Print this article Font size 16

It is quite simple to determine the malfunction of the release bearing on the VAZ 2109 by the characteristic symptoms. Today we will talk about signs of wear on an element, and also tell you in detail how to replace it.

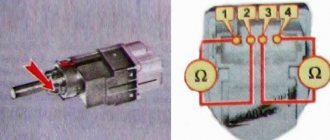

Element appearance

Signs and causes of clutch failure

The VAZ 2108, 2109, 21099 clutch consists of a basket, a pressure bearing, a drive and driven disk. The main signs of a clutch malfunction are clutch slipping and incomplete disengagement:

- When switching off is incomplete (the pedal is pressed), there is difficulty shifting gears with the engine running, noise and crackling noises when changing gears, and large free play of the clutch pedal.

- When the clutch “slips” (the pedal is released), a burning smell may be felt in the cabin from the burning of the clutch disc linings, the car’s dynamics will deteriorate, the engine may overheat, and fuel consumption will increase.

Most often, the cause of a breakdown of the VAZ 2109 clutch is improper operation of the car. For example, if the car “sits down” in the snow and you continue to accelerate hard, or really like to start with slipping, all this shortens the life of the clutch.

In addition to the clutch disc itself, the release bearing can also fail - it serves to smoothly engage and disengage the clutch. When the release bearing wears out to the limit, you can hear a characteristic squealing sound - this is a sure sign that the bearing needs to be replaced. The cause of clutch failure may also be a breakdown in its drive mechanism, for example, a break or jamming of the clutch drive cable, a breakdown of the lever system, a fluid leak from the hydraulic drive if the clutch is hydraulic, or other similar breakdowns in the drive.

By the way, when replacing the release bearing at a service station, they may advise you to also replace the clutch disc. Usually, if problems begin with the clutch, it is better to replace all these parts, because replacing the clutch is very difficult: you need to remove the gearbox. But if someone wants to save on this, then all clutch parts can be purchased separately.

To work you will need the following:

- wrenches 8, 10, 13, 17 mm;

- torque wrench, 8 mm socket;

- jack;

- container for draining oil;

- inspection hole or lift.

- flat screwdriver, hammer.

When removing or installing the gearbox, do not rest the input shaft of the gearbox on the clutch pressure spring petals, so as not to damage them.

Clutch selection

When choosing a clutch kit, you should focus not only on your available budget. By saving or buying a fake, you risk getting even more problems in the future.

Valeo kit

Today there are several main manufacturers whose clutches should be purchased for the VAZ 2109.

| Manufacturer | Peculiarities |

| VIS | This is a stock clutch that the VAZ 2109 is equipped with from the factory. If there are laser markings on the discs, this is definitely not a fake. Plus, the company allows you to send an SMS indicating an identification code. If it is a fake, you will be notified accordingly. Not bad quality, but nothing special can be said about them. |

| Valeo | A French manufacturer, which is actively counterfeited on the domestic market. To catch fraud, pay attention to the cost and quality of components. Although the brand is from France, Valeo couplings can be produced in Italy, Spain, and South Korea. Good quality components ensuring smooth, easy operation. Perfect for female drivers. If you use the clutch correctly, it will last for about 150 thousand kilometers. The flywheel is almost eternal, and the discs are not afraid of overheating within acceptable limits. |

| Luk | A German company that has proven itself well in its homeland and has also earned a lot of praise among Russian motorists. They dampen vibrations perfectly, and real Luk clutches always have an element for damping vibrations of the pressure and driven disk. |

| Kraft | You can only find negative reviews about Kraft couplings from competitors. An impressive part of the sets under the Kraft brand, presented in Russia, were produced in Turkey, but under a German license. The kit includes a soft release bearing that performs well even under heavy use. The flywheel is very durable. On average, the clutch can withstand 150 thousand kilometers. But if you don’t spare the clutch, the service life will be significantly reduced. |

Kraft kit

Regardless of the quality of the selected kit, if it is installed incorrectly or due to rough operation of the vehicle, the life of the clutch will not reach those declared by the manufacturer. Therefore, drive your car accordingly.

Replacing the clutch on a VAZ 2109/21099 without removing the gearbox

Replacing the VAZ 2109/21099 clutch without removing the gearbox is quite difficult. You will not find instructions or recommendations on this topic in the car's owner's manual. These recommendations are based on the experience of car enthusiasts who share their experience of replacing the clutch.

The main problem when replacing a clutch is that not every motorist has an overpass, a pit, and especially a lift, and it is necessary to make sure that the massive gearbox does not fall to the ground. But lifting it is problematic, since it is impossible to crawl under the car with it. All steps for removing the gearbox are almost the same as the instructions above, with the exception of some nuances:

- Purchase two bolts from the upper arm of the classic front suspension from the store. Their threads are exactly the same as those on the bolts that secure the box and the engine block together.

- Screw them in from above, only after that, with a small crowbar or screwdriver, we begin to disconnect the nodes. After moving away, the rear part of the box will rest on the transverse rod, and a gap of about 15 centimeters will form between the clutch housing and the flywheel.

- The release bearing is removed through the resulting gap and the bolts on the basket are unscrewed.

But the installation is slightly different from the process shown in the instructions:

- Place the new release valve in its place. Then a disk is installed on the flywheel and a basket on top of it.

- Just tighten the bolts a couple of turns, but do not overtighten!

- Carefully begin to slide the input shaft onto the splines in the disc.

- Then we move the box back and tighten the bolts on the basket. The basket fastening bolts are tightened only after the box is installed in its place.

- After this, you can install the gearbox and tighten the bolts on it.

When replacing the clutch without removing the gearbox on a VAZ 2109/21099 car, there is no need to center the disc!

Which clutch bearing should I install?

The original clutch bearing number is 2108 1601182.

- Pilenga PC-P 2108 — 360 rub.

- Luk 500 0439 20 — 1156 rub.

- Fenox TP2116C3 — 345 rub.

We remove the “negative” terminal from the battery “4”, remove the connector from the mass air flow sensor (MAF) “2”, loosen the clamp securing the corrugation to the MAF “3”, remove the air filter housing “1” from the car.

Remove the clutch cable from the clutch fork. Loosen the two nuts securing the cable to the bracket on the gearbox.

Remove the clutch protective cover. Disconnect the ground wire and the top dead center sensor from the clutch housing. Disconnect the wires from the reverse light switch. Drain the oil.

Unscrew the 3 bolts securing the bracket to the body. Unscrew the nut securing the arm extension.

We jack up the car. We remove two bolts “1” and disconnect the ball joint of the suspension arm from the steering knuckle. Unscrew the nut “2” securing the brace to the suspension arm, and remove the longitudinal brace together with the lever.

We remove the wheel, unscrew the hub nut and unscrew the fastening of the ball joint to the steering knuckle, then remove the CV joint from the bearing hole.

Having rested the pry bar against the gearbox housing, we press the internal drive joint from the side gear, to do this we sharply hit the body of the internal joint with a hammer. We knock out the hinge from the side gear.

Mounting a ball joint without front wheel drive.

Loosen the clamp and disconnect the gear shift rod from the gear selection hinge. It is also necessary to support the engine, otherwise it may drop too low and tear off the interior heater hoses.

Having unscrewed the bolts securing the rear suspension support of the power unit, remove the suspension bracket from the eyes of the body spar.

Using a 17mm wrench, unscrew the nut and remove the bolt of the left engine mount. Unscrew the three starter mounting nuts and remove the starter.

Using a 19mm wrench, unscrew the three bolts and one nut securing the clutch housing to the cylinder block, remove the gearbox from the engine and remove it.

Using an 8-mm spanner, unscrew the six bolts securing the clutch housing to the flywheel. To loosen the bolts easily, tap their heads with a copper hammer. You can also use a 8mm socket to loosen the bolts.

Remove the driven and driven clutch discs. We check the degree of wear of the friction linings. If the rivet heads are recessed less than 0.2 mm, the surface of the friction linings is oily or the rivet joints are loose, the disc must be replaced. Cracks or mechanical damage to parts of the driven disk are not allowed.

If a visual inspection reveals loosening of the rivet connections of the clutch basket and drive disc parts, the clutch drive disc assembly should be replaced.

Lubricate the release bearing seat on the shaft, as well as the clutch guide forks, then install the bearing.

When installing the clutch, we orient the driven disk with its protruding part towards the drive disk and insert the centering mandrel.

We insert the mandrel into the hole in the crankshaft and secure the clutch drive disc in this position, tightening the bolts evenly (one turn per pass). We tighten the bolts no more than one turn each, so as not to deform the flange of the clutch drive disc. We assemble everything in reverse order.

It is quite simple to determine the malfunction of the release bearing on the VAZ 2109 by the characteristic symptoms. Today we will talk about signs of wear on an element, and also tell you in detail how to replace it.

Element appearance

Order of Operations

To carry out repair work, you need to place the car on an inspection hole, put it on the handbrake, disconnect the negative terminal to de-energize the on-board network, and remove the engine mudguard. Now you can start disassembling:

- Install a jack that will temporarily replace the front pair of wheels. You need to unscrew the nuts on them, remove the chassis and put them aside.

