Replacing silent blocks of the cross member of a VAZ 2110

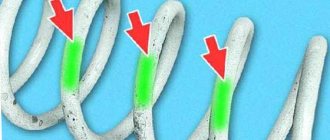

In this article we will talk about replacing the silent blocks of the cross member of the front suspension of the VAZ 2110. We will carry out the repair in the inspection pit without removing the cross member from the car. The first step is to remove the engine protection and brace. Then you need to find a bolt and suitable washers, as well as pipe sections in order to press the rubber silent block towards the front of the car.

If you can’t press it out, then cut off the rubber collar on the side with a smaller diameter. Next, you need to thoroughly clean the silent block seat from dirt and rust, then thoroughly lubricate the silent block and the socket with a soap solution to facilitate its pressing.

We will press in the same sections of pipes with a bolt and washers.

Pressing must be carried out carefully to avoid damage to the rubber silent block. We press in until the smaller flange completely comes out of the hole in the front cross member.

That's all, if you have questions, ask us in the comments, and also read other interesting articles about how to build a cramp yourself on our website and join our VKontakte group.

When should you change?

Usually, the driver will probably guess that the silent block has failed. If a replacement is needed, discomfort while driving will tell you about it. You can feel distinct “iron” impacts and noises in the suspension. But that's not all.

If urgent measures are not taken, the VAZ 2110’s fastenings and connections will break and play will appear. The wheel alignment angles will also suffer, which obviously will not lead to any good.

There are some symptoms to look out for that these rubber parts are worn out:

- When driving, the tires on the wheels squeak. Not necessarily much. There shouldn't even be a slight squeak;

- A knocking sound is heard in the wheel area. The point here is the poor rotation of the collapsing silent blocks;

- As the silent block wears out, it first becomes covered with cracks and then completely falls apart. Here only the deaf can no longer hear the knocks.

Tools for replacement

On a VAZ-2106 it is almost impossible without the use of special pullers. This device is very simple in design - a metal cup, the diameter of which is equal to the size of the rubber-metal element, a washer and a bolt with a nut (their threads have a large pitch, since the requirement for it is to withstand heavy loads). In addition, you will need a few more special devices. It is better to purchase them in advance or borrow them from friends. Having all the tools makes repairs much easier.

Firstly, this is a spring puller - two pins, at the ends of which there are multi-faceted threads, with grips screwed onto it. Secondly, it is advisable to have a ball joint remover, because it is possible that during repairs you will decide to replace it. Thirdly, you definitely need a good tool - wrenches, screwdrivers, nuts. If you don’t have a puller, it will help. It is needed to burn the rubber out of the joint. In this way, you can quickly break the rubber-metal element to remove it from its seat.

Consequences of consumables malfunction

It should be noted that silent blocks and bushings are consumables.

Due to heavy loads, it is possible that the rubber part of the silent block may be pressed through, detached from the metal bushing, and the rubber itself may delaminate. As a result, they are no longer able to work properly.

This results in knocking from the suspension, the appearance of creaks, when driving, especially over uneven surfaces, the car can throw from side to side, and the more wear on the silent blocks, the stronger the tossing will be.

Also, due to worn silent blocks, the angles of the wheel position - camber and toe - change, because of which the car will no longer hold the road, it will begin to drift in any direction, the tires will quickly wear out due to incorrect angles.

So, the condition of all rubber elements of the car suspension must be constantly monitored, and if signs of malfunction appear, they must be promptly replaced.

With certain knowledge and the availability of tools, you can replace silent blocks yourself without contacting a service center.

It should be noted right away that even if damage to one or two silent blocks is detected, it is better to completely replace all rubber parts of the suspension, and not just the damaged ones.

Also, all elements are replaced immediately on the left and right sides of the car.

Rear beam device

The metal rear beam, a photo of which is presented on our resource, is structurally represented by 2 longitudinal levers and connection elements, which are connected by welding through reinforcement components. At the rear of the product there are special holders with holes for mounting shock-absorbing elements. There are also flanges with holes for fastening the axles of the rear wheel pair together with the casings of the stern brake systems.

In the front part of the rear axle beam of the VAZ 2110 there are levers with welded bushings, in which rubber-metal type hinges are installed by pressing. The rear beam mounts pass through them, which connect the lever part of the stern suspension to stamped-welded type holders. Those, in turn, are mounted with welded bolts to the body side members.

