An element of the car, such as the crankcase ventilation system of the VAZ 2114, serves to remove unexhausted gases and re-supply them inside the engine for afterburning, as a result of which the toxicity of the exhaust is sharply reduced. But, during the operation of the car, this system becomes clogged, resulting in problems with the engine. Today we’ll talk about what crankcase ventilation includes and how to clean it with your own hands.

Crankcase ventilation system

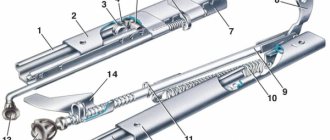

Diagram of the standard crankcase ventilation system

The crankcase ventilation system of VAZ engines consists of two circuits that operate at different load modes and speeds:

- The small ventilation circuit is connected to the valve cover and the intake manifold (behind the throttle body). This connection diagram provides intensive crankcase ventilation due to the vacuum that occurs in the intake manifold when the throttle is closed. To avoid an effect such as hyperventilation, the cross-section of the small circuit is limited by a jet in the cable throttle body with a diameter of 1.7 millimeters. This circuit operates in the region of 800-1500 rpm.

- A large ventilation circuit is connected to the valve cover and the air pipe (in the pre-throttle space). This scheme provides intensive crankcase ventilation at high speeds. The cross section of the large contour is 16-18 millimeters

Examples demonstrating the shortcomings of the standard crankcase ventilation system:

- A car is going down a hill with the gear in gear. In this mode, the engine operates at higher speeds with a reduced load. A high vacuum is created in the crankcase, and a large ventilation circuit is connected, in which there are no control valves. Since both circuits are connected to one volume of the oil trap, a strong vacuum in the crankcase will draw a fresh portion of air bypassing the throttle. The mass air flow sensor will show increased air flow, and the ECU will try to close the throttle. Having realized that this is not possible (it is already closed), the lean mixture will be corrected by increasing the fuel supply (fuel consumption will increase). As a result, the entire internal volume of the engine will work as a parallel receiver of very significant volume, connected to the intake, bypassing the throttle. It is this volume that will interfere with the formation of a high-quality mixture.

- A car in a traffic jam drives under tension with additional consumers (for example, the air conditioner is on). The compressor clutch is connected, the load increases abruptly. The engine does not have enough air, it begins to pull it from the crankcase, bypassing the throttle. But the ECU is also aware of the clutch engagement and also supplies more air by opening the throttle. The vacuum drops sharply, the vacuum brake booster (VBR) does not have enough strength to hold the car. Leap forward. The ECU sees an increase in oxygen and closes the throttle. A sharp increase in vacuum, VUT seizes. The car jerks, the transmission hits. And so on ad infinitum.

As a result, in both cases, when the engine is running, speed jumps occur and the engine choke under the load. Jerking and vibration are possible on manual transmissions, automatic transmissions and automatic transmissions. To eliminate these shortcomings, it is proposed to modify the design according to one of the presented schemes.

What is a PCV valve

Theoretically, without this valve, the forced ventilation system cannot work correctly a priori. After all, it is the PCV valve that doses the supply of crankcase gases to the most important area - the space behind the throttle valve, right in front of the combustion chamber.

The PCV valve is not a check valve at all, as many people think. Yes, it is not blown in the opposite direction, but it also does not simply have two positions, open and closed. Everything is much more complicated. Inside the PCV valve there is a plunger loaded with a spring, the force of which is calculated depending on the engine volume, or more precisely, on the vacuum created in the manifold.

PCV Valve Design

The valve has four operating positions:

- The engine is switched off. The valve is completely closed, gases do not enter the manifold, and now they have nothing to do there.

- The engine is running at idle speed. In this mode, the vacuum in the manifold is the highest, the valve is completely open (100%) to ensure the supply of gases (essentially air) into the throttle space. Moreover, the amount of gases is strictly regulated and clearly controlled by the ECU, and the ECU already controls the idle speed controller depending on the amount of air supplied and a number of other factors.

