The Lada Granta 8 valve engine with a volume of 1.6 liters is currently the most popular among buyers of a budget sedan. The design of the motor is well known not only in the official service center, but also in any garage. Therefore, repair and maintenance of this motor does not cause difficulties and is relatively inexpensive. Today we’ll talk about this engine in more detail.

Gasoline power unit Lada Granta VAZ-11186 with a power of 87 hp. with a displacement of 1.6 liters, it replaced the VAZ-11183 injection engine developing 82 horsepower. The new lightweight piston group from Federal Mogul managed to increase the power and efficiency of the power unit. Of course, the engine is not distinguished by enchanting dynamics and low fuel consumption, but its relatively simple design and maintainability allow us to talk about a good option for our harsh operating conditions.

As for the technical part, it is based on a cast-iron cylinder block, an aluminum head, an aluminum cylinder head cover, and a steel engine sump. The timing drive of the Lada Granta is 8-cl. there is a belt. The eight-valve timing mechanism does not have hydraulic compensators; valve adjustment occurs rarely, but the process is quite painstaking. It is necessary to select “nickels” of different thicknesses and place them between the camshaft cams and the bottoms of the pusher cups. The first time such a procedure is carried out is at the so-called “0” zero maintenance, after 3000 km.

The age-old question : Do the valves on the Grant VAZ-11186 engine bend when the timing belt breaks? The answer is clear: when the valve belt breaks, it bends! The engine is paired with a 5-speed manual transmission; no other options are provided.

Further technical characteristics of the base Lada Granta engine 8 valves 87 hp.

Engine Lada Granta 1.6 (87 hp), fuel consumption, dynamics

- Working volume – 1597 cm3

- Number of cylinders/valves – 4/8

- Timing drive - belt

- Cylinder diameter – 82 mm

- Piston stroke – 75.6 mm

- Power hp/kW – 87/64 at 5100 rpm

- Torque – 140 Nm at 3800 rpm

- Maximum speed – 167 kilometers per hour

- Acceleration to the first hundred – 12.2 seconds

- Fuel consumption in the city – 9.0 liters

- Fuel consumption in the combined cycle – 6.6 liters

- Fuel consumption on the highway - 5.8 liters

AI-95 gasoline as fuel .

Problems with the motor 11189

Despite all the advantages, with long-term operation of the 11189 engine, the following breakdowns may occur in Lada:

Malfunctions in the operation of the indicators of the electronic throttle drive E-gas, which in most cases lead to the appearance of floating idle speed. Burnout of valves and malfunction of the ignition coil, which causes the engine to trip (1-2 cylinders of the engine stop working completely). Damage to the mass air flow sensor is considered the most common reason that the “iron horse” stalls while driving. A breakdown can lead to an accident. Overheating occurs, most often caused by an unreliable thermostat. Knocks and noises may be heard from under the hood. They appear mainly due to incorrectly set valve clearances. According to reviews, the 11189 engines have significantly reduced oil leaks compared to earlier engine models, but this problem has not yet been completely eliminated. Due to a design miscalculation, the occurrence of jamming of the water pump becomes inevitable for the engine

Experts recommend monitoring her condition with special attention.

The most common problems of internal combustion engines 11186

VAZ 11186 borrowed the design from its predecessor. The engine is a cast iron block with 4 cylinders in line and a head with 8 valves. One camshaft. There are no hydraulic compensators, so the valve clearances have to be set manually. The timing belt is driven by a belt.

Related article: High engine idle speed

The modernization has made improvements to the characteristics of the engine: it has become less capricious, more reliable and economical. However, the engine is not without its drawbacks:

- While the engine is running, knocking noises are heard. Often the problem is solved by adjusting the valve clearances. If this does not help, install new pistons or crankshaft bearings;

- RPM fluctuates at idle. The cause of the malfunction is glitches in the automatic throttle and sensors;

- increased oil consumption. Observed when the main liners or piston rings are worn;

- misfire. The problem is in the ignition module. It is beyond repair and must be replaced.

Granta owners also complain about the unreliability of the Itelm ECU. The electronic unit fails when exposed to moisture. To prevent damage, the ECU can be moved into the interior to avoid getting wet during rains. It is not recommended to cover the module with film, as condensation will occur.

The most critical problem with the 8-valve Lada Granta is that the engine bends the valves. The damage can only be corrected by replacing it with new parts. It remains to find out why the valves bend and how to avoid trouble.

Characteristics of motor 11186

The project of a “people's car” at a budget price for the average LowCost user was seriously hampered by the economic crisis. For the Lada Granta Standard configuration, the technical characteristics of the existing ICE 11183 were sufficient.

However, for the Norma and Lux trim levels, a more powerful internal combustion engine was needed, so the management of AvtoVAZ, not having sufficient funding for the project of a new engine, came out of the situation as follows:

- the existing version 21114 became the basis for the ICE 11186;

- to reduce costs, pistons from the American manufacturer Federal Mogul were replaced with domestic products of a suitable size;

- The manufacturer changed the engine markings, but no more design changes were made.

Piston 11186 is smaller than 11183

Unlike 11183, the piston of the 11186 motor bends the valve when the timing belt breaks, but the performance characteristics are improved:

| Manufacturer | AvtoVAZ |

| Engine brand | 11186 |

| Years of production | 2020 – … |

| Volume | 1598 cm3 (1.6 l) |

| Power | 64.2 kW (87 hp) |

| Torque moment | 140 Nm (at 3800 rpm) |

| Weight | 140 kg |

| Compression ratio | 10,5 |

| Nutrition | injector |

| Motor type | in-line |

| Injection | electronic multipoint |

| Ignition | the electronic unit |

| Number of cylinders | 4 |

| Location of the first cylinder | TVE |

| Number of valves on each cylinder | 4 |

| Cylinder head material | aluminum alloy |

| Intake manifold | plastic receiver, electronic throttle |

| An exhaust manifold | combined with catalyst |

| Camshaft | from 11183 |

| Cylinder block material | cast iron |

| Cylinder diameter | 82 |

| Pistons | lightweight |

| Crankshaft | ductile iron, oil channels |

| Number of main bearings | 5 |

| Piston stroke | 75.6 mm |

| Fuel | AI-95 |

| Environmental standards | Euro 4 |

| Fuel consumption | highway – 5.7 l/100 km mixed cycle 7.3 l/100 km city – 8.5 l/100 km |

| Oil consumption | maximum 1 l/1000 km |

| Engine oil for 11186 | 5W-30 and 10W-30 |

| Engine oil volume | 3.5 l |

| Operating temperature | 95° |

| Motor life | declared 150,000 km actual 300,000 km |

| Adjustment of valves | washers between camshaft cams and tappets |

| Cooling system | forced, antifreeze/antifreeze |

| Coolant quantity | 7.8 l |

| water pump | polymer impeller |

| Candles for 11186 | BPR6ES, A17DVRM |

| Gap between spark plug electrodes | 1.1 mm |

| Timing belt | 163 teeth, pitch 8 mm, belt width 26.7 mm |

| Cylinder operating order | 1-3-4-2 |

| Air filter | Nitto, Knecht, Fram, WIX, Hengst |

| Oil filter | catalog number 90915-10001 replacement 90915-10003, with check valve |

| Flywheel | from 2110, steel crown placed on a cast iron body |

| Flywheel mounting bolts | box MT – M10x1.25 mm, length 26 mm, groove 11 mm box AT – M10x1.25 mm, length 26 mm without groove |

| Valve stem seals | code 90913-02090 inlet light code 90913-02088 exhaust dark |

| Compression | 13 bar |

| XX speed | 650 – 750 min-1 |

| Tightening force of threaded connections | spark plug – 18 Nm flywheel – 62 – 87 Nm clutch bolt – 19 Nm bearing cap – 68 Nm (main) and 53 (rod) cylinder head – three stages 29 Nm, 49 Nm and 90° |

Since the engine does not have hydraulic valve lash compensators, it is practically not important for the user which oil to choose based on the fuel manufacturer. Both domestic and foreign companies are suitable, for example, ZIK, Lukoil, Mobil, Rosneft. On the other hand, relevant information is which oil to pour into the engine based on viscosity:

- for regions of the Russian Federation, the manufacturer recommends all-season oils 10W40, 5W40 and 15W30;

- Synthetic and semi-synthetic lubricants are allowed;

- It is better not to use mineral oil.

To reduce temperature loads on the valves, the engine circuit provides nozzles that inject oil onto their surface. Unlike homemade channels, nozzles fire only when pressure increases, that is, when the lubricant heats up from intense loads. Oil does not enter the crankcase and does not cause increased wear of gaskets in the engine.