The spring elements of the suspension rest with one plane on the support of the shock absorber strut, and with the other, through a rubber insulating gasket, into the welded support of the hidden arch of the body tail. The shock absorber strut of the rear suspension beam of the VAZ 2110 is a hydraulic telescopic system of a two-way operating principle.

Through fasteners in the form of a bolted connection, it is articulated with the holder of the longitudinal-type stern suspension arm. The upper fastener of the rack is made in the form of a pin connection, while the fastening of the rod to the upper support is made through rubber pads and a support washer.

The factory “tens” rear beam, the dimensions of which differ from the parameters of similar products, has the item number 2110-2914008, while the “eight” beam has the catalog number 2108-2914008-10.

Replacing daisies. — logbook Lada 2112 2007 on DRIVE2

After replacing the supports, stabilizer struts and tips, the knocking still did not go away, I read on the drive and somewhere else that it might be daisies, they just looked tired to me, well, I think they were, I took them all apart, they really died, I pressed out the old ones , I stuck the new ones in and put them on one side for now, at least to check whether they were there or not, I took it for a ride, it felt a little rougher, maybe because I pulled everything together well, at first I was glad that the knocking had disappeared, but that was not the case, I drove up to the house, everything was smooth when braking and starting, but much quieter, tomorrow I'll change the right side and look at the caliper, most likely there's nothing more wrong with it, so tomorrow I'll look on the right side to see if the caliper is hanging there and then I'll think further, but the problem is almost gone :)

Beam structure

On the inside, brackets with special holes necessary for installing shock absorbers are attached to the suspension arms. There are also flanges located there, bolted to the axle of the rear wheels and shields located on the brake mechanism. Bushings are attached to the suspension arms on the front side. They are inserted into hinges made of a special rubber-metal material.

Bolts pass through them, connecting the suspension arms together with the stamped-welded brackets. They, in turn, are attached with bolts welded into the side member of the car. The springs of the rear beam of the VAZ 2110 are located in such a way that the first end rests against the recess of the shock absorber, and the second passes through a special gasket directly into the support area attached to the underside of the arch on the car body.

The gasket acts as an insulator and is made of rubber. The shock absorber mounted on the rear suspension is double-acting. It is attached with short bolts directly to a bracket located on the trailing arm in the rear suspension area. In the upper part, fastening is done using the rod method. The rod is fixed in the upper support directly on the suspension spring. The shock absorber is fixed through a protective rubber pad and a support washer.

A double row thrust bearing is located in the middle of the hub. Its structure is very similar to the bearing located in the hub of the front wheels, but it is much smaller in size.

FakeHeader

Comments 7

Hello. Two years have passed. I just came across your story. Now I was tightening the upper silent blocks, the rubber bands on the outside stupidly came out from under the washers. And I didn’t make it to 60. I’m sitting here scratching my turnips. True, my graphics are blurry. But the lower ones were also lubricated, they were tightened for 80 minutes and did not come out.

Hello! Thank you for remembering) The range is 60-90 N*m because our rubber products are produced according to specifications. It’s not clear to anyone what specifications a particular manufacturer has. You shouldn’t pinch the rubber bands—that’s a fact. My silent blocks drove for 3000, then I swapped them as is with levers onto a friend’s car, tightened them by eye - and it’s still running.

In addition, if you go to a good service center for wheel alignment, they will tighten the wheel alignment there. properly, because the nuts will be unscrewed.

If I understand correctly, did you tighten the silent blocks on the unassembled suspension? You only need to tighten the silent block nuts (!) when everything is already assembled, the wheel is in place and the car is lowered to the ground. When you tighten the nuts, the levers should be in the position they are always in when the car is at rest. Otherwise the silent blocks will die very quickly.

Thank you. Based on the experience of repairing Lada cars, what is the conclusion? The lever will tilt down during assembly, the silent block relative to the mudguard and the bolt are the same, no matter how you look at it, and somehow I didn’t think about what you said. Anyway, before replacing the lower ones I wanted to check

What you need to prepare for self-repair of silent blocks

Replacing silent blocks or daisies is simply necessary, because this part is responsible for the operation of the car’s suspension. To carry out independent repairs, it is worth preparing a set of spanner wrenches, reliable socket wrenches, a standard vice (if you are used to working with them when pressing out small components), a chisel and a hammer, but this is in case the fasteners have soured and you will have to use force.

Set of tools

You will have a special silent block puller at the beginning of the repair, good, this will certainly make the work easier and speed up the replacement process. You will also have to purchase a new set of silent blocks for replacement in advance and decide how to change the daisies on a VAZ 2114.