- The engine operates in normal mode at medium speed and medium load. The PCV valve is approximately 50% open. The flow of crankcase gases is average, they burn efficiently in the cylinders.

- Maximum load and high speed mode. The PCV valve is open by 20-25%, the maximum amount of crankcase gases is burned, thereby the pressure in the crankcase is not dangerous for oil seals and gaskets, since it is completely controlled due to the vacuum in the manifold.

Algorithm of operation of the crankcase ventilation valve

On the Lada Vesta, the ventilation system is designed in such a way that in fact it always works the way a normal system works in the fourth mode. The flow of gases is limited only by a 1.7 mm jet built into the throttle pipe. In theory, the expectation was that the system would operate as a dual-circuit system.

This is how the ventilation scheme is implemented on 8 and 16-valve VAZ engines

The first circuit operates in the speed zone from idle to 1500 rpm. The pipe behind the throttle and the same 1.7 mm jet are involved here. The second circuit is connected to the ventilation already at high speeds, and gases begin to flow into the intake manifold up to the throttle through a hose with a diameter of 18 mm.

Schemes for upgrading the crankcase ventilation system

Schemes for modifying the crankcase ventilation system, as well as a description, are provided by IgorRV.

For LADA cars with manual transmission and AMT (“robot”), scheme No. 1 “Crankcase ventilation scheme with PCV valve for E-GAS and cable throttle” is suitable:

It is necessary to install a PCV valve (article 94580183, price about 400 rubles) from a foreign car into the small crankcase ventilation circuit. When connecting the PCV valve to a small circuit on an E-GAS, use a new hose (petrol-oil-resistant 8 mm without fabric reinforcement). On a cable choke, connect to the receiver, not to the choke.

As a result, the valve will shut off the circuits in transient modes, which will allow:

- Accept the load without jerking or dropping engine speed (for example, when the compressor is running, heated windows, seats, etc.).

- Reduce vibration load at idle

- Increase traction from the bottom (noted by owners of automatic transmission with VAZ-21126 engine, manual transmission with VAZ-21227, 21126 and 11186 and AMT with VAZ-21127).

- Get a sharper response to the gas pedal and faster shifts (on AMT). Perhaps due to the fact that the valve does not allow the engine to slow down, maintaining a more optimal switching algorithm.

- Reduce oil consumption through ventilation.

The valve replacement period is 40,000 km.

For LADA cars with automatic transmission (Jatco) and AMT (“robot”), scheme No. 2 is suitable:

Description of scheme No. 2: The pressure reducing valve is connected in series to a large ventilation circle. Thus, it regulates the flow of crankcase gases at high speeds and during transient processes. This allows:

- Exercise full control over the flow of crankcase gases between the small and large circuits.

- Improve engine operating mode.

- Reduce vibration load.

- Reduce oil release into ventilation.

For LADA cars with automatic transmission (Jatco) and AMT (“robot”), scheme No. 3 is suitable:

Description of scheme No. 3: To improve the operation of the braking system and facilitate the process of holding the car on the brakes in mode “D”, an “Ejection Pump” was used. Due to the flow of crankcase gases from the small circuit, the vacuum in the tube leading to the vacuum booster increases. This happens at low speeds, which is very helpful when driving in traffic jams. Keeping your foot on the brake all the time is not very easy, but this pump makes the task easier.

- Getting rid of vibrations, failures, transmission shocks.

- The engine begins to operate more calmly and softly.

- The force on the brake pedal becomes less.

- The air conditioner turns on almost imperceptibly.

- ejection pump (article 10793 VIKA, price 546 rubles);

- pressure reducing valve (article 1117701500 JP GROUP, 422 rubles);

- PCV valve (article 94580183 GENERAL MOTORS, 400 rubles);

- clamps (about 10 pieces, 600 rubles);

- thin, petrol-resistant 8 mm hose 50 cm (100 rubles);

- standard ventilation pipe.

