Based on long-term experience, engineers have prepared optimal recommendations for shock absorber pumping technology:

Before installing a twin-tube shock absorber on a car, it must be brought into working condition. During transportation and storage, in twin-pipe shock absorbers, the working fluid can flow from the inner to the outer cylinder, and boost gas enters the inner cylinder. In this case, the shock absorber will make knocking noises when operating in the car’s suspension, and its throttle valves will be destroyed. To avoid damage to the shock absorber, it MUST be brought into working condition (pumped) before installation. For this:

A. Turn the shock absorber over with the rod down and compress it smoothly, without jerking;

B. Fix the shock absorber rod in this position for 2-3 seconds. ;

B. While holding the rod, turn the shock absorber over with the rod up, fix the shock absorber in this position for 3-6 seconds. ;

D. Keep the shock absorber in a vertical position for the specified time and smoothly extend the rod to the end of the stroke;

D. Turn the shock absorber with the rod down, pause for 2-3 seconds. and repeat operations A, B, C, D 5-8 times;

E. Having finished pumping the shock absorber, following the sequence, stop at point D;

G. Holding the shock absorber vertically, with the rod up, perform a control operation (with sharp but short movements of the rod, make sure that the piston moves smoothly, without failures). A well-pumped shock absorber means smooth piston movement without failure.

Good afternoon to all car owners and enthusiasts. Since many of us are engaged in independent repairs of our cars, it would not be amiss to consider such an issue as pumping the shock absorber before installation. Many people do not pay attention to this point, but in vain. Actually, why it is necessary to pump shock absorbers and how to do it, we will try to consider in this article.

Why bleed shock absorbers?

To be brief, bleeding the shock absorber before installation is necessary to extend its service life. If you neglect this procedure, then this part will fail much earlier. And you will again have to buy shock absorbers, which will bring absolutely no pleasure, both materially and morally. Since we repair the car ourselves, we do not take service stations into account. If the new shock absorbers are not pumped, then during movement you can observe some noise, knocking, and it may be that the shock absorber piston simply fails. It is also worth noting that pumping shock absorbers allows you to identify various types of defects, for example, jamming of the valve mechanism. If such a breakdown occurs, you are unlikely to be able to exchange it for a working part under warranty.

So, point by point why it is necessary to pump the shock absorber before installation:

- bring the shock absorber into working condition;

- to remove oil and air from the inner sleeve;

- to detect various defects.

During transportation and storage, shock absorbers are usually located horizontally. But we all know very well that the working position of shock absorbers is vertical. Actually, to remove the air layer from the inner liner and to identify defects, you will need to pump new shock absorbers.

Repair or replacement? What you can do with your own hands

In fact, this is not such a simple task. Before carrying out work, you should carefully study the material and follow safety precautions. First of all, you need to determine whether your shock absorber is collapsible or not. The monolithic body cannot be repaired; opening it with a grinder and welding it is unacceptable.

We recommend: What to do if the starter turns, but the car does not start?

If there is a nut or retaining ring where the rod enters the pipe, such a shock absorber strut can be serviced and repaired.

This is what a repairable rack looks like

How to properly bleed shock absorbers

Now let's look directly at the process of pumping shock absorbers. It won’t take you much time, the main thing is to do everything right. So, first we install the shock absorber in a vertical position so that the rod is located on top and gradually, without sudden movements, press it in until the working surface is located at the level of the upper edge of the shock absorber cup by 2-3 cm. Next, hold the rod in this position for several seconds and pull it back. The process must be repeated several times. After this procedure, we need to check the shock absorber and this is done like this: we install the shock absorber vertically again with the rod up. Next, you need to squeeze it with short but sharp movements. In this case, the movement of the rod should be smooth without any dips or jerks.

It is worth adding to the above that it is recommended to replace shock absorbers (shock absorber struts) in pairs, i.e. On one axle, both shock absorbers are changed regardless of their condition. In addition to this article, you can familiarize yourself with the choice of shock absorbers, since many often have difficulties in this matter. It’s also worth saying that after bleeding the shock absorbers, you shouldn’t lay them horizontally: we pumped them in a vertical position, and install them that way. That's actually the whole process of pumping the shock absorber before installation. I hope this article was useful to you.

I also suggest watching a short video about pumping shock absorbers

Hi all! When shock absorbers are used on a car for a long time, they gradually wear out and need to be replaced. At the same time, changing the node includes some important nuances. If you decide to take on the job yourself, you definitely need to know how to bleed shock absorbers before installation and do it correctly.

