It is impossible to imagine driving a car without reliable and effective brakes. Vehicle safety and people's lives depend on them.

Recently, the number of sales of VAZ cars has been increasing, which leads to an increase in demand for consumables, including brake pads. For VAZ cars, the car market offers a wide range of elements for brake systems. They are divided according to the materials used in production, their methods of fixation and brands.

In our rating, we will help highlight the Top leading brands of brake pad manufacturers for VAZ cars, guaranteeing their quality.

AC Delco

The brand is registered in the USA (a division of General Motors). One of the best brake pads used in many car models, including VAZ cars. They are reliable, last a long time, and are easy to install. Efficiency, safety, reliability, heat removal from the rotor, ensures the use of advanced technologies in the production process. Specialists have created a special semi-metallic composite mixture using steel fibers.

ACDelco has been tested to SAE J2784 standards and is proven to provide high friction braking performance. The pads have slots and chamfers that suppress noise, vibration and harshness when braking.

The drum pads are reliably protected with an anti-corrosion coating. The environmentally friendly production process does not use heavy metals or asbestos. They are similar in shape to the original brake system components and no adjustment is required during installation.

Advantages:

- reliability;

- strength;

- durability;

Flaws:

- high price.

Pros and cons of different types of brake pad materials

Organic brake pads

They include Kevlar, rubber, glass, resins and carbon materials.

Their advantages include:

- Products made from this material are soft.

- They do not make loud sounds when braking.

The disadvantages include:

- They wear out quickly.

- In wet weather, the braking distance increases due to the deterioration of the adhesive properties of the material.

- When driving a car in dusty areas, the holes in the brake discs become clogged, which leads to their overheating.

Metal based brake pads

The composition of this product includes organic substances and metal (steel or copper).

Product advantages:

- The material has a long service life.

- They have high-quality braking in any weather.

- The material has heat dissipation properties, which prevents skidding when cornering.

Minuses:

- High price.

Ceramic brake pads

The top layer of the product is made of various non-ferrous metals; it also contains iron and ceramic elements.

Product advantages:

- Resistant to high temperature loads that appear during vehicle movement and braking.

- They do their job well during braking.

- Not afraid of rust.

- Keep the ventilation holes in their original form.

Minuses:

- Very high cost.

Semi-metallic brake pads

The product includes:

- various metals (in the form of copper, steel);

- inorganic substances;

- graphite;

- friction modifier.

Product advantages:

- Has high-quality heat dissipation.

There are significantly more disadvantages:

- They wear out quickly.

- They produce noise during braking.

- They cannot cope with sub-zero temperatures, which increases the braking process in winter.

Glued brake pads

Special overlays are glued to a metal base using a special adhesive.

Pros:

- Products can be used until the wear mark is reached.

- Acceptable cost depending on the manufacturer.

Minuses:

- It is imperative to monitor and erase this brake system so as not to damage the entire brake disc.

Rivet Brake Pads

The composition of the rivet elements resembles adhesive ones.

Their feature is the same as that of adhesive ones, however, the disadvantage is that when worn they make a creaking sound, which indicates the disc is braking against the rivet.

Bosch BC905 Quiet Cast

The German brand Bosch is famous for its quality products. This brand produces ceramic and semi-metallic brake pads with effective braking capabilities. The manufacturer uses cast pad technology, which protects the nozzles, provides stability, strength, and noise reduction. Slots and chamfers with original design ensure good fit and performance.

The gasket with a rubber core has good insulating properties and provides quiet and soft braking. The kit includes fasteners and synthetic lubricant. These parts are suitable for cars whose drivers prefer ceramics, but do not want to lose speed in extreme conditions.

Advantages:

- low dust levels;

- use of aerospace alloy;

- reliable protective layer.

Flaws:

- high price.

Fenox

The most inexpensive pads in the review: four (!) cheaper than the original ones. The most interesting thing is that the Belarusian company Fenox spared no expense on packaging. A very good branded box, and the only one of all that is completely Russified. The data sticker looks a little different, but there is an interesting point: not all suitable ones are listed, but only those car models that were officially sold in the CIS countries.

