02/04/2022 13,616 VAZ 2109

Author: Ivan Baranov

Modern cars are mostly equipped with an internal combustion engine. In order to cope with various unforeseen situations on the road, you need to know the structure of the machine. The article describes the operating procedure of the VAZ 2109 cylinders, as well as possible malfunctions in the operation of the power unit.

[Hide]

The principle of operation of a four-stroke power plant

You can understand why it is important to connect high-voltage wires correctly if you study the principle of operation of the power plant. The carburetor or injector of the VAZ-2109 operates on approximately the same principle, since both power plants are four-stroke.

- First, the cylinder volume is filled with the fuel mixture and exhaust gases. This process is called "inlet".

- The engine then goes into compression. With it, the valves are closed, and the crankshaft and connecting rod move the piston upward. The mixture of fuel and air is transferred to the combustion chamber.

- During the expansion stage, the ignition is switched on and a spark appears. It ignites the fuel mixture, resulting in the formation of gases. They put pressure on the piston, causing it to move down. This force is transmitted through the connecting rod to the crankshaft.

- The process is completed by the “release” of exhaust gases through the exhaust system.

In order for the engine to operate smoothly and without jerking, the processes must take place in a certain order. This, first of all, concerns the order in which the cylinders are put into operation.

Features of the ignition module

Now let's talk about a more complex issue - the ignition module and its design features.

The design includes several components, each of which has its own nuances.

Component

Peculiarities

There are always two coils on a VAZ 2109. This mechanism is responsible for generating current

Switch keys also work together. Through them, the current goes to the spark plugs, plus the controller regulates the time the current is turned on, which is calculated by receiving information from the crankshaft sensor

Engine workflow through cylinders

The cylinders are activated as follows:

- In the first there is an upward movement. The gases expand and the mixture of air and fuel burns.

- In the third, to carry out the compression procedure, the piston rises.

- In the fourth, “injection” occurs - the piston moves down and at the same time a mixture of air and gasoline enters the cylinder.

- In the second cylinder, the piston rises and takes the upper position so that gases escape through the valve system. After which the exhaust gases are removed from the power unit.

Based on the principle of operation of the cylinders, their activation diagram looks like this: 1-3-4-2. It is important to connect them correctly so that the cylinders work in that order.

What to do if the candles are flooded

How to start a car if the engine spark plugs are flooded. In the case where the spark plugs are wet from gasoline in an injection engine, you should unscrew the spark plugs, hold them on the fire with pliers (dry them), and turn the starter without installed spark plugs for about 10 seconds to ventilate the pistons. After this, the spark plugs are tightened and, as a rule, the car starts.

How to dry the cylinders without unscrewing the spark plugs in the injector

Dry the cylinders in this order:

- The gas pedal is pressed all the way to the maximum.

- Turn the ignition key and turn the starter for about 10 seconds.

- Release the gas pedal.

If the gas pedal is pressed, the throttle valve is open, due to which air circulates and the spark plugs dry out.

In this simple way, you can start a fuel-injected car after filling the spark plugs with gasoline.

If the method of drying without dismantling the candles does not help, then you will have to dry the candles manually. Manual cleaning is better, since the electrode itself can also be quickly cleaned of carbon deposits and heated over a fire, and the gap can be checked.

Spark plugs are not expensive; those who don’t want to bother and clean them buy new ones that are appropriate for the given engine.

The service life of spark plugs is from 15 to 25 thousand kilometers.

If simple minor repairs and simple actions to eliminate this cause do not help, then it is necessary to carry out in-depth diagnostics: checking the ignition system, ignition coil, injectors, temperature sensor, Hall sensor.

How to connect wires correctly

When replacing high-voltage conductors, they are first connected to the ignition distributor. The distributor cover is convenient in that it is always installed in one position. There is a special mark on it, thanks to which it will not be difficult to place the part in place. Before connecting the wires, inspect the cover. It must be intact, since if cracks appear, the performance of this unit is not guaranteed.

The mark on the distributor cover is located next to the wire socket of the first cylinder. The firing order of the cylinders is slightly out of order (1-3-4-2) due to the ignition slider. It moves around the circle (distributor) counterclockwise. It is precisely by this principle of movement of the slider that it is easy to remember the order of the wires. They need to be connected to carburetor and injection VAZ-2109 according to the same principle. On the distributor cover, connect the wires according to the principle of movement of the slider, this is the only way you can set the ignition correctly:

- the socket of the first cylinder is located at the mark;

- the third one is connected at the very bottom;

- on the same line with the socket of the first, there is a place for the wire to the 4th cylinder;

- at the top point the second cylinder is connected.

On the engine itself, the cylinder numbering goes from the location of the timing belt to the starter, that is, from left to right. The fourth cylinder is closest to the starter, and the first is closest to the timing belt. When connecting, it is important to look at which socket of the distributor cover the wire comes from, if you confuse their location, the car will not start.

If you have connected the wires correctly, but the car still does not start, then the problem may be in them. Check high-voltage conductors for integrity. If you haven't changed them in a while, it's worth buying a new set. The peculiarity of these wires is that over time microcracks can form on their surface. They lead to a lack of spark when the ignition distribution system is working. Moisture and dust get into these cracks, which damages the wire from the inside, although it appears intact from the outside.

Car enthusiasts recommend purchasing sets of high-voltage wires from foreign manufacturers, as they last much longer than stock or domestic ones. It is advisable to replace the spark plugs along with the wires, especially if cracks or carbon deposits appear on their surface. This is necessary so that after repair you definitely do not have problems with ignition.

Block head and timing device

All front-wheel drive cars of the VAZ family, be it 2109, 2110 or 2114, have one cylinder head, common to all cylinders. They are mounted to the block using ten screws. During installation, a metal gasket is placed under it. This gasket is for single use and cannot be reused. There are five camshaft bearings at the top of the cylinder head.

The camshaft of the engine of the VAZ-2109 car has the index 21083. Some engines are equipped with 2110 or 2111 shafts; their design is slightly different from 21083, which allows for an increase in engine power. The shaft is cast from cast iron, there are five supports and eight cams on it that open the valves. It is driven by a toothed belt from the crankshaft pulley. The shafts can be correctly installed relative to each other using the alignment lug on the rear timing belt cover and the marks on the drive gears and flywheel.

Seats are pressed into the cylinder head, as well as valve guides. On the inside of the bushings there are grooves for supplying lubricant; the bushings are closed on top with oil deflector caps.

The valves are made of steel, and the intake head is made of heat-resistant steel. They are mounted obliquely in one row. The inlet valve has a larger diameter than the outlet valve. The gaps between the valves and camshaft cams are adjusted using shims that have increased wear resistance.

Pushers are metal cups moving in the cylinder head holes. To improve wear resistance, the surface in contact with the ends of the valve stems is cemented.

The operating order of the VAZ 2109 cylinders

Very often, during repairs, high-voltage wires are removed from the ignition distributor or spark plugs. The only problem is that few people remember how they were connected before. To avoid confusion, you need to know the sequence of connecting the high-voltage wires of the VAZ 2109, first to the ignition distributor, and then to the spark plugs of each cylinder.

Connecting wires to the ignition distributor

The ignition distributor cover is placed on it only in one position; it cannot be put on in another way.

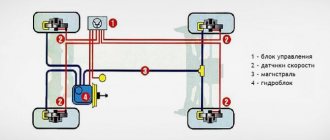

The distributor cap has a mark; this mark indicates the socket of the high-voltage wire of the first cylinder of the VAZ 2109 engine. The operating sequence of the engine cylinders is as follows: 1-3-4-2. The ignition distributor slider rotates counterclockwise when viewed from the cover. Therefore, the lower socket corresponds to the high voltage wire of cylinder No. 3. The next socket, going counterclockwise, corresponds to cylinder #4, and the top socket corresponds to cylinder #2. All this is depicted in the picture below. The numbering of engine cylinders starts from the timing belt and goes from left to right.

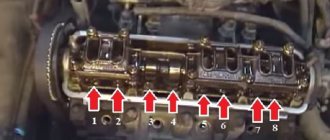

Cylinder arrangement VAZ 2109

That is, the cylinder closest to the timing belt is the first, the cylinder closest to the starter is the fourth. If the wires from the ignition distributor are mixed up, the car will not start. Therefore, if you remove high-voltage wires, then you need to connect them back as they were before. And then there are comrades who remove the wires, mix them up and then start a panic that the car has stopped starting.

Several conditions for the correct connection of high-voltage wires to the distributor cover

1. It should be remembered that the distributor cover itself is installed on the distributor in only one position, so it is impossible to confuse anything.

2. There is an installation mark on it that identifies the wire socket to the first cylinder.

3. The wires are installed in the sequence 1 – 3 – 4 – 2, in a counterclockwise direction, when looking at the cover from the side of the expansion tank.

4. On carburetor engines (2108, 21081, 21083) of VAZ 2108, 2109, 21099 cars and their modifications, cylinder counting begins from the timing drive.

5. Each wire has a certain length and reaches from its socket in the lid to the desired spark plug with a slight sag.

The image below shows the correct procedure for connecting high-voltage wires to the distributor cover of the contactless ignition system of VAZ 2108, 21081, 21083, 2109, 21091, 21093, 21099 cars.

The procedure for connecting high-voltage wires to the distributor cover on VAZ 2108, 2109, 21099 cars

And this is the order of numbering and counting of the cylinders of carburetor engines 2108, 21081, 21083 of VAZ 2108, 2109, 21099 cars and their modifications. We connect the high-voltage wire to the socket with the required number on the distributor cover, and then to the spark plug in the cylinder with exactly the same number. We select the length of the wire experimentally.

Numbering order of engine cylinders 21083 (21081, 2108) of VAZ 2108, 2109, 21099 cars and their modifications

The operating order of the VAZ 2109 cylinders

Thus, the working cycle of the VAZ 2109 internal combustion engine is represented by the following sequential actions: 1. In the 1st cylinder, a downward movement occurs, the working stroke, that is, the combustion of the working mixture and the expansion of gases. 2. “Compression” occurs in the 3rd cylinder, the piston moves up. 3. In the 4th cylinder there is an “intake”, the piston moves down, and the working mixture is pumped into the cavity. 4. “Exhaust” is carried out in the 2nd cylinder; exhaust gases leave the cavity through the exhaust valves.

Now let's look at several cases of malfunctions in the operation of the VAZ 2109 engine. In order to find out the cause of the breakdown, you should use the following algorithm of actions:

• Start the engine and go to idle speed. Listen to the sounds of exhaust. If uniform, periodic popping noises are observed, then most likely the cylinder is not working due to suction, a faulty spark plug, reduced compression or lack of spark. • Inspect the spark plugs; there should be no traces of soot, oxidation or moisture. The gap between the electrodes should average 0.8-0.9 mm. • Replace the spark plug set. • Check the condition of the high-voltage wires of the ignition system. The insulation must be intact, and the contacts must not be oxidized or burnt. If the wires are damaged, they must be replaced. • Inspect the rotor and distributor cap. The lid must be intact, without cracks and clean, without traces of soot. The carbon contact must not be worn or damaged. The rotor must also be intact and have no signs of burnout. All faulty elements must be replaced. • If, after the actions taken, interruptions in the operation of the cylinders continue, then you should contact a service station for a full diagnosis and adjustment of the ignition system, which should be carried out on a stand. • It should be noted that normally the compression should be above 1.1 MPa. If fluctuations within 0.1 MPa are observed in one of the cylinders, then it is necessary to urgently repair the engine itself.

Thus, it is quite obvious that knowledge of engine operation will allow timely repair work and avoid serious breakdowns.

We independently regulate the system

In order for the motor to operate normally, you need to set the angle. To complete this task, you will need to prepare tools, in particular, keys and screwdrivers. Before proceeding with the adjustment, you should start the internal combustion engine and let it run until it warms up. Please note that the idle speed should be at least 800 rpm.

After the internal combustion engine is warmed up, you need to open the hood and disconnect the silicone pipe, which produces vacuum from the fitting. One end of this pipe must be brought to your finger - if after this the pipe suctions, this indicates that there is a vacuum in the system. If this is the case, you will need to reduce the engine speed until the vacuum stops. Next, you will need to turn off the engine and bend the pipe until the clearance disappears. Using a wrench, you will need to loosen the fixing nuts that secure the distribution unit (the author of the video is the Engine Repair channel! And interesting!).

