A three-phase voltage regulator (charging relay) is installed on the generator. Responsible for maintaining the voltage of the on-board network within a given limit in all operating modes.

The output voltage may be affected by changes in rotor speed, electrical load, and ambient temperature.

Failure is considered one of the most common problems associated with the operation of the generator. Replacing an element does not require practical skills.

Changing the generator regulator relay on Lada Kalina

A three-phase voltage regulator (charging relay) is installed on the generator. Responsible for maintaining the voltage of the on-board network within a given limit in all operating modes.

The output voltage may be affected by changes in rotor speed, electrical load, and ambient temperature.

Failure is considered one of the most common problems associated with the operation of the generator. Replacing an element does not require practical skills.

Checking the rectifier unit (diode bridge)

To perform this diagnostic, it is necessary to remove the diode bridge from the Kalina generator; this was described in more detail in previous articles in this section.

Then we connect the tester with the black wire to the negative plate of the block, and the red one in turn to the three contact terminals of the diodes. This way we check all the rectifiers in the block. The values on the device should be in the range from 400 to 800 Ohms. Personally, on my Kalina, during this test, all diodes showed a resistance within 535 Ohms. But the repair instructions from the Third Rome publishing house talk about numbers of 580-620 Ohms. I will say right away that when I rang two serviceable generators, the values specified in the manual were not achieved, although there were no problems with charging, so I personally doubt the accuracy of the data in this instruction.

Then we carry out the same operation, only swapping the contact wires of the multimeter. In this case, the device, with working diodes, will show infinity, that is, its readings will not change:

Replacement process

The process of removing the generator on Kalina depends on whether it has a tensioner on it or not. A belt without a tensioner can only be removed together with the generator or simply cut (if it’s old).

Use a 13 key to loosen the tensioner and remove the belt.

By pressing the latch, we snap off the plastic block.

Lift the boot and unscrew the nut by 10.

The mounting bolts are located at the top and bottom of the generator.

The latches are located on the side surface of the cover.

Mounting the regulator relay: 1 – contact under the bushing, 2 – bolts securing the relay body.

View of the generator with the relay removed.

After assembling the unit, it is necessary to check the reliability of the wire connections and tighten the generator belt.

Important! Before installing a new generator charging relay on Kalina, it is recommended to check its condition: make sure that the brushes are intact (they must protrude from the relay housing by at least 5 mm ); easy, without delay, clicking into the initial position after pressing.

Critical wear of the brushes on the old relay.

Briefly about articles and applicability

We should talk about the applicability of a particular charging relay after the model of the generator from which it was removed has been installed.

9402.3701-06 or 9402.3701-14 ( 14 V , 85 A were predominantly installed on Kalina, Granta and Priora . Part numbers of compatible voltage relays:

- KZATE "Orbita" (Saransk) 849.3702 , costing 500-750 rubles .

New voltage regulator made in Saransk.

Important ! On Priors with a generator 3701010 , which has an output current of up to 115 A, is not interchangeable with the Kalinovsky one !

If you need to replace the roller or brushes?

When, during operation of the engine, the owner of a Lada Kalina hears a distinct “rustle” coming from the rotating roller of the tension unit, then a detailed inspection of this element will be required and, if necessary, replaced.

To carry out this repair operation, it is recommended to stock up with ordinary keys and a screwdriver with a flat-tipped tip. All replacement procedures do not cause any difficulties, so we act with confidence.

- First, we resort to loosening the degree of belt tension. To do this, unscrew the stem.

- Using the designated screwdriver, carefully pry up the protective cap of the roller and unscrew the bolt holding the bearing.

- From the worn-out roller we remove the bushing together with the washer (they are necessary for installation in conjunction with a new product).

- The entire assembly is mounted in its proper place and secured with a bolt.

- We tighten the belt and start the engine. We make sure that the new product functions correctly.

One of the factors characterizing weak battery charging is wear on the brushes of the generator set. In order to eliminate this negative aspect, the generator brushes will need to be replaced. To monitor their condition, they will need to be dismantled. Replacing generator brushes is available both on a removed generator set and on one installed on a Lada Kalina car.

In order to achieve safety of work and eliminate the risk of a short circuit in the circuit, before repair work it will be necessary to disconnect the network from the battery (remove the terminals). Now you need to dismantle the protective cover and remove the plug. This can be done conveniently using the previously designated screwdriver.