The set of pads is incomplete - there are bolts, but no guides. The warranty card is included in a separate booklet. The pads themselves are very similar in appearance to the original ones, but without a chamfer. The working material is lighter than the original one, with a lower concentration of metal inclusions. Back plate with hooks, with full information including brand name.

The inscription Germany is striking, but the absence of the words Made in in front of it is confusing. Although the company has production in both Germany and Belarus, the catalog of the famous online store (and, of course, the price) clearly indicates the country of production - the Republic of Belarus. But the fact that the pads are certified in Germany is indicated by the E1 marking.

STS

The Russian company “STS Company” produces good quality products for the low-price niche.

They have good friction properties and thermal stability. Together with the Friction Materials Group company (monitoring compliance with norms and standards), a unique friction composition of 15 components was created. “STS Company” produces a large line of brake pads for rear and front discs, suitable for the entire model range of VAZ cars. Based on the test results, it was found that at a speed of 100 km/h, with cold brakes, it showed good friction coefficients of 0.48.

What to look for when choosing brake pads?

The main criteria that help in choosing pads include:

- you need to purchase pads in a store and check for the appropriate certificate marked 90R/R90;

- carrying out an inspection for the absence of foreign particles, defects in schools, cracks or dents;

- checking the metal structure for the evenness of all elements, absence of damage to the friction layer of the product and its bends;

- The attached instructions must indicate the braking temperature of the pads. The standard temperature for VAZs should be from 280 to 350 degrees Celsius;

- pay attention to the markings: the higher the friction coefficients, the better the braking process and the wear of the pads;

- It is advisable to purchase the original originally installed at the factory.

ROSDOT

A team of experienced professionals and JSC TIIR, with the participation of European specialists, create elements of brake systems for VAZ cars from harmless friction materials. The raw materials for the friction composite do not contain asbestos, nickel, or copper; they are purchased in Austria and Germany, some of which have no analogues in Russia.

Considering their low cost, ROSDOT brake pads have good wear-resistant characteristics and heat dissipation. Thanks to the use of Italian mastic, the pads do not emit extraneous noise at low temperatures and when they get wet. In terms of price-quality ratio, Rosdot front and rear brake pads have no equal. The products maintain stability of the friction coefficient over the entire operating range of temperatures, speeds and pressures;

Advantages:

- high braking efficiency;

- ergonomics;

- disc-saving properties;

- reasonable price.

Flaws:

- wear out quickly.

Where to buy pads with quality guarantee for Lada?

The question of where to purchase brake equipment is quite complicated. Many people say that it is worth ordering products on the Internet - there are the fewest counterfeits and the best prices. Perhaps, but in this case you should stick to the official websites of manufacturers and official dealers. But finding them is not so easy, especially in the regions. When choosing a place of purchase, you should consider the following features:

- availability of documents - the originality of the product can be confirmed by factory documents and accompanying papers with characteristics and other parameters, they can be requested additionally;

- not the lowest prices - it is almost guaranteed that the lowest prices indicate fakes, of which there are too many on the Russian market, so it is not worth saving much;

- good assortment or specialization - it is better to buy pads from specialists who can offer an excellent selection or products from only one trusted brand;

- warranty - you may be surprised, but these products should also be covered by a warranty, and the coupon should not be thrown away until a year has passed from the date of purchase of the equipment;

- all necessary components are in stock - buy products only in those stores that offer goods in stock, and not on order with delivery in a few weeks.

These are important criteria for quality and worthy acquisition, which should always be taken into account when purchasing. Contact professional stores, specialized points of sale of products of certain brands. Avoid buying brake pads simply through advertisements on the Internet. This way, you are guaranteed to buy a fake or an illiquid product that will not last you even a few months without unpleasant surprises. You should respect your safety while driving.

We offer a video about brake pads to see the importance of this element:

EzATI

Manufacturer: Yegoryevsk plant of asbestos technical products. The range of pads competes with Western similar products, with prices 30% lower. E55 code pads are made without the use of asbestos in the friction material, using expensive organic elements. Such pads are recommended for use in cars whose drivers love fast and aggressive driving (friction coefficient 0.46). With this driving style, their service life is 40-45 thousand km.

