The ignition coil in the 8-valve version of the Lada Kalina power unit, as in the 16-valve version, plays a primary role. It allows the engine to start easily even in very unfavorable climatic conditions. This circumstance encourages owners to pay increased attention to this product. Even a minor deviation in the functioning of the coil can immobilize the car for a long time. To minimize the risks of such a situation, we urge owners to follow the manufacturer’s regulatory recommendations. If the owner neglects this aspect, he will provoke himself into replacing the coil, which is very expensive. And in general, the ignition system must be maintained and operated carefully.

Replacing the ignition module

Replacing the ignition module on a Lada Kalina yourself will take you no more than half an hour, without going to a car service center or other workshops. To perform this work you will need a minimum of tools, namely:

- Hexagon 5 with a wrench or ratchet - the best option

- Or a regular L-shaped hexagon for 5

- 10mm wrench to disconnect the terminal from the battery

Checking the secondary windings of the module:

- So, we take the ignition module of the Lada Kalina and turn it so that the conclusions of the high-voltage wires are facing us. Now we connect the device wires to the outputs of the 1st and 4th cylinders. And then we check the 2nd and 3rd cylinders in the same way.

All these testing procedures are best carried out with the module removed; this is much more convenient than doing everything directly under the hood of the car. Removing this part is quite simple, you only need a 5 hexagon and a couple of minutes of time.

Removal and installation of the ignition module VAZ (Lada) Kalina 1117 2004-2013

- Hex key 5 mm

- Open-end wrench 10 mm

Parts and consumables:

If the ignition module is not working correctly, the engine may start to stall, since the module will stop sending an impulse to some high-voltage wire, or maybe to several wires, and accordingly the spark plug will not produce a spark.

1. Disconnect the negative terminal from the battery.

2. Disconnect the high-voltage wires from the ignition module.

It is advisable to remember the connection of the wires, but if you have forgotten where to connect which wire, then look at the numbers written on the ignition module body, these are the cylinder numbers, and insert the required high-voltage wires according to them.

3. Now disconnect the block with wires from the module by pressing the latch.

4. We unscrew the four bolts that secure the ignition module with a 5mm hexagon and remove it.

5. Operations for installing a new ignition module occur in the reverse order.

The article is missing:

- Photo of the instrument

- Photos of parts and consumables

- High-quality photos of repairs

Source

Repair

Ignition module VAZ 2107

The module is dismantled and opened for repair purposes. For this you will need:

- Socket wrenches with heads 1, 13 and 17.

- Hexagon 5.

- Screwdriver.

- Soldering iron.

- Flux for aluminum.

- Stranded wire.

- Nail polish.

Opening the ignition module

Repair of the ignition module is carried out in the following order:

- On the removed device, open the case by prying it off with a screwdriver.

- Remove the silicone film covering the board.

- All aluminum is removed from the explosive contacts.

- On the board, new wires are soldered in place of all the dismantled old ones. To do this, the surface of the collector is cleaned of deposits, after which the board is heated to 180 o C (a characteristic smell will indicate when the desired temperature has been reached). During the soldering process, the ends of the wires are connected to the module.

- At the end of the operation, all contacts, the board and the module are covered with nail polish.

- The device is assembled in the reverse order, installed on the car and the engine is started. In case of normal operation, the ignition module is sealed tightly with sealant, while the wires are tucked inside the cavity so that they are not pinched at the edges by the plate.

If the device does not work, then a breakdown inside the module should be looked for more carefully. The transistor, electronic component may have failed, or there may be a break in the coil. Such a repair makes sense only if its price is significantly lower than the cost of a new part.

Replacing the ignition module on a viburnum and checking it

Welcome! Ignition module - someone else calls it a coil, but this is the wrong name and it came from the people; in fact, inside this module there are two ignition coils, one of which goes to two cylinders and the other of which also goes to two cylinders.

Note! In order to change the ignition module in a car, you will need tools, namely you will need: A hex wrench with which you will unscrew the hex bolts that secure the module itself, in addition, be sure to stock up on a wrench with which you will blue the minus terminal from the battery batteries!

Summary:

Where is the ignition module located? On the eight-valve native engine of the Kalina car, it is located in the front part of the car between the engine and the TV (The TV is the very front part of the car that connects both side members together, it is made in the form of metal; headlights, front bumper, etc. are also put on it ., the wings no longer belong to it), for a more detailed location, see the photo located just below:

Note! If you own a 16 valve car, then in this case the module is located in a completely different place and you have four of them (above the spark plugs) and if you need to replace them, then follow the link to another article that is posted on our website and read it, it’s called: “Replacing Spark Plugs”!