Engine 11186 - a domestic favorite

Engine 11186 is the minimum power unit in terms of power. which is standard equipment on Lada Granta and Lada Kalina cars. The VAZ 11186 engine is standardly coupled with a manual transmission. The start of serial production of the engine is in 2011. Environmental standards Euro-4.

The engine is structurally designed as an in-line gasoline four with a volume of 1586 cubic centimeters. Maximum power of 87 hp. reaches at 5100 rpm. Maximum torque of 140 Nm is produced at 3800 rpm.

It is the second iteration of the modification of the classic front-wheel drive engine 21083. The predecessor is the VAZ 21114 engine with a volume of 1.6 liters. The engine has an additional index VAZ 21116. The main difference is the use of a piston system on 11186, manufactured by AvtoVAZ OJSC, and not by Federal Mogul.

The declared engine life is 200,000 km. The actual mileage before the first major overhaul is not recorded. The Russian manufacturer does not have the practice of monitoring typed cars by mileage. According to existing unverified reviews, the actual mileage exceeds the service life of 21,114, but does not reach the declared one.

SOHC engine design diagram. One camshaft located at the top of the engine. Accordingly, we have 8 valves, 2 for each cylinder. The camshaft is driven by a belt. During operation, the belt does not require replacement, since the declared life of the belt coincides with the life of the engine. The belt tension is automatic and is designed by design.

Fuel supply system is injection with electronic control. Spark plugs are standard A17DVRM. The spark is supplied by the ignition unit according to the 2-2 scheme, i.e. spark is supplied to two cylinders at the same time

Repair of power unit components

As practice shows, nothing lasts forever, and neither do the components of VAZ power units. In this part of the article, we will consider the main malfunctions, as well as methods of elimination and repair.

Timing belt or how not to bend valves

Probably the most interesting question for most motorists is whether the valves on VAZ engines bend? As for the VAZ 11189 engine, we can say with confidence that the valves bend when the timing belt breaks. Of course, valves can bend for other reasons, but the most common is considered to be a broken timing belt.

Another question that car enthusiasts ask in car repair shops and on forums regarding the timing belt is how to prevent valve bending? Everything is very simple - change the timing belt and rollers according to the technical recommendations of the manufacturer. Thus, in the maintenance manuals for engine 11189, the recommended belt replacement period is 45-50 thousand kilometers.

What happens if the valve bends? Everything is very simple - after the valve mechanism is bent, such important elements as the valve guide, valve seat, and oil seals fail. Subsequently, it may happen that this problem affects the piston mechanism. In a word, if the valve bends, then you should hope for the best and expect the worst - that is, a major repair.

How to replace the timing belt and rollers:

- First, you need to remove the protective casing.

- Then, we fix the camshaft, but before that it is necessary to set the timing marks.

- Unscrew the tension roller to release the belt.

- Next, we dismantle the belt itself.

- We change the tension roller.

- Reinstall the timing belt.

Water pump malfunction

The water pump circulates coolant through the engine system. This is done for cooling and to prevent the motor from burning out. The failure of such a unit means that further operation of the power unit is impossible, since overheating will occur and the first thing that will be affected is the cylinder head. To avoid this, you should regularly diagnose the part and replace it on time.

There is nothing difficult about replacing the pump. The procedure is similar to changing the timing belt. After removing the belt, unscrew the bolts securing the water pump and replace it. It should be noted that the coolant must be drained from the system and, after replacement, topped up to the required level.

ECU diagnostics

One of the most common procedures that motorists carry out is diagnosing faults in the electronic engine control unit. This procedure is often performed in a car service center, since not every driver has a special portable diagnostic PC.

Cautions and Consequences

Valve bending on a Priora is mainly due to the piston meeting the first parts. If the timing belt breaks, the car owner cannot avoid expensive repairs. In such a situation, auto mechanics recommend:

- regularly check the condition of the belt,

- determine the presence of chips and cracks on the belt,

- check if there are any threads on the belt.

- remove the engine from the car,

- take it apart

- drain and replace oil,

- remove the crankshaft,

- remove the pistons

- remove the connecting rods.

In this case, you will also need to buy a new, lighter piston group. From an official dealer it will cost no more than 2-5 dollars. Some auto mechanics recommend buying a car of another brand, the price of which is practically no different from the cost of the Priora. It could be a KIA RIO or a Chevrolet Aveo. This problem can be solved using an optimized cooling system for the block and cylinder head.