Pads with code T266 with stable performance characteristics and effective braking (friction coefficient 0.37). The manufacturer declares in the documentation a service life of 20-25 thousand km with a calm driving style, without constant overloads and emergency braking.

When installed, these products do not require adjustment and ensure performance for the entire declared service life. The products meet the requirements of AvtoVAZ and are supplied to its conveyors. Considering multiple counterfeits, the company, as part of product protection, began to paint metal frames using triboelectric spraying with blue polymer materials. In addition to protection against counterfeiting, this method creates mechanical and corrosion resistance, as well as a beautiful appearance.

Varieties

Depending on the material used, there are the following types of pads:

- Organic . They have a gentle effect on the discs and are characterized by almost silent operation. But as temperatures increase, their performance parameters deteriorate greatly. Suitable for drivers who like a measured and quiet ride.

- Semi-metallic . Quiet and work well when hot. They are usually chosen by fans of fast driving.

- Ceramic . Contains about 15-40% metal elements. They are characterized by a weak effect on disks and quiet operation. Operational parameters depend on the composition.

- Metal . They are quiet and do not lose their operating parameters when heated. This type of spare part is worth choosing for those who like to drive at high speed.

Organic pads are considered the cheapest, and ceramic pads are the most expensive.

There are also such auto parts:

- In front of them.

- Rear.

Depending on the condition of the car part, you can buy:

- New one.

- An old one that could not be repaired.

- Used, which has been restored.

Auto parts available by manufacturer:

- Original.

- Unoriginal.

Car parts available at the place of purchase:

- From the online store.

- From the vehicle dismantling point.

- From the car market.

- VAZ 2110 cars purchased through an advertisement from owners.

- From a store that sells spare parts for VAZ.

By manufacturer there are spare parts of the following brands:

- Craft.

- AvtoVAZ.

- Lavs.

- Ferodo.

- Lucas.

- Allied Nippon.

One of the car consumables that has to be changed quite often is brake pads. The effectiveness of braking depends on the brake pads, as well as on the discs. Let's try to choose brake pads for the VAZ 2110.

Pads from different manufacturers can be made from different materials (material ratios). Therefore, the same brake pads paired with different brake discs can show different results. In other words, the pad components may be incompatible with the brake disc material. Because of this, it will be difficult to single out the best brake pads for the VAZ 2112.

Poor and low-quality pad material can also cause squeaking pads.

Replacement

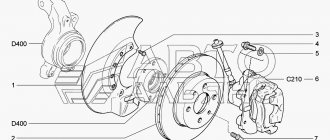

PROCEDURE FOR REPLACING FRONT BRAKE PADS

We hang and remove the front wheel.

We bend the edges of the locking plate of the lower bolt securing the wheel cylinder to the guide pin. The plate prevents the bolts from loosening.

Holding the guide pin with an open-end wrench “17”, use a wrench “13” to unscrew the lower bolt...

...and take it out along with the plate.

Using a screwdriver, lift the caliper and cylinder up.

Remove the brake pads from the guide. In case of significant wear of the disk and an edge that eventually forms on its edge that prevents the removal of the pads, remove it by cutting it off with a file or grinder. Because later the pads will be just as difficult to install as they are to remove.

Before installing new brake pads, it is necessary to move the piston as far inside the cylinder as possible. This operation can be performed using different methods.

Using large pliers or a gas wrench, press the piston into the cylinder. The cylinder will move easily when the bleeder fitting is open.

Another method: install the outer pad in place and lower the caliper to the working position. Leaning a suitable metal rod (or mounting blade) on the disk, press the piston. The cylinder will move easily with the bleeder valve open.

A wear sensor is installed on the inner pad. Since the new set of pads contains wear sensors, we cut the wire of the old sensor with side cutters.

Disconnect the electrical connector of the sensor from the vehicle wiring.

We remove the sensor wire from the rubber rings covering the brake hose.

When installing new pads, we connect the connector of the wear sensor and the car wiring, pass the sensor wire through the rubber rings of the brake hose and insert the tip of the sensor into the hole in the pad.

Install the pads in reverse order.

We lock the bolts securing the wheel cylinder to the guide pin.