At the final stage of the process, unscrew the bolts, after which we remove the regulator itself with the brushes present on it. Replacement of generator brushes is complete. Brush wear is assessed by measuring their height. This parameter should not be less than 5 mm. If the brushes are worn out, then replace them and the regulator included.

Causes and symptoms of malfunction

The regulator will need to be replaced if the part fails. This can happen for several reasons:

- Short circuit in the circuit , which led to its breakdown. This happens quite often, since the “relay” is a power source, and there is no fuse between it and the rotor.

- Brushing of brushes resulting from friction against the rotor .

You can find out about problems with the operation of the generator, in particular with the charging relay, by changing the voltage of the on-board network.

In practice, during the operation of the car this is determined by the following symptoms:

- Headlight beams of different brightness . When you press the gas pedal they light up brighter, at idle they dim.

- An undercharged battery will affect the morning start-up. The starter turns much harder than usual.

Battery overcharging due to increased voltage . It can affect you in several ways:

- Electrolyte boiling in jars . It will manifest itself as a sharp, unpleasant odor emanating from the battery;

- Frequently blown fuses . If they are missing, the “weakest” part of the wiring will burn out (places with pockets of copper oxidation, poor contacts).

Traces of electrolyte are visible along the edges of the battery. This occurs due to overcharging.

Circuits protected by fuses

- F1 - immobilizer control unit, hazard warning switch, instrument cluster

- F2 - power windows

- F3 - hazard warning switch

- F4 - Windshield wiper

- F5 - Heater, electric power steering control unit

- F6 - Sound signal

- F7 - Instrument cluster, interior lighting

- F8 - heated rear window

- F9 - Side lights (right)

- F10 - Side lights (left)

- F11 - Immobilizer control unit

- F12 - Low beam (right)

- F13 - Low beam (left)

- F27 - electric power steering control unit (large red 50 A)

- F28 - ABS system control unit (in this case, an empty space, since ABS is not installed)

- F14 - High beam (right)

- F15 - High beam (left)

- F16, F17 - Fog lights

- F18 - seat heating

- F19 - ABS

- F20 - cigarette lighter

- F21 - Reverse lock

- F22 - Electrical package control unit

- F23, F24, F25 - reserve

- F26 - ABS

Replacing the voltage regulator on Kalina

Today we’ll talk about removing the generator brushes on a Lada Kalina car. In order to remove the voltage regulator with brushes, you need to remove the plastic cover of the generator. After removing the cover we will need a key for 8 and 13.

Use a size 8 wrench to unscrew the 2 bolts, and use a size 13 wrench to loosen the nut.

Then we remove the regulator with brushes. If necessary, we replace the part with a new one. Install in reverse order.

The minimum permissible height of the brushes must be at least 5 millimeters. If this value is not reached during measurement, then the part must be replaced along with the voltage regulator. The price for a voltage regulator along with alternator brushes for a Lada Kalina will be about 350-400 rubles.

Let's sum it up

As it turned out, repairing or replacing the generator in a LADA Kalina car does not require much effort, so such manipulations are accessible even to inexperienced owners; a connection diagram is used to make the task easier. An important point in operation is periodic diagnosis of the condition of both the unit itself and its component elements, including the tension system. Timely prevention will significantly extend the life of the unit, and the owner of LADA Kalina will have considerable savings.

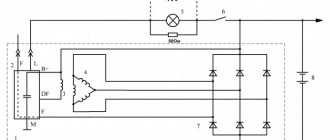

Lada Kalina cars are equipped with generators of two brands - 5132.3771 or 9402.3701-06. The standard Kalina generator is a three-phase alternating current device, which has a built-in rectifier unit and an electronic voltage regulator.

There are very different reviews regarding the quality and reliability of the devices with which these cars are equipped during factory assembly. If the unit fails, you can replace or repair it yourself.

Video on removing the voltage regulator with brushes Lada Kalina

If the voltage regulator unit, capacitor and not a tight fit of the brushes are faulty, or if they are worn out, the vehicle's supply voltage deviates from the norm. In this case, it is necessary to check the above listed elements and, if necessary, replace them. In this article we will talk in more detail about diagnosing and replacing generator elements in a Lada Kalina car.