When do you need to change the ignition module? As mentioned earlier, there are two coils inside it, one of the coils leads to the first and fourth cylinders, and the other to the third and second, thus if one of the coils fails, the engine will start to double (Many car enthusiasts ask the question after the word double, namely, they ask: “How is it, this doesn’t happen?”, in fact, you can simply hear these words rarely, many are accustomed to the word the engine is tripping and they don’t know how it doubles, in general, doubles means two cylinders are not working) , due to the fact that two cylinders have stopped working, you can immediately say that the car’s power will decrease by half, in connection with this, “Check engine” will light up on the instrument panel, which will tell you that something is wrong with the engine, and of course But there will be a problem with the idle speed, namely it will float, then the tachometer needle will go up, then it will fall down, etc.

Causes of malfunction

If translated literally, “Check Engine” is an engine error, which, according to the developers, should indicate to the driver that it is worth checking this particular system. So, there are several malfunctions associated with the activation of such an alarm. Let's look at the main problems that cause a "CHECK" in the engine.

Bad fuel

Low-quality gasoline, or as it is popularly called, “bad gas,” can cause the engine warning light to appear on the dashboard. So, troubleshooting can take a lot of time and labor. In order to get rid of the effect, you will have to clean the fuel system. To do this you need to do the following:

- Remove and clean the fuel tank.

- Remove the fuel rail and wash the injectors using a special stand.

- Replace the fuel filter, because as practice shows, after low-quality fuel it becomes clogged and completely loses its service life.

Spark plug

If one of the spark plugs is damaged, Check Engine appears on the dashboard. To fix the problem, you will have to dismantle all the elements and check them for resistance, as well as visually inspect their condition. Thus, if necessary, it is worth replacing the spark plug. As practice shows, it is best to install a completely new kit, which should be pre-adjusted, check the gaps, as well as the resistance. We have already talked about the choice of candles here.

Low fuel level

When the fuel level is low, the Check Engine sign appears on the instrument panel, which may also indicate that the fuel tank cap is not closed completely and the seal is broken.

Ignition coil

The absence of a spark in the cylinders immediately signals the electronic unit, which displays the inscription “check”. This may primarily be due to the fact that the ignition coil has failed. As a rule, it cannot be repaired and must be replaced.

Oxygen sensor

A clogged lambda probe is immediately visible from the inscription on the dashboard. Here, there can only be one way out - replacement. Of course, some car enthusiasts try to clean the oxygen sensor and are quite successful, but in practice it doesn’t last long and it quickly breaks down. Therefore, it is recommended to replace it immediately.

Catalyst

The catalyst may be another reason why the Check Engine message appears on the dashboard. Usually, this is due to the high mileage of the car, so when the car starts to take oil, you should prepare for the fact that this particular part will fail. But this is not the only reason. So, bad fuel or mechanical damage will lead to the replacement of this unit.

Wiring

Cases have been repeatedly noticed that when there are problems with the explosive wire, the message Check Engine pops up. Of course, the reason should be looked for in this system and, if necessary, it is worth replacing.

ECU

The electronic engine control unit can cause a “check” to appear. Thus, accumulated errors that have not been reset for a long time may cause the dashboard to display Check Engine.

This can be treated quite simply by resetting all accumulated errors. But, as experience shows, things can get to the point where you have to change the software and flash the ECU.

The mass air flow sensor repeatedly causes the Check Engine to appear on the dashboard. In order to determine serviceability, diagnostics should be carried out. If necessary, replace this unit.

How to replace the ignition module on a VAZ 1117-VAZ 1119?

Note! We want to tell you right away, remember once and for all, if you go to a car store to buy new spare parts, be sure to look at the markings on the old ones and according to it and buy new parts, for greater clarity, first find the module where it is installed in you (Where the module is installed in Kaliny was shown above in the photo), after finding it, look at the marking on the module body (indicated by a red arrow) and write it down on a piece of paper and give it to the seller in the store before purchasing the part, if you install any other module, then the same engine operation will not guaranteed since they are all different for VAZ cars!

Check if the winding is shorted to ground

This diagnostic stage is done quite simply and will not take much time. The main thing is to connect everything correctly.