After the plug is removed and the inspection hatch is cleaned, you will see strips with which you can adjust the torque. The flywheel itself should be turned until it coincides with the elongated mark. These actions will allow you to optimally adjust the moment.

When everything is done, you will need a strobe or a simple light bulb with wires connected to it, the setup procedure is as follows:

- The red cable from the light bulb should be connected to the positive terminal on the coil under the hood.

- The black cable is the ground cable, which means it needs to be connected to the vehicle body.

- Start the engine and then rotate the switchgear housing. The strobe should send signals in time to the flywheel. The housing itself should be rotated until the mark is aligned with the mark on the flywheel.

What is the order of operation of the cylinders in the VAZ 2109 engine?

Operating procedure

Often when repairing an engine, it becomes necessary to disconnect high-voltage wires. Some drivers, after disconnecting the wires, do not remember the order in which they were installed. As a result, there may be confusion with the wires, and if they are connected incorrectly, the car will not start. To avoid an unpleasant situation, you need to know how the internal combustion engine operates.

Connecting wires to a VAZ 2109

The principle of operation of the power unit is based on such a property of gases as the ability to expand when heated. A standard four-cylinder engine operates in 4 strokes:

- During the first stroke, the air-fuel mixture and part of the exhaust gases are “injected”. This mixture completely occupies the volume of the cylinder.

- In the second cycle, the “compression” process occurs. In this case, the valves are closed, and the piston moves upward due to the movement of the crankshaft and connecting rod. The working mixture fills the combustion chamber.

- On the third stroke, called “expansion,” a spark appears thanks to the spark plugs, which ignites the working mixture. The expanding gases exert pressure on the piston and force it to move downward. Then, thanks to the connecting rod, the crankshaft begins to move.

- On the fourth stroke, the process of “release” of exhaust gases is carried out. Through the exhaust valves they enter the exhaust system of the VAZ 2109.

In order for the operation of a multi-cylinder engine to be smooth and the crankshaft not to experience uneven loads, it is necessary that the work processes be carried out in a certain order.

There are different schemes that determine in what sequence the cylinders will function. The VAZ 2109 uses the following scheme: 1-3-4-2. The cylinders are numbered starting from the front cover of the power unit.

Cylinder numbering on the VAZ 2109

If we imagine the working process of the engine through the cylinders, then the order of operation is as follows:

- In the first cylinder, an upward movement occurs, the working process takes place: the air-fuel mixture burns, the gases expand.

- In the third, a “compression” process is carried out, in which the piston moves upward.

- The fourth receives the working mixture as the piston moves downwards, thus carrying out the “injection” process.

- In the second, the piston moves upward, while the exhaust gases exit through the exhaust valves.

Possible causes of failure

During the operation of the internal combustion engine, various malfunctions are possible. To detect them, you should perform the following sequence of actions:

- First you need to start the car. The engine should idle. At this time, you should listen to what sounds are coming from the exhaust pipe. If you hear regular popping noises, then one of the cylinders is faulty. The cause may be faulty spark plugs and lack of spark. The malfunction can also be caused by a large amount of incoming air or insufficient compression in the cylinder.

- It is necessary to inspect the candles. If there is carbon deposits, moisture or oxidation, you need to clean it. Check the gap between the electrodes, which should be 0.8 - 0.9 mm.

- Replace all spark plugs, regardless of their appearance and vehicle mileage.

- If there are irregular emissions, you need to inspect the high-voltage wires. There should be no traces of oxidation on their tips, and the insulation should not be damaged. If defects are found, the wire should be replaced.

Wires connecting to the coil - The gas distributor cap should be inspected. There should be no soot or cracks on it. The carbon contact should be checked for damage and wear.

- The rotor needs to be inspected. It must be solid and have no signs of burnout. All parts with defects must be replaced.

- The pressure in the cylinders is allowed to be no lower than 1.1 MPa, and the compression difference should not exceed 0.1 MPa. If the indicators do not correspond, engine repair is necessary.