Engine tuning VAZ 11183 (21114)

Let's consider the potential of the 11183 8V engine without replacing the cylinder head with a 16 valve (the 124 engine and its modifications are mentioned in a separate article). The easiest way is to replace the camshaft with an OKB Dinamika 108 or Nuzhdin 10.93, install a split gear, adjust the phases, this will give us about 85-90 liters .With. and a cheerful pick-up at the top. We don’t skimp on the receiver, 54 mm damper and 4-2-1 spider exhaust, this config will perform better than a 16 valve 124 engine, while the cost of modifying the VAZ will be quite reasonable. Refinement of the cylinder head and intake manifold, lightweight T-shaped valves and milling of the cylinder head will allow us to get the most out of it. The estimated power of the VAZ 21114 engine in this case will reach 110-115 hp. Let the engine spin more easily, maybe a light Priorov piston, install it and get 120+ hp.

Compressor for Kalina engine

An alternative method for obtaining such returns is to install a PK-23-1 compressor, and to increase its efficiency we add Vali Nuzhdin 10.42 or 10.63. The well-known video clearly explains everything that is required for a successful project.

Attention MAT (18+)

It is possible to increase power without using a turbine up to 170 hp. and higher, but the service life of the VAZ 11183 engine is noticeably reduced. The right step would be to increase the potential by increasing the efficiency of the engine, namely by installing a 16-valve cylinder head, which, together with the damper, receiver and exhaust on 51 pipes, will give 110-120 hp. without significant loss of resource.

Turbo viburnum engine

The configuration of a turbo engine based on an 8-valve cylinder head is described HERE, the principle is the same.

The problem of a broken timing belt and subsequent damage to the valves was familiar to many Lada Kalina owners. The improved Granta, according to many buyers, has lost this problem.

But still, fears on this score do not go away. Therefore, it is first recommended to find out whether the valves on the 8-valve and 16-valve Grant bend, and which engine models are most reliable for operation.

Main reasons

Car owners of Lada Priora 21126 are interested in knowing the reasons why the valves on their car bend. Auto mechanics claim that on all modern models of this car, as a result of a broken timing belt, the valve motor bends. The first engines for front-wheel drive VAZ 2110, unlike similar units for rear-wheel drive, had a volume of 1.5 liters. Somewhat later, similar designs with a volume of 1.6 liters appeared. with 8 valves and one camshaft. Some car enthusiasts do not know whether the valves on such engines bend. This process does not occur due to the first elements not meeting the pistons at the dead center. After evolution, new 16-valve units with two camshafts appeared. This made it possible to increase power from 76 hp. up to 92 hp, while the engine size has not changed.

Experts say that such units are also unreliable, since when the timing belt breaks, valves and pistons meet even at a dead center, and as a result, the engine bends the second elements on the Priora. Such repairs are expensive. In addition to replacing the valve, sometimes the pistons also have to be replaced.

AvtoVAZ designers, having modified the 16-valve engine, installed it for the first time on the new VAZ 2112. The engine received the abbreviation 124. The distinctive features of the new unit from previous analogues are the presence of an updated piston group. They received “grooves” or so-called “notches”, with the help of which reliable protection is created against timing belt breakage. The VAZ 2112 with this engine is considered a reliable and powerful vehicle.

Adjusting thermal clearances in the valve drive of the gas distribution mechanism

We adjust the thermal clearances in the valve drive of the engine gas distribution mechanism in accordance with the maintenance regulations every 30 thousand km. We carry out operations on a cold engine.

Use a Phillips screwdriver to loosen the clamp securing the crankcase gas supply hose to the cylinder head cover...

...and remove the hose from the cover pipe.

Use a Phillips screwdriver to loosen the hose clamp (the main circuit of the crankcase ventilation system)…

...and remove the hose from the cylinder head cover pipe. Similarly, loosen the tightening of the hose clamp (the idle circuit of the crankcase ventilation system)…

...and remove the hose from the cylinder head cover pipe.

Using a 10mm socket, unscrew the three nuts securing the receiver bracket...

...and remove the bracket.

Two studs securing the bracket to the receiver are screwed into cage nuts installed in the grooves of the receiver.

Using a 10mm socket, unscrew the two cap nuts securing the cylinder head cover.

Remove the metal washer from the stud...

...and a rubber bushing. Similarly, remove the cover fastening parts from the other stud.