- First, we set the position of the pointer of the device for measuring resistance; I think there is no need to explain this in detail.

- Then you need to connect one contact terminal of the device to the central contact on the coil, and connect the second to ground. If you explained something incomprehensibly, then you can see how it all should look visually in practice. The photo below shows everything perfectly.

Operations for removing and installing the ignition coil and checking it on a Lada Granta car

1. Disconnect the wire from the negative terminal of the battery.2. By pressing the plastic clip, disconnect the ignition coil power wiring harness block.

3. Disconnect the high-voltage wires from the ignition coil.

4. Remove the four screws securing the ignition coil to the bracket...

5. ...and remove it from the bracket.

This is what the ignition coil looks like when removed from the car. Pay attention to its markings so that you can purchase a similar one for replacement.

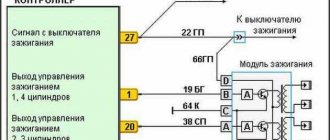

6. Perform the following checks. Checking the short to ground of the ignition coil windings of a Lada Granta is performed as follows: connect one ohmmeter wire to terminal “15” of the ignition coil (middle terminal of the coil), and the other to the metal part of its body. If the ohmmeter shows infinity, then there is no short circuit and the circuit is working.

Checking for an open circuit in the primary circuits of the ignition coil is performed as follows: connect one ohmmeter wire to terminal “1a”, and the second wire to terminal “15”. If the ohmmeter shows infinity, then there is an open circuit in the circuit and the coil is faulty.

Checking for a break in the secondary windings of the ignition coil is as follows: connect one ohmmeter lead to the high-voltage terminal of the 1st cylinder, the second one to the high-voltage terminal of the 4th cylinder. If the ohmmeter shows infinity, it means there is an open circuit and the coil is faulty. Carry out a similar check for the chain of the 2nd and 3rd cylinders.

Checking high-voltage wires of Lada Granta

is performed as follows: connect the ohmmeter wires to the terminals of the high-voltage wire, the resistance of the wires should be less than 15,000 Ohms. If the resistance is greater, then the wire is faulty.

Connect high-voltage wires to the coil terminals in accordance with the cylinder numbers indicated on the coil body.7. Install the ignition coil in the reverse order of removal.

The ignition system (IS) is the most important unit of a modern car, which ensures the timely occurrence of a spark. The system consists of a large number of parts, on the serviceability of which the entire operation of the system depends. The article discusses the main components of the SZ Lada Largus and Granta: ignition lock (IZ), ignition coil (IC).

Mounting block fuse block VAZ tenth family

| without electronics | Search |

| -201212 | Search |

| required amount: 1 Voltage [V]: 12 | Search |

| required amount: 4 Voltage [V]: 12 | Search |

| Quantity: 1 Voltage [V]: 12 Number of connected contacts: | Search |

| Quantity: 1 secured with bolts/screws Number of mounting holes: 4 Number of Poles: | Search |

| SAE connector version Number of poles: 3 | Search |

| Voltage [V]: 12 Output voltage [V]: 27 | Search |

| without ignition cable Rated voltage [V]: 14 Output voltage [V]: 30 | Search |

| Search | |

| required amount: 4 Number of poles: 3 Voltage [V]: | Search |

| Mounting block (fuse block), also called a black box. If your car's electrical system suddenly stops working, then the first thing to do is check the fuses and relays. |

Fuse box diagram

- headlight high beam relay (K5);

- low beam headlight relay (K4);

- relay for monitoring and checking the serviceability of lamps (K1);

- tweezers for removing fuses;

- door power window relay;

- relay for turning on direction indicators and hazard warning lights (K3);

- starter relay;

- spare fuses;

- installation location of the fog lamp relay;

- relay for switching on windshield wipers and windshield washers (K2);

- rear window heating relay (K7);

- additional relay (K6);

- top row of fuses (F1-F10 are installed in numerical order from left to right);

- bottom row of fuses (F11-F20 are installed in numerical order from left to right)

- F1 5A License plate lighting lamps Instrument lighting lamps Side light warning lamp Trunk lighting lamp Left side side light lamps

- F2 7.5A Left headlight (low beam)

- F3 10A Left headlight (high beam)

- F4 10A Right fog lamp

- F5 30A Electric door window drive

- F6 15A Portable lamp socket Cigarette lighter

- F7 20A Electric cooling fan Sound signal

- F8 20A Rear window heating element. Relay (contacts) for turning on the heated rear window

- F9 20A Cleaners and washers for windshield, rear glass and headlights. Relay (coil) for turning on the heated rear window.

- F10 20A Reserve

- F11 5A Left side marker lamps

- F12 7.5A Right headlight (low beam)

- F13 10A Right headlight (high beam)

- F14 10A Left fog lamp

- F15 20A Electric seat heating Trunk lock lock

- F16 10A Relay-breaker for direction indicators and hazard warning lights (in hazard warning mode) Hazard warning lamp

- F17 7.5A Interior lighting lamp. Individual backlight lamp. Ignition switch illumination lamp.

- Brake light bulbs. Clock (or trip computer).

- F18 25A Glove box lighting lamp. Heating and ventilation control unit.

- F19 10A Door locking (central locking) Relay for monitoring the health of brake signal lamps and side lights Turn indicators with warning lamps Reversing lamps Generator excitation winding On-board control system display unit Instrument panel

- F20 7.5A Rear fog lamps

xn--2111-43da1a8c.xn--p1ai

Ignition switch and features of its replacement

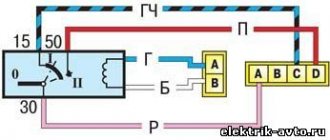

The ZZ is secured with one screw and is located on the steering column on the right under the steering wheel. Its design includes a locking device and a contact group. They are interconnected, working synchronously, and are activated using the ignition key.

When diagnosing faults in the electrical circuit, it is necessary to check whether the contacts close correctly when the position of the key changes. If any irregularities in the operation of the ignition protection are detected, it should be replaced (the author of the video is Renault Repair).

The procedure for replacing the ZZ on the Lada Largus consists of the following steps:

- Before work, disconnect the negative terminal from the battery to turn off the power supply to the car.

- Next, remove the steering column casing.

- At the next stage, by releasing the latch, we disconnect the connector with the wires of the contact group.

- Then, inserting the key into the ignition switch and setting it to the first position, remove the 33 wires from the dashboard.

- Next, unscrew the bolt that secures the ZZ.

- Use a screwdriver to press out the latches and remove the 3Z from the housing.

- We dismantle the faulty unit.

- Having installed a new spare part, we assemble it in the reverse order.

Rules for using the lock

- Position 0 is fixed. The ignition key can be removed from this position. In this position, external lighting devices can operate, including fog lights, illuminating the road ahead of the car. The hazard warning system works, you can use high and low beams, and turn on the audio system.

- Position 1 is fixed. The key cannot be removed from this position. The ignition is on. In this case, electrical power is supplied to all energy consumers of the vehicle, with the exception of the starter. Leaving the key in this position for a long time can drain the battery. Before turning on the starter, it is recommended to hold the key in this position for several seconds. During these seconds, the electric fuel pump will create the required pressure in the fuel system, which will greatly facilitate starting the engine, especially when it is cold.

- Position 2—turn on the starter. The key does not lock in this position. When released, it returns to position 1.

Do not hold the key in the starter position for more than 10 seconds. If the engine does not start, you need to take a break for 10-15 seconds and try again. Do not hold the key in this position while the engine is running. While Kalina’s car is moving, it is prohibited to remove the key from the lock. If you do this, steering failure will occur due to locking of the steering column and a sharp deterioration in the functioning of the braking system.

If during operation of the car the key remains in the lock, then when the driver's door is open, a continuous trill will be heard, signaling this. If the ignition is completely turned off and the key is removed from the hole, but the side lights are on, short beeps will be heard when the driver's door is open. The lock is capable of blocking the starter from turning on while the engine is running.

- directly from the ignition key;

- key for trunk and all door locks;

- remote control;

- immobilizer key APS-6.

- ignition;

- trunk and door lock key;

- APS-6 immobilizer learning key.

How to check the ignition coil?

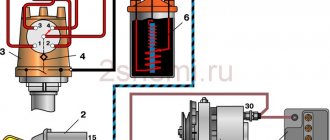

The ignition coil consists of two electric coils, which are controlled by the engine controller. It serves to convert low-voltage 12-volt voltage into high-voltage to produce a spark.

Typical unit malfunctions

The short circuit is a reliable unit with a long service life, but it can fail.

