simply be thrown into a landfill, since it will be impossible to recover them.

When choosing how to clean the air flow sensor, never use the following liquids:

- Products containing acetone;

- Ketone-containing products and any other artificial solvents;

- Liquids containing sulfur ethers.

Also, do not try to clean the mass air flow sensor on a VAZ 2114 using cotton ear buds or a toothbrush - any mechanical contact with the sensitive element of the device is unacceptable.

What kind of service is this?

The mass air flow sensor is a device that is designed to accurately determine the amount of air entering the car engine for its efficient operation. Since it is one of the most important elements of the electronic engine control system of a car, a complete replacement of the mass air flow sensor is necessary if the balance of the air-fuel mixture is imbalanced. Often, along with this service, a replacement of the oxygen sensor is ordered. The mass air flow sensor is a cylindrical plastic housing with a sensing element installed inside. The engine draws air from outside the vehicle and passes it through the air filter. The mass air flow sensor measures the amount of air entering the engine.

Sensor design

This device is a plastic cylinder with a sensing element inside and is installed directly inside the intake tract immediately after the air filter. In addition, its design includes platinum wires with a cross-sectional diameter of 70 microns, which pass through the measuring tube, which is located in front of the throttle valve.

Principle of operation

The operation of the sensor that controls the mass air flow is based on the principle of constant temperatures. For optimal operation, one power stroke should ideally receive one part of fuel and fourteen parts of air into the engine. The sensor monitors this ratio and sends information to the main computer, which calculates how much fuel is needed to operate the engine. If this relationship is disrupted, then either a decrease in engine power or excessive fuel consumption will be observed.

For proper engine operation, it is necessary to maintain a certain air/fuel ratio in the air-fuel mixture. The computer estimates the amount of air entering the engine based on the mass air flow sensor and then calculates the amount of fuel required for a given engine operating mode. If the sensor fails, it is unknown how much fuel should be added to the mixture, which causes problems including poor fuel economy, loss of power, etc. Often the MAF sensor becomes dirty (especially if the air filter is dirty) and loses its ability to correctly estimate the amount of air entering the engine . If the vacuum hoses are leaking, a fault code may appear corresponding to a faulty mass air flow sensor.

When doing this work, your mechanic may recommend replacing the electrical connector that connects the mass air flow sensor to the engine control module. The wires in the connector may be damaged, causing the mass air flow sensor to malfunction. Replacing the throttle position sensor is necessary for such manifestations as the car jerking when moving, engine stalling when idling, engine failure to operate when switching to neutral, jerking when accelerating, etc.

Cleaning the sensor step by step

Having decided how to wash the mass air flow sensor, you can proceed directly to the procedure itself.

In addition to the cleaning liquid, you will need a regular syringe with a 10-20 cc needle, a screwdriver and a 10 cc wrench to remove the sensor.

- We dismantle the device: remove the block connected to the sensor with power wires (on its lower part there is a locking button that must be pressed, after which the block can simply be pulled out) and using a 10mm wrench, unscrew the two screws that secure the sensor to the air filter housing;

- In the place where the block with wires is connected to the sensor, there are two screws connecting the parts of its protective casing; they must be unscrewed with a Phillips screwdriver, after which you can disassemble the casing and pull out the mass air flow sensor itself;

- We wash all sensitive elements of the sensor (temperature sensor wire, contacts) with cleaning liquid. If it is VD-40 or a carburetor cleaner, which are supplied from a can, carefully monitor the jet pressure on the elements of the device; it should not be too strong (the optimal distance of the can nozzle from the structure is 5-10 centimeters);

- Apply WD-40 for the first time, let it dry for 30-40 seconds and reapply (2-3 times is usually enough);

- Next, use a syringe to rinse the sensitive elements and sensor contacts with a mixture of medical alcohol and distilled water.

This completes the procedure. Knowing how to clean the mass air flow sensor on a VAZ 2114, all the work can be done in 15-20 minutes. All that remains is to install the device in place and check its functionality.

This technique can also be used on the VAZ 2114 and VAZ 2115.

Replacement

It is not difficult to replace the mass air flow sensor with your own hands, even if you do not have any special skills in car repair. Having checked the condition of the device and determined that cleaning will not help, all that remains is to replace it.

- Place the car on a level surface, lift the hood and remove the negative terminal from the battery.

- Disconnect the sensor connector. We have already talked about its location, so there will be no problems with the search.

- Using a screwdriver, remove the clamping bolt of the clamp that secures the corrugation to the mass air flow sensor.

- The corrugation is removed.

- Using a 10mm wrench, unscrew the two bolts that hold the sensor to the air filter housing.

- After removing the failed oxygen sensor, install a new regulator in its place.

- Screw back a couple of bolts, secure the corrugation and secure it with a clamp.

- Reconnect the connector and return the negative terminal to the battery.

If everything is done correctly and the breakdown is correctly identified, then the engine will return to its previous performance and the error signal on the dashboard will disappear.

Replacing the device

To finally check the result of the repair, go out onto the road, do a test drive and be sure to try to press the gas pedal sharply. If the dynamics and power become the same as before the problems arose, you did everything correctly, and it was the mass air flow sensor that was the culprit of the malfunction.

A car engine is a complex system consisting of many components. To operate in each mode, the engine requires a mixture of air and gasoline. The mass air flow sensor sets and regulates the volume of air entering the engine cylinders. During the operation of the car, the mass air flow sensor can become clogged and fail, and therefore it will be useful to know how to clean this device.

Operating principle of the mass air flow sensor

Auto parts sellers ask a lot of money for a mass air flow sensor. However, repairing a mass air flow sensor is not difficult. Therefore, before you listen to the seller who stubbornly insists that the mass air flow sensor is not restored, but replaced, try your luck and have this device repaired.

The mass air flow sensor plays a very important role. The controller will mix fuel with air in the required proportion only if it receives accurate data on the engine's air consumption.

If the sensor supplies data that does not correspond to reality, then the air-fuel mixture will become of poor quality for a given engine mode and the engine will lose power, fuel consumption will increase, and the dynamics and “response” of the car will deteriorate.