IA Neftegaz.RU.

Liquefied Natural Gas (LNG) is natural gas artificially liquefied by cooling to -160°C for ease of storage and transportation. LNG is a colorless, odorless liquid whose density is 2 times less than the density of water. 75-99% consists of methane. Boiling point − 158…−163°C. In a liquid state, it is non-flammable, non-toxic, and non-aggressive. For use, it is evaporated to its original state. When vapors burn, carbon dioxide (carbon dioxide, CO2) and water vapor are formed. In industry, gas is liquefied both for use as a final product and for use in combination with low-temperature fractionation processes of APG and natural gases, which make it possible to separate gas gasoline, butanes, propane and ethane, and helium from these gases. LNG is produced from natural gas by compression followed by cooling. When liquefied, natural gas decreases in volume by approximately 600 times.

When does a gas turn into a liquid?

To evaporate any liquid, heat must be supplied to it (it is called the heat of evaporation). The evaporation of liquid nitrogen, liquid hydrogen or liquid helium occurs at low temperatures. By evaporating liquid helium in a vacuum, it is possible to obtain a temperature only 0.7 K above absolute zero. ...

Interesting materials:

What is the most delicious beer in Belarus? What generation of Intel processors? What field exists around moving electric charges? Which hemisphere of the brain is more developed in left-handed people? What kind of government is there in Canada? What nickname did Alexander Sergeevich have at the Tsarskoye Selo Lyceum near St. Petersburg? What is the distance between Anapa and Sochi? What is the distance from Odessa to Turkey across the sea? What decision can the appellate court make? What's the safest place?

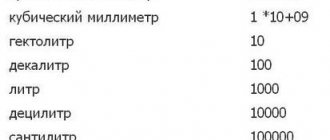

Converting 1 ton of LNG to cubic meters (m3).

1 ton of LNG is approximately 1.38 thousand m3 of natural gas after regasification. Approximately - because the density of gas and components is different in different fields. No one has canceled the Mendeleev-Claiperon formula. In addition to methane, natural gas may include ethane, propane, butane and some other substances. The gas density varies in the range of 0.68 - 0.85 kg/m³, but depends not only on the composition, but also on the pressure and temperature at the place where the gas density is calculated. Standard conditions for temperature and pressure are the physical conditions established by the standard to which the properties of substances that depend on these conditions are correlated. The National Institute of Standards and Technology (NIST) specifies a temperature of 20 °C (293.15 K) and an absolute pressure of 1 atm (101.325 kPa), and this standard is called normal temperature and pressure (NTP). The densities of gas components vary greatly:

- Methane - 0.668 kg/m³,

- Ethane - 1.263 kg/m³,

- Propane - 1.872 kg/m³.

Therefore, depending on the component composition, the amount of m3 of gas changes when converted from tons.

Conversion of 1 m³ of LNG into 1 m³ of regasified natural gas

The proportions also depend on the component composition. On average, the ratio is 1: 600. 1 m³ of LNG is approximately 600 m3 of natural gas after regasification.

The liquefaction process occurs in stages, at each of which the gas is compressed 5-12 times, then cooled and transferred to the next stage. Liquefaction itself occurs during cooling after the last stage of compression. The liquefaction process thus requires significant energy consumption - up to 25% of the amount contained in the liquefied gas.

Currently, 2 technical processes are used:

- condensation at constant pressure (compression), which is quite inefficient due to energy consumption,

- heat exchange processes: refrigeration - using a cooler and turbo-expander / throttling to obtain the required temperature with a sharp expansion of gas.

In gas liquefaction processes, the efficiency of heat exchange equipment and thermal insulation materials is important.

During heat exchange in the cryogenic region, an increase in the temperature difference between the flows by only 0.5ºC can lead to additional power consumption in the range of 2 - 5 kW for compression of every 100 thousand m3 of gas.

The disadvantage of throttling technology is the low liquefaction coefficient - up to 4%, which requires multiple distillation.

The use of a compressor-expander scheme makes it possible to increase the efficiency of gas cooling by up to 14% due to the work performed on the turbine blades.