Before we get started, I advise you to read our recent article, which discussed the front shock absorber struts. I'll leave the link here. Go ahead, read, get new useful information.

Pumping is considered a key condition for proper installation and further effective operation of the unit. If you do not do this, the part will fail. Moreover, such a malfunction does not fall under the terms of the warranty case. Everything will have to be corrected at your own expense.

We determine that the element has failed

There are several signs by which a malfunction can be identified:

- The body vibrates intensely on the comb on the side of the damaged shock absorber;

- There is a beating sensation in the steering wheel;

- The braking distance becomes longer;

- When turning, the car skids;

- Traces of oil leaks;

- When driving in a straight line, the car drifts to the side;

- There are knocks and extraneous noises in the rack.

Device diagram

If you do not repair the front struts in a timely manner at a service station or with your own hands, this can lead to dire consequences:

- The support bearings will be destroyed;

- Tires will wear unevenly, jump, and form bumps on the rubber surface;

- The wheel bearings will fail;

- The braking distance will become longer, which is dangerous on any section of the road;

- The brake pads will malfunction and their service life will be significantly reduced.

There are two main ways to check elements for malfunction. One is professional, the other is artisanal, but also quite effective.

- Special vibration stand. A car is driven onto it, and the computer calculates the efficiency of the shock absorbers. It should be noted that new racks may show a result of about 75%, but this is quite normal. If the percentage is less than 50, then it’s time to change the part.

- Manual rocking. You need to grab the front of the car, its wing, and start swinging. Try to achieve the maximum amplitude that your body weight allows. If anything, ask a friend to help. The point is to suddenly remove your hands after swinging and look at the car. If it immediately returns to its original position and does not fluctuate anymore, then everything is fine. If even a slight vibration is detected, you can assume that it is advisable to replace the racks in the near future.

Article on the topic: Selecting and replacing struts on a VAZ 2114 car

Why is pumping done?

Not everyone understands why pumping is done and whether it is necessary at all. Some clarity should be provided on this score in order to finally understand the meaning of pumping and the urgent need for such a procedure.

The working mechanisms of shock absorbers include special sleeves in their design. If air gets inside them, then the device will not be able to return to its original position. Moreover, before installation, air must be removed from new and old parts if you suddenly bought used shock absorbers because their price turned out to be lower. It cannot be ruled out that during the suspension repair process or during troubleshooting, air penetrated inside the mechanism.

During storage and transportation, the oil included in the shock absorber penetrates the outer cylinder of the structure, which is why the gas ends up inside the system. This phenomenon leads to the fact that after installing even a new part, a knock is heard.

What is the difference between gas-oil products and oil products?

From the name itself it is already clear that their main difference is the working composition that is used inside the device.

In oil shock absorbers, the working space is filled with hydraulic oil.

The main disadvantage of these types of devices is aeration (oil foaming), which occurs as a result of changes in the physicochemical properties of the liquid when a piston acts on it in a small space.

This is manifested by a failure in the operation of the device and uncharacteristic sounds.

A partial reduction in aeration is achieved by replacing air with nitrogen gas; as a result, gas-oil analogues have appeared, which come in one or two pipes.

Single-pipe ones are often called gas ones, because there the oil and gas are separated by a movable jumper and do not mix.

IMPORTANT TO KNOW: Causes of shock absorber knocking. Strong backpressure ensures gas pressure in the region of 10 - 30 atmospheres; there are also adjustable analogues

Mainly installed on sports cars

Strong backpressure ensures gas pressure in the region of 10 - 30 atmospheres; there are also regulated analogues. Mainly installed on sports cars.

Twin-pipe gas-oil shock absorbers have less gas pressure - from 3 to 10 atmospheres.

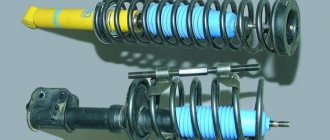

But he won’t delve into the topic, because that’s not what you came here for. The shock absorber structure can be seen in the photo below.

Important nuances of proper pumping

Currently, an impressive number of different automotive shock absorbers are sold, including:

- Kayaba;

- Monroe;

- Phoenix;

- Demfi;

- Bosch;

- Sachs;

- SS20, installed mainly on VAZ;

- Febi;

- Boge;

- ASM;

- Delphi;

- RTS, etc.