Replacing rear brake pads VAZ - 2112

At the rear, the twelfth car has drum brakes, the kind that are installed on most budget cars. If you just unscrew the bolts, nothing will work, the drum will not come off.

During operation, the pads make a groove in the drum with an edge, which they then cling to when you remove the drum. Therefore, as a rule, the drum has to be literally knocked out of its seat.

It is better to take a heavier hammer and hit through the spacer so that nothing breaks off from the drum. Well, then we remove the springs from the pads on which they are held and take out the pads.

An expansion plate is installed between the blocks, which prevents the blocks from closing, and the handbrake cable is attached to one block. There’s nothing more to see there, but it’s advisable to check the condition of the brake cylinder to see if it’s leaking. Then we put everything back together and enjoy the good brakes.

How to sort out a brake cylinder using the link.

Which ones are better to choose?

After such an unsuccessful experience, I decided that I would not experiment with such components anymore and, if possible, would rather buy something more expensive and of higher quality. I did so at the next replacement. Before settling on any particular company, I decided to read the forums of foreign car owners and find out which pads are installed by the factory on Volvos? as the safest car in the world. As a result, I found out that on most models of these foreign cars, ATE brake pads are installed at the factory. Of course, the braking efficiency on the VAZ 2112 will not be the same as on the Swedish brand, but you can still be sure about the quality.

As a result, I went into the store and looked at the assortment, and luckily for me there was only one set of pads made by ATE. I decided to take it without hesitation, especially since I didn’t even hear any negative reviews from car owners in the domestic auto industry.

The price for these components at that time was about 600 rubles, which was practically the most expensive product. As a result, after installing these consumables on my VAZ 2112, I decided to check the effectiveness. Of course, for the first few hundred kilometers I did not resort to sharp braking so that the pads would get used well. Yes, and it took time for the brake discs to level out from the grooves that remained after the previous ones.

As a result, when they were completely run-in, so to speak, then without a doubt the car began to brake much better, without any squeaks, whistles or grinding noises. Now you don’t have to press the pedal with force, since even when pressed smoothly, the car slows down almost instantly.

As for the resource, we can say the following: the mileage on those pads was more than 15,000 km and they have not yet worn out even half. I can’t say what happened next to them, since the car was successfully sold to another owner. But I am more than sure that you are unlikely to encounter problems with this company if you take real components from ATE.

Rear pad selection

Regarding the rear ones, I can say that ATE could not be found at that moment, so I took an option that also deserves positive reviews - this is the Ferodo company. Also, there were no complaints about operation. The only problem that arose after installation was the need for almost maximum tension on the handbrake cable, since otherwise it refused to hold the car even on a minimal slope.

Most likely this is due to a slightly different design of the rear pads (the difference could be in millimeters, but this plays a big role after installation). The braking quality is excellent, there were no complaints during the entire driving period.

Vati

JSC "VATI-AVTO" produces good environmentally friendly pads for domestic cars, this positions the products as safe for the environment, thereby satisfying European standards and safety requirements.

Friction properties in cold conditions and high temperatures after warming up show good results. Test results: at a speed of 100 km/h, with cold brakes, the friction coefficient is 0.35, when they are heated to 250 degrees, the coefficient increases to 0.37. During the mountain test cycle, the braking coefficient is 0.40, and during cooling – 0.47. The products are characterized by good wear resistance, no dust formation, and a gentle effect on brake discs.

Advantages:

- good quality/price ratio;

- durability;

- work without squeaks and noises;

Flaws:

- limited model range.

Bosch BP976

Like all Bosch products, brake pads guarantee quality. They provide braking power, sound insulation, reliability and durability. For production, special ceramics, organic, non-asbestos, semi-metallic and NAO materials are used. They guarantee safety and durability.

A rubber gasket with a core is installed on the pads. The slots and chamfers ensure a good fit. Designed for a relaxed driving style. Tests showed the following indicators: at a speed of 100 km/h, with cold brakes, friction coefficients are 0.48. When they were heated to 250 degrees, the coefficient decreased significantly, to 0.3. During the mountain test cycle the braking coefficient was 0.36, and during cooling it was 0.46.