If after the above steps the problems remain, then you need to contact a service station to undergo a more accurate diagnosis of the VAZ 2109 engine and adjust the ignition system on the stand.

Sources

- avtozam.com/vaz/2109/poryadok-raboty-tsilindrov/

- navaze.ru/108-poryadok-raboty-cilindrov-vaz-2109.html

- vaz2109.net/ekspluatatsiya-avtomobilya/poryadok-raboti-cilindrov-vaz-2109.html

- ladaautos.ru/vaz-2109/kakoj-poryadok-raboty-cilindrov-vaz-2109.html

Causes of failure

Once you have figured out the order of operation of the elements, you can begin diagnosing the motor. As stated above, the failure of one or more components is directly related to the motor tripping, so it is necessary to find out the reasons for its failure.

- Start your VAZ 2106, let it run in neutral gear. Then go to the muffler and listen to how the exhaust pipe works. If there are no interruptions in the functioning of the engine, the exhaust sound will be smooth and soft. If you hear popping noises from time to time, this means that one of the components is not functioning due to a broken spark plug. This may also indicate a lack of spark at the spark plug, excessive oxygen leakage, or an incorrect compression level.

- If the exhaust pipe pops are irregular, that is, they occur from time to time, then this may indicate incorrect operation of the carburetor, failure of the spark plugs, or their wear. This may also indicate a faulty ignition. To fix the problem, you should diagnose the carburetor, ignition system, and replace broken spark plugs.

Non-working car spark plugs

Distributor cover VAZ 2106

Auto working spark plugs

If, as a result of these actions, the problem of engine tripping remains, then contact a specialist and diagnose the ignition system.

This is done using specialized equipment, so it is unlikely that you will be able to accurately make a “diagnosis” yourself.

This is a reminder for drivers of the VAZ 2107 (also relevant for other classics), I decided to create it because minor technical questions often arise, and it takes a lot of time to find the answer. And here everything is in one place. Save this reminder in your bookmarks or on your page on a social network, and use the social network buttons under the article for your health.

So, VAZ 2107 technical characteristics, dimensions, parameters.

VAZ 2107 was produced from March 1982 to April 2012. It has been produced in Egypt since 2006 to this day. It has a 5-seater sedan-type body, in-line 4-cylinder gasoline engines, paired with a 4 or 5-speed manual transmission. It is included in the class of subcompact cars, according to the European classification - class “B”. And not C, as they say on the forums. C class is Ford Focus, KIA Ceed, etc. Wheel formula 4x2, rear wheel drive. The ancestor is the Italian Fiat 124.

General parameters of the VAZ 2107

Length - 4145 mm Width - 1620 mm Height - 1446 mm Base - 2424 mm Front wheel track - 1365 mm Rear wheel track - 1321 mm Ground clearance - to the front suspension cross member - 159 mm, to the rear axle beam - 154, up to muffler housing - 120 mm. Not bad, for example in the Opel Zafira, only 150 mm to the highest point. Load capacity - 400 kg Trunk volume - 385 liters Curb weight - 1060 kg Gross weight - 1460 kg Towed trailer weight, without brakes - 300 kg, with brakes - 600 kg.

VAZ 2107 engines

The VAZ 2107 was equipped with several engines (for Russia and the USSR), these are:

VAZ 2103 engine (8 cells, 1500 cm3, 71 hp, carburetor) VAZ 2105 engine (8 cells, 1300 cm3, 64 hp, carburetor, timing belt drive) VAZ 2106 engine ( 8 class, 1600 cm3, 79 hp, carburetor) VAZ 2104 engine (8 class, 1500 cm5, 68 hp, central injection) VAZ 21067 engine (8 class, 1600 cm3, 74 hp, distributed injection) RPD engine (rotary, 1300 cm3, 140 hp) Piston

diameter and stroke:

- for 1300 = 79 mm x 66 mm - for 1500 = 76 mm x 80 mm - for 1600 = 79 mm x 80 mm - for 1700 = 82 mm x 80 mm Compression ratio for all engines - 8.5 Cylinder operating order: 1-3-4-2 For carburetor VAZ 2107, DAAZ 2107-1107010 carburetors and their modifications were used.

