This article will talk about the purposes for which the VAZ 2110 fuel pump is used. As you know, the heart of any car is the internal combustion engine. With its help the car is set in motion. Among the main systems that are the most important in a car, the fuel system stands out. It is with its help that gasoline is supplied from the tank, which is located in the rear of the car, to the internal combustion engine. The fuel pump ensures uninterrupted pumping of gasoline at the required pressure. Moreover, the fuel pump operates in different modes, everything depends on the load on the engine itself, its saturation and performance. And don’t forget about the VAZ 2110 fuel pump fuse; if suddenly there is no fuel supply, check it first.

Pump operation

Anything can happen while operating a car. In particular, the fuel pump may break down. Or the fuel tank is dirty, and therefore the filter installed at the bottom of the pump. It is worth paying attention to the fact that VAZ cars are very popular in our country. There are a lot of spare parts for them; you can find them in any auto store. True, the quality of products is not always good. Sometimes you come across outright fakes on the market that cannot last even a few months. Of course, you can run into a low-quality spare part even if you purchase it for a foreign-made car. The service life of the VAZ 2110 pump is about 100 thousand km. If we take into account the fact that on average a motorist travels about 30 thousand kilometers per year, then in the time period the pump service life will be about three years. After this, it is necessary to replace the VAZ 2110 fuel pump.

A brief tour of brands

We recommend purchasing original OEM parts for your vehicle. You won’t have to choose for long, since you are buying a fuel pump specifically for your model. The market for originals is represented by some of the brands that we will list below. The difference is in labeling and approach to quality assessment. For example, at Mercedes-Benz factories, fuel pumps are tested several times additionally, so that only the best parts are sent to assemble the car.

If your finances are not very limited, pay attention to the following analogues: Pierburg, Bosch, Siemens (Germany). The products are cheaper than original parts, but are slightly inferior in quality.

Cheaper options: JP Group (Denmark), Meyle (Germany). It cannot be ruled out that they will last a little less than 200 thousand kilometers.

We advise you to take analogues of a high price category - it’s worth it.

Symptoms of a problem

There are several signs of a broken fuel pump. The sound it makes can be heard when the ignition is turned on. At this time, gasoline is pumped into the fuel rail to achieve the required minimum pressure value. If the sound suddenly begins to change, most likely the pump is broken. Also, extraneous noise may indicate a malfunction. If the car moves jerkily, the engine revs poorly. Or it has difficulty moving in first or second speed, most likely the reason lies in the fact that the fuel pump cannot provide a normal level of pressure in the fuel system. In this case, the internal combustion engine may suddenly stop because the VAZ 2110 fuel pump does not work. The injector functions only if a certain pressure is maintained in the ramp. And it is created by a pump.

Making a purchase

At an auto parts store, tell the manager the VIN code of your car and ask them to select the original or analogues. The priority is the original, but we will also talk about possible options for purchasing an analogue.

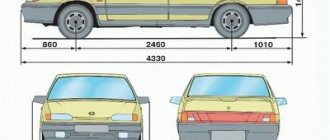

When making your own selection, consider this: the make of your car, model, installed engine, body type. If you are searching online, this is all you need to enter into the search engine. The same is communicated to store managers. This way you will find analogues and original parts. In this case, the geometric parameters of the new pump must be identical to those of the old one. Of course, adapters solve the problem, but it’s not worth complicating an already complex system with a new unit.

System pressure

Now let’s talk about how to determine if the fuel pump is faulty. And also about how to diagnose its breakdowns in the early stages. If suddenly all of the above symptoms begin to appear, it is necessary to clamp the fuel return hose to determine whether there is pressure in the system. In this case, it is necessary to perform this action as sharply as possible. As a rule, the maximum pressure value in the fuel rail is about 7 kgf/cm2. On average, a more or less normal gasoline pump shows an outlet pressure of about 5 kgf/cm 2 . In the car's operating instructions you can read that the minimum permissible pressure value is about 4 kgf/cm2. But this is in theory; practice shows that provided that the pump develops such pressure, it can still last for quite a long time. But replacing the VAZ 2110 fuel pump will still be necessary.

Electric fuel pump for VAZ 2107

Increasingly, owners of “classics”, including the VAZ 2107, are installing modern devices on their cars. So, the mechanical fuel pump is replaced with an electric one. The main goal of introducing an electric fuel pump is to get rid of the problems that arise with standard pumps. However, you need to understand that if on injection “sevens” such a mechanism is installed directly in the gas tank, then on carburetor cars it is placed under the hood.

Which one can be installed

As an electric fuel pump, you can install any device designed to work on fuel-injected cars on the “classic”. Based on reviews from Zhiguli car owners, Chinese-made pumps are often used, as well as Magneti Marelli and Bosch

It is important to know that the product must provide low pressure. A standard mechanical pump produces about 0.05 atm

If the indicator is higher, then the needle valve in the carburetor will simply let fuel through, which will lead to it leaking out.

VAZ can be equipped with low-pressure electric fuel pumps from different manufacturers

Installation of an electric fuel pump

To install an electric fuel supply pump on a carburetor “seven”, you will need a certain list of materials:

- tee 8x6x8 mm;

- fuel line for VAZ 2107;

- check valve from the "eight";

- 8 mm threaded fitting;

- clamps, blocks from Kalina for a four-pin relay (3 pcs.) with a fuse holder;

- the four-pin relay itself (3 pcs.);

- fuel jet (150);

- fuel return hose from the V8;

- wires;

- non-latching button.

We carry out the work in the following sequence:

- We lay the fuel pipe (return) parallel to the standard fuel line, securing it in the factory locations.

- We cut an 8 mm fitting into the fuel level sensor cover.

- We install the electric fuel pump under the hood in a convenient place, for example, on the left mudguard.

- At the inlet of the carburetor we install a tee with a thread cut inside the tube with a diameter of 6 mm, after which we screw in the fuel nozzle to 150: it is necessary to create pressure, otherwise gasoline will go into the tank (return) and not into the carburetor. This will lead to failures when pressing the gas.

- We install a check valve that prevents gasoline from draining into the tank during prolonged inactivity.

- The electrical connection of the electric fuel pump is carried out according to the diagram.

- We also place the block with the relay on the mudguard, but it can be moved higher.

- We dismantle the mechanical fuel pump and replace it with a plug (metal plate).

- We mount the inflation button in the cabin, for example, on the steering column cover.

Video: installing an electric fuel pump on a VAZ 2107

https://youtube.com/watch?v=S3K4whY6–0

Once the installation of the mechanism is complete, it will function according to the following algorithm:

- after turning on the ignition and pressing the pumping button, the pump is activated and pumps up gasoline;

- when the starter starts, the fuel pump turns on;

- while the engine is running, the pump is powered by a generator;

- after the engine stops, the operation of the unit stops.

Installation benefits

Owners of Zhiguli cars who have installed an electric fuel pump on their cars note the following advantages:

- an engine with such a device operates more stable at idle speed;

- when accelerating sharply, the car responds well to the pedal, there are no dips, which is not the case with a mechanical pump;

- when switching gears there is a smooth ride, and when the gas is abruptly released there is no twitching;

- at high speeds the engine spins better;

- there are no jerks at low speeds when starting the car after a long trip.

The VAZ 2107 fuel pump sometimes has to be repaired or replaced. Doing this is not as difficult as it might first seem. Repair and adjustment work is carried out with a minimum set of tools in accordance with step-by-step instructions.

Pressure check

But we should not forget that the automaker wrote all its requirements based on the experiments carried out. If the gas pump does not pump fuel into the system at a pressure of 4 kgf/cm2, then the best way out would be to install a new element. Of course, it is quite possible that the filter at the bottom of the fuel pump has simply never been cleaned. If you replace it, it is possible that the level of pressure created by the VAZ 2110 fuel pump will increase significantly. And it will be quite enough for the car to have normal throttle response and dynamics when driving at high speed. Conventionally, you can carry out a small diagnostic of the fuel pump by disconnecting the fuel line from the ramp. When the power is turned on, a one and a half liter bottle should run to the pump in exactly a minute. Such a check is very relative; it can only be performed if there is no pressure gauge at hand or computer diagnostic systems.

Conclusion

Fuel pumps are represented by a wide range of spare parts, as they are designed to work with a specific type of fuel and specific engines. By purchasing an OEM pump, you are guaranteed to get what you need. Priority is also given to purchasing analogues from the popular Bosch. Don't buy a used pump if you don't want problems! Without forgetting about the operating rules, you can keep even a cheap Meyle, and you will only pay once for purchase and installation.

Interesting posts:

- 7 best tablet manufacturers

- 10 best trekking pole brands

- Car sharing rating in Moscow as of 2022

- 10 best plastic window companies in Novosibirsk

Extraneous sounds

If suddenly there is an extraneous sound when the fuel pump operates, you will need to completely remove it. It is worth noting that the VAZ 2110 fuel pump consists of several parts; the base is an electric motor. It drives an impeller, which pumps gasoline from the tank into the fuel line. As a rule, extraneous sounds appear when the engine itself wears out or when the mesh is excessively contaminated, as well as when a non-original one is installed. If you suddenly have such a symptom, it is necessary to either replace or repair this mechanism, since there is a very high risk that in the near future this unit will simply fail.

Relay and fuse

If the engine suddenly stops starting, you should not immediately blame the fuel pump for everything. First of all, make sure that the switching relay is working properly. Also be sure to check the VAZ 2110 fuel pump fuse to see if it is receiving power from the battery. The relay, which turns on the tens fuel pump, is located in an additional compartment, which is located at the passenger's feet. It happens that the contact disappears in the relay connection block itself. Therefore, it is enough to just pull out and install a new one of this relay. If the car is quite old, then it is quite possible that the circuit board has begun to deteriorate. Small cracks form at the soldering site, which prevent current from flowing normally. As a result of this, the VAZ 2110 fuel pump relay does not turn on.

As a rule, when tuning cars, problems with fuel supply are very often associated in one way or another with the fuel pump or injectors. Here I will describe simple but nevertheless the most effective methods for checking the fuel supply system and criteria for selecting its components. Injectors.

Correct operation

Car enthusiasts should wash the coarse filter, which is located in the pump - it quickly becomes clogged with debris from low-quality fuel. It is also important to maintain the fuel level in the tank. If there is too much gasoline/diesel oil, the pump will start to heat up and eventually fail. It is also worth filling up at a gas station with good fuel - you will save not only the engine, but also the pump.

Despite their high resistance to overheating, mechanical pumps can also fail when exposed to high temperatures. Frequent idling is a very common cause of breakdown. One of the simplest methods to solve this problem is to apply a wet rag to the case.

Do not forget also about the “glass” in which the pumping device is fixed. A large amount of dirt and paraffin often accumulates there if you have a diesel car.

We have already said that there are two possible options for installing a fuel pump: inside the fuel tank and outside it. In this case, pumps placed inside the tank have a lock or are sold without it.

To carry out the replacement, you need to have the following on hand: gloves, fire extinguisher, tools. In this case, the best place to work will be a clean, ventilated garage or workshop. After safety, the most important condition is cleanliness. Along with the new pump, under no circumstances should dust, cobwebs or dirt get into the fuel line.

You should look for video tutorials on replacement or find them in test format. In fact, no special skills are needed. If something doesn’t work out for you, use the services of specialists at a service station.

What kind of fuel pumps are installed on VAZ 2110/2112 cars

VAZ 2110/2112 cars, depending on the year of manufacture and the type of engine installed, may differ in the method of supplying fuel to the cylinders.

Table: features of fuel supply systems to engine cylinders depending on vehicle modification

| Model/ modification | Year of issue | Engine volume, cm3 | Number of valves, pcs | Injection system |

| VAZ 21100 | 1996–2000 | 1500 | 8 | Carburetor |

| VAZ 21101 | since 2004 | 1600 | 8 | Injection |

| VAZ 21102 | since 2004 | 1500 | 8 | |

| VAZ 21103 | since 2001 | 1500 | 16 | |

| VAZ 21103M | since 2001 | 1500 | 16 | |

| VAZ 21104M | since 2001 | 1600 | 16 | |

| VAZ 21120 | 1999–2008 | 1500 | 16 | Injection |

| VAZ 21121 | 1999–2008 | 1600 | 8 | |

| VAZ 21122 | 1999–2008 | 1500 | 8 | |

| VAZ 21124 | 2004–2008 | 1600 | 16 | |

| VAZ 21128 | 2004–2008 | 1800 | 16 | |

| VAZ 21123 | 1999–2009 | 1600 | 16 |

Only the first modifications of the VAZ 2110 were equipped with a carburetor injection system. From the factory they were equipped with mechanical fuel pumps of the DAAZ brand (catalog number 2108–1106010). Previously, they had proven themselves well on cars of the Sputnik and Samara series.

A mechanical fuel pump was installed in the engine compartment of the VAZ 2110 to the right of the engine valve cover, and was driven by the camshaft.

All injection VAZ 2110/2112 are equipped with submersible fuel modules. The design of such a module includes:

- electric fuel pump;

- coarse filter;

- fuel level sensor.

The fuel module is installed directly into the vehicle tank. In other words, the gas pump is completely immersed in gasoline. Injection VAZ 2110/2112 were and are equipped with electric fuel pumps of domestic, joint or imported production. These are products of the Utes, Pekar, Saratov plant, as well as the world famous one, the pumps of which are equipped in all modern VAZs. The catalog number of the stock electric pump is 2112–1139009. There are also modifications whose numbers have two additional digits: 02 or 03. Depending on them, products may differ in length and diameter.

Instructions for replacing the fuel pump

To begin, move the rear seat to the side and fold back the piece of carpet that covers the fuel module hatch.

Next, unscrew the two bolts securing the hatch and remove it.

A fuel module with two tubes will be visible in front of us.

Before unscrewing the pipes, it is necessary to relieve the pressure in the fuel system. To do this, you will need to remove the fuel pump fuse, or turn off the power to the module and start the engine. After the remaining fuel in the system has been used up, the car will stall and you can begin replacing the fuel pump.

Read more: 5 best heat pumps ranking 2022 top 5

Our fuel module can be of different types - quick-release and screw-on, depending on the year of manufacture of the car. If the fuel pipes are on nuts, unscrew them with a 17mm wrench; if they are on quick releases, then simply tighten the clamps and remove them from the module.

Now, using a 7mm wrench or tube, unscrew the 8 bolts securing the fuel module clamp.

We move the fuel pipes to the sides, lift the clamp and carefully, so as not to spill gasoline, pull out the fuel module.

Disconnect the fuel pump plug

Remove the lock shown in the photo

Using a flat screwdriver, unscrew the two bolts

Remove the rubber bushing and the plastic part underneath it

Now you can remove the fuel pump from the module and replace it with a new one.

To install a new fuel pump and perform assembly, you will need to put a new corrugated hose on the pump. To ensure that this hose does not allow air to pass through, it must be heated when it is put on the pump.

Then we reassemble in reverse order.

Design features of fuel pumps for carburetor and injection fuel injection systems

Mechanical fuel pumps, which were installed on the first modifications of the VAZ 2110/2112, have a simple design. It is based on a set of membranes made of special rubberized fabric that is resistant to the chemical action of gasoline. The pump body has two valves: inlet and outlet. The membranes are driven by a rod (pusher). It is driven by a cam mechanism rotated by a camshaft.

Such a mechanical fuel pump can serve for decades until the drive rod wears out or one of the membranes breaks. And even then, if this happens, you can replace these elements in half an hour.

The first modifications of the VAZ 2110 with a carburetor injection system were equipped with mechanical fuel pumps

With an electric fuel pump, things are much more complicated. Its design is based on a small electric motor. It is no different from a regular one, although it works completely immersed in gasoline. The pressure in the system here is created not by a membrane (although there are such pumps), but by a specially shaped impeller mounted on the electric motor shaft.

The service life of the electric fuel pump is 150–200 thousand km. But it can fail much earlier. The main cause of breakdowns when the resource is not used up is additives added to gasoline, as well as various kinds of mechanical impurities. The former destroy the brushes and commutator, while the latter clog the valve mechanisms.

In the injection VAZ 2110/2112, the fuel pump has an electrical design and is part of the submersible fuel module

Main types

The following fuel pumps are available on the market:

- Mechanical;

- Electrical.

The design of a mechanical pump is simple and time-tested. They must have evolved from old mine water pumps that were powered by a steam engine. Automobile pumps are powered by an engine. The electric pump is connected to the generator and battery located in the car, and therefore it is easy to install it immediately inside the gas tank (or along the length of the fuel line).

Pumps also differ in pressure: low pressure, high pressure. The former are usually auxiliary, while the latter are actively used in diesel cars and cars in which gasoline is directly injected.

Hence the following classification: mechanical (used in injection pumps and carburetors), electrical (used in injection pumps and injectors).

Signs of a faulty fuel pump VAZ 2110/2112

Signs of pump malfunction appear the same, regardless of its design and type of injection system. These include:

- difficulty starting the engine;

- unstable engine operation at idle speed (vibration, tripping, stopping of the power unit);

- failures during acceleration in motion;

- reduction in power and traction qualities of the engine;

- absence of the characteristic sound of a fuel pump starting (for injection engines);

- presence of traces of fuel leakage (for carburetor power units).

Determining a fuel pump malfunction on your own is quite problematic, because the first three signs, which are the main ones, may indicate other problems in the fuel system, such as:

- fuel filter clogged;

- problems with sensors for mass air flow, throttle position, oxygen level, etc.;

- clogging of one or more nozzles;

- failure of the pressure regulator.

In addition, similar symptoms are observed when problems with ignition occur. It can be determined that the cause of the listed symptoms is the fuel filter by checking the device.

Advantages of injection models

The main function of the pump is to supply fuel to the combustion chamber. It must meet certain requirements. The main criterion is pressure.

The pumps for injection and carburetor engines are different. Thanks to the engine with direct fuel injection, there is no need for preliminary preparation of the combustible mixture. As you know, the carburetor is the weak link. Difficult adjustments, clogged jets, difficult starting in cold weather create inconvenience for owners of classic VAZ brands.

Tens and VAZ-2112 internal combustion engines have significant advantages. Let us note the advantages of injection units:

- support for environmental standards;

- direct injection into the combustion chamber;

- fuel economy;

- system reliability;

- increased engine power;

- starting a cold unit without warming up;

- dispensing a portion of the mixture;

- The fuel module is controlled electronically.

Unfortunately, the injector has a number of disadvantages. Maintenance and repairs have to be carried out at a service station. It also requires qualified personnel and a computer to determine the malfunction of electronic components. Let us point out other disadvantages:

- design complexity;

- high requirements for the octane number of gasoline;

- complex diagnostics and repairs;

- expensive spare parts and equipment.

How to Test a Mechanical Fuel Pump

To check a mechanical fuel pump, you will need the following tools and tools:

- screwdriver with Phillips bit;

- slotted screwdriver;

- key (head) 10;

- key to 13;

- 2 clean dry plastic bottles with a volume of 2 liters;

- a piece of hose (50 cm) of the same diameter as the fuel one;

- 1–1.5 liters of gasoline;

- caliper (ruler);

- stopwatch (clock).

Let's start with performance. A working VAZ 2110 mechanical fuel pump with a obviously clean filter should pump at least 1 liter of fuel per minute. The verification algorithm is as follows:

- We lift the hood and find the pump.

- Using a screwdriver, unscrew the screw of the pump outlet hose clamp. Loosen the clamp and remove the hose from the pump fitting.

A performance test involves measuring the amount of fuel pumped over a specified period of time.

If the amount of fuel pumped in 1 minute is less than 1 liter, the fuel pump is faulty

Removing the pumping unit

The VAZ-2110 fuel pump is equipped with an electric drive. Its body is lowered into the fuel tank. Gasoline is both a pumpable fuel and a coolant. It should be remembered that traveling with an empty tank is fraught with overheating of the VAZ-2110 injector fuel pump.

This electrical device is an independent unit. Accordingly, its operation does not depend on the state of other mechanisms. A necessary condition for rotating the VAZ-2110 fuel pump rotor is maintaining normal voltage on the on-board network.

Read more: TOP 10 best waterproof watches

The voltage comes through the ignition switch. When the key is moved to position 1, the circuit is closed to turn on the drive. The VAZ fuel pump fills the fuel rail. The engine is ready to start.

If symptoms of poor fuel system performance occur, the pump should be checked. We list the signs that make it possible to replace the VAZ-2110 fuel pump:

- the car is malfunctioning;

- accelerates poorly;

- twitches while driving;

- won't start at all

- gasoline does not flow to the ramp.

First of all, a hearing test is performed. After turning the ignition key to position No. 1, there should be a noise under the rear seat. The sound lasts for a couple of seconds. This means that the pump has pumped up the required pressure.

Before starting work, you must disconnect the terminal from the battery. This will prevent damage to electrical equipment. In addition, replacing the fuel pump may cause a fire.

Let's prepare tools and materials. To remove the VAZ-2110 fuel pump, you need the following:

- Screwdriver.

- 10mm socket wrench.

- Collar.

- Open-end wrench 13.

- Rags.

The device itself is located under the rear seat cushion. To get to the installation location of the fuel pump 2110, you need to remove the seat. Under the casing we find a hatch. We unscrew the hatch. Disconnect the electrical drive connector.

Using an open-end wrench, unscrew the tips of the fuel pipes. We pull off the pipes. Using a spanner, unscrew the 8 nuts around the perimeter of the clamping ring. Release the flange.

There is a gasket under the pressure ring of the fuel pump 2110. The gasket is removed. It is better to change worn tires.

Then we raise the VAZ fuel pump together with the float. Gasoline will leak from the body. To avoid staining the interior, place a rag. There will be up to 1 liter of gasoline left in the old building. Drain it into the tank.

Assembly is carried out in reverse order. There is an arrow on the top of the cover. It should point towards the trunk. This is the correct pump position.

When replacing, do not forget to remove the float and level sensor.

These spare parts are installed on the new structure.

All operations, including preparation, will take less than an hour. After replacement, perform a test. Start the engine. Finally, you should check the fuel pump, make sure the connections are tight and there are no leaks.

Mechanical replacement

If you find problems with the fuel pump, you can try to repair it yourself, or replace it with a new one. In the first case, it is better to buy a repair kit. It includes all the elements of the device that can fail: valves, gaskets, diaphragms and pusher.

If you decide to replace the pump assembly, it is even easier.

After dismantling the faulty device, you need to:

- Install new gaskets and pusher.

- Place the pump in place and secure it with nuts.

- Connect the fuel line hoses and secure them with clamps.

- Press the manual primer lever several times to fill the pump with fuel.

- Start the engine and check its operation.

A new fuel pump is installed on new gaskets

Fuel pump repair

To replace or repair the pump, it will need to be removed from the engine. Tools you will need:

- 13 mm wrench;

- crosshead screwdriver.

Removing the fuel pump

We dismantle the unit in the following order:

- Wipe the pump with a rag.

- Disconnect both hoses (inlet and outlet) by loosening the clamps with a screwdriver.

- We pull the hoses from the fittings.

- Using a 13 mm wrench or a socket with an extension, unscrew the 2 fastening nuts.

- Carefully remove the fuel pump.

To replace the rod, remove it from the heat-insulating spacer

Once a situation arose on my car when engine oil was leaking from the installation site of the fuel pump (in the area of the gaskets). It was not immediately possible to identify the cause. At first I made mistakes on the gaskets between the engine block and the spacer, as well as between it and the fuel pump. I replaced them, but did not achieve a positive result. After dismantling the mechanism again, I examined all the elements more carefully and discovered that the heat-insulating spacer had a crack through which oil was leaking. I had to replace it, after which the problem disappeared. In addition to the described case, there was a similar situation when oil was leaking at the location of the fuel pump. This time the pump itself turned out to be the culprit: oil was oozing from under the axis of the manual fuel pumping lever. There were two options to get out of the situation: accept it or buy a new product. I bought and installed a new pump (DAAZ), which to this day works properly and does not leak.

Disassembly

To disassemble the fuel pump you need to prepare:

- 8 and 10 mm wrench;

- Phillips screwdriver.

The disassembly procedure is as follows:

- Unscrew the bolt holding the top cover.

- We dismantle the cover and remove the filter from the fine mesh.

- Unscrew the 6 screws securing the two parts of the device body.

- Separate the body parts.

- Rotate the diaphragms 90° and remove them from the body. We remove the spring.

- Unscrew the nut with an 8 mm wrench.

- We disassemble the diaphragm assembly, removing the elements sequentially.

- We examine the diaphragms. If there are delaminations, tears or the slightest traces of damage on the elements, we replace the diaphragms with new ones.

- We clean the filter, and then reassemble the pump in the reverse order.

When installing, the mesh filter must be positioned with the hole above the valve

Replacing valves

The VAZ 2107 fuel pump valves are included in the repair kit. To replace them, you will need a needle file and suitable attachments for dismantling.

The fuel pump repair kit contains all the necessary parts for repairs.

The disassembly sequence is as follows:

- We remove the cores using a needle file.

- Press out the valves using suitable fittings.

- We install new parts and core the seat in three places.

Checking the electrical circuit

Unlike a carburetor engine, where the fuel pump is mechanically driven, on the injection VAZ 2110/2112 a special relay and fuse are responsible for the operation of this device. Therefore, before moving on to diagnosing the pump itself, it is necessary to check the indicated elements. If any one of them is faulty, the pump will not work at all.

Turn on the ignition without starting the engine and listen. When the fuel pump is running, it emits a characteristic “whistle” when started. If it is not there, it means that either the pump itself has failed, or one of the elements of its power supply circuit has failed.

The pump relay and fuse are located in an additional mounting block located inside the vehicle's center console. It can be accessed by removing the plastic trim (near the front passenger's left foot). It is secured with several screws. Under the cover you will find three relays and three fuses. Typically, the fuel pump circuit protection elements are located centrally.

The relay and fuse are located in an additional mounting block under the cladding

To check the fuse, remove it from its socket and “ring” it with a tester. If necessary, replace it, observing the rating (15 A). It is unlikely that it will be possible to check the relay for functionality without special equipment. But you can take another relay, for example, the radiator fan (far left), and install it in place of the one being diagnosed. Turn on the ignition and listen to see if the fuel pump starts working. If yes, buy and install a new relay. If the problem persists, continue diagnostics.

To check the fuel pump relay, you can install the radiator cooling fan relay in its place.

Checking the fuel rail pressure

But even the fact that the fuel pump starts pumping when the ignition is turned on does not mean that it is working properly. The main indicator of its operation is the pressure in the system. You can check it using a regular pressure gauge with a measurement limit of 5–7 atmospheres, which is used to measure tire pressure. In addition, you will need a piece of gas-resistant hose with an internal diameter of 9 mm and two clamps of the appropriate size.

The verification procedure is as follows:

- We relieve the pressure in the system. To do this, disconnect the negative terminal from the battery. We remove the plastic lining of the additional mounting block, which contains the relay and fuse for the gasoline pump. We remove the fuse from the socket. Connect the removed terminal to the battery. We start the engine and let it run until it stalls. After that we put the fuse in place.

- On the fuel rail we find a fitting specially designed for measuring pressure. Using the wheel valve cap, unscrew the spool valve from the fitting.

The fitting is designed specifically for measuring pressure

A regular tire pressure gauge is suitable for measuring fuel pressure in the rail.

For engines with a volume of 1500 cm 3 it should be 2.8–3.2 atmospheres, and for power units with a volume of 1600 cm 3 – 3.6–4 atmospheres. If the device indicators are lower, the pump is unsuitable for further use.

Fuel pