There are quite a few different types of mass air flow sensors: mechanical, ultrasonic, hot-wire and some others.

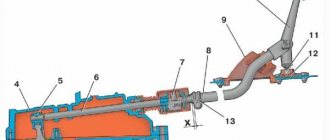

In this case, we will consider the design of the HFM-5 hot-wire sensor from Bosch, which is most often installed on VAZ cars. The sensor's sensitive element is a thin film on which several temperature sensors and a heating resistor are located. In the middle of the film there is a heating area, the degree of heating of which is controlled using a temperature sensor.

On the surface of the film, on the side of the air flow and on the opposite side, two more thermal sensors are located symmetrically, which record the same temperature in the absence of air flow. In the presence of air flow, the first sensor is cooled, and the temperature of the second remains unchanged, due to the heating of the air flow in the heater zone. The differential signal of both sensors is proportional to the mass of passing air.

- 1 – dielectric diaphragm

- H – heating resistor

- SH – Load temperature sensor. resistor

- SL – Air temperature sensor

- S1 and S2 – temperature sensors before and after the heater.

- QLM – air flow mass

- t – temperature

The sensor's electronic circuit converts this signal into a constant voltage proportional to the air mass. This design is called Hot Film (HFM), its advantages include high measurement accuracy and the ability to record reverse air flow, but its disadvantages include low reliability in conditions of contamination and moisture.

To measure the amount of air that enters the engine means to determine the engine load. When the driver presses the gas pedal, the throttle valve opens and the amount of intake air increases. At the same time, we say that the load has increased. When you release the pedal, the load drops. It's quite simple. However, this is only at first glance. If we take into account the fact that in real driving conditions the engine often changes operating modes and the incoming air in the intake system participates in several gas-dynamic processes, then the problem of measuring the air in the system is not so simple.

In older systems (ECU January-4 and GM-ISFI-2S), other hot-wire mass flow sensors were used, the sensitive elements of which were made in the form of threads. Such sensors are called Hot Wire MAF Sensor. The output signal of these sensors was frequency, that is, depending on the air flow, it was not the voltage that changed, but the frequency of the output pulses. The sensors were less accurate and did not allow registering reverse flow, but these shortcomings were offset by very high reliability.

Several types of mass air flow sensors were installed on VAZ cars: GM, BOSCH, SIEMENS and Russian-made. In 1999-2004 Two types of sensors were installed on VAZ cars: 0 280 218-037 and 0 280 218-004. These sensors produce different output voltage (calibration) parameters at the same air flow rate and interchangeability (or rather, replacing 004 with 037) is only possible with the replacement of calibration tables in the firmware. The same applies to the new sensor 116, which has been installed as standard since the beginning of 2005.

The sensor is supplied only assembled, with a code and marked with a green circle.

On some classic cars, together with the January 7.2 ECU, Siemens-VDO sensors (5WK97014. AVTEL) were used:

They differ in calibration (from zero volts) and connection diagram.

VAZ 2110 air sensor pinout diagram

- Yellow (closest to the windshield) - mass air flow sensor signal input;

- Gray-white—sensor supply voltage output;

- Green — sensor grounding output;

- Pink-black - to the main relay.

The wire colors may change, but the pin locations remain the same.

Let’s also add that the mass air flow sensor with endings 004, 037, 116 (for Bosch) and 00, 10, 20 (for Pekar) are different in calibration. You can only change it by flashing it.

Connecting the MAF air sensor VAZ 2112

If the mass air flow sensor is operational, then when the engine is running at 900 rpm, the volume of air used will be at least 10 kg per hour. When the speed increases to 2 thousand, this figure will increase to approximately 20 kg. If the volume of air at such speeds drops, the dynamics of the vehicle will also decrease, and accordingly, this will lead to a decrease in gasoline consumption.

If these indicators increase, this will also contribute to an increase in fuel volume. Deviations of the parameter by 2-3 kg should not be allowed, since in this case the operation of the power unit may be incorrect.

Useful: Connection diagram and pinout of the VAZ power window button

Connection diagram for air flow sensor 2114

A common cause of incorrect operation of the mass air flow sensor is the failure of electronic components, which increases the sensor’s response time to changes in air flow. A working sensor monitors changes at a speed of 0.5 ms, and if it breaks down, the response time increases by 20-30 times. The defect is detected only by recording the operation graph with an oscilloscope. Such a sensor cannot be repaired; it must be replaced with a new one.

Checking and repairing at home

There are eight ways to independently check amplitude and frequency mass flow sensors.

Method No. 1 - disabling the air flow meter

The method consists of disconnecting the sensor from the fuel system of the car and checking the functionality of the system without it. To do this, you need to disconnect the device from the connector and start the engine. Without a mass air flow sensor, the controller receives a signal to switch to emergency operation mode. It prepares the air-fuel mixture only based on the throttle position. If the car moves faster and does not stall, it means that the device is faulty and requires repair or replacement.

Method No. 2 - flashing the electronic control unit

If the standard firmware has been changed, then it is unknown what reaction of the controller is programmed in it in case of an emergency. In this case, you should try to insert a 1mm thick plate under the throttle stop. The turnover should increase. Now you need to pull out the chip from the air flow meter. If the power unit continues to work, then the cause of the malfunction is the firmware.

Checking the air sensor yourself

When a malfunction of the mass air flow sensor occurs, the air-fuel mixture becomes over-rich or lean, which immediately affects the operation of the engine and may ultimately result in engine failure.

Symptoms of a malfunctioning mass air flow sensor:

- Check Engine error appears;

- Increased fuel consumption;

- Doesn't start well when hot;

- The car began to accelerate slowly;

- Engine power lost.