Remove the cylinder head cover. Remove the front upper timing belt cover (see “Checking the condition and replacing the timing belt”). The procedure for checking and adjusting the clearances in the valve drive mechanism is as follows. We turn the crankshaft by the bolt securing the generator drive pulley clockwise until the installation marks on the camshaft pulley and the rear timing belt cover align (see “Checking the condition and replacing the timing belt”). Then turn the crankshaft clockwise another 40–50° (2.5–3 teeth on the camshaft pulley). In this position of the shafts, we use a set of feeler gauges to check the gaps (between the adjusting washers of the pushers and the cams) at the first...

...and the third camshaft cam. The clearance between the camshaft cams and shims should be 0.20 mm for intake valves and 0.35 mm for exhaust valves. The clearance tolerance for all jaws is ±0.05 mm. The gap is equal to the thickness of the feeler gauge, which fits between the cams and the washer with a slight pinch. If the gap is different from the norm...

...then we install a device for adjusting the valves on the studs of the camshaft bearing housings.

We rotate the pusher so that the slot in its upper part faces forward (along the direction of the car). We insert the “fang” of the device between the cam and the washer (see figure below).

Recessing the valve pusher when replacing the adjusting washer

: 1 – device; 2 – pusher

By pressing down on the lever of the device, we recess the pusher with the “fang”...

...and install a clamp between the edge of the pusher and the camshaft, which holds the pusher in the lower position.

Fixing the valve tappet when replacing the adjusting washer

: 1 – retainer; 2 – adjusting washer Move the device lever to the upper position.

Use tweezers to pry the adjusting washer through the slot and remove it. If you do not have a device for adjusting the valves, you can use two screwdrivers. Using a powerful screwdriver, leaning on the cam, press the pusher down. By inserting the edge of another screwdriver (with a blade width of at least 10 mm) between the edge of the pusher and the camshaft, fix the pusher and remove the adjusting washer with tweezers. We adjust the gap by selecting an adjusting washer with the required thickness.

To do this, use a micrometer to measure the thickness of the removed washer. The thickness of the new adjusting washer is determined by the formula: H = B+ (A–C), mm,

where A

– measured gap;

B

– thickness of the removed washer;

C

– nominal gap;

N

– thickness of the new washer. The thickness of the new washer is marked on its surface with an electrograph. We install the new washer in the pusher with the marking down and remove the lock. Check the gap again. When adjusted correctly, a 0.20 or 0.35 mm feeler gauge should fit into the gap with slight pinching. Consistently turning the crankshaft half a turn, check and, if necessary, adjust the clearances of other valves in the sequence shown in the table:

We assemble the engine in the reverse order. Before installing the cylinder head cover...

...replace its sealing gasket with a new one.

This is interesting: Average fuel consumption per 100 km on Lada Kalina - characteristics

Comfort package overview

The car is equipped with an 8-valve engine producing 87 hp, the equipment can be called average. I like the silver color. The cost is 522,500 rubles including paint. If the color is white, the price will drop by 6,000 rubles.

The car has a small set of options, but the most necessary ones are there:

- Air conditioner.

- Electric power steering.

- Electric windows.

- 2 airbags.

- Heated seats.

We won’t pay much attention to the configuration; everyone already knows about this.

Why does the Granta 8 valve bend the valve?

The breakdown procedure itself is also equally important to study. Having understood which areas are most susceptible to damage, the owner will be able to pay more attention to them or seek help from specialists

After diagnostics, our technicians will perform a full service and help you avoid numerous causes of timing belt failure: jamming of the pump, rollers, camshaft or crankshaft. The process of valve damage itself occurs according to the following scheme:

1. The timing belt breaks.

2. The camshaft stops.

3. The crankshaft continues to rotate (the flywheel transmits rotation).

4. The pistons hit the open valves when the timing belt breaks.

Thus, the valves become bent, and in the future they will need to be completely replaced. You can also find out whether the valves of the Lada Granta 8 valve are bent from specialists working at the service station.

After all, a breakdown does not necessarily affect every owner of a domestic car. Damage occurs in exceptional cases when the motorist does not devote enough time to servicing the car. Therefore, the root cause is insufficiently conscientious operation.

Many craftsmen recommend that immediately after purchasing a Granta, you have it checked at a service station, since even small nicks on the shafts can lead to a rupture of the timing belt.