Preparing for work

So, first you need to prepare the appropriate set of tools. In addition to new silent blocks (polyurethane or rubber-metal, it doesn’t matter), a standard set of heads with a ratchet, a soap solution, and universal lubricant VD-40 are required. As an alternative, you can use an analogue from. The product costs several times less, but the effect is the same, as noted by reviews from car owners.

Replacing lower arm joints

When you're done with the top one, you can start with the bottom one. His fastening is done a little differently. And the replacement of VAZ-2106 silent blocks is carried out without removing the suspension arm. You just need to unscrew the nut, which, by the way, needs to be replaced with a new one during assembly. And remove the washer. That's all, now use the hollow bolt of the puller to press out the hinge. The second one is extracted using the same exact technology.

Installation of new hinges is done by pressing. To do this, a silent block is inserted into the hole by hand. Then, using a stand, carefully strike with a hammer. You don’t need to hit with all your might, a sharp but weak blow is enough. But this is if there is no puller, and if there is one, then the task is simplified many times - place it on the hinge and slowly, avoiding distortions, screw in the bolt. After pressing, check that there is no gap. When finished, screw in a new nut, not forgetting the washer. That's all, the replacement of the VAZ-2106 silent blocks is completed, you can put the upper arm in place.

The silent block is an important part of the suspension, which ensures the mobility of the elements relative to each other, and also eliminates friction from metal parts. If so, it needs to be changed. On all VAZ classic models (2101, 2102, 2103, 2104, 2105, 2106 and 2107), the silent blocks of the front levers change in the same way. The procedure for replacing the silent block of the VAZ upper arm is as follows: 1. Jack up the car and remove the front wheel.2. Unscrew the nut on the axis of the upper arm (you need a 24mm wrench).

Knock in the front suspension of Lada Kalina

Many motorists dread the day when strange knocking noises appear in the suspension, especially the front suspension, which increases with increasing speed. Of course, there is reason to worry, but at the same time, a car’s suspension is a strong and reliable unit that will clearly withstand a few more kilometers to a service station or garage, where it can be diagnosed.

There are four main reasons for the occurrence of knocks and squeaks in the front suspension of the Lada Kalina. Of the three possible causes of knocking, two of them can be eliminated independently.

So, the first reason why a knocking sound may occur in the suspension is the quality of the road surface. Yes, suspensions, even the most ideal and new ones, can squeak and knock on a bad road, even if this has not been observed before. To test this theory, you should drive onto a well-paved road and drive a few hundred meters; if there is no knocking, everything is fine with the suspension; if not, look at the second reason.

The second reason for the knocking sound, if it is accompanied by vibration in the steering wheel, is a malfunction of the steering, or rather the steering rack, or thinning of the brake discs. If the discs can be replaced independently, then in the case of steering, if you are not a level 80 mechanic, it is better not to flirt with it right away bring the car to the service station.

The third reason is the springs that have lost their tone, as a result of which the car body practically hits the suspension. You should not deal with this problem on your own - it is better to immediately take the car to a service station or service center, since self-repair may seriously damage the front suspension strut.

The fourth reason is a worn-out silent block, which is designed to dampen vibrations and knocks when driving. You can replace the silent block yourself; see the step-by-step replacement of the silent block in the Lada Kalina mono in the next paragraph.

Replacing front suspension silent blocks

Replacing the silent blocks of the Lada Kalina front suspension is necessary after 15-17,000 km, otherwise noises and knocks may be observed when driving. In most cases, the loss of its functions is observed after 15-17,000 km; knocking noises that appeared during this period of kilometers are a problem of faulty silent blocks.

Silent block

The silent block replacement diagram looks like this:

- The machine is placed above a hole or ditch in order to be able to comfortably see the entire suspension. The movers are fixed by the wheels, we put the car itself on the handbrake, then it’s worth checking again that the car is stationary.

- Use a jack to lift the car and remove the front wheel.

- After this, you should fix the bolts of the ball joint with your hands, after which its fastenings are removed.;

- The SPU nut is unscrewed, before this the ball-type support is knocked out into the lower part, after these manipulations the bolts are removed.

- After removing the bolts, the sleeve blocking the lever is pulled out. After pulling out the bushing, the lever is pulled out.

- There are marks on the lever that indicate the direction of installation of new silent blocks; this should be taken into account when installing new blocks.

- The silent blocks must be lubricated at the point of contact with the lever. Using a vice or pliers, apply pressure to the blocks until they fall off.