Installing the PCV valve on Granta

:

Installing the PCV valve on Vesta:

By the way, there are other ways to modify the crankcase ventilation system. Are you ready for such modernizations? Let us remind you that modification of the ignition system (installation of capacitor ignition coils in the harness) is also common among owners of LADA cars.

Cons of SVKG in Lada Priora

By cleaning the atmosphere from the emission of toxic substances, SVKG creates problems for the engine. The gases that are removed from the pan, despite the presence of an oil separator, are saturated with microscopic oil particles, which after some time leads to contamination of the fuel intake system.

This leads to engine interruptions. Gas particles settle on the valve components, which leads to its failure. This disrupts the fuel injection system into the combustion chamber and increases oil consumption. If contamination is severe, fuel injection does not occur. In this case, the valve must be completely replaced. It is necessary to periodically inspect the crankcase ventilation hoses, because under the influence of the environment they age and crack.

If you detect oil stains, an increase in the amount of oil consumption, an increase in the consumption of fuel and lubricants, as well as disturbances in the engine (stopping, does not start for a long time, makes exhaust and other uncharacteristic sounds), be sure to immediately contact a service center to have the engine checked and repaired. Timely treatment will reduce the cost of engine repairs and prolong its operation.

If, while operating a LADA car, you notice that during load (when the air conditioner is running, the heating is on, etc.) in a traffic jam, the engine begins to operate unstably (troits, pulls poorly, etc.), perhaps the reason lies in the ventilation system crankcase The article proposes to solve the problem by installing a PCV valve from a foreign car.

Design and principle of operation

As was said at the very beginning, the ventilation system removes crankcase gases from the VAZ 2114 back into the engine, preventing unburned fuel oil mixture from entering the atmosphere. It includes a pair of pipes through which gases are removed, and a filter that traps solid particles and clots.

The whole system functions as follows:

- the fuel mixture entering the engine burns and forms exhaust gases, most of which are discharged from the engine into the exhaust line;

- a small part of the gases leaks through the piston rings and enters the lower pipe of the ventilation system;

- From the lower pipe, gases enter the filter (made in the form of a multilayer mesh), after which, already purified, they return to the engine, where they burn out.

Necessary tool

To clean the breather on a VAZ engine, check and replace the hoses, you don’t need any special skills or specialized equipment; a standard kit is enough. To complete the work you will need:

- set of keys No. 7-13;

- flat and Phillips screwdrivers;

- washing liquid, kerosene will do;

- container where washing will take place;

- rags;

- breather gasket;

- heat-resistant silicone-based sealant;

- if necessary, a set of new hoses will be required - separately for the carburetor and injector.

This tool can be found in any garage, so there are no problems with its selection. It is better to take rags that do not separate into individual elements, since during washing they can get into the engine.

How often should cleaning be performed?

If the ventilation system is clogged and its filter is unable to clean the mixture passing through it, then not only unburned gases, but also oil particles and other pollutants will enter the engine. All this will ultimately have a negative impact on both the operation of the engine and its remaining service life.

The frequency with which the crankcase ventilation of the VAZ 2114 should be cleaned directly depends on the condition of the engine. So, if the car just recently came off the assembly line, and its engine has not clocked up 50,000 km, you shouldn’t even think about cleaning it, since the piston rings are still new, and there is practically no leakage of gases through them.

The first cleaning (as recommended by AvtoVAZ itself) should be performed after the car has covered 60,000 km. And all subsequent cleanings should also be performed after every 60,000 km.

Many owners of domestic cars with extensive experience say that 60,000 km is too much, and cleaning should be done at least every 30,000 km - this will help avoid many problems with the engine and extend its life. In this case, the first cleaning should be carried out after the first 60,000 km.

Stories from our readers

“Fucking basin. "

Hi all! My name is Mikhail, now I’ll tell you a story about how I managed to exchange my two-wheeler for a 2010 Camry. It all started with the fact that I began to be wildly irritated by the breakdowns of the two-wheeler, it seemed like nothing serious was broken, but damn it, there were so many little things that really started to irritate me. This is where the idea arose that it was time to change the car to a foreign car. The choice fell on the melting Camry of the tenth years.

