At the stage of manufacturing car suspension springs, the last operation is to control the static load. Springs that do not fall within the tolerance are rejected, and the rest, depending on the obtained control load value, are divided into 2 classes. Springs with a positive load tolerance range belong to class A, and those with a minus tolerance – to class B. In this case, the suspension springs are marked with paint (a stripe is applied with a spray on the outside of the coils) corresponding to the class.

By hardness they are marked as follows: A - standard (hard); B - soft.

Color coding of springs by stiffness for VAZ

What to put?

Most of the springs installed on cars are marked with green (hard) or yellow paint (soft). The question arises: which ones to install, hard or not? Of course, class A or B springs have an equal right to exist. The division into classes was adopted to reduce the difference in the length of the springs on the right and left sides of the car - this is inevitable in mass production - which negatively affects handling and stability.

It is recommended to install only springs of the same class on the car. Of course, in some cases, it is allowed to install class A springs in the front suspension, and class B springs in the rear suspension. But, on the contrary, it is not possible. If you often drive with a full load, you should choose class A springs, because... They can withstand a little more load. You should know that the difference is insignificant and can range from 0 to 25 kilograms.

It’s time to replace the support ones, which is discussed in a new post, so I read a lot about the combination of support 2108 and cups 2110, supposedly 1.5 cm lower... (Do not confuse support 2110 and cups 2108, it will overwrite anyone because of the design) I didn’t go far, purely D2 Purchase Part 3 in general the last 29 They became a little lower. Part 1 (installation of suspension -50) Purchase part 3! in general, the last SS-20 Queen Racing (-10): REVIEW

In general, the guys claim that such a hodgepodge lowers the flow by another 1.5 cm, actually I asked myself a question and decided for myself, at the expense of what? The mating planes are at the same level, due to the fact that on the 2110 cups the spring is compressed by the same 1.5 cm due to the structure of the cup? Hmm, absurd... I threw it on old cartridges - everything is at the same level, I won’t risk it, and I don’t have time to experiment with my health, if anything. Or, I will be glad to have arguments.

When the rear of the car begins to sag significantly, the suspension springs need to be replaced. The “fatigue” of this part creates many inconveniences:

- the car's ground clearance decreases, which is why the muffler and rear end hit bumps on the roads and cling to the asphalt;

- Rubber friction occurs in the rear wheel arches;

- shock absorbers wear out more, which leads to damage to other parts of the suspension and body;

- the machine warps to one side (usually due to broken coils);

- the car sways, often violently.

Properties of suspension springs

When torsion bars on vehicles were replaced with springs, handling improved and suspensions became more convenient to maintain. Springs maintain the vehicle's ground clearance, reducing vibrations and shocks while the vehicle is moving.

To make the ride comfortable, you need to choose the right parts. If the technical characteristics are unsuitable, then the positive properties of the suspension will be reduced to zero. Therefore, it is important to consider the following parameters:

- diameter - its increase affects rigidity;

- number of turns - as the number increases, the rigidity decreases;

- form.

Often, car owners strive to install stiffer parts in the suspension. This helps to increase the sensitivity of the steering wheel to the driver's control, but the grip on the road deteriorates.

Fans of a sporty driving style believe that, on the contrary, it is better to install parts with reduced rigidity. However, this suspension can create problems on country roads.

Let's take a closer look at which springs are best installed on a VAZ.

Replacing springs yourself

Replacing a spring on a VAZ 2110

Tools

In such cases, it is simply impossible to do without repairing or replacing equipment. You must have the following tools, devices, and parts on hand:

- Keys with numbers "22" and "13".

- Jacks: screw and hydraulic.

- Bolonnik.

- Metal brush.

- Hammer.

Replacing a spring on a VAZ 2110

When each of the tools is near the car, you need to start replacing the front spring. This work involves some risk of injury. Such work must be performed with care, attention and compliance with all safety rules. Perhaps some help from an experienced mechanic would be helpful. Personnel can be found at the nearest service stations.

Correspondence of spring markings to the model

When installing springs on a VAZ suspension, it is advisable to ensure their compliance.

- 2101 install on rear-wheel drive sedans.

- 21012 is tougher, made from a larger diameter rod. Installed on a VAZ with left-hand drive, with special equipment, when a front suspension with increased energy intensity is needed.