In some cases, changing the belt to a stronger one helps: the factory component may not meet the required load and operating conditions. The tension force must fully comply with the stated recommendations of the manufacturers. Therefore, self-regulation can only worsen the situation.

You should also contact a specialist if primary signs appear that may indicate a subsequent belt rupture. It could be minor noise from the timing drive. It is this that will indicate possible wear or partial wedge of the rollers or pump.

All these factors are decisive and can lead to the need for expensive repairs, and in extreme cases, to calling a tow truck if the driver was outside the city at the time of the rupture. The owner of the Grant needs to take into account all the considered nuances and solve the slightest problems immediately after they arise.

It is practically impossible to answer this question unambiguously whether the valves bend on the Lada Grant; it all depends on what kind of engine is installed in the car. Motorists are well aware that the Lada Granta is a prototype of the Lada Kalina car, with its very reliable power unit and durable valves that are not subject to mechanical bends. Unfortunately, according to experts, only the Grant “standard” engine valves can safely withstand a broken timing belt.

If we consider the question of whether the valves on a Grant with a “norm” engine bend, unfortunately we must admit that if the timing belt breaks, this eight-valve engine with a lightweight connecting rod-piston mechanism cannot withstand such damage, the pistons will definitely hit the valves, which will inevitably result in they will bend. This happens for the reason that these two seemingly almost identical engines still have some differences. For example, eight-valve standard pistons have special recesses for the valves, as a result of which, if the belt breaks, the valves remain intact.

Grant engines of the “norm” type have not only a lightweight connecting rod and piston group, but also shortened pistons on which it is physically impossible to make valve recesses, so a broken timing belt in engines of this type is fraught with major, expensive repairs, which once again reminds us of the need for constant monitoring the technical condition of the timing drive.

By the way, the engine of the Lada Priora car has exactly the same defects, although due to the fact that the timing belt itself is very wide and extremely durable, breakdowns of this type occur extremely rarely. This usually happens when trying to start the engine from a pusher or by towing, which is strictly prohibited by the car’s operating instructions. In general, no matter what engine is in your car, preventive maintenance and periodic maintenance of the timing drive is necessary; this can protect you from many major troubles associated with the car.

Why does the belt break?

The valve bends when the timing drive breaks, so it is important to monitor its condition. On 11186 AvtoVAZ installs Gates belts art. 5670XS with automatic tensioner art. T43228. According to the manufacturer, the service life of the consumable is equal to the engine service life - 200,000 km. In reality, the belt runs about 50,000 km. Experts recommend checking the part during each maintenance, after 15,000 km.

In addition to the quality of the belt, how it is tensioned is also important. In engine model 11186, when backlash or jamming occurs in the pump or tension roller, the belt cuts off the teeth and the pistons bend the valve. It cuts teeth instantly, so it is rarely possible to avoid breakage.

Quality of spare parts

Gates has been cooperating with AvtoVAZ since 2003. The company's products are not cheap. A set of timing belt and tension pulley will cost at least 3,000 rubles. Is it worth saving and buying a cheap Chinese equivalent if there is a danger that if the drive breaks, the engine bends the valve?

However, even if you want to buy an original product, you can run into a fake. Under the name Gates there are counterfeits made from cheap material at a dubious price. You need to buy spare parts from official distributors. Addresses can be found on the company website.

The original timing belt is made of hydrogenated heat-resistant rubber with high resistance to various chemicals. The part has a rounded toothed profile. There are 113 teeth, 17 mm wide. Length - 1.076 m.

Similar article Engine temperature indicator and sensor on Lada Grant

Belt wear is determined by the quality of the material, the presence of cracks and delaminations. The surface of the part should be elastic, not too hard. It is not permissible to stretch or shift the belt relative to the required position, otherwise it will fly off and a situation will occur in which the valve bends.

Incorrect belt installation

On a Grant with engine 11186, the valves bend in case of any damage to the timing drive. Since the slightest loosening of the belt causes teeth to be cut off, the drive must be installed strictly according to the diagram, using a special key.

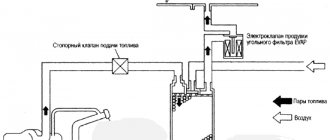

If you look at the drive tension, then on the right side from the camshaft to the crankshaft you get a long arm in a free state. The force is from 15 to 20 Nm. Next, the belt covers the crankshaft sprocket. It rises to the water pump, going around the gear on the left. It goes to the tension roller on the right and returns to the camshaft.