Signs of a short circuit fault:

- engine power decreases;

- failures at certain speeds;

- misfires;

- high fuel consumption;

- work with jerks at idle;

- coil overheating due to internal short circuit;

- The Check Engine light comes on.

Based on these signs, it is impossible to say for sure that the short circuit is faulty. Therefore, its diagnosis is necessary.

Let's sum it up

If the results of the diagnostic actions of the LADA Kalina car reveal that the ignition coil is faulty, then replacing this unit is a very simple undertaking. To implement the process, you will need a hex wrench. Before dismantling, we recommend that you remember the location of the high-voltage cables at the corresponding coil terminals. This will eliminate switching errors when installing the device.

still quite good Lada-Image. Novosibirsk. On March 17 I bought it in Voronezh - 720 rubles! This is on the engine, I just buy them, the mileage is more than 100 thousand km on one of them, the second coil has also covered almost 100! This reel is the “thickest”, largest and heaviest.

Instructions for repairing and replacing the ignition coil

Removing and replacing short circuits is carried out according to the following algorithm:

- First you need to de-energize the car by disconnecting the negative terminal of the battery.

- Having released the latch, you need to disconnect the block with the wires coming from the controller.

- Then the high-voltage wires should be disconnected from the short circuit.

- Next, unscrew the screws securing the ignition module to the bracket and remove it from the bracket.

- The new module is installed in place of the old one. Next, perform the reverse steps of removal.

Photo gallery “Replacing the ignition coil”

About the Kalina ignition system

Kalina is a car of the famous AvtoVAZ and is equipped with two types of engines: 8 valve and 16 valve. The difference in these engines is quite significant, both in power characteristics and design.

Depending on the type of engine installed, the spark formation system in the combustion chamber also changes. For example, in 8-valve Kalina engines, an ignition module is used that is responsible for 4 cylinders at once, but in 16-valve engines, individual ignition coils are used, that is, each cylinder has its own coil, which is responsible for the formation of a spark in that particular cylinder.

Since this article is devoted to the ignition system of the Lada Kalina car, namely the ignition coils, after reading this article you can easily check your car’s coil for malfunction and possible failure.

How to remove the ignition with your own hands?

It is better to check the functionality with the device removed. On an 8-cl engine, the ignition module is located in the front of the car.

Location of module 8 cells

On an engine with 16 cells there are 4 modules and they are located in a different place.

The device removal procedure consists of the following steps:

- First of all, you need to de-energize the car by removing the negative terminal from the battery.

- If the engine has protection, it must be removed.

- Next, press the latch and disconnect the wire block from the unit.

- Then we disconnect the four high-voltage wires and put them aside so that they do not interfere.

- Next, using a key set to “13” you need to unscrew the fastenings of the module to the motor.

- Use a hex screwdriver to unscrew the mounting bolts and remove the device from the engine.

Depending on the tester’s performance, the issue of replacing the device or repairing it is decided. Before installing the module in its original location, its mounts and the engine housing mounts should be cleaned, which will improve the transmitted voltage across the ground. After installation, it is necessary to check the functionality of the engine ignition system.

In order not to make a mistake when connecting high-voltage wires, you need to check the numbers on the block with the numbers on the wires; they must match. You should buy a new module with the same markings that were on the old one. To do this, you need to remember it when removing it. Then there will be no problems when installing a new device.

Location of the marking

If the problem is the spark plugs

Engine with 8 cl. Engine with 16 cl. А17ДВРМ АУ17ДВРМ 14R-7DU 14FR-7DU RN9YC RC9YC BPR6ES BCPR6EC W20EPR Q20PR-U11 LR15YC DR15YC WR7DC FR7DCU. Spark plugs have different prices in different regions of the country. A set of them costs approximately from 200 to 500 rubles.

It is recommended to change spark plugs every 30,000 km. Many owners of Lada Kalina cars identify the following spark plugs as the best brands: Brisk, Denso, NGK. A fairly significant group of car enthusiasts highlights the A17DVRM spark plugs produced in Engels. To replace spark plugs on Kalina you need a special spark plug wrench. The procedure is quite simple.

The ignition switch in a car is a reliable unit that can operate for a long time and without failure. But sometimes it has to be removed for repairs or for complete replacement. You can do this yourself. At the same time, you can check the functionality of parts that may fail.