Yes, I had matured morally, but financially I just couldn’t handle it. I’ll say right away that I am against loans and taking a car, especially not a new one, on credit is unreasonable. My salary is 24k a month, so collecting 600-700 thousand is almost impossible for me. I started looking for different ways to make money on the Internet. You can’t imagine how many scams there are, what I haven’t tried: sports betting, network marketing, and even the volcano casino, where I successfully lost about 10 thousand ((The only direction in which it seemed to me that I could make money was currency trading on the stock exchange, they call it Forex. But when I started delving into it, I realized that it was very difficult for me. I continued to dig further and came across binary options. The essence is the same as in Forex, but it’s much easier to understand. I started reading forums, studying trading strategies. I tried it on a demo account, then opened a real account. To be honest, I didn’t manage to start earning money right away, until I understood all the mechanics of options, I lost about 3,000 rubles, but as it turned out, it was a precious experience. Now I earn 5-7 thousand rubles a day. I managed to get the car buy after half a year, but in my opinion this is a good result, and it’s not about the car, my life has changed, I naturally quit my job, I have more free time for myself and my family. You’ll laugh, but I work directly on the phone)) If If you want to change your life like me, then here’s what I advise you to do right now: 1. Register on the site 2. Practice on a Demo account (it’s free). 3. As soon as you get something on the Demo account, top up your REAL ACCOUNT and go to REAL MONEY! I also advise you to download the application to your phone, it’s much more convenient to work from your phone. Download here.

Simple, but not brilliant: what might not work in the crankcase ventilation system?

Sometimes things happen to a car that really upset its owner. Something started to eat oil, the throttle valve is constantly dirty, oil flows from all the cracks... Even the air filter is covered in this oil. It's probably time to think about capital. Money money money. Pain, melancholy, hopelessness. Or maybe it’s too early to sharpen the razor and fill the bath with warm water? Maybe not everything is so bad, and the solution to the problem lies in a small and not so expensive part with the strange name “PCV valve”?

Gas theory

We all remember very well that the engine works due to the combustion of the fuel-air mixture. At the moment when this very beautiful, but invisible to the eye process begins in the combustion chamber, the pressure there sharply increases. This pressure pushes the piston down, the piston presses on its crankshaft journal, and it does its direct work: it converts the translational motion of the piston connecting rod into rotational motion, which is transmitted to the engine flywheel. The picture is perfect, but in life, as you understand, something always goes wrong. In our case, not all gases formed during combustion then exit through the exhaust valve into the exhaust system. Some of them will definitely break into the crankcase. Roughly speaking - under the piston. This happens for a simple reason: no matter how tightly the compression rings fit, they always have at least a minimum gap - otherwise the piston simply would not be able to move inside the cylinder. And on a cold engine this gap is even larger, so the gas, which is under very high pressure, will always find a loophole in the engine crankcase. What does this mean?

These gases contain everything that motor oil does not like. Incompletely burned gasoline, water vapor (they are always in the air), soot particles - all this settles in the engine oil. Nothing good, of course, happens after this: the oil ages rapidly and stops working normally. But that's not the worst thing.

It is much worse that there simply should not be high pressure in the crankcase, and crankcase gases greatly increase it. The consequences of this process are very unpleasant. The gases literally burst the engine, and it begins to squeeze out everything unnecessary. And when the engine “swells,” everything seems superfluous to it: crankcase gases and oil. Gases try to escape through the oil dipstick, pushing it out through the oil filler neck and all other places. Including through all seals and seals. If he manages to push out the crankshaft oil seal, then oil will flow through it.

In a word, these gases must be removed somehow. And for this they came up with a crankcase ventilation system.

Open and closed

Initially, the ventilation system was primitive - open type (or ejection). Do you remember such an amazing word - breather? This was the very open ventilation system. Through a proudly protruding breather, crankcase gases with all their delights in the form of soot, oil and other nasties were released into the atmosphere. And sometimes nothing was thrown out of there, because such a system was not particularly effective.