In reality, bleeding shock absorbers yourself is not that difficult. You just need to know about some basic nuances, general recommendations, and also take into account the type of part. Each variety has its own special instructions. You can easily emphasize a lot from the video tutorial on leveling up.

Often, you don’t even need a special tool. The main thing is to have gloves at your disposal to prevent damage to your hands and also to protect yourself from contamination.

As for the general rules, they are approximately the following:

- After bleeding and immediately until installation, the shock absorber should be kept strictly in a vertical position;

- If you turn the element over, air will get inside again;

- Some shock absorbers require draining the oil;

- The bleeding procedure largely depends on the type of part used;

- The oil can be drained by dropping the piston into the lower part of the structure, without pressing about 30 mm;

- An alternative option is to use a special groove provided by the manufacturer.

In addition to general recommendations, be sure to refer to the instructions that are relevant for a specific type of car shock absorber.

When the front and rear shock absorber struts need to be checked

Typical malfunctions of this unit are known to everyone:

- Depressurization of the rod seal. Leads to oil leakage from the strut. It can leak at any time. Characteristics change until complete loss of performance.

- The rod moves too freely in the pipe. In fact, the shock absorber strut turns into a guide for the suspension spring. The malfunction is related to the internal valves.

- Play during compression or rebound. Associated with production in the rod or cylinder. The consequences are similar to broken valves. The shock absorber does not perform its function in the car, it knocks, rattles and makes other unpleasant sounds, which is why driving in such a car becomes uncomfortable and dangerous.

- External damage - dents on the body, cracks in the eyelet. They affect the chassis as a whole and can lead to more serious damage.

If any malfunction is detected, it is necessary to remove the strut and free it from the spring. Dismantling is carried out in the garage, without the use of special tools.

Sometimes owners of foreign cars, noticing that their struts have leaked, turn to a service station for diagnostics, where they carry out a test on a stand.

Pumpable types of shock absorbers

Surely you know that shock absorbers are divided into oil, gas and gas-oil. All of them are quite actively used in the design of vehicles.

In this case, pumping is required for all categories of suspension units:

- front shock absorbers;

- rear;

- new parts;

- used;

- original;

- analog;

- single-pipe;

- two-pipe;

- collapsible;

- non-separable.

As you can see, it doesn’t matter what kind of shock absorbers we are talking about. All of them are subject to preliminary pumping before installation. Let you have at your disposal an ordinary old Gazelle or a brand new Audi. Although owners of expensive cars often prefer to have their car serviced at a car service center. But that’s not about that now.

Although it is not fundamentally important whether the shock absorbers are rear and new, or front and used, special attention should be paid to the specific type of element. Gas, oil and gas-oil shock absorbers have their own instructions. Relying on them, you can pump the part with your own hands, and the rack will work for a long time, efficiently and effectively.

Gas shock absorbers

Let's start with pumping these particular shock absorbers. The gas most often used here is nitrogen. It's not difficult to upgrade them. You just need to follow a certain sequence of actions:

- Turn the assembly over so that the rod is pointing down toward the floor;

- Now slowly begin to compress the shock absorber;

- After squeezing, hold it in this position for a few seconds;

- Then turn the part the other way around;

- Hold the rod clamped for 4-5 seconds;

- Pull the rod back until it stops;

- Turn the shock absorber over;

- Leave the element in a horizontal position and install it on the car.

Choosing which ones to buy

It is impossible to say unequivocally which front struts are best to choose for the VAZ 2110. Some choose factory ones because they are not rigid enough for them, others prefer analogues for their softer and more comfortable behavior.

Some people even want to install a sports version of struts , since they are the stiffest and the springs are the thickest.

Sports

Focus on what you want to get out of driving. But from the point of view of manufacturers, Samara CC20 devices have proven themselves to be excellent. If necessary, you can figure out how to pump up such racks.

The choice is between oil and gas (gas-oil, actually). The former are more affordable from a financial point of view, but they do not have such a wide temperature range, which is why the shock absorbers become stiffer in winter.

Gas analogues have a more complex design, a high price, but an excellent “tenacity” indicator.

Among the manufacturers, in addition to CC20, the following manufacturing companies can be distinguished:

- KONI

- Sachs

- Kayaba

- Monroe

- Brillstein.

All of them have approximately the same devices, so there should be no problems with selecting suitable parts.