- To remove the contact part of the ball joint from the hub, you need to unscrew the bolts.

- Instead of the 2 upper conventional bolts, you need to install cylinder head fasteners.

Now you can remove the starter; it is attached to three nuts that need to be unscrewed.

At this stage it is necessary to install a jack under the engine. After this, the side motor support is detached.

After this, you can disconnect the rear engine mount and unscrew the gearshift linkage.

The protective cover must be removed from the clutch.

- The box is secured with several bolts; first you need to unscrew the front one.

- Now the transmission is accessible, the rear nut is unscrewed first.

The gearbox bolts are located on the left wing side; they need to be unscrewed until they stop and the gearbox should be removed. It is important to ensure that the end of the assembly rests on the lever extension. This will create a gap that will allow you to remove the clutch. IMG9

Disassembly is complete. At this point, the guide for the clutch remains. It needs to be thoroughly lubricated. After this, you can put the release bearing on the guide.

- Subsequent operations are performed in the reverse order of the above steps. Important! There is no need to rush while completing the work. All operations are performed consistently and calmly. Make sure that after assembly there are no “extra” spare parts left.

How to replace a VAZ 21099 clutch, watch this video:

Replacement

Not all car owners decide to replace the release bearing (TR) themselves. But if you are ready for this kind of work, then go for it.

VI components

The main difficulty in replacing the gearbox is the need to dismantle the gearbox. Without this event, it will not be possible to replace the component.

Therefore, think twice before making a final decision. There is always the opportunity to contact a car service.

To work you will need the following set of tools and materials:

- Set of wrenches;

- Jack;

- Several durable bricks;

- New release bearing;

- Screwdriver Set;

- Container for draining transmission fluid;

- Clutch holder;

- Garage with a pit or lifting mechanism.

It is better to divide the entire replacement procedure into two main stages.

- Removing the gearbox.

- Bearing replacement.

Many people make the mistake of relaxing too much when they finally change the bearing. In practice, reassembly often causes more problems than dismantling work. Please take this into account.

Dismantling the gearbox

- Place the car over a hole or overpass.

- Lift the hood, remove the negative terminal from the battery and throw it aside.

- Disconnect the ground wire from the clutch housing.

- Use a screwdriver to remove the engine splash guard. To do this, you need to unscrew several screws that hold the mudguard to the elements of the side wings. For the VAZ 2109, a key size of 8 is used. Having removed all the screws there, remove the parts of the engine mudguard and put them away for now.

- Disconnect the transmission drive rod. To do this, use a 13mm wrench to loosen the clamp bolts. Next, use a screwdriver to separate the ends of the clamp and disconnect the element from the gearbox.

- Be sure to disable the reverse optics sensor.

- Place blocks or bricks under the rear wheels of the car to prevent the car from moving.

- Remove the front wheels by first loosening the bolts and lifting the front part of the body. After removing the wheels, place pre-prepared bricks under the body.

- Using a 17 wrench, unscrew the nuts securing the ball joint to the steering knuckle on both sides.

- The extension is moved to the side, and the fastening screws of the left extension to the vehicle's suspension arm are unscrewed.

- Using a 10 mm wrench, remove the fasteners of the lower clutch housing cover.

- Remove the transmission mounts. This is done as follows. Place supports or bricks under the engine and a jack under the box. Unscrew the mounting screws of the support to the body with a 17mm wrench. After removing the bolt, remove the support bracket by unscrewing several corresponding nuts.

- We proceed directly to dismantling the gearbox. Using a 19 wrench, unscrew the fasteners of the clutch housing to the cylinder block. Use a jack to lower the gearbox slightly and move it away from the engine. Lower until the input shaft begins to come out of the box.

- Enlist the support of a partner, since it is quite difficult to remove the gearbox alone.

- Make sure that the gearbox input shaft does not rest on the clutch spring petals. If you allow this situation to happen, you will simply damage them.

- Carefully place the gearbox on the supports, being careful not to hit it. Otherwise, repairs will cost much more than buying a new bearing.

Removing the box

Removing the VAZ 2109 box

- The mudguard and engine crankcase protection are dismantled;

- The oil is drained from the gearbox;

- The drive nuts break off.

Note. It is necessary to turn off the power to the battery and hang the front of the car using reliable supports.

- The clutch cable is dismantled;

- The speedometer cable is turned off;

- The bolts securing the ball joints are unscrewed;

- The longitudinal stretch is removed;

- The drives are pulled out of the gearbox.

Note. To prevent the differential from turning or falling apart, a special stopper is inserted into the gearbox.