- 2102 are installed on station wagons VAZ-2102, 21014. Their length is increased by 21 mm compared to 2101, so they are installed on sedans only when you often have to drive on country roads so as not to hit bumps - when installing 2102, the ground clearance under body They cannot be used to increase the load capacity, since they inevitably lead to premature destruction of the body.

- 2108 is installed on all front-wheel drive models, except for modifications with a 16-valve engine and Oka. By the way, in the markets they often deceive owners of VAZ-21099 sedans by offering to purchase scarce “99 springs”. In fact, there are ordinary “eighths” there, and “99ths” do not exist at all.

- 2110 European ones are installed on the rear suspensions of VAZ 21102-21104, 2112, 2114, on the front and rear suspensions 21122 and 21124. The European version is created for cars intended for export. The ground clearance here is reduced by 20 mm, the compliance of the springs is reduced in order to increase their stability at high speed when turning. The cross-country ability of vehicles on off-road and dirt roads is significantly deteriorated.

- 2111 are installed on the rear suspensions of VAZ 2111 and 2113.

- 2112 are installed on the front suspensions of VAZ 21103, 2112, 21113.

- 2121 is used on all-wheel drive models, except Oka.

Selection of springs and gas-filled shock absorbers

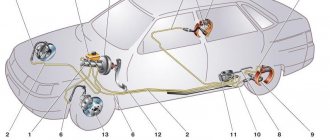

Rice. 1

| Lсж is the length of the shock absorber in the compressed position; Lstretch—the length of the shock absorber in the extended position (until it touches the travel stop); Lgab - overall length of the cartridge; H is the length of the pin to the beginning of the thread, to the first shoulder, to the end of the bushing or to the surface of the cone at a diameter equal to the outer diameter of the thread; P is the size before the beginning of the spring support coil. | Shock absorber type: PT - cartridge; D - two-pipe hydraulic; DG - two-pipe hydraulic with low gas pressure; O - single-pipe hydropneumatic. Mounting type: ШП - rod on top, eyelet on bottom; C - stand |

Many owners of the “ten” are sometimes forced to do suspension tuning.

Firstly, to be honest, the quality and service life of the factory suspension struts (especially the front ones, which are more loaded) leave much to be desired. Secondly, the already short-lived racks suffer most from the poor quality of our roads. Thirdly, with a very significant volume of luggage compartment, the “tens” do not have a high load capacity, so the inveterate summer resident and car traveler, willy-nilly, has to strengthen the elastic elements of the rear suspension. The main requirements for the shock absorbers of the front and rear suspensions are as follows: ensuring a smooth ride, stability and controllability of the car, reducing body roll during sudden braking, reducing the possibility of the wheel lifting off the road.

As a rule, when tuning, factory hydraulic telescopic shock absorbers are replaced with gas-filled ones - single-tube or double-tube. This allows you to raise the car slightly (increase ground clearance). The vehicle's handling and stability will also improve, since on uneven surfaces, stiffer shock absorbers allow the wheels to maintain contact with the road longer. The downside of such modifications to the car is a slight deterioration in the smoothness of the ride. When replacing shock absorbers, it is necessary to comply with the characteristics and overall mounting dimensions of the factory shock absorbers and those installed when replacing them. The suitability of shock absorbers is determined using interchangeability tables compiled by manufacturers. The main dimensions of shock absorbers are shown in Fig. 1 and in the table.

Basic parameters of shock absorbers

| Manufacturer | Designation | Type | rod diameter, mm | Outer diameter of the tank, mm | length in compressed position (Lсж), mm | Stroke of the rod* and (or) din in the extended position | Resistance force, N (at piston speed, m/s) | Tank color | |||

| Compression | Stretching | ||||||||||

| Throttle mode | Valve mode | Throttle mode | Valve mode | ||||||||

| Car front suspension | |||||||||||

| VAZ1 parameters | 2110-2905002/003 (left/right) | D | 22 | 52 | 361,9 | n.n. (167.4) Lrast=529.3 | 94 (0,105) | 153(0,314) | 612 (0,105) | 752 (0,314) | |

| SAAZ | 2110-2905002/003 (left/right) | Corresponds to VAZ values | |||||||||

| 2110-2905002-40 /003-40 (left/right) | Corresponds to VAZ values | ||||||||||

| GSAA | 22.2905008-50 | PT, D | 22 | 45 | 425 | 168 | n.n. | 208,7(0,314) | n.n. | 752(0,314) | |

| 19.1.2905008 | PT, O | 39,3 | 44 | n.n. | 110Lrast=543 | n.n. | 208,7(0,314) | n.n. | 752(0,314) | ||

| "Plaza" | AB 65.00.00 | PT, O | 38,02 | 45,3 | 409,5 | 111 | Corresponds to VAZ values*** | ||||

| AP12. 2905004 | PT, DG | 22 | 45,3 | 352** | 188 | Corresponds to VAZ values | |||||

| "Lada - Set" | 2210-2905002 / 003(left/right) | D | 22 | 52 | 361,5 | 167,6 | 98 (0,105) | 147 (0,314) | 617,4 (0,105) | 852,6 (0,314) | |

| 2210-2905002-10 / 003-10 (left/right) | DG | 22 | 52 | 361,5 | 167,6 | 113,68 (0,105) | 211,68 (0,314) | 705,6 (0,105) | 921.2 l(0.314) | ||

| KONI | 86-2621 SPECIAL Series | PT, D | 21,7 | 43,7 | n.d. | n.d. | n.d. | n.d. | n.d. | n.d. | |

| 8610-1348 Sport Series | PT, D | 21,7 | 43,7 | 410** | 168 | 320 (0,12) | 500 (0,33) | 390 (0,12) | 750 (0,33) | ||

| KAYABA | 665089 | PT, D | 22 | n.d. | n.d. | 174 Lrast=536** | n.d. | n.d. | n.d. | n.d. | |

| Car rear suspension | |||||||||||

| VAZ2 parameters | 2110-2915004 | D | 14 | 45 | 364,5 | n.n. (229) Lrast=593.5 | 153 (0,105) | 247 (0,314) | 565 (0,105) | 799 (0,314) | |

| SAAZ | 2110-2915004 2110-2915004-01 | Corresponds to VAZ values | |||||||||

| GZAA 12 49.2 | 45.2..2915006-10 | ABOUT | 12 | 49,2 | n.n. | 215 min Lrast=595 | n.n. | 255 (0,314) | n.n. | 803,6 (0,314) | |

| "Plaza" | AB 39. 00. 00-01 | 0 | 12 | 45,3 | 383 | 227,5 | Resistance forces increased l rear by 20% of VAZ values*** | ||||

| YES11. 2915004-10 | DG | 14 | 45,3 | 364** | 230 | Corresponds to VAZ values | |||||

| Lada-Kit" | 1410-2915004-10 | DG | 14 | 45 | 363 | 230,5 | 152,88 (0,105) | 246,96 (0,314) | 637 (0,105) | 862,4 (0,314) | |

| KONI | 80-2586 SPECIAL Series | D | 11,7 | 42 | 361** | 230 | 190 (0,12) | 300 (0,33) | 460 (0,12) | 750 (0,33) | |

| 80-2772 Sport Series | D | 11,7 | 42 | 408** | 183 | 330 (0,12) | 450 (0,33) | 600 (0,12) | 1000 (0,33) | ||

| KAYABA | 441055 | D | 16 | n.d. | n.d. | 215 Lrast=590** | n.d. | n.d. | n.d. | n.d. | |

Note.

1 – fastening type – C; H=16.5 mm max; Р=227 mm; SAAZ supplier; 2 – type of fastening ШП; H=30 mm max; P=258.5 mm; SAAZ supplier; * – from the fully compressed position to the fully extended position (until touching the travel stop); ** – size (L+H/2); *** – additional version; n.d. - no data; n.n. – they don’t standardize. Suspension springs take the weight of the car and soften the dynamic impacts transmitted to the body from the road surface when driving.

Spring characteristics

| 1 - linear; 2 — nonlinear (progressive) P is the load on the spring; f - spring deformation |

The spring characteristic shows the dependence of the spring deformation on the load on it.

The characteristic can be linear (stiffness remains constant for any deformation) or progressive (stiffness increases). Springs with a progressive characteristic increase the smoothness of the vehicle. Table 2. Marking of shock absorbers

| Shock absorber manufacturer | Shock absorber markings: contents (place and method) of the shock absorber | Manufacturer's logo |

| Skopin Automotive Assembly Plant (SAAZ), Skopin, Russia | Manufacturer's logo, shock absorber designation, month and year of manufacture (on the tank, impact stamping) | |

| Republican Unitary Enterprise "Grodno Automobile Unit Plant" (GZAA), Grodno, Belarus | The inscription “GZAA”, shock absorber designation, certification marks of Russia and Belarus, the inscription “Made in Belarus”, batch number, month and year of manufacture (on the tank, extruded) | |

| CJSC "Plaza", St. Petersburg, Russia | Trademark, mark of conformity, designation (bottom of tank, label) | |

| LLC "Lada-Komplekt", Syzran, Russia | Shock absorber designation, month and year of manufacture, manufacturer's trademark (knurling); serial number (label) | |

| KONI, Holland | Designation, date of issue, manufacturer (stamping) | |

| KAYABA, Japan | Designation, date of issue (bottom of the tank, branding) | |

| BILSTEIN, Germany | Designation, date of issue (bottom of the tank, impact stamp). Designation (in the middle of the tank, label) |

To obtain progressive characteristics, the working coils of the spring are made of different stiffnesses or are wound with variable pitch.

The rigidity of one turn depends on the shape (diameter) of the spring and the diameter of the rod, which can be variable along the length. As the load increases, the “soft” turns (or those with a smaller pitch) gradually fall on top of each other, ceasing to work, while the harder ones (or those wound with a larger pitch) continue to deform. However, at the points of contact of the “soft” coils, additional stresses arise, reducing the service life of the spring. The coils of the spring with a linear characteristic are compressed evenly, completely closing at maximum load.

There are no contact stresses; the spring, all other things being equal (steel grade, deformation, etc.), lasts longer. The suspensions of cars of the “tenth” family use cylindrical compression springs with a linear characteristic, wound from a rod of circular cross-section, constant in length.

It is better to purchase springs from those recommended by the car plant, from a manufacturer with a good reputation.

It is impossible to accurately determine the spring parameters when purchasing. All checks are approximate, but in many cases they will help to avoid counterfeits.

Springs in stores are often sold without packaging. However, its presence and information about the manufacturer indirectly indicate its reliability.

Markings on the spring (trademark of the manufacturer, month and year of manufacture, catalog number), contrary to OST, are applied extremely rarely by Russian manufacturers. But there is almost always a mark about sorting into groups (classes), and it must be the same on both springs purchased. If the groups (classes) are not marked or their markings do not correspond to the data in the table below, it is better to refrain from purchasing.

The quality of the surface of the rod, which affects the service life of the spring, is checked visually in factories (sometimes with a magnifying glass with a fivefold magnification) before painting. Therefore, minor defects will not be visible in the store. But obvious ones (large scratches, cracks, cavities) are unacceptable. The mark from the clamp (a dent similar to a bald spot) at the end of one of the end turns is not terrible.

The total number of turns of the spring is easy to count. The permissible deviation according to OST is ±0.125 turns (or ±45°), unless otherwise indicated in the table.

| Spring class paint marking. |

| The correct shape can be checked by rolling the spring over a flat surface - all coils must touch it in any position. If there is a gap of more than 1.5–2 mm for at least one turn, it is better to refrain from purchasing such a spring. Under load, the defect will appear more strongly, the coils will be loaded unevenly, and the durability of the spring will decrease. |

| The ends of the supporting turns must be perpendicular to the axis of the rod and have no burrs. The protrusion of the ends of the support coils beyond the outer cylindrical surface of the spring should not exceed the norm. |

| Burrs, excessive protrusion, and recessing will make it difficult to seat the spring in the support cup. |

Main parameters of springs

| Front suspension | Rear suspension | |||

| VAZ-2110, 2111 | VAZ-2112 | VAZ-2110, 2112 | VAZ-2111 | |

| Spring designation according to the catalog | 2108-2902712 | 2112-2902712 | 2110-2912712 | 2111-2912712 |

| Rod diameter before winding, mm | 12,9±0,05 | 13,2±0,05 | 11,6±0,05 | |

| Spring inner diameter, mm | 124,8±1,0 | 84,85±0,85 | ||

| Protective covering | enamel | epoxy | ||

| Coating thickness, mm | 0,10±0,05 | 0,10±0,05 | ||

| Total number of turns | 7±0,05 | 11,5±0,05 | ||

| Number of working turns | 5,5 | 10 | ||

| Spring height in free state, mm | 383,5 | 403 | 418 | |

| Control load, N (kgf) | 3188±118 (325±12) | 3482,55±137(355±14) | 3188±137 (325±14) | 3433,5±137(350±14) |

| Spring height at control load, mm | 211 | 240 | ||

| Groups (classes) of springs by control load, N (kgf) | class A - more than 3188 (325) class B - less than or equal to 3188 (325) | class A - more than 3482.5 class B - less than or equal to 3482.5 (355) | class A - more than 3188 (325) class B - less than or equal to 3188 (325) | class A - more than 3433.5 (350) class B - less than or equal to 3433.5 (350) |

| Designation of groups (classes) of springs | paint stripe: class A - yellow, class B - green | class A - stripe of orange paint class B - no mark | class A - no mark class B - stripe of black paint | paint stripe: class A - orange class B - blue |

| Marking location by group | outer side of middle turns | |||

| Spring stiffness, N/m (kgf/cm) | 18620±590 (19,0±0,6) | 20600±740 (21±0,75) | 19290±580 (19,7±0,60) | 20400±610 (20,8±0,62) |

The free height of the spring is not controlled in production. Even springs suitable for installation in a car may differ from each other by 6...8 mm. Nevertheless, it is advisable to compare the selected springs by placing them side by side. It is not recommended to buy springs with a difference in height of more than 10 mm or with a noticeable uneven pitch of the working coils.

| When measuring the internal diameter this way, errors will be significant. |

| Recommended measurement method. |

The diameters of the rod and spring can be measured with a micrometer and caliper, respectively.

But the measurements will be inaccurate - the profile of the rod will be slightly deformed during winding, and the inner diameter of the spring will have to be measured “obliquely”. When measuring the outer diameter, it is necessary to take into account the diameter of the rod - this is an additional error. In addition, an adjustment should be made for the thickness of the paint layer, and the diameters of the rod should be checked on all turns in different accessible positions and the average value should be determined. When comparing the measurement results with the data in the table, you need to take into account: a deviation from the nominal diameter of the rod by more than 0.2 mm, and from the internal diameter of the spring by 1.5–2 mm, is a reason to doubt whether the characteristics of the spring correspond to the specified ones.

Installing springs from a car of a different model or brand should in no case be a reason to increase the vehicle’s load capacity, since its other components and assemblies (body, brakes, shock absorbers, suspension guides) remain the same.

In addition, using springs that are too high can greatly reduce the downward travel of the wheel. When driving an unloaded car on an uneven road, jerking will be felt, the smoothness of the ride will decrease, and the load on the body will increase.

Springs (and shock absorbers) should only be replaced in pairs (on the front and/or rear axle).

Choice depending on manufacturer

Often, when parts break down, drivers try to buy original factory parts as replacements, not wanting to experiment. However, there is a decent choice from other manufacturers, whose products are sometimes no worse than the original ones.

Sirius

There is a large assortment for different brands of cars, and parts are also manufactured in any configuration according to customer drawings.

Phobos

The quality is satisfactory, but, according to some car enthusiasts, after 2 years they begin to sag, losing rigidity. In total, about 500 types of springs are manufactured under this brand for any brand of car; there are standard, reinforced and lowered springs. Clearance kits with increased ground clearance are also available.

Technospring

Good quality for little money. They lose rigidity over time, but do not sag. Quite good as a budget option.

Very durable, no sagging. They have a stiffness adjustment directly on the car, done with a special thumb under the hood.

Eibach

High-quality, very durable, practically do not “age” - do not sag, do not lose rigidity. There is no roll when turning. But they cost one and a half times more than Koni.

Products of the SS20 brand undergo mandatory testing at test benches, after which they are selected in pairs with similar characteristics. This check ensures, according to the manufacturer, 100 percent product quality. A large assortment allows you to choose the right characteristics depending on your driving style and operating conditions. There are 3 options available:

- hot coiling of standard height with linear compression characteristic;

- cold coiling of standard height with linear and progressive compression characteristics;

- cold coils are lowered, with a progressive compression characteristic.

Kilen

Alternative original springs from Kilen are of the highest quality. The service life, as the manufacturers claim, is twice as long as the original VAZ products.

Asomi

Excellent springs made from special alloys, coated with epoxy coating to increase service life.

Recommendations for changing front springs

In order to carry out such repairs yourself, it is necessary to follow a certain technological sequence.

- You need to disassemble the front wheel. The side where the spring needs to be replaced is disassembled.

- The wheel is removed.

- The steering wheel turns in the direction opposite to the removed wheel.

- The cotter pin is removed.

- The nut connecting the steering rod and the strut is unscrewed.

- The finger is being removed. For this type of work you need a puller. If it is missing, there is no need to completely remove the nut. It is enough to make the fastening weaker and remove the finger with light blows of a hammer.

- The brake hose coupling is removed.

- The upper part of the guide post rests on a rubber plug. It must be replaced.

- The shock absorber rod mount is unscrewed. To prevent the nut from turning, you need to firmly clamp the opposite part.

- Before releasing the bolt holding the strut, you need to mark the mounting bracket and the bolt itself.

- The nut tightening the upper bolt is unscrewed. There should be no scrolling. If necessary, it must be firmly secured.

- The washer is removed. Using a drift, the bolt is released. The lower bolt is removed using a similar method.

- The steering wheel tip is released. There should be no sagging of the brake hose. Its tense position is not allowed.

- The upper support is secured with three nuts. Each one needs to be unscrewed with a 13 key.

- The stand is removed, the ties are installed at the same level on the springs. Typically five turns are attached.

- The tie screws are turned until the spring is completely free. The spring is removed.

After all operations, each part must be thoroughly washed with white spirit. Then the new springs are secured with ties. Slowly tightening the screws of the ties gradually compresses the spring. Then, without removing the spring ties, the front strut is mounted to the lower support. The upper support of the new spring is installed.

Replacing springs on a VAZ 2110 (rear)

The technology for replacing rear suspension springs involves completely dismantling the struts. However, do not be afraid - there is nothing complicated about it. The first step is to remove the plastic plug on the strut cups and unscrew the top nut on the shock absorber rod. A special wrench will help us with this: having two degrees of freedom, it prevents the rack from turning when trying to unscrew the nut. This key can be freely purchased at any VAZ spare parts store.

Under the nut there will be a large metal washer and a rubber pad. It will be extremely convenient to remove them from the glass using a screwdriver with a magnetic handle. Now it's finally time to use the jack, lifting the rear of the body and tilting the wheel to the side. It will be convenient to loosen its mounting bolts while the VAZ 2110 is still on the ground. It is correct to place the removed wheel under the car body as a jack insurance.

Next we proceed on the following points:

- 1. Unscrew the nut securing the lower part of the strut to the rear suspension of our car (penetrating lubricant will help you);

- 2. We pry the shock absorber with a lever, removing it from its seat in the beam, after which it will freely fall to the floor;

- 3. Don’t forget to remove the special rubber band from the inside of the glass, which is likely to stick to the car body;

- 4. You can now freely remove the spring from the strut. The replacement is almost complete;

- 5. You can also visually check the technical condition of the rack and the condition of the anthers.

Please note that there is a special protrusion on the stand cup where the lowermost coil of the spring fits. When installed, it faces the direction of the wheel. It will be convenient to tape the upper rubber gasket to the spring with electrical tape so that during installation its protrusion does not move relative to the coil. Further assembly is performed in reverse order.

Replacing springs on a VAZ 2110 (front)

In a classic way, we begin the replacement process by loosening the nut that secures the strut in the car's glass. There is no need to unscrew it completely. Jack up the front of the car and remove the wheel. Don’t forget about insuring the jack as in the previous section. Then everything is done simply and point by point:

- 1. Take penetrating lubricant in your hands and pre-wet the nuts securing the steering tip and the swing arm to the front pillar of the VAZ 2110;

- 2. Next, armed with one 17 and one 19 wrench, unscrew the above-mentioned nuts;

- 3. It is convenient to remove the steering end from the ball joint using a special puller. You can, of course, do it the old-fashioned way, with the help of a guide and a hammer. But in the latter case, you should be extremely careful not to damage the tip itself;

- 4. We knock out the bolts of the swing arm using the adapter. After which you can move the stand and brake disc assembly with the VAZ 2110 caliper to the side;

- 5. Don't forget to also remove the brake hose from its engagement with the strut;

- 6. Return to the top of the strut and use a 13mm wrench to unscrew the 3 nuts securing the shock absorber support, and the entire strut structure along with the spring is no longer held in place under the hood of the car. You can immediately begin disassembling the shock-absorbing module.