AvtoVAZ does not recommend tensioning the drive belt yourself. According to the manufacturer, for the service you need to contact specialized services, where the part will be installed in accordance with the requirements of the plant. This is especially important if there is warranty service.

Why Granta 8-valve valve bending

The valves do not bend on all Grants. In the “Standard” modification, another unit is installed - 11183 or a transitional version 11183-50. It is less powerful, noisier and more gluttonous, but it does not bend the valves. But “Norma” and “Lux” are equipped with 11186, which requires special attention.

To achieve the best technical performance, AvtoVAZ engineers lightened the connecting rod and piston group (CPG) of the engine by 39%. But the updated ShPG did not include counterbores in the piston heads. The “oversight” led to the fact that if the timing belt on the 11186 engine is damaged, the valves bend in 99% of cases. Here's how it happens:

- The timing drive has broken.

- The camshaft has stopped.

- The valves remained open.

- The crankshaft rotates by inertia from the flywheel.

- The pistons push back and hit the valves.

- The impact bends the valve stems.

VAZ tried to fix the problem that caused the valve stems to bend. Federal Motors, the ShPG supplier, learned to produce pistons with recesses on the bottom, which finally helped get rid of the critical flaw. Grants with a non-plug motor went on sale from August 15, 2022.

The modified design of the pistons includes recesses for the full stroke of the valves, so the possibility of collision of parts, which causes valve bending, is excluded. In addition, the piston skirts have become more wear-resistant due to a new coating and geometry. The modifications helped reduce noise and improve gas economy.

Modifications applied to the engine

To ensure normal temperature conditions of 95C when using gasoline with an octane rating of at least 95, the cooling system has been modified. Changed to increase the area and flow area of the cooling channels, and increased the volume of antifreeze poured.

Changes were made to the internal channels of the engine head. To ensure increased second consumption of antifreeze, a pump from a 16-valve engine is installed on the engine. In addition, the design of the thermostat has been changed.

In order to reduce fuel consumption and increase engine reliability, major modifications have been made. The engine is equipped with a connecting rod and piston group that is lightened by almost 40% compared to the VAZ-21114 engine. This change not only reduced the weight of the engine itself, but, more importantly, reduced the inertia of the entire system. The design innovation made it possible to increase the declared service life before major repairs.

Externally, the motor also differs from its predecessor. A longer intake tract was installed, which made it possible to achieve a higher torque value and bring the performance of the 8-valve engine closer to the 16-valve engine.

The exhaust manifold has elongated pipes and a more voluminous resonator, which significantly facilitates the engine's breathing at the exhaust, since the aerodynamic resistance of the exhaust tract is reduced.

The generator mounting bracket has been changed to make it possible to adjust the drive belt using an eccentric tensioner roller. This design is also used on VAZ Vesta car engines.

Do the valves on the Lada Granta 8 valve bend: 11186 (82 hp) and 21116 (87 hp), + video?

Options for 8-valve engines are well known to Lada Granta owners from previous AvtoVAZ models. These engines have indexes 11183 and (11186, 21116), their power is 82 and 87 horsepower, respectively.

Main article: What engines are installed on Lada Granta cars.

Domestic consumers are very afraid of a broken timing belt. Therefore, this issue plays an important role when choosing a car modification.

In the event of such a situation, bending of the valves may occur, which has given rise to the popular saying “fist of friendship.” There is even slang that refers to motors that bend valves as “plug-in”, and motors that do not have this disadvantage as “plug-in”.

To prevent the belt from breaking, it is necessary to change the belt on time (read more about when it is necessary to change the timing belt according to the recommendation of the factory and the experience of Grantovodov here).

Modification 11183 (Standard package, 82 hp)

Engine 11183 (under the hood of Lada Kalina)

The very first modifications of the Grant car came with a non-lightweight connecting rod and piston group; on such engines the valves do not bend, it all depends on the speed at the moment the belt breaks. These engines were installed on cars in the “Standard” configuration and had the designation 11183. The advantage of this engine is its high-torque power; at the bottom it drives like a diesel engine!

In fact, this is a complete copy of the VAZ-2108 engine, only with an increased volume, and the owners of the nines boasted about stories about how the timing belt broke and nothing happened to the engine.

Engine 11186 (87 hp) - the valves bend!