Sources

- https://vaz-russia.ru/remont-vaz-1117-kalina-universal/zamena-zamka-zazhiganiya-na-kaline.html

- https://expertvaz.ru/lada-kalina/zamok-zazhiganiya.html

Self-diagnosis of the module

You can check the module in the following ways:

- Checking for weight. To carry out the test you will need a multimeter. The tester should be set to resistance measurement mode. One probe of the tester must be connected to pin 15, and the second one must be shorted to the housing. If the unit is working properly, the resistance should tend to infinity.

- Checking the primary windings of the short circuit. The primary windings are checked for breaks using a tester. To check, you need to connect the probes of the meter to the outer contacts on the short circuit. If the resistance tends to infinity, this indicates the presence of a break in one of the windings.

- Checking secondary windings. Since there are two windings, the test is carried out in two stages. First you need to check the short-circuit winding of cylinders 1 and 4. To do this, the multimeter probes must be placed in the appropriate terminals. A resistance of about 5.4 kOhm is considered normal. If the resistance tends to infinity, then there is a break in the winding. The short-circuit winding of cylinders 2 and 3 is checked in the same way.

In case of malfunction, the ignition module is replaced with a new one.

2302-3-2-09-06 (Copy)

When installing the spark plug, you must screw it in by hand to avoid damaging the threads of the spark plug hole in the cylinder head.

If the spark plug does not follow the thread, strong resistance to rotation will be felt. In this case, it is necessary to completely unscrew the spark plug and, after cleaning the threads, re-tighten it.

Finally tighten the spark plug to a torque of 25–30 N. m.

Attention! Over-tightening the spark plugs can damage the threads in the spark plug holes in the cylinder head.

We replace the remaining spark plugs in the same way.

On an 8-valve engine

Replacing the ignition module with a new one

After checking the wires, no defects were found and it was decided to change the ignition module, since nothing more reasonable came to mind. In order not to waste money, they first decided to remove it from my car and check whether it was the problem. Now, a few technical details for those who will carry out similar operations, I’ll tell you what tools you will need:

- Hexagon 5 either regular or in the form of a bit attachment

- If you use a bit with a hexagon attachment, then it is most convenient to unscrew it using a ratchet rather than a regular wrench, since there is very little space near the module and it is very inconvenient to unscrew without a ratchet

Ignition module Lada Granta

The engine ignition system uses one ignition coil. It consists of two two-terminal ignition coils, made in a single housing. Sparking occurs in two cylinders simultaneously (1–4 or 2–3).

The ignition coil is connected to the spark plugs by four high-voltage wires with permanent tips.

2. Having released the latch, disconnect the wiring harness block 1 from the terminals of the ignition module 2.

3. Turning on the ignition, use a voltmeter to measure the voltage between terminal 15 and the ground of the wiring harness block. After taking measurements, turn off the ignition.

4. Disconnect the high-voltage wires from the spark plugs.

5. Using a 13 mm socket wrench, unscrew the two bolts of the upper fastening of the ignition coil bracket.

6. Using a 17 mm wrench, loosen the tightening of the lower bolt securing the ignition coil bracket and remove the bracket together with the coil.

7. Disconnect the high-voltage wires from the ignition coil.

8. Using an ohmmeter, we measure the electrical resistance between the central terminal 15 and the housing (bracket).

The device should show that there is no short circuit of the primary winding of the coil to ground. We sequentially measure the electrical resistance between the central terminal 15 and the outer terminals -1a and 1b. The resistance of each of the primary windings of the coil should be about 0.5 ohms.

When measuring small values of electrical resistance (about 1 ohm), it is necessary to take into account the internal resistance of the device, which can be determined by shorting the ohmmeter probes.

BB: professional replacement

Replacing spark plugs for VAZ 2114 8 valves. how often do you need to change spark plugs on a vaz

If you have decided to contact the service for the process of replacing high-voltage wiring, then it is, of course, a good thing, but not worth the money that will be asked of you. They can also confuse your brain on the topic of how often high-voltage wires need to be changed, with the logic that it is better to take care of prevention in advance than to get stuck on the highway.

You won’t get stuck on the highway, the contact is not a sensor, even the last one doesn’t die right away. Replacement will cost from 1000 rubles. The advantage of service in this case will be the fact that they will look at the candles for you. And they will definitely be cleaned (they tend to become oily, which negatively affects the throughput for pulses through high-voltage wires).

Replacing high-voltage ignition wires is a simple operation accessible to every car enthusiast.