Advantages:

- the pads are effective in braking on the mountain cycle;

- low level of wear;

Flaws:

- reduction in the efficiency of characteristics at elevated temperatures.

A special device that alerts you to pad wear

Today you can install a special device on both the rear and front pads, it will warn about the degree of wear. Such devices can be mechanical or electronic. In the first case, an unpleasant creak is heard when worn. In both cases, replacing the front brake pads of a VAZ 2110 can be much easier. In the case of an electronic device, when the pad wears out, a special indicator on the dashboard lights up.

Note! Brake pads need to be changed in pairs on two wheels. In the worst case, new and already worn pads will brake the wheels differently.

ATE

The manufacturer Continental Teves produces front and rear ceramic pads with good braking performance, low wear resistance, disc-saving, silent, and soft braking. The products belong to the upper price category.

Test results showed that at a speed of 100 km/h, with cold brakes, friction coefficients are 0.58. When they were heated to 250 degrees, the coefficient decreased slightly, to 0.47. During the mountain test cycle the braking coefficient was 0.43, and during cooling it was 0.48. The friction coefficient turned out to be one of the highest among the pads for VAZ cars.

Products do not lose their performance qualities until maximum wear. This is achieved through the use of innovative manufacturing technologies and friction composite materials. They use non-ferrous metals (chrome, nickel, titanium), this classifies these ceramic products as “luxury”. Thanks to the large assortment, ATE products can be used in all VAZ car models.

Advantages:

- proven quality;

- wear resistance;

- stability of characteristics.

Snapshot

We take out the plug and through the window evaluate the condition of the front brake pad lining. If the lining thickness is less than 1.5 mm, the brake pads of both wheels must be replaced. The pads also need to be replaced if the linings are oily, have deep grooves and chips on them, or if the linings are detached from the base of the pads.

Attention! The brake pads of the rear wheels must be replaced as a set - all four pads. Replacing the pads of only one brake mechanism can lead to the car pulling to the side when braking.

To check the condition of the wheel cylinders and brake drums of the rear wheels, remove the drums. There should be no cracks or chips on the drums. If the working surface is severely worn, or if there are deep grooves on it, we replace the brake drum. To check the condition of the sealing cuffs of the wheel cylinder, alternately on each side we move the edge of the boot from the protrusion of the cylinder body. If there is brake fluid under the boot, indicating a faulty seal, the wheel cylinder must be replaced.

If the fluid level in the brake hydraulic reservoir is at the MAX mark, then before installing new pads, use a syringe or a rubber bulb to pump out some of the liquid from the reservoir so that when the pistons are recessed into the working cylinder of the brake mechanism, liquid does not flow out from under the reservoir cap. The parking brake lever must be lowered all the way (the car is released). Next, release the parking brake cables as much as possible.

MarKon

MarKon brake pads are considered the best in the budget price segment. The product line is extensive, with over 500 models. The manufacturer uses a soft friction mixture for the pads with more than 20 components in its composition.

The products adhere well to the discs, thereby preventing them from wearing out prematurely (although their service life is short, 20-30 thousand kilometers). Before grinding in, the pads initially make a squeaking sound, but during operation it disappears. The reason is the mismatch between the geometry of the pads and VAZ discs. When testing on dynamic stands, the friction coefficient turned out to be stable throughout all cycles (0.42-0.44).

Advantages:

- cheap price;

- efficiency;

- maintainability;

- rapid heat removal from the contact zone.

Flaws:

- needs to be changed frequently;

- insufficient strength of the material;

- gathering dust.

TEXTAR

This company, founded in 1913, has managed to do a lot over the century of its history: cooperate with the largest automakers in Germany, produce many pads and change the principles of their production several times, constantly introducing new technologies. Having our own research laboratory allows us to improve in the search for the ideal technology.

Of course, the cost of most models is far from budget, but the high quality of the products offsets the high cost. So it’s worth taking a closer look at TEXTAR - maybe this is what you need?

9.8 /10 rating

Advantages

- high quality of the final product;

- constant improvement of creation technologies;

- excellent characteristics;

- great production history.

Flaws

- the price is above average.