It didn’t differ, if only simply because at idle the pressure of the crankcase gases was not enough to remove them from the engine. Everything that broke into the crankcase was deposited in the oil. In addition, there was always the possibility of catching dirty air through the breather, which would then end up in the crankcase. There, all the impurities from this air would settle into the oil, and this would significantly reduce the life of the cylinder-piston group. In general, there was nothing good about the breather, and the system really required a serious revision. And as a result of this revision, a modern PCV (positive crankcase ventilation) system appeared - a forced ventilation system.

PCV systems differ in implementation. They can be simpler or more complex, with two circuits, with an ejector pump, with a pressure reducing valve. But we will look at the simplest and most common system with a single PCV valve. So how does it work?

The developers of this system used a feature of the intake manifold: a vacuum is created in it. It is especially strong at idle or minimum speed. If you connect that same imaginary open system breather to the intake manifold, the vacuum will draw out crankcase gases. In addition, they will flow back into the intake, and not into the atmosphere, which will greatly please environmentalists. There are only two problems left to solve: how to dose this very “suction” from the side of the manifold and how to prevent oil and other unnecessary fractions from getting into the intake along with crankcase gases.

The first problem is solved by the same PCV valve. When operating at minimum speed, it is practically closed. This means that a vacuum remains in the manifold, and since in this mode the emission of crankcase gases is minimal, even a small removal of them is quite enough. As the crankshaft speed increases, the valve begins to open. This is necessary for two reasons: firstly, the vacuum decreases, which means that gases need to be pumped out more intensively, and secondly, the amount of these gases increases. Opening the valve allows a large amount of gases to be removed even with a small vacuum in the intake manifold.

The second issue is cleaning crankcase gases. There are several ways, but the simplest and most obvious is installing an oil separator. It has a complex labyrinth through which gases move. During the passage of the labyrinth, the speed of movement drops, and droplets of oil settle on its walls, from where they flow back into the crankcase. More or less clean air then flows back into the intake. Of course, oil separators come in different designs - labyrinth or centrifugal, but they solve the same problem.

avtoexperts.ru

Among various auto systems, the crankcase ventilation system plays a significant role in the formation of the air-fuel mixture, stable and economical operation, full power delivery, protection of engine oil and extension of the life of the cylinder-piston group.

In the design of a car, the crankcase ventilation system is the “lungs” of the engine, necessary for its normal functioning. The system is called PCV (Positive Crankcase Ventilation). However, it is the one that is undeservedly given a minimum of attention and maintenance, and many car owners do not even know about its existence. In this article we will try to understand why this system is needed, how it works, its inherent faults and methods for checking its performance.

What are “crankcase gases”?

During combustion, the fuel-air mixture sharply increases in volume, creating enormous pressure inside the combustion chamber. The expanding gases from combustion force the piston to bottom dead center, causing the engine crankshaft to rotate. Some of the gases penetrate through the leaks between the rings and the cylinder mirror into the oil pan, where, mixing with oil vapor, they create pressure that aggressively affects the crankshaft seals and the pan gasket, and the oil dipstick channel.

The expansion stroke is repeated in each cylinder, constantly pumping the next portion of gases into the sump, and if the crankcase ventilation does not work, the gases will either squeeze out the crankshaft oil seals, or “knock out” the oil dipstick and expel the oil from the crankcase, with all that follows.

In addition, particles of unburned fuel, small fragments of soot, and moisture vapor are transferred to the sump along with the gas, which are mixed with the engine oil located in the engine sump. This, in turn, leads to oxidation of the oil, clogging it with wear products, reducing its performance properties and reducing its service life.

System design

In order to minimize the impact of gas pressure, the engine design provides crankcase ventilation systems. Modern cars use a closed ventilation system, which is necessary to comply with environmental standards.

Despite the differences in systems on different brands of cars, they all have three common components, such as:

• Air pipes for removing gases from the crankcase;

• Ventilation valve, responsible for regulating the gas pressure;

• An oil separator that cuts off oil vapors as gases exit the engine sump.