Thermodynamic schemes allow achieving 100% efficiency of natural gas liquefaction:

- cascade cycle with sequential use of propane, ethylene and methane as refrigerants by successively reducing their boiling point,

- dual refrigerant cycle - a mixture of ethane and methane,

- expansion liquefaction cycles.

There are 7 different technologies and methods for liquefying natural gas:

- for the production of large volumes of LNG, the leading technological processes are AP-SMR™, AP-C3MR™ and AP-X™ with a market share of 82% from Air Products,

- Optimized Cascade technology developed by ConocoPhillips,

- use of compact GTL units intended for internal use in industrial plants,

- local LNG production plants can be widely used for the production of natural gas motor fuel (GMF),

- the use of sea vessels with a liquefied natural gas (FLNG) plant, which provide access to gas fields inaccessible to gas pipeline infrastructure facilities,

- the use of offshore floating LNG platforms, for example, which is being built by Shell 25 km off the west coast of Australia.

Areas of application

In addition to the fact that liquefied gas (grade PBA, used at air temperatures not lower than -20 degrees, and PA) is used in the automotive sector as a fuel that is more economical, safe, cheap and environmentally friendly, it is used in heating systems and in industry (as a source of heat and cold in metalworking, ceramics and glass processing), for household and utility needs (BT, PBT, PT brands).

The main players in the fuel segment are butane, methane and propane, which combine the following indicators:

- no smell. On the contrary, such fuel is given an aromatic marker to quickly detect leaks;

- safety, i.e. resistance to possible fire, which occurs at temperatures of plus 429 degrees (butane), at 466 (butane) and at 537 (methane). For comparison, diesel fuel and gasoline ignite when they reach 250-300 degrees;

- combustion is complete, thereby minimizing harm from emissions into the environment;

- minimal carbon deposits, allowing to extend the service life of piston cylinders, spark plugs and the engine combustion chamber;

- high octane number: 110 for methane and 100 for a propane-butane mixture. It should be noted that the mixtures can be used in different climatic zones, but taking into account the fact that in a liquefied state they are not frost-resistant, but are immune to zones with a hot climate: these components in the mixture complement each other and form a fairly stable substance. Unlike them, propane reacts to high temperatures, which leads to an increase in pressure in the cylinders where it is stored.

Important: Gas stations sell different mixtures for different seasons, which differ in the percentage composition of gas mixtures: in summer, for example, butane should be 60%, in winter - 40.

The requirements regarding liquefied hydrocarbon gases can be found in GOST 27578-2018.

Manufacturers

The main countries producing liquefied gas are, according to 2009 data:

- Qatar - the volume reaches almost 50 billion m³;

- Malaysia and Indonesia - 29.5 and 25 billion cubic meters, respectively;

- Australia and Algeria – 24 and 21 billion m³.

Japan ranks first among LNG importers. Gas is also purchased by: Spain, USA, France, India.

There are also 2 operating factories in Russia. One of them is the Sakhalin-2 project launched in 2009. The controlling stake is owned by Gazprom. The co-owners are: 27.5% Shell, 12.5 Mitsui, 10% Mitsubishi. At the end of 2015, annual production reached 10.8 million tons, which is 1.2 million tons more than the designed capacity. Unfortunately, due to falling prices on the world market, exports have decreased noticeably in recent years.

Another significant player in Russia is Novatek (Yamal-LNG).

The Americans did not stand aside either: they commissioned 5 LNG export terminals, the total capacity of which is 57.8 billion tons/year. It is clear why there has been a fierce confrontation between these countries for many years.

How many liters of gas does it take to heat a house?

The average production of LPG from a gas tank for the entire heating season is approximately 20 liters per meter of heated area with a total housing area of up to 200 square meters.

Interesting materials:

How to remove dye from jeans? How to call Yandex Taxi in Kaliningrad? How to call a taxi in Alushta? How to whip up fluff in a down jacket with a vacuum cleaner? How to embalm flowers? How to bind a mouse wheel jump? How are chickens slaughtered at a poultry farm? How to block the microphone? How to block a user on wifi? How to block a site in a search engine?