The diagram is approximate and is for informational purposes to understand how many manipulations need to be made to replace silent blocks.

Replacing the silent blocks of the upper arm

That's all, now you have the upper lever in your hands, you need to knock out the hinges from it. But, of course, you shouldn’t hit it hard, since the rubber reflects the blow, so you can hit yourself in the eye with a hammer if you swing it well. It is best to use a puller for this purpose. If you are repairing a car, then you should have tools available. In particular, a good vice will not be superfluous. Now begins the replacement of the silent blocks of the VAZ-2106 lever, which you have been looking for for so long.

The lever is securely fixed in a vice. You put the puller on the hinge and, screwing in its nut, begin to press out the silent block. Before repairs, it is recommended to treat all components with penetrating lubricant - hinges. And if you do not want to suffer with the puller, then your only helper is fire. Just warm up the silent block under an open fire. All the rubber burns out, leaving only the metal part of the hinge, which is easily knocked out of the lever with one blow. Of course, this method can be called barbaric, but on the VAZ-2106, silent blocks can be replaced with its help. Especially in cases where the puller fails to remove the hinge.

Making a puller

As already written above, it is not recommended to remove this part from the car without a puller. When removing, you can hit the paw (lever) and damage it. Moreover, the worst thing here is microcracks that can come out at the most inopportune moment. This will lead to an accident. Hammering a new silent block into place damages the mounted part. Soon after the replacement, your car's suspension will begin to knock again. It is also possible that the wheel alignment angles may be disrupted (this is only possible on models with four-link suspension). In this case, you will not only get an extraordinary replacement of the joints, but also the need to purchase new wheels. A purchased tool, in this case, is not always the best choice. They are not always reliable. Also, you should buy them, but why spend money on something that you can easily make yourself from practically waste material. Another reason why people try to make such a device on their own is the need to change the hinge, but there is no puller at hand. First you need to figure out how the puller works. In the simplest version, by tightening the nut, the silent block is squeezed out of the lever eye. There are also hydraulic devices. They work on the same principle, but are driven in different ways. It is almost impossible to assemble a hydraulic puller in a garage. Therefore, we will make a screw version of the device.

To work you will need the following:

- Bolt. It is selected empirically;

- Cylinder. It should be slightly wider than the hole in which the silent block is placed;

- Several washers. One should reliably cover the cylinder hole. Sometimes it is simply welded onto one of its ends.

- The rest should be smaller than the diameter of the silent block;

- Suitable size nut.

- Remove the silent block axis. For greater convenience, it is better to remove the lever from the machine. But, on some models you can do the work directly on the car. We clamp the removed paw in a vice;

- To press out the hinge, you need to install a cylinder on one side. The bolt is inserted into the hole. Please note that its length should allow you to place several washers on the other side and screw on the nut;

- Place the washers and begin to tighten the nut on the resulting puller. Gradually, it will squeeze the silent block out of the mounting hole.

Dismantling without a puller

. In some cases, it may not be possible to make such an accommodation. Sometimes the task is simplified as much as possible; the silent blocks turn out to be so worn out that they can be removed by hand without any difficulty. You can also carefully knock them out through a wooden punch.

Conclusion

Replacing front arm silent blocks on VAZ-2110 cars

- Remove the engine splash guard.

- Remove and disconnect it from the lever.

- Holding the extension with a 24mm spanner, use a spanner of the same size to unscrew the extension nut.

- Using two 17" wrenches, unscrew the nut of the bolt securing the transverse stability to the lever. Use a soft metal drift to knock out and remove the bolt.

- Using two 19mm wrenches, unscrew the nut of the bolt securing the lever to the body. We remove (or knock out) the bolt and remove the lever from the bracket.

- Remove the washer and lever from the stretcher. On the extension behind the large washer there are washers for adjusting the pitch angle of the steering axis.

- To remove the brace from the cross member of the front suspension, use two 24mm wrenches to unscrew the nut, remove the washer and remove the brace from the silent block.

- To replace the silent block of the lever, press it out in a vice with suitable pieces of pipe (or use a puller).

- We wet the new silent block with soapy water and press it into the lever.

- We knock down the silent block of the guy wire with a chisel. Having removed one, we similarly dismantle the second. We pre-press the new silent block in a vice and finally press it by striking a drift with a diameter of 8 mm through three windows in the rubber layer.