The easiest way to check the mass air flow sensor on a VAZ 2114 is to disconnect the plug. If there is no signal, the engine control unit goes into emergency operation mode, determining the approximate air volume based on the throttle position. At the same time, fuel consumption increases slightly - for the VAZ 2114 it reaches 10-12 liters per 100 km. A characteristic feature is the increase in idle speed to 1500 rpm. But when using a January 7.2 or Bosch M7.9.7 controller, the idle speed does not increase due to the software features.

The normal voltage at the output of the new sensor is 0.996 - 1.01 Volts. During operation, it gradually changes and, as a rule, increases. The greater the value of this voltage, the greater the wear of the mass air flow sensor.

Here is the reference voltage in volts:

- 1.01 – 1.02 – good condition of the sensor.

- 1.02 – 1.03 – not a bad condition.

- 1.03 – 1.04 - the life of the mass air flow sensor is coming to an end.

- 1.04 – 1.05 — emergency condition.

- 1.05 and above - it’s time to replace the mass air flow sensor.

The measurement is made between the yellow and green wires. Voltage values can be displayed on the screen of some on-board computers (menu voltage from sensors, U Mass air flow sensor).

Important: the limits and fluctuations of the output voltage in at least 30% of cases for a faulty sensor will be NORMAL and will not cause the “Check” icon on the panel. That is, voltage measurements are uninformative, but the rate that it will produce in kilograms of air will correspond to the movement not where it actually is, and the ECU will interfere with the mixture based on it - hence the extra consumption!

You need to check the sensor at a service center, preferably with a proprietary scanner, which itself indicates by blinking if there is a imbalance in some parameter (in this case, air flow in kilograms), comparing it with the reference values stored in its memory.

The second way is using a multimeter

Before performing these diagnostics, it should be noted that this will only work with a Bosch mass air flow sensor. Before performing the test, set the limit on your multimeter to 2 V, and then switch the device to constant voltage operation.

Turn on the ignition and connect the red wire to the yellow one on the block. Connect the black wire to the green one. At this moment the engine should not be running. Measure the voltage If the reading is between 1.01 and 1.02 then everything is fine. The multimeter shows voltage up to 1.03 - there is nothing to worry about, this is acceptable. The limit level is 1.05. If it is higher, then you can again look for the cause of the breakdown.

Replacing the sensor - instructions

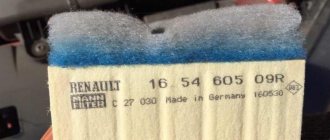

Using a screwdriver, unscrew the clamp of the air intake corrugation at the sensor outlet, pull it off and carefully inspect the internal surfaces of the sensor itself and the corrugation. These surfaces must be dry and clean; traces of condensation and oil are unacceptable. If the air filter is changed rarely, then dirt getting on the sensitive element of the sensor is the most common cause of its breakdown in VAZ cars.

There may be oil in the mass air flow sensor as a result of an increased oil level in the engine crankcase, or the oil sump of the crankcase ventilation system is clogged.

Next, unscrew the 2 screws of the sensor with a 10mm wrench and remove it from the air filter housing. There should be a rubber sealing ring on its front part (at the entrance edge). It prevents unfiltered air from being sucked into the intake tract through the sensor.

If the ring is out of place and stuck somewhere in the air filter housing, then there will be a thin layer of dust on the inlet mesh of the sensor itself. This is the second reason that destroys the mass air flow sensor ahead of time.

Correct assembly should take place in the following sequence: put a sealing rubber band on the sensor, check the sealing skirt, then insert everything together into the filter housing.

This concludes the visual check of the mass air flow sensor at home. You can check its operation 100% only with the help of special equipment in a car service center. For example, using a technique for assessing the oscillogram when the throttle is sharply opened to the cutoff mode (a motor tester is needed), or assessing the oscillogram when the ignition is turned on.

Resuscitation of a damaged air flow sensor is successful in no more than 5% of cases. In extreme cases, you can rinse with ethereal liquid to clean matrices and optics. It will evaporate without a trace. After making sure that there is no more dust or debris in the device, you can dry it thoroughly and put it back in place. Sometimes after such a simple procedure the device will work.

On most foreign cars, a mass air flow sensor was installed until 2000; subsequent generations of models began to be equipped with a pressure controller. Replacing a non-working sensor is simple and can be done on your own without any problems, you just need to buy a mass air flow sensor that matches the ECU firmware version. Its price is around 3,000 rubles, depending on the manufacturer.

Flow meter failure: signs and causes of failure

Of course, the absence of a sensor or incorrect readings will not lead to a complete stop of the car. Moreover, the mass air flow sensor is checked, among other things, by the on-board computer. However, the symptoms will not allow you to move normally on the road:

- loss of engine power, up to the inability to drive uphill;

- engine jerking when moving evenly;

- hanging at high speeds after releasing the gas (this can be dangerous);

- increase in fuel consumption up to two times;

- engine vibrations reminiscent of “triple movement”, leading to increased wear of mechanisms.

With the exception of natural wear (any mechanism has a service life), other causes of malfunctions are associated with contamination of the MAF sensors or moisture and oil entering it. These problems arise due to an irresponsible attitude towards car maintenance.

- untimely replacement of the air filter;

- installation of low-quality or “zero” filters;

- water getting into the air duct channel (driving through puddles at high speed, careless car washing);

- penetration of oil vapors into the flow meter housing due to a malfunction of the crankcase ventilation system;

- debris and foreign objects that have entered the measuring channel after repair work or car maintenance.

Advice: do not rush to change a clogged flow meter; you can try to clean it with compressed air or a special aerosol for mass air flow sensors or carburetors.