A-92 gasoline is used as fuel. The injector for Euro-3 standards is already designed for A-95 gasoline. Spark plugs for VAZ 2107:

- for carburetor engines - A17DVR or A17DV-10;

- for injector - A17DVRM. Oil for VAZ 2107:

For all classic engines, the optimal choice is semi-synthetic 5W40. If your region has severe frosts, and most of the time it is below minus 30, then choose 0W40. If your frosts are not severe and the summer is hot, then the oil is better than 10W40. Oil change is done once every 10,000 km

All-metal, load-bearing, with 4 doors. Body rigidity - 7200 Nm/deg. The width of the interior of the VAZ 2107, and all the classics in general (from the rear door trims at the seat level) - 1250 mm Between the central pillars of the cabin, at a level of 80 cm from the floor - 1234 mm The length of the front door opening of the VAZ 2107 (and all the classics) - 889 mm , rear door - 819 mm.

Electrical equipment VAZ 2107

Wiring type: single-wire, negative on the car body (ground). Battery: 6ST-55, capacity 55 Ah. Batteries with a capacity of 60 and 65 Amperes are also suitable, but you need to check the dimensions. Typically it is 242mm x 175mm x 192mm. Operating voltage in the network: 13.6 -14.6 volts. The generator (G221) must deliver a current of no more than 1/10 of the battery capacity, i.e. approximately 2 to 5.5 Amps. Ignition coil - B117 or B117-A (for carburetor engines) Starter - ST221 Lamp type:

— low and high beam lamp: H4 or AKP2-60+55 (in Russian) — side marker lamp and side turn signals: T4W or A12-4-1 — turn signal lamp in the headlight, fog lights, reverse and brake lights: P21W or A12-21-3 - license plate and interior lighting lamp: C5W or AC12-5-1

Fuel tank (including a reserve of 5 liters) - holds 39 liters of gasoline Lubrication system (including oil filter) - holds 3.75 liters of oil Engine cooling system (including interior heater) - 9.85 liters of antifreeze Washer reservoir - 2 liters Gearbox housing - 1 .35 liters of transmission oil (semi-synthetic GL-5 75W90) / for a 5-speed gearbox - 1.59 liters Rear axle housing - 1.3 liters of semi-synthetic GL-5 (75W90) Clutch hydraulic system - 200 ml Brake system 660 ml

Suspension and wheels of VAZ 2107

Front suspension: independent, double wishbone, with anti-roll bar and hydraulic shock absorbers. Rear suspension: dependent, with a rigid rear axle beam and 5 reaction rods, on hydraulic shock absorbers. Standard VAZ 2107 wheels: 5Jxl3H2 with an offset of 29 mm, mounted on 4 bolts with a hole diameter of 98 mm, hole diameter for the hub - 58.5 mm) Tires: tubed or tubeless 175/70R13 or 165/70R13 Recommended tire pressure: - front wheels - 1.7 kg/cm2 - rear wheels - 2.0 kg/cm2 For a softer and more comfortable ride, you can reduce it by 0.1 kg/cm2

Maximum speed:

from 4 speed

Gearbox - 145 km/h with 5 speed. Gearbox - 152 km/h Acceleration to 100 km/h:

with engine. 1300 - 19 seconds from the engine. 1500 - 17 seconds from the engine. 1600 - 16 seconds Fuel consumption, highway/city: 6.9 / 9.6 liters for all models, approximately the same.

The engine is the heart of any car. It’s not for nothing that the word “car” means “self-propelled” when translated from Latin. It is the power unit that distinguishes any bicycle from a car. The engines of the VAZ classic family, to which the VAZ 2107 belongs, were for their time advanced in their class - quite quiet, economical, and unpretentious. The weight of the power unit and the weight of the car are 10% and 90%, which is not bad for the development of traction. Let's talk more about the engine.

All engines of the classic family, including the VAZ 2107, are gasoline, four-stroke. All units have four cylinders, four pistons, which are arranged in a row, and a carburetor is installed. The unit is eight-valve, two valves for each cylinder. The camshaft (or timing mechanism, gas distribution) is located on top. At the top is the supply of the mixture of fuel and air, which is supplied by the carburetor.