Engine 11186 (under the hood)

11186 engine specially for CarFrance.ru from Grantovod Igor

When the timing belt breaks on engine 11186 of a Lada Granta, the valves bend; there have already been many cases that have confirmed this hypothesis. The most successful scenario for the development of events in the event of a timing belt break on this engine is the bending of the intake valves.

Engine 11186 (removed from the car)

Engine 21116 (87 hp) - the valves bend!

21116 engine bends valve

This engine is installed on the Lada Granta in the “Norma” configuration. And it also bends the valves, unfortunately.

Main article: Engine 21116: reviews, service life before major overhaul - a detailed review of the engine from Grantovodov!

Engine 21116 (87 hp) is one of the most common in Lada Granta cars.

In order to increase power, AvtoVAZ designers had to install a lightweight piston group in the 114 engine. This has led to the fact that the space for the recesses in the pistons is now completely absent, which means that the piston will 100% bend. Since the piston has become thinner, with a high degree of probability the piston, after “meeting the valves,” will also become unusable and fall apart.

The only difference between 21116 and 11186 is that the first is installed with an imported connecting rod and piston group, and the second with a domestic one.

Repair (cost, warranty)

The timing belt broke and the valves of the Lada Granta were bent. Repair in the simplest situation will start at 15 thousand rubles, depending on the region and the qualifications of the technician. The saddest thing is that these situations also arise at short mileage, about 15,000 km. But in this case, you can still contact your official dealer for warranty. This type of work is guaranteed.

Since when the timing belt breaks, the valves also break on 16 valves, a heated discussion has developed on our website about which engine is better: 8 or 16 valves.

How to check the condition of the timing belt?

To visually check the timing belt, you must remove the timing cover. This is not difficult to do; with 8 valves there is a lot of space under the hood. Remove the cover and begin a visual inspection of the belt. It should be like new, without cracks or rips, without dirt or deposits, and dry.

If the condition of the belt causes concern, then it must be replaced, for more details, see the article: replacing the timing belt on an 8-valve Granta.

How to prevent valve base from bending

Compliance with technical inspection intervals is rule No. 1 for preventing sudden car breakdowns.

Bent valves in a row

The operation of the timing belt is discussed in detail in the article https://remont-avtovaz.ru/remen-grm-na-lade-granta/. We just remind you that the manufacturer recommends replacing the timing belt every 40,000 km. Violation of the technical inspection period of the car increases the risk of its further use, creating an emergency situation on the road.

Engine operating temperature

We have learned the resource, now we move on to another important indicator. The optimal operating temperature is 90-95°C. After 97°C, engine number 126 with 16 valves will “slow down” a little, but according to the rules, temperatures up to 100°C are considered normal. If the Lada unit is operated with this indicator, then you need to be sure that the radiator fan is running at this time. When you see an indicator below +90°C on the dashboard, you need to assume that this is underheating. Of course, in cold weather the power plant needs more time for the temperature to reach normal levels.

- Operating temperature – 90-95°C.

- Normal temperature (engine runs worse) is 97-110°C.

- Reduced temperature – 90°C and below.

Engine disassembly and repair

Repairs are carried out according to the standard procedure - we find faulty parts and replace them with working ones. The instructions below describe the process of disassembling the unit itself; before that, you need to dismantle it from the Lada Priora and thoroughly clean it of grease and dirt.

From the tools we will need regular and ring wrenches, a ratchet with an extension, screwdrivers, a pry bar and a stand. It is best to carry out repairs in a garage with good lighting.

Instructions

- Using the 13th key, remove the bracket fastenings. 4 nuts hold the front cylinder block support;

- We remove the bracket and move on to the left support - it is removed in exactly the same way;

Thus, you can completely disassemble the 16-valve engine and repair and replace faulty parts. But if the unit bends the valve, then only an experienced mechanic can handle the malfunction with his own hands. In any case, you will find out whether the motor bends the valves or not after removing the head cover.

How much does engine 126 cost?

Let's see how much engine 21126 costs on a Lada Priora if yours is in a faulty condition. The price of a used engine starts from 70 thousand rubles.

Major repairs can cost 40 thousand rubles. Repairing 16 valves will cost 20 thousand rubles. While preventive inspection and repairs will cost 10,000 rubles. Therefore, it is better not to neglect preventive measures and bring the motor to a service center once a year for performance testing.

In our service center you can buy a new or used VAZ 21126 engine with a guarantee.