The valve opens when excess pressure appears and closes when there is a vacuum, that is, the principle of its operation is based on the difference in pressure behind and in front of it.

The separation of oil particles is carried out by the passage of gases through a system of labyrinths, vortices and grids in oil separators. The separated oil then flows back into the engine sump. This not only saves oil, but also protects engine parts from carbon deposits. In this case, oil separators can be located inside the valve covers, built into the engine, or made as a separate unit.

Principle of operation

The system works as follows. The ventilation pipe is connected to the intake manifold, where immediately after starting the engine, a vacuum is created, due to which crankcase gases are “pulled” from the pan and passing through the oil separator enter the intake, where, mixing with the incoming air, they enter the combustion chamber and burn out.

Advantages of the ventilation system

The use of crankcase ventilation allows you to reduce the percentage of harmful emissions into the atmosphere, reduce engine oil waste, and maintain stable engine speeds when warming up, since the intake air mixes with crankcase gases and heats up, which generally has a beneficial effect on the operation of the power plant.

Flaws

Despite the presence of an oil separator, the air ducts and intake elements become dirty from the passage of crankcase gases, causing frequent failures of the devices during operation. So, on gasoline car models, the throttle valve assembly and idle speed control become coated, since they have special channels that perform an exhaust function. This can also be observed on carburetor models, for example, with a Solex carburetor equipped with a fitting for crankcase ventilation.

The throttle valve assembly and gas exhaust valve on carburetors are the so-called small branch and are activated when the vacuum in the air filter is insufficient.

Symptoms of a PCV Problem

• The appearance of traces of oil in the air filter;

• Fogging of oil seals and the joint of the engine valve cover;

• Smoke from the exhaust due to oil particles and gases entering the combustion chamber;

• Traces of oil around the filler cap and on the valve covers.

The role of the oil separator

An oil separator, often called an oil sump, is designed to capture large and fine oil particles. Its role is extremely important for the proper operation of the mass air flow sensor (MAF). As oil mist settles on the walls of the intake tract, it quickly becomes covered with dust. Because of this, the operation of the flow meter’s sensitive element is disrupted. The engine control unit receives incorrect readings about the amount of air entering the intake tract. Therefore, forced crankcase ventilation of a modern engine may include several types of oil separators.

Labyrinth oil trap

When gases move through the labyrinth, large oil particles under the influence of inertial forces are pushed towards the walls of the oil separator. The oil flows by gravity through the separator plates into the pan. An oil trap similar in operating principle, consisting of a set of plates, is installed in the valve cover of VAZ injection engines.

Cyclic oil trap

Designed to capture fine particles of oil suspension. As crankcase gases pass around the circumference of the oil separator housing, oil droplets move outward, settling on the walls of the oil separator housing.

Oil separator with filter element

Filter paper or fiberglass filler is installed inside the housing. Passing through the filter, the oil is retained on the walls of the filter element, after which it flows into the pan.

Turbulence of exhaust gas flows moving through the crankcase ventilation hose impairs the uniform filling of the cylinders. Therefore, many cars have an additional sedation chamber installed. In addition to a gas flow retarder, the chamber also acts as an additional oil separator.

The carburetor engine ventilation system is clogged, signs and causes

There are several signs of clogging of the ventilation system of a carburetor engine, upon discovering which it makes sense to inspect it and diagnose the causes of the malfunction.

Signs of a clogged carburetor engine ventilation system

Using the example of the engine ventilation system 21083 of VAZ 21083, 21093, 21099.

— “Drives” engine oil under oil seals and engine seals

On a 21083 carburetor engine, engine oil can “drive” under the crankshaft seals (front, rear), camshaft oil seal, valve cover gasket, valve cover oil filler plug, engine sump gasket, dipstick, system hose mounting locations. Oil leaks can vary in size depending on the degree of clogging of the crankcase ventilation system. It will not be possible to eliminate a leak by replacing a part (gasket, oil seal), since the cause of the malfunction is not its wear, but an increase in gas pressure in the engine crankcase.