Initially, the VAZ 2107 was equipped with a carburetor, a “six” engine, like the VAZ 2106, its volume was 1.6 liters. In the future, we will keep in mind this particular carburetor engine.

You can also install the 21067 engine, its volume is 1.6 liters. The mass of these two types of engines is almost the same

In addition to this standard, the old VAZ 2107 models were equipped with power units 2103 and 2104, with a different cylinder size, which was not 79 mm, but 76. Accordingly, the engine power was slightly less.

In all power units, the cylinder operating order is 1-3-4-2.

Power unit, section in the frontal plane

The power of the units installed on the VAZ 2107, and most of all in the VAZ 2106, is 54.8 kW, or 74.5 hp. There is a direct relationship: the larger the cylinder volume, the higher the engine power. A carburetor adds more reliability to the engine, compared to an injection engine, in case of engine failure, the ability to give it a “light”, etc.

The assembled engine weighs about 120 kg, so it is not recommended to try to remove the power unit without having an electric hoist or overhead crane at hand.

The engine structure is as follows:

- The cylinder block is a high-strength cast iron. It contains 4 high-precision cavities - cylinders in one row. The figure shows a diagram of the cylinder block and the coolant passages in it. Its mass is large; it is the heaviest part of the power unit.

- The crankshaft is also made of high strength cast iron and rests on five bearings called journals. The mass of the crankshaft is large, and the precision of its processing is also great; its journals are hardened by high-frequency currents. The figure shows the diagram, structure and main tolerances in the production of the crankshaft.

- Connecting rods are made of high-strength forged steel, as it experiences heavy loads. There are 4 of them, one for each cylinder. The piston pin is pressed into the connecting rod. Since the connecting rods cannot be replaced from one to the other, they are marked according to the cylinders. The figure shows the structure and main dimensions of the piston (right) and connecting rods (left) and their maximum tolerance diagram in mm.

- Pistons are cast from light aluminum alloys, with tin coating on the outer surfaces. This technology makes it possible to improve the running-in of the piston to the cylinder wall. Three rings are installed on the pistons, two of which are called compression rings, and one oil scraper ring.

- The cylinder head is made of light aluminum alloy, its weight is relatively small, and between it and the cylinder block there is a special gasket that is not subject to shrinkage. The figure shows the structure of the BC head and valves.

- The camshaft with sprocket and valve train, together with the chain, constitute the timing mechanism. The chain drive works together with the chain tensioner and damper.

- The flywheel is located at the rear pole of the crankshaft. The flywheel has a cast iron ring gear that meshes with the starter to start the engine. To increase engine power, you can reduce the weight of the flywheel by installing a lightweight version.

- The schematic diagram of the unit includes many others, for example, the engine lubrication diagram will also be presented, for example, this way:

In this diagram, without going into detail, you can see special channels and cavities in cast parts, the so-called lubrication passages and cavities for the circulation of coolant in the cylinder block.

It should be noted that the power of the unit cannot be maximum or close to it for a long time, without an adequate cooling and lubrication system.

In conclusion, it is worth noting that if you choose whether to choose a carburetor or an injector, then we can say that the first option is simpler and more reliable to repair, but the second is more modern and economical.

On the engine itself, the cylinder numbering goes from the location of the timing belt to the starter, that is, from left to right. The fourth cylinder is closest to the starter, and the first is closest to the timing belt. When connecting, it is important to look at which socket of the distributor cover the wire comes from, if you confuse their location, the car will not start.

Drops in the trunk

This often happens due to an incorrectly attached spoiler. Typically, bolts and double-sided tape are used for this. If it gets wet and moves away, water will begin to seep under the structure, which will penetrate inside the body and collect at the bottom of the trunk. A heated muffler will cause moisture to evaporate.

To eliminate the problem, it is necessary to degrease the surfaces and treat them with sealant. It is also worth checking the trunk seal, tail lights and all rubber plugs.

So, caring for the condition of the car should be comprehensive.

In the case of condensate, it is important to understand the mechanism of this physical phenomenon. And then finding the optimal solution will be much easier

Source