To remove the Lada Kalina voltage regulator you will need the following tool:

flat-blade screwdriver, 8mm and 10mm open-end wrenches and 7mm, 8mm and 24mm socket wrenches, hammer, soldering iron, universal meter (with DC voltmeter and megger)

Checking the functionality of the voltage regulator on the Lada Kalina generator

1. Move aside the rubber insulating boot of the positive terminal from the generator. 2. Start the engine and allow the engine to warm up so that the vehicle operates normally at idle speed. 3. Measure the voltage between the positive terminal and the body (negative terminal). The voltage should be 14.5-15.1 volts.

If there is a deviation from the specified range, the voltage regulator must be replaced. See also checking the Lada Kalina generator regulator in the section “Replacing the voltage regulator”

Checking the functionality of the Lada Kalina generator capacitor

The capacitor is usually checked with a specialized meggometer, since not all universal devices have a measurement of up to 10 MoM. The device is set precisely in the range of 1-10 MΩ. Before connecting to the capacitor, the device shows infinity. If connected to a working capacitor, it begins to charge and an electric charge accumulates on its plates - current flows and, accordingly, the resistance on the device drops. After charging it (saturating the capacitor plates), the resistance again becomes infinite.

Replacing the voltage regulator Lada Kalina

carried out as follows

1. Disconnect the negative cable from the battery. 2. Disconnect the excitation block from the generator.

3. Disconnect the positive terminal from the battery by unscrewing the nut.

4. Remove the factory seal from one of the screws holding the plastic casing and remove the screws. Remove the protective plastic cover. 5. Remove the two screws securing the regulator and remove the voltage regulator.

6. Check the ease of movement of the brushes. They must protrude at least 5 mm from the voltage regulator housing. 7. You can check the voltage regulator by connecting a 12 V lamp to its outputs and applying a voltage in the range of up to 12 volts to its inputs, while the lamp should light and the voltage is more than 12 V to 16 V.

If the voltage is too high, the lamp should go out. If this algorithm does not work, then the regulator must be replaced. Installation of the regulator is done in the reverse order.

Replacing the rectifier unit with a capacitor Lada Kalina

1. Using a soldering iron, unsolder the six leads and remove the 3 bolts.

2. Remove the rectifier unit from the generator. Installation of the rectifier unit is carried out in the reverse order

Checking diodes on the rectifier block Lada Kalina

1. Dodas are checked with a universal device. (6 diodes in total) Attach the black “negative” probe to the negative plate, and the positive “red” probe alternately to the three contact terminals of the diodes. The resistance should be 580-620 Ohms.

Attach the red “positive” probe to the negative plate, and the negative “black” probe alternately to the three contact terminals of the diodes. The resistance should be 580-620 Ohms.

Checking the windings of the Lada Kalina generator

1. Check the generator windings with a device. All windings should have approximately equal resistance, without significant deviations. Deviations indicate a break or short circuit.

About the principle of operation of a car generator

The operation of the Lada Kalina generator unit is based on the following principle: an alternating current is induced in the stator winding, which is subsequently transformed into direct current through a rectifier module located on the body of the unit. The generator cover is also equipped with an electronic voltage regulator and a brush holder. The rotor of the device receives torque from the crankshaft pulley. The transmission link is a poly V-belt.

The basic characteristics of the generator set include the following parameters:

- maximum generated current – 85-90 Amperes;

- operating range of on-board voltage – 14.4-15.1 Volts;

- rotation ratio of the motor and rotor – 1:2.4;

- right-hand direction of rotation.

The housing of the unit is held together by pins that tighten the stator with the covers. The mounting sockets of the indicated covers contain bearings, which ensure the ability of the rotor to rotate. The rear bearing is installed inside the cover with a minimum gap. The front element is equipped with the ability to slide along the surface of the rotor shaft. It is fixed inside the front cover with a slight interference fit, and a pressure plate covers it from the outside. The back of the device is protected by a plastic casing.

Disassembling the device

To disassemble the generator, you need to perform several simple manipulations:

- Remove the drive pulley. Try not to lose the key.

- Unscrew the nuts from the back cover that secure all parts of the structure.

- Remove the voltage regulator. At the same time, evaluate the condition of the brush assembly.

- Disconnect all parts of the generator.

After this, you can begin to carry out repairs.

Bearings often fail, especially the one located in the front cover. The reason for this is excessive belt tension. To make a replacement, you need to unscrew four screws and press the bearing out of its seat. Instead, install a new bearing. To increase reliability, change both rollers at once.