High voltage wires are designed to transmit the impulse from the ignition module or coil to the spark plugs. If the high-voltage ignition wires malfunction, interruptions in engine operation occur; it may vibrate and “triple” at idle.

Main malfunctions of high-voltage wires:

- insulation breakdown, current leakage

- core rupture

- increase resistance

- mechanical grinding of insulation

- unreliable attachment to the spark plug or ignition module

To replace high-voltage wires, you need to buy a new kit. When purchasing, it is better to choose silicone wires; they better retain elasticity and flexibility, especially in winter.

Before replacing, make sure that the ignition is turned off.

Don't remove all the wires at once

It is important not to disturb, since the spark must enter the cylinders in a certain sequence. For example, VAZ engines have cylinders operating in the order 1-3-4-2

That is, the spark is supplied first to the first cylinder, then to the third, then to the fourth and second.

Cylinder numbers are usually counted from left to right, with the first cylinder being the one closest to the timing belt.

The sockets on the ignition module are also numbered, but usually this module is located in places where it is simply not visible or is splashed with dirt.

Therefore, it is better to remove the wires one at a time. For example, remove the tip of the wire from the spark plug of the 4th cylinder and pull out the second end from the ignition module socket. Replace the removed wire with a high-voltage wire from a new set.

Usually the wires for each cylinder differ in length, so it is better to compare the removed wire with a new set and select one of a similar length from it.

We perform similar actions with the remaining wires.

When laying new wires, make sure that they do not touch moving parts anywhere or rub against adjacent elements.

After replacing the high-voltage wires, start the engine. If it “troubles” or stalls, it means you have violated the order of connecting high-voltage wires, which was mentioned above.

Diagnostics of Lada Kalina wires

Before connecting high-voltage wires on Kalina purchased at a car dealership, you need to assess the current state of the car's wiring. For diagnostics, the car owner will need an analog or digital multimeter.

Before connecting the device, you need to inspect the wires for external defects. These include:

If no external damage is observed, you need to connect a multimeter. You need to check the resistance of the armor wire, so you need to switch the device to ohmmeter mode. After this, the armored wire is disconnected from the spark plug and ignition coil. The ends of the wire are connected to the contacts of the multimeter, after which the device will show the current resistance level.

Data on normal resistance values are applied to the insulating layer. For passenger cars, normal values are in the range of 4-10 kOhm. In this case, on one specific car, the data values for individual wires should not differ by more than 2.5-3 kOhm. If this threshold is exceeded, then there is a problem in the ignition system.

There are several ways to check the functionality of the wiring without using measuring instruments:

- Use of additional insulated wire. You need to strip both ends of the additional wire. Short one end to ground, and run the other bare end along the caps, joints and the entire contour of the wire being tested. If there is a defect, the tester wire will give a spark;

- You need to drive the car into an unlit box, open the hood, and start the engine. If there is a breakdown in the VP insulation, the damaged area will spark.

The easiest way is to take a working high-voltage wire and test it on each cylinder by elimination.

Buying new wires

In this section we will describe which high-voltage wires are best purchased for Kalina at a car dealership. Standard wires from universal parts from AvtoVAZ will cost approximately 500-600 rubles. Set includes 4 pieces. Components for Kalina from early years of production are cheaper - about 400 rubles. High-voltage wires Kalina 8 cells. 50-70 rubles cheaper.

Wires from third-party manufacturers, including foreign ones, are available for sale. For example, wires of the “HUCO” brand are distinguished by an increased insulating layer and, accordingly, cost more - about a thousand rubles. A complete ignition wiring harness for a Kalina costs about five thousand rubles in online stores.

Among “Kalinovodov” “high-voltage” brands “SLON” are popular. These products are distinguished by their ductility, resistance to fractures and, in general, have a longer service life compared to factory components at a competitive price - about 700 rubles.

Ignition coil malfunction factors

When the first signs of a breakdown appear, inexperienced owners first of all suspect the ignition switch or high-voltage wires as the culprit. Owners of Lada Kalina with experience recommend a balanced approach to resolving the issue. How to check the fault? If the coil fails, the dashboard will remind you of this by means of an indicator light.

A voltage surge or a short circuit inside the unit can cause damage to the spark plugs. In this case, the spark will not be able to generate correctly between the electrodes.

Device failure can also be caused by the following factors:

- the car getting into an accident, as a result of which you can observe the destruction of some components of the ignition unit;

- the car was struck by lightning;

- the previously completed repairs turned out to be of poor quality;

- use by the owner of non-original components in the designated system;

- ignoring maintenance intervals.