“Drives” engine oil under the camshaft oil seal of engine 21083

— Engine oil in the engine air filter housing

There is a constant release of engine oil into the engine air filter housing through the holes in the ventilation system. This oil, as well as soot and other soot carried by crankcase gases from the sump, clogs the filter element of the engine air filter.

Engine oil in engine air filter housing

— The carburetor becomes clogged with oil

If you look at the carburetor from above (removing the cover of the air filter housing), you can observe an oily coating on the walls of the carburetor mixing chambers, the air damper, and the air jets of the gas turbine engine. Engine oil enters the carburetor from the air filter housing. Clogging of the carburetor air jets (especially in combination with a dirty engine air filter) leads to a sharp over-enrichment of the fuel mixture. And these are problems with starting, idling, power and throttle response of the car engine.

Contamination of the walls of the carburetor, its air damper, and air jets of the gas injection pump with engine oil

— Oil deposits on the spark plug electrodes

The spark plug electrodes, as well as their threaded part and insulator, are constantly clogged with dark oily deposits as the oil released from the crankcase ventilation system enters the combustion chambers through the engine air filter and carburetor. In this case, the spark plugs stop working effectively, and misfires appear (the spark goes to ground after flying). Deposits of unburnt fuel mixture (black or dark gray soot) begin to actively deposit on the spark plug.

Oily spark plug electrodes

— Blue (grey) smoke from the muffler

When motor oil burns in the combustion chambers of the engine, characteristic gray (blue) smoke is released, which comes out of the exhaust pipe of the car muffler. Smoke comes out constantly, to a greater or lesser extent (depending on how much oil gets into the combustion chambers).

It should be noted that other car engine malfunctions have similar symptoms - wear of piston group elements, stuck piston rings, wear of oil seals. Therefore, when diagnosing a malfunction yourself, you should take these possible engine problems into account.

— Increased engine oil consumption

As the engine crankcase ventilation system becomes clogged, the consumption of engine oil will increase as it is squeezed out through the oil seals and other seals by the increased pressure in the crankcase, and is also released through the ventilation system into the carburetor and further into the combustion chambers. Where it burns. Therefore, at an early stage of clogging of the ventilation system, a phenomenon is possible when there are no oil leaks anywhere, but it goes somewhere.

Causes of clogging of the crankcase ventilation system of a carburetor engine

— Long engine life

On engines with high mileage (more than 100-120 thousand), the crankcase ventilation system gradually becomes clogged with soot, soot, oil, and crankcase gases. All this constantly settles on the walls of the system channels, narrowing their clearance, as well as on the oil separator under the valve cover, clogging its honeycombs. The ventilation system ceases to effectively remove gases from the crankcase. The gas pressure in the crankcase increases. At elevated pressure, engine oil begins to ooze out from wherever possible. In addition, due to high pressure, oil is released along with gases into the air filter housing.

— Wear of parts of the piston group of a car engine

Wear (due to age or operational use) of piston group parts (cylinders, rings, pistons) leads to the breakthrough of a large volume of gases from the combustion chambers into the engine crankcase through the enlarged gaps. Accordingly, the load on the crankcase ventilation system increases, and the formation of deposits on the walls of its channels accelerates many times over.

A similar effect will occur when the engine piston rings are stuck and the grooves in the pistons become coked by deposits.

— Use of low-quality motor oils

Long-term operation of the engine on low-quality engine oil leads to an increase in the volume of soot and soot in the crankcase gases. Which also affects clogging of the crankcase ventilation system. In addition, low-quality motor oil or one that does not correspond to this type of engine can cause coking of the piston rings.

In what places does the crankcase ventilation system most often become clogged?

— Calibrated hole for the crankcase gas sampling fitting from the small branch of the ventilation system in the carburetor

— Small branch hose from the valve cover to the carburetor fitting

— Fitting on the valve cover for the small branch hose

— Oil separator under the valve cover

— Breather outlet under the hose to the valve cover

What to do if signs of clogging of the crankcase ventilation system are detected?