- It's time to remove the starter;

- After which the reverse speed sensor is dismantled;

- The flywheel protective casing is separated from the box;

- The gearbox linkage is detached (the position should be marked before removing it);

- The bolts securing the gearbox to the engine are unscrewed one by one.

Note. It is imperative to secure the engine with a hydraulic jack or something else.

- We unscrew all the gearbox supports that connect the box to the car body;

- We weigh the box away from the engine (you can’t do it alone, you need an assistant).

Note. Only about 10 cm is enough for the input shaft to pop out of the clutch basket.

We remove the box, but do it very carefully so as not to damage the input shaft.

What to do next

First we install the guide, the disk, tighten the basket, then remove the guide and put on the box. How to replace the clutch on a VAZ-2109?

Do not forget to lubricate the splines inside the clutch disc with oil or lithol before installation. This is necessary to make it easier to put on the box. It is also easy to put on; unlike foreign cars, there is no need to remove the subframe. There is no muffler at the front, everything is very convenient and good. All that remains is to look at the tension of the handbrake, some electrical nuances, and the rest was done. The grip was exceptional.

Tools required for repairs

To replace the VAZ 2109 clutch basket you need to prepare the following tools:

- standard set of keys;

- jack.

Do-it-yourself repairs are quite advisable, since the price for replacing a VAZ 2109 clutch as of March 3, 2022, on average in car services is 3.2 thousand rubles.

On a note! At a car service center, the work will be completed in one and a half to two hours, since the service station has lifts and overpasses. The most difficult part of the work is disassembly and assembly; replacing parts and the unit itself takes no more than half an hour. When working in the garage yourself, you can spend one or several days on dismantling and installation.

But self-repair is quite accessible even without an assistant, and without completely removing the gearbox. The principle of repair and the sequence of work are identical for models 2108-2115, so we suggest you see how such dismantling is performed on a VAZ 2114:

Increased noise when turned on

- If there is increased noise when the clutch engages, this indicates wear or damage to the release bearing. There may also be a grease leak from the release bearing. The solution is to replace the bearing (step-by-step instructions for the process are given below).

- Increased noise when the clutch is engaged can also be caused by a breakdown of the damper springs that make up the clutch driven disc. In this case, you will have to replace the driven disk itself.

- If jerking is observed when shifting the clutch, then the friction linings may have become oiled. Remedy: Thoroughly rinse the surfaces of the linings with a special liquid and be sure to replace worn gearbox and engine seals.

- Jerking can be caused by jamming in the clutch release drive. To eliminate this problem, you first need to find the reasons that contribute to the jamming. Then replace these same parts.

Clutch device VAZ 2107-2101

Replacing the VAZ 2107 clutch with your own hands without knowledge of the operating process and design of this unit is practically impossible, due to its structural design. This unit is the most important part for transmitting torque from the engine to the transmission, which, accordingly, allows the car to move. The part was developed a long time ago and did not undergo any fundamental changes during the production of this model. Therefore, regardless of the year of production of the machine, a single standard model of the unit is installed.

Let's summarize

If the check shows that the free play is normal, but you doubt your competence in adjusting the unit, contact a service station. Incorrect settings can cause rapid clutch failure. If you want to complete the work yourself, you can find the necessary information on the vehicle manufacturer’s website or in its service book. It is important to complete the work in a timely manner so as not to get into an unpleasant situation on the road. Monitor the service life of clutch parts; for example, the service life of the driven disc is 100 thousand kilometers. But, if a motorist has an aggressive driving style, it can decrease by 2-3 times.

How to replace the clutch - next steps

Remove the speedometer limit switch. All we have to do is turn off the cardan, which is located under the boot. Unscrew the stopper. They disconnected everything from above and unscrewed it, removing the clutch pedal cable.

Now you need to unscrew the rear airbag. The engine will hang, the box will tilt down a little. We unscrew the bolt securing the pillow to the side member and pull it to the side. Due to the fact that the engine is suspended, the box can flop around. We check that all the bolts have been unscrewed. Let's take a small montage. If you are removing the box for the first time, then place a board under it. Otherwise, without knowing the actual weight of the gearbox, you may drop it.

You will have to lower the engine a little, since the bracket does not allow the box to come out. With a slight movement of your hand, remove the box. Her weight is twenty kilograms. The problem was with the clutch, we see a half-dead release bearing, worn out petals that were sticking. Water got into the basket and there was rust.

Next, let's see how worn the clutch basket is. Here we see a leak of antifreeze from under the pipe. The wear on the clutch disc is visible. The car has traveled many kilometers, not 150 thousand, but more. The bolts all unscrew like clockwork.