Regardless of the reasons, the owner of the Lada Kalina should diagnose the ignition system in detail. Sometimes a problem can be generated by the influence of several negative factors at the same time. This situation warns an inexperienced driver to tend to independently search for and eliminate breakdowns, because there is a likely risk of forced failure of other known-good components.

BB: what do they look like?

Naturally, the technical conditions for the existence of working wires are the conditions of a permanent conductor. If we add here temperature changes and the imperfection of our world, we get the fact that the contact system fails within a certain period of time. And it comes with a frequency of 30,000 km.

This is a control figure that tells you when to change high-voltage wires. The fact is that over time, internal resistance begins to increase in them, preventing the impulse from passing as it should. In this case, you may notice the following behavior of the fourteenth:

- You want to press your sneakers to the floor, but the engine doesn’t respond

- The engine may simply stall

- At idle the engine troits

- It often happens that car owners themselves do not notice how high-voltage wires are pierced

Of course, this is not an indicator of a malfunction only in high-voltage equipment, but there is a high probability that it was they who flew. Surely, it is worth carrying out a test procedure for all contacts.

And the tester showed that the wires had a long life. Well, the high-voltage wires on the VAZ 2114 need to be replaced. The procedure, in principle, is not troublesome. If you were able to test them, then you can replace them. The main thing is to understand the order of connecting high-voltage wires.

The fourteenth is an improved version of the nine, it has higher ignition power. Therefore, contacts have been added to the four high-voltage wires for connection to the ignition terminal itself, through which a signal goes to the spark plugs; Also, in the fourteenth system there are contacts leading to the switch, as well as contacts for connecting the adsorber valve to the gasoline injection system control unit.

The connection diagram for high-voltage wires is quite simple:

- Cylinder 1 clings to the lower left contact

- Cylinder 2 clings to the upper left contact

- Cylinder 3 clings to the upper right contact

- Cylinder 4 clings to the lower right contact

This is sometimes called module bay interface in schematics. Essentially, everything is correct. The main thing is to understand that all cylinders are counted from left to right, like any count adopted from the logic of writing from left to right: 1,2,3,4. And the connection is obtained according to the following scheme: 1,3,4,2. Many people sketch and write down how the contacts were before removal. But, if you look at the module itself, there are docking numbers there. It's impossible to make a mistake.

Operational Aspects

Frequent cases when owners call for service are when the coil fails or does not function correctly. You can also diagnose the ignition module yourself. To do this you will need to acquire the appropriate equipment. One such diagnostic tool is a multimeter. It is used to measure the actual resistance value at the coil terminals in the 8-valve versions of the Lada Kalina, as well as in the 16-valve version. In order for the results of measuring actions to have maximum correctness, the procedure should be followed at least twice.

Damage to the ignition system can occur in any part of the circuit. This circumstance requires maximum care and attention during diagnostic procedures. The check begins with making sure that the winding is connected correctly to ground. Now let's diagnose the central terminal of the coil. We apply the positive contact of the device to it, and connect the negative contact with the vehicle ground. We look at the screen. If there is a symbol of infinity resistance, then this indicates the absence of a short circuit on this section of the circuit. From this information, the owner must conclude that the ignition module is working.

Now we connect the device with the terminals of the module located at the edges. A specific parameter on the screen indicates the presence of a malfunction inside the LADA Kalina ignition switch. If a defect is not found here either, then the next step will be to diagnose the secondary winding of the coil. We place the ignition module in front of us so that both contacts are facing us. We connect the diagnostic device with the terminals for the 4th and 1st cylinders. Having made sure that there is no malfunction (short circuit), we proceed to checking the circuit for the 2nd and 3rd cylinders. There should also be no short circuit here.

Source

Misfire video

The ignition coil in the 8-valve version of the Lada Kalina power unit, as in the 16-valve version, plays a primary role. It allows the engine to start easily even in very unfavorable climatic conditions

This circumstance encourages owners to pay increased attention to this product. Even a minor deviation in the functioning of the coil can immobilize the car for a long time.

To minimize the risks of such a situation, we urge owners to follow the manufacturer’s regulatory recommendations. If the owner neglects this aspect, he will provoke himself into replacing the coil, which is very expensive. And in general, the ignition system must be maintained and operated carefully.