You can clean the engine crankcase ventilation system yourself, since its main parts are easily accessible. To carry out cleaning, you should stock up on solvent or diesel fuel, rags and wire. The entire procedure is described in detail in the article “Cleaning the ventilation system of a boat carburetor engine VAZ 2108, 2109, 21099.”

Notes and additions

The crankcase ventilation system of a carburetor engine is designed to ensure the effective removal of gases from the engine crankcase into its intake tract, thereby ensuring their afterburning in the combustion chambers and preventing the release of toxic substances contained in the gases into the atmosphere.

Gases from the crankcase pass through the breather and a large hose under the engine valve cover. Under the cover, an oil separator separates the oil from the gases. The small branch hose removes gases under the carburetor throttle valve at idle. The large branches are removed through the hose into the air filter housing and then into the carburetor in other engine operating modes.

Article: 2112-1014056, additional articles: 2112-1014056Р

Order code: 006580

- Buy with this product

- show more

- Passenger cars / VAZ / VAZ-21101 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2110-10/sistema_smazki_i_ventilyacii-105/#part40486″>Lower hoseEngine / Lubrication and ventilation system

- Passenger cars / VAZ / VAZ-21121 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2112-12/sistema_smazki_i_ventilyacii-105/#part49102″>Lower hoseEngine / Lubrication and ventilation system

- Passenger cars / VAZ / Lada Priora 21701 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/lada_priora_2170-480/sistema_smazki_i_ventilyacii-77/#part1578912″>Lower hoseEngine / Lubrication and ventilation system

- Passenger cars / VAZ / Lada Kalina 2192, 21941 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/lada_kalina_2192__2194-1646/sistema_smazki_i_ventilyacii-56/#part3652972″>Lower hoseLubricating system / Lubrication and ventilation system

- Passenger cars / VAZ / Lada Kalina 21941 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/lada_kalina_2194-1886/a501__sistema_smazki_i_ventilyacii-130/#part4210486″>Lower hose Lubrication system / A501. Lubrication and ventilation system

- Passenger cars / VAZ / Lada Granta 21901 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/lada_granta_2190-1893/a501__sistema_smazki_i_ventilyacii-122/#part4242903″>Lower hoseLubricating system / A501. Lubrication and ventilation system

- Passenger cars / VAZ / VAZ-21111 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2111-11/sistema_smazki_i_ventilyacii-105/#part44794″>Lower hoseEngine / Lubrication and ventilation system

- Passenger cars / VAZ / VAZ-2110, 2111, 21121 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2110__2111__2112-415/sistema_smazki_i_ventilyacii-120/#part1302912″>Lower hoseEngine / Lubrication and ventilation system

- Passenger cars / VAZ / Lada Kalina 1119 Sport1 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/lada_kalina_1119_sport-1556/sistema_smazki_i_ventilyacii-33/#part3438987″>Lower hoseLubricating system / Lubrication and ventilation system

- Passenger cars / VAZ / Lada Priora 21728 Coupe1 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/lada_priora_21728_coupe-1878/sistema_smazki_i_ventilyacii-80/#part4190138″>Hose lower Lubrication system / Lubrication and ventilation system

- Passenger cars / VAZ / Lada Priora 2170 FL1 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/lada_priora_2170__fl-1889/a501__sistema_smazki_i_ventilyacii-146/#part4224085″>Lower hoseLubricating system / A501. Lubrication and ventilation system

- Passenger cars / VAZ / Lada Vesta1 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/lada_vesta-1883/141010__separator-148/#part4202781″>Crankcase VENTILATION HOSEAdsorber, separator / 141010. Separator

- There are no reviews for this product yet.

Today, in the next article in the series “Crystal VAZs or typical breakdowns of domestic cars,” we will talk about the latest developments of the Volzhsky Automobile Plant: Lada Grante and Lada Largus. Let's talk about the history of the creation of these models, as well as their characteristic malfunctions.