Let's put another basket. Try to choose a clutch disc with a large number of springs and a clutch with a large number of petals, then everything will work smoothly. There is very little left to do to replace the clutch. Assembly is carried out in reverse order.

Worn clutch release bearing

Clutch VAZ 2109

Typically, those who like to drive fast are more likely to encounter the problem of bearing wear. At the same time, people who are supporters of quiet driving have often never even heard of this problem. If it is noticeable that the bearing is failing, it urgently needs to be replaced, otherwise:

- The very next trip can be fatal for the car.

- The disc will overheat, causing the pads to crumble.

- It will be necessary to change not only the bearing, but also the clutch disc.

- In addition, the clutch itself can become “covered.” A sign of this may be an incomprehensible noise coming from it.

To change the release bearing, you will need to completely disassemble the entire assembly, and this is a rather labor-intensive process.

How to replace

Clutch for VAZ 2109

To ensure that replacing the clutch bearing does not cause inconvenience, it is advisable to drive the car onto a lift or place it over an inspection hole.

Note: bearing replacement can also be carried out in “field” conditions, that is, with a jack

However, it is very important to ensure that the car does not roll down

Replacement occurs as follows:

- Remove the negative battery terminal.

- Disconnect the flashlight connector.

- Disconnect the driveshaft.

- Remove the slave cylinder.

- Remove the gearbox, which is secured by several large bolts.

Note: to make this easier, you can bend the gear knob all the way. At the same time, the handle must not be allowed to “hang” freely. It is advisable to provide it with reliable support.

Once you have access to the clutch basket, you can begin removing it. To do this, unscrew the bolts that secure it to the flywheel (it must be completely motionless).

Note: You can use a large screwdriver for this.

- Pull out the clutch release fork.

- Remove the bearing.

- Change it.

- Press in properly using a key.

- Wipe the surface of all parts with a degreaser to remove dirt and foreign objects. This may cause the car to slip.

- Reassemble everything in reverse order.

Note: Before you begin assembling the gearbox, it is advisable to apply a little lubricant to the sprockets of the input shaft.

- When all the parts are assembled, the clutch should be adjusted.

- The length of the working cylinder should be slightly reduced.

Replacing the clutch bearing can be done at home and with your own hands. Usually in car services the price of this procedure is quite high. Therefore, if you want to save your money, you need to give preference to home repairs. Any instructions will also help you quickly and begin to review many photos and videos on this topic. perform quality work.

1200 rub. for the photo report

We pay for photo reports on car repairs. Earnings from 10,000 rubles/month.

Write:

Clutch failure is one of the troubles that can await a driver on the road. Usually, the car simply stops moving, even though the engine is running normally. Such a breakdown does not always occur suddenly; often before this you can observe some signs of an imminent breakdown.

Symptoms of malfunction

The clutch release bearing itself will tell you that its life is already at its limit or it has completely failed. Therefore, your task is to monitor the behavior of the car and promptly respond to emerging problems.

Sign of breakdown

Peculiarities

The clutch pedal becomes hard to press

Initially, this only causes a certain discomfort, since you have to apply more force to change gears. But this phenomenon should not be ignored. Bearing needs to be replaced

Difficulty engaging first and reverse gears

This indicates that the bearing's life is gradually ending, and you urgently need to take action. If you don't do this, you will soon be unable to engage any of the gears in your transmission.

The car doesn't pull

There is a loss of efficiency and performance of the box. Consequently, it is not possible to change gears correctly and quickly. This makes maneuvers, overtaking and a banal increase in speed more difficult.

This happens occasionally at first, and therefore almost every time you change gears. This symptom clearly indicates that it is time to send the car to a service station or garage for repairs.

Old and new VP

If the release bearing is not replaced in a timely manner, the gearbox will soon fail, the clutch will not work, and this will lead to dire consequences.

Consequences of wear

If you have encountered such a phenomenon as wear of the clutch release bearing, then you probably often drive your own VAZ 2109. It is time and the many kilometers traveled that lead to such breakdowns.

If the bearing is not replaced in time, this will result in the following consequences:

- Any subsequent trip may be the last for the car;

- The clutch disc will overheat, which will lead to destruction of the lining;

- In addition to replacing the bearing, you will have to replace the entire clutch disc;

- It is not uncommon for the clutch to fail. If you hear an incomprehensible noise coming from the clutch system, then there is a problem with it.

Required spare parts

To install the VAZ 2109 clutch you will need a new unit. It is better to take models recommended by the machine manufacturer with article numbers 2109-1601000, 801122, 2108-1601085, FR 761. The price of the set depends on the manufacturer and seller, ranging from 2300 to 3600 rubles.