Starting investments

The initial investment in an autonomous gasification system can be easily calculated based on the proposals of various companies. For example, installing an underground gas tank with a volume of 6.5 m3 on a turnkey basis in one day with all the necessary equipment will now cost from 400 to 500 thousand rubles. Such a gas holder is capable of supplying gas to an average house or cottage with a plot and household plot throughout the year, including gas consumption for heating and hot water supply.

With connection to the gas main, if gasification of houses or objects is not provided for in the master plan, everything is not so simple and unambiguous, and the proximity of the gas pipeline does not at all guarantee an easy solution to this problem. Firstly, connection may simply be impossible, since the capacity of gas pipelines is limited, and additional capacity may not be available.

Operating and Maintenance Costs

Well-regulated gas equipment requires virtually no maintenance, since neither liquefied nor main gas forms carbon deposits and soot. Preventive maintenance and control inspections are carried out regularly regardless of the type of fuel, and the costs are approximately the same.

Operating costs when using liquefied gas may include electricity costs if the system uses electrically heated evaporators. Evaporators are installed in powerful industrial systems to increase the rate of formation of the vapor phase, as well as with ground-based gas holders, since the natural evaporation of the butane component stops at subzero temperatures.

But electric evaporators are usually used in systems with relatively little gas consumption, and they do not consume as much energy. High-performance systems use liquid-heated evaporators, the heat for which is produced by burning the same liquefied gas.

So, the operating and maintenance costs for systems running on mainline and liquefied gas are almost the same.

LNG plant equipment

- gas pre-treatment and liquefaction plant,

- LNG production lines,

- storage tanks, including special cryocankers, designed according to the principle of a Dewar flask,

- for loading onto tankers - gas carriers,

- to provide the plant with electricity and water for cooling.

There is a technology that allows saving up to 50% of energy on liquefaction, using the energy lost at gas distribution stations (GDS) when throttling natural gas from the main pipeline pressure (4-6 MPa) to consumer pressure (0.3-1.2 MPa) :

- Both the actual potential energy of the compressed gas and the natural cooling of the gas when the pressure decreases are used.

- additionally, the energy required to heat the gas before supplying it to the consumer is saved.

Pure LNG does not burn, is not flammable and does not explode on its own.

In an open space at normal temperatures, LNG returns to a gaseous state and quickly dissolves in the air. When evaporating, natural gas can ignite if it comes into contact with a flame source. For ignition, it is necessary to have a concentration of vapors in the air from 5% to 15%. If the concentration is up to 5%, then the vapors are not enough to start a fire, and if it is more than 15%, then there is too little oxygen in the environment. To be used, LNG undergoes regasification - evaporation without the presence of air. LNG is an important source of energy resources for many countries, including Japan, France, Belgium, Spain, and South Korea. LNG transportation

is a process that includes several stages:

- sea passage of a tanker - gas carrier,

- auto delivery using special vehicles,

- railway delivery using tank cars,

- regasification of LNG to a gaseous state.

Regasified LNG is transported to end consumers via gas pipelines.

Ecological fuel

Liquefied gas has a fairly high octane number and is distinguished by high energy indicators, which allows it to be used for refueling cars. Without harming the environment, the use of this fuel reduces oil consumption and engine wear. Its price is lower than the cost of gasoline. In addition, liquefied gases are safe, and refueling is carried out at specialized gas stations. This explains why it is considered a more economical fuel than gasoline.

Advantages

- Convenience of energy storage (due to the high density of liquefied gas), delivery and consumption. The cryogenic non-toxic liquid is stored at minus 162 degrees Celsius. For large volumes, above-ground containers are used, where it is under atmospheric pressure;

- Intercontinental transportation, for which gas tankers, tank trucks or railway tanks are used;

- Opens up the possibility of gasification of objects located at considerable distances from gas mains. There is no need to build expensive pipelines.