Varieties of backstage

There are many models and designs. Each of them is characterized by its own characteristics. They are usually classified into two main types:

- long stroke;

- short-stroke.

Long-stroke scenes are often called standard. They were used in the production of cars of the domestic VAZ brand (starting from 2109, etc.). Short-stroke rockers are typical for Kalina cars. They are similar in design to long-stroke ones.

Attention! The main difference between long-stroke and short-stroke is size. It is due to this that it is more convenient to change gears to second.

Sports

We noted that for the VAZ 2114 you can install a sports short-throw rocker. Outwardly they are quite similar, but the difference in work is felt immediately. On a sports unit, gears shift faster and smoother. It's all about the design of the backstage itself. Unfortunately, it is precisely because of this that the process of independent replacement becomes almost impossible.

Sports model

If you decide to install a short-throw rocker on your VAZ 2114, contact trusted car services, or even better, a studio that specializes in tuning. Such events are classified as technical improvement, which is why no one understands this better than tuning specialists. Even official AvtoVAZ car services.

Backstage adjustment

- Loosening the nut located on the clamp;

- Adjusting the position of the lever (at this stage you need to place it in the reverse position, and then tighten the nut on the clamp;

- Checking the gear engagement (here you need to carefully monitor the position - if the left side prevails when engaging reverse gear, then you need to smoothly move the cardan counterclockwise; if, on the contrary, the speed has “gone” to the right, then you need to turn it clockwise).

The correctness of the result of the adjustment process can be easily verified. To do this, you just need to install the lever in the middle. If everything was done correctly, the neutral gear will engage.

Advice! Watch the position of the lever itself. When installed correctly, the part will move freely. If it still interferes with the passenger or driver’s seat, then re-adjustment is required.

What is a short-stroke link?

The standard rocker on the VAZ 2114 is a very reliable device, and even in the event of any malfunctions, it is easily repaired, is unpretentious to donor parts and creates a general impression of an analogue of a Kalashnikov assault rifle from the world of automobile rockers.

But what is really not pleasing about it is the attitude of the designers towards the comfort of the car enthusiast; perhaps some of them think that clogging the gears with a sweeping click is stylish, but in reality it only distracts from the road. It was to resolve this situation that the short-stroke slide was created.

Short-stroke rocker VAZ 2114

This engineering idea is not something innovative; this idea came to civil vehicles from the world of sports competitions, where fractions of seconds decide everything. Initially, to reduce switching time and increase its accuracy in sports, boxes with a lever mounted in the gearbox housing were used, but it transmitted vibrations and did not allow the creation of more convenient control methods.

Therefore, a mechanism called a rocker was developed, the task of which was to convey the motorist’s decision to shift the gear forks into the gearbox through racks located outside the gearbox housing. This gearbox control inherited the sweeping switching of the forks from its older brother - the “lever in the body”.

Therefore, this engineering solution was further improved, as a result of which a short-stroke rocker appeared on the VAZ 2114 and other cars.

Pros and cons of a short-throw rocker

The motorist should understand that replacing the VAZ 2114 backstage will bring not only positive aspects to his life, but also some difficulties, which is worth knowing in advance.

So, the clear advantages of such modernization include:

- reducing the travel of the gearshift lever by two or more times;

- eradication of backlashes present in the standard scenes of cars;

- high switching accuracy;

- minimal use of the driver's shoulder to change gears (the load is transferred to the hand).

Short-stroke kit

There is only one downside: reducing the force lever leads to an increase in the load on the synchronizers, which increases the rate of their depreciation by two or more times.

Is it worth fixing the problem?

Many people don’t even try to fix the gearshift lever of a VAZ 2114, but this task is completely solvable, it doesn’t require skills, and the undeniable advantages are worth an hour of time. The difference is so noticeable that if a breakdown has been present in your life for a long time, you will constantly remember that there is not enough noise.

The main thing to remember is that a machine is like a person, what “cured” one is not the fact that it will help the other, and don’t get upset.

The repair will take very little time, you can get away with a small sum, and in return you will receive a number of huge advantages, such as:

- the unpleasant sounds accompanying the increase in speed will disappear;

- the gearshift lever will be fixed;

- switching will become smooth;

- At idle, the lever will stop “dancing the lambada” under your hand.

Modernization of standard to short-stroke

If you are not afraid of the minus associated with reducing the time before repairing another unit, but it is too easy to buy a ready-made copy, know that the standard rocker on a VAZ 2114 can be converted into a short-stroke one with due effort.

To carry out this operation you will need:

- standard rocker 2114;

- backstage repair kit 2114 (the bushings and axle from it will be useful);

- ball nut;

- metal tube with a diameter of 15 mm;

- steering cardan.