To replace the front arm silent blocks on VAZ-2110 cars you will need:

- new silent blocks VAZ 2110;

- liquid soap (can be replaced with detergent or soapy water);

- standard set of wrenches (both socket and socket) for 24, 17 and 19;

- chisel and hammer;

- penetrating fluid WD-40;

- a universal cup puller or a piece of pipe, the diameter of which allows for free entry of the silent block;

- metal brush;

- knife and screwdriver (with a blunt end);

- inspection hole and jack;

- vice;

- gas burner or blowtorch.

Everyone knows that it is with the help of silent blocks that the angles of the car's wheels are influenced.

Therefore, it is very important to ensure that they are always in good condition. Replacing the front silent blocks of the VAZ 2110 in some cases is simply necessary. And it’s worth noting that replacing the front silent blocks on a VAZ 2110 can easily be done with your own hands

see also

Could there be a knocking noise in the VAZ 2110 due to the silent blocks of the rear beam?

- 0 4 515

Replacement of rear silent blocks of VAZ 2110

- 1 0 6k

Replacing the rubber-metal bushing of the rear shock absorber of a VAZ 2110

- 0 2 2k

The rubber bands flatten when the tension nut is tightened

- 0 3 938

What are the signs of worn silent blocks?

- 0 2 2k

Car silent blocks require monitoring and timely replacement. The service life of a silent block is up to 100,000 km , but Russian conditions dictate their own rules; silent blocks have to be replaced every 50,000 km .

Broken silent blocks of the front suspension arms on VAZ-2110 vehicles are indicated by a characteristic knocking or grinding sound that is heard when the car is moving. The car not only begins to rattle, but also loses stability on the road and becomes more difficult to control. It happens that when a car undergoes a wheel alignment, it is discovered that the silent blocks are faulty.

It is quite possible to change the silent blocks of a VAZ 2110 with your own hands. Of course, you will have to get dirty and spend several hours of your time to repair the car. The same procedure for replacing a set of silent blocks at a service station will cost 1100-1400 rubles . You can decide whether to take on the work yourself or entrust it to others after viewing this photo report.

It is worth noting that the photo instructions are based on the experience of car enthusiasts and contain tips for drivers with a minimum set of necessary tools. In the repair instructions you can find another solution to this problem.

Removing the rear block

Replacement of the rear beam is carried out after transporting the car to an inspection ditch or lift. To begin, remove the brake pads located at the rear of the VAZ 2110. Disconnect the steel ropes that secure the parking brake to the underside of the beam attached to the rear of the bracket.

Now disconnect the thin brake hoses leading to the brake cylinders located at the rear of the car. Disconnect the brake pipes attached to the beam. In addition, you will need to disconnect the elastic lever from the beam, which is located on the drive responsible for regulating the pressure.

Using a size 17 wrench, unscrew the 4 mounting bolts holding the hub axle together with the rear suspension beam. Remove the axle itself along with the brake mechanism shield and, if necessary, separate them by unscrewing the two fastening screws using a Phillips screwdriver. Bend the bracket and remove the brake pipe.

It is necessary to disconnect the lower ends of the shock absorbers and the nuts attaching the beams to the brackets from the beam

After this, you need to remove the bolts from the beam and carefully remove it. Using a size 17 socket, remove the 3 nuts securing the bracket to the body

Rear suspension structure: 1 — rubber-metal hinge; 2 — suspension arm mounting bracket; 3 — shock absorber casing; 4 — compression stroke buffer; 5 — casing cover; 6 — support washer; 7 — shock absorber cushion; 8 — spacer sleeve; 9 — shock absorber; 10 - insulating gasket; 11 — rear suspension spring; 12 — lever connector; 13 — rear suspension beam arm; 14 — shock absorber mounting bracket; 15 - flange; 16 — lever bushing

Axial play, what is it and how to eliminate it

This is a fairly common “disease” of the lower arm of domestic cars, and the VAZ 2110 is no exception. Backlash occurs when the bracket on the body to which the lever is attached has loosened for some reason, and a gap has appeared between the lever and the bushing, which is why the silent block begins to move inside the lever.

Axial play has a very negative effect on the operation of the front suspension, so, of course, it should not exist. If there is a backlash, it can be eliminated in several ways. First, you can try to slightly compress the bracket on the body. It will be very difficult to do this, because it is undesirable to hit the body with a hammer, and in order to use pliers or a clamp, you will need a fair amount of physical strength, and it will be inconvenient to work under the car with these tools.

It is much easier to eliminate axial play by placing several washers between the bracket and the silent block. Although according to the rules it is necessary to replace the entire lower arm along with the silent block.