When all the necessary spare parts have been found, you must perform the steps in the following order:

- We cut the ball from the wings.

- We grind the lower edge of the cut so that it fits the tube.

- We put on the pipe and scald.

- We weld a ball nut to the lower edge of the structure.

- We attach the cardan to the gearshift lever.

- Then we proceed as when replacing the rocker seal and put everything back together.

Replacing the backstage with a short-stroke one

CLARIFICATION! The essence of this procedure is that reducing the stroke is achieved by changing the length of the pressure lever. The action we performed is aimed at reducing the shift lever on our side, by increasing it on the side of the box.

If you carry out the modernization using this “makeshift” method, you will not have to remove the standard rocker.

Price issue

If you decide to replace the rocker seal at the same time as installing the rocker itself, this can be considered absolutely the right thing to do. Additionally, replacing the driveshaft will not cost much, but the efficiency of such a comprehensive repair will be much higher.

Short walker

Actions on your own, you only have to purchase the necessary parts and ordinary consumables. If you contact a car service, the minimum cost of the service will be 800-1000 rubles. That is, the savings are obvious.

The curtain itself costs about 400 rubles. From here it becomes clear why we did not advise buying a repair kit, but rather completely replacing the part. There will be no savings as such, but the difference as a result of the repair will be significant.

Installing a shop short-throw rocker on a VAZ 2114

If you purchased a ready-made unit, but don’t know how to change the rocker on a VAZ 2114, you just need to follow these steps one by one:

- Remove the decorative casing.

- We put the car in a pit or lift it on a jack.

IMPORTANT! Do not forget about safety precautions; place a support under the rear wheel on the opposite side of the jack, or under diagonally opposite front and rear wheels when working in a hole.

- We dismantle the console hiding the backstage.

- We twist four bolts (they are at “13” and there are six of them).

- You will have to cut off the upper ones and look for a spanner wrench and make an analogue of a power lever for it.

- Pull off the boot and remove the clamp.

IMPORTANT! Changing the rocker is the ideal time to replace such components as the cardan, hinge, and oil seal. They are very short-lived, so if you are changing the rocker itself, change the accompanying units to delay the next meeting with the bottom of your car as far as possible.

- We put a new stage in place of the dismantled “old” one.

- We assemble the entire assembly in reverse order.

Replacing the backstage

Replacement instructions

Before starting work, we advise you not only to purchase a new spare part, but also to watch training videos on replacing the slide. The procedure is not very complicated, but a visual aid will never be superfluous. Especially if you do not have much experience in repairing a car and transmission in particular.

Replacement procedure

The process involves performing several sequential steps.

- Remove the housing from your gear shift knob.

- Raise the car using a jack. In some cases, an inspection hole will do, if you have one in your garage.

- Now you should dismantle the console, which will give you access to the backstage.

- The element is held in place by six bolts, which can be removed using a regular 13 mm wrench.

- But it's not that simple. You won’t be able to unscrew the top two bolts with a wrench, so don’t even try. They are specially planted as tightly as possible, so to dismantle them you simply need to cut them down with a grinder.

- Now you can safely remove the remaining two bolts in the lower fastening of the rocker, for which your effort and a 13 key will definitely be enough.

- The next step is to remove the clamp and move the boot. You will need to remove the hinge. At the same time as replacing the link, we recommend changing the hinge. It would be a good idea to replace the oil seal and cardan shaft. These elements have a limited service life, and since you decide to change the slide itself, there are objective reasons to do everything as efficiently as possible.

- After this, install the new unit in place of the old one. Act carefully so that the rubber bands of the slides fall on the welded bolts, which you previously sawed off using a grinder.

- The assembly is now reassembled, operating in the opposite sequence to disassembly. It is not necessary to seat the top mounting bolts tightly, but try to tighten them firmly.

Adjusting QC

If you manage to replace the unit yourself, then it makes no sense to contact a specialist to adjust it. True, it will be very difficult to do this yourself; it is better to ask someone you know.

There are two methods for setting up a freshly installed rocker:

- In reverse gear, we put a friend behind the wheel and ask him to engage reverse gear. We install the lever in the most convenient position, in your opinion, and climb under the car, where we put the lever in place of the reverse gear and tighten the clamp.

- In first gear - if you can’t get the rear one in, put in the first one. We loosen the clamp as in the first case, but this time we must turn the drive, this must be done so that it reaches counterclockwise until the stop of the plastic clamp, after which we fix the clamp.

Let's get down to business

The short-stroke rocker for the VAZ 2109 requires the following tools for manufacturing:

- Grinder and cutting wheel for metal or, at worst, a hacksaw for metal

- A piece of pipe and a piece of flat metal

- Welding (welding machine)

- be sure to purchase a lever drive from Lada Kalina

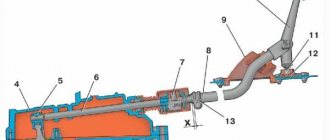

- The photo shows the places where you will need to make an incision.

Cut locations for your standard lever

- Everything is quite simple: you will need to remove the rocker from the car

- Moreover, it is not necessary to remove everything (I admit, I did just that and regretted it a little - it’s a chore, it turns out) it will be enough to disassemble your ball joint (to do this, unclench the locking metal ring so that the plastic fastening tabs separate and the ball is released)

- Then loosen the clamp near the gearbox and turn off the traction

- After this, carefully pull the rod through the dirt cover and get out of the car.

- Now you need a grinder with a cutting wheel for metal, a familiar welder with a welding machine, or someone who has access to one (you have the machine and know how to weld yourself - generally a test)

- Next, use a grinder to cut the parts according to the marks in the top photo. Then we weld a piece of pipe (with a wall thickness of 2 - 3 millimeters) into the rod and a piece of sheet metal with a thickness of 5 - 6 millimeters

- These pieces must certainly have the same length, otherwise you will have an unpleasant distortion, which is not at all desirable and the drive will only work worse

- For myself, I lengthened it by only 2 centimeters

- However, the space in the cabin allows you to lengthen it by 3 - 5 centimeters

After the cut, prepare pieces for insertion of the same size

- At first two centimeters was quite enough for me, but then I got used to them and it seems not enough again

- By the way, regarding the pieces, welders have nowhere to put them; as a rule, finding a suitable one does not cause any problems

- The VAZ 2109 short-stroke rocker is installed in the reverse order of removal

- However, among other things, the hinge with a hook, which serves to prevent erroneous engagement of reverse gear, rises automatically and no longer fits into a special slot on the blocking plate

- In order to avoid this, either remove this plate completely (this is for the especially lazy) you can ride without it, or you should move it upstairs to the height to which the hinge has risen

When you have installed the rocker on the VAZ 21093 gearbox, all that remains is to replace the drive shaft to eliminate play in the lever

In conclusion

Now you know how to replace the short-stroke linkage and understand that it is within your power. The main thing is to be patient and the convenience of a short gearbox will appear in your car.

Published April 11, 2018

A problem with the lever when changing gears is sometimes found among domestically produced cars. Unfortunately, the VAZ 2115 is no exception. The most likely cause is a broken linkage. Of course, any problem can be fixed at a car service center. but the operation of this part can be adjusted independently. In this article we will talk about adjusting the VAZ 2115 rocker panels, what types of rocker panels exist and why it is important to know about it.

Varieties of backstage

All existing models can be divided into two large groups: long-stroke and short-stroke. Within these groups, various designs with their own characteristic features are allowed.

- Long-stroke scenes are usually called standard. These are the parts that the manufacturer installs on various VAZ models (from 2109 onwards).

- Short-travel rockers are more common in Kalina cars. However, the design of both parts is very similar.

What then is the difference between these devices? It's their size. The short-stroke rocker is smaller, so its big advantage is the convenient lever travel. Gear shifts with higher precision. Perhaps the most serious drawback of this device is its price. As a rule, a short-stroke link costs much more than a long-stroke one. In addition, some car owners note that after replacing a standard part with a short-stroke one, they have to use more force to change gear. So, how to adjust the rocker on a VAZ 2115?

This procedure can be carried out using the following simple steps:

- The nut located on the clamp needs to be loosened.

- Adjust the position of the lever - move it to the reverse speed position, and then tighten the nut on the clamp.

- Check how the gears are engaged: if the reverse gear has moved too far to the left, you need to loosen the clamp a little and smoothly turn the cardan counterclockwise. If the speed goes to the right, the cardan must be rotated clockwise.

How to check whether the adjustment was carried out correctly? To do this, the lever must be installed in the center. If the transmission is in neutral, then everything was done correctly.

Important reminder: The lever must be positioned so that it can move freely without impacting the passenger seat (in fifth gear) or the driver seat (in reverse). Otherwise, the lever must be readjusted.

The cardan installed by the manufacturer on the VAZ 2115 is characterized by small backlashes. To get rid of the associated vagueness in switching, you simply need to replace the “native” part with a cardan from Kalina. The experience of many motorists shows that it is more reliable and can last much longer than the standard one. It is worth considering that the Kalinovsky cardan is slightly longer than the standard one. For this reason, it must be shortened before installation. For this procedure you will need the following equipment: a grinder, a clamp, tape and a grinding tool. And, of course, it is important not to forget to first remove the “native” cardan. How to make the driveshaft from Kalina shorter:

- Compare the sizes of the standard and Kalinovsky universal joints, and wrap the part that needs to be cut with tape.

- Install the cardan into the clamp and get rid of the excess length using a grinder.

- Go over the finished part with a sanding tool. This will make it easier to install.

The following are the steps on how to install a prepared cardan on a VAZ 2115:

- Check how accurately the cutting was done - to do this, the part must be inserted into the hole allocated for it. If the cardan fits in without problems, then the trimming was completed successfully.

- Install the backstage boot.

- Place the newly shortened cardan and secure it with a wrench.

- Pull the previously installed boot completely onto the cardan.

It is important to remember that the oil seal may also need to be replaced. So during the process of replacing the cardan, it is worth inspecting the oil seal for damage.

Replacing the universal joint

Most often, faults occur in the cardan, and not in the rocker itself, so it is this that needs to be replaced. Even the slightest displacement of the cardan can cause failures in the entire gear shift mechanism.

- Step 1. Release the clamp on the drive rod and pull it off the rod.

- Step 2. Remove the boot and knock down the cardan. This must be done carefully, with light blows of a hammer. If cuts or other damage is found on the boot, it is best to replace it with a new one.

- Step 3. Install the new universal joint. In this case, you need to do all the steps in reverse order, but do not tighten the clamp. After this, you need to adjust the system (the sequence of actions is described in the corresponding subtitle of the article).

In this guide, we talked in detail about adjusting the shift link on the VAZ 2115, listed the types of this part, suggested how it can be modified, and also described the process of replacing the gear shift link.

Content

Varieties of backstage

Despite the different design models, only two types can be distinguished:

- Long-stroke (standard, previously installed on cars of model 2109 and similar).

- Short-wheel drive (installed on Kalina cars).

Structurally they are very similar, only different in size. The advantage of short-throw ones is that with their help, gears are engaged easier and faster.

True, many myths have formed around the gear shift: some claim that the dynamic characteristics of the car are significantly improved. This is all wrong; there is no connection between the dynamics of the car and the view of the backstage. But still, the short-stroke one has advantages over the standard one.

Why change the backstage

There are situations when it is necessary to intervene in the gear shift mechanism due to the failure of a component. But there are cases when an extreme measure is required - replacing the VAZ-2109, 2114 rocker.

In these cases, replacement is required:

- An oil leak appeared due to damage to the oil seal. Only the oil seal can be replaced.

- Complete failure of the scenes.

- You have realized the advantages of a short-stroke design and you have the funds for this kind of tuning.

Symptoms of gear shift mechanism failure:

- Increased gearshift lever play. Please note that this behavior may also be caused by a loose cardan. Sometimes the bolt securing it gets screwed out, so to reduce the backlash it is enough to tighten it, and first apply a drop of thread locker.

- Difficult to shift into gear. Sometimes extraneous sounds are heard.

- Gear shifting is not possible.

- Inconsistency between the position of the lever and the selected speed. For example, the back one disappears, and the first one is in its place.

If a slight play appears, it is advisable to carry out diagnostics and identify the breakdown of the unit. Make repairs immediately, otherwise one or more speeds will disappear at the most inopportune moment.

If you detect an oil leak from the gearbox, carefully inspect the crankcase. The leak will reveal itself. Lubricant usually leaks out through the CV joint seals and rocker panels.

In the latter case, to replace you will need to perform a number of actions:

- Purchase a new gearbox seal for VAZ-2109, 2114. Its price is about 100 -200 rubles.

- Drain the oil completely from the gearbox by unscrewing the plug from the bottom using the key “17”. If necessary, you can replace the lubricant later. It is recommended to pull out the upper dipstick to facilitate oil drainage.

- Disconnect the cardan from the rocker arm.

- Remove the boot, use a 10mm wrench to unscrew the bolt securing it to the gearbox rod.

- Using an awl or a thin screwdriver, remove the old oil seal. Inspect it for damage.

- Install the new oil seal using a pipe or large washer to press in.

After replacement, install the boot. Assess the condition of the cardan: if it has too much play, it will need replacement. After carrying out all the work, be sure to check that the speeds are turned on correctly.

In most cases, it is not the rocker itself that fails, but the cardan. Due to its displacement, even a small one, a failure occurs in the gear shift mechanism.

Standard VAZ-2109,2114 scenes are rarely installed during repairs; similar parts from Lada Kalina are used. The replacement looks like this:

- Using two keys set to “13”, unscrew the clamp securing the cardan to the rod.

- Using a screwdriver, pull the boot towards the box housing. If desired, you can remove it completely, and if it has cuts or other damage, replace it with a new one.

- Unscrew the fixing bolt with a “10” key.

- Knock down the cardan with a hammer, strike carefully so as not to damage anything.

- The Kalinovsky universal joint is much more durable and reliable, so install it instead of the standard one.

- Reassemble the entire structure in reverse order. But do not rush to tighten the bolt on the clamp - adjustment is necessary.

Video: Replacing the VAZ 2109 Backstage Repair Kit

How to adjust the wings of a VAZ 2110?

It should be noted that the block is replaced only after full adjustment. Failure to do so could result in you losing a significant amount of money for a completely different reason.

It is recommended to adjust the curtain in the following cases:

When one of the above symptoms occurs;

- After removing the gearbox;

- after replacing the cardboard or unscrewing the fixing clips;

- after turning the wings on their hinges.

Keep in mind that even minimal changes in spacing make a difference when making adjustments.

For example, a displacement of the wings relative to the cardan by 1-2 millimeters can lead to complete restoration of the functions of the gearbox.

To adjust the wings, proceed as follows:

- Sit on the overpass (try hard, but put it in first gear).

- When you reach altitude, do not touch the shift knob (leave first gear engaged).

- Turn on the handbrake and place the cartridges.

- Sit under the car and locate the clamp that secures the hinge and joint.

- Loosen the collar.

- Get into the car and move the lever behind the scenes to the left (other directions are prohibited).

- Get under the car and lock the clamp.

- Check the gearbox.

Guide to replacing the wing of a VAZ 2110

If the setting didn't work, here's the best option. replace the VAZ 2110 or repair it (if you have the necessary skills).

The job of replacing the scenery is as follows:

1. Culinary tool. You will need a screwdriver, side knives and a set of wrenches.

2. Buy a VAZ 2110 for body repairs.

3. Open the cover.

4. Locate the nut that connects the transmission rod to the handle tip.

5. Remove the special cover and press the disc away from the nut.

6. Get into the car and remove the arm control frame. Generally, latches can interfere with this operation. Don't worry. just apply the force and everything should be demolished.

7. Replace the cover.

8. Using a sharp knife, cut out the retaining collar and remove the cover.

Warning! Don't be afraid to damage the collar. it will still have to be replaced once.

9. Remove the tunnel lining on the floor.

10. Disconnect the jumper from the gear handle.

11. Pull out the shift knob (just pull it up).

12. Insert the guide sleeve inside the lever.

13. Remove the four mounting bolts that secure the arm to the housing.

14. Remove the housing and remove the shaft.

15. Carefully inspect all components. If there are signs of wear on the rubber array, it is better to replace the bushing completely. If there is severe wear on the hole under the handle axis or play is visible, the wings must be replaced.

16. Put everything in its place.

17. Adjust the gearbox drive.

As a rule, installing and replacing scenes takes no more than 30-40 minutes. So you don't need to be afraid of this job and rush to the station immediately. you will do everything yourself. Good luck on the roads and of course no breakdowns.

Backstage adjustment

There is nothing complicated in the procedure; you can do it yourself, but you will have to run from the pit to the salon.

Yes, it is advisable to do this work in a pit or overpass. You need to act approximately according to this principle:

- Loosen the nut on the clamp.

- Set the gearshift lever to the reverse gear position.

- Set the box rod to the reverse speed position. This is difficult to achieve, so adjustments will have to be made.

- Check how the gears shift. If the rear one is too far to the left, loosen the clamp and turn the cardan counterclockwise. If the fifth speed (including reverse) has gone too far to the right, then the cardan rotates clockwise.

By adjusting the position of the gearshift rocker, you will notice that when the lever is installed in the middle, neutral speed will be engaged. When turning on the fifth gear, the lever should not catch the passenger seat, and when moving in reverse, the driver's seat should not interfere with the movement of the lever.

Adjustment

1. Move the gear shift lever to the neutral position.

2. Loosen the tightening of the drive rod clamp of the gear shift mechanism (see above, paragraph 10).

3. Inside the car, an assistant sets the lever almost vertically (moving it slightly back) and holds it in this position.

4. 13 mm

tighten the nut of the coupling bolt of the drive rod mounting clamp, holding the bolt from turning with a wrench of the same size.

5. Check that all gears shift easily. If necessary, repeat the adjustment.

Note: When engaging third or fifth gear, your hand should not rest on the instrument panel console. When engaging reverse gear or fifth gear, the gear shift lever should not fall onto the front seat cushions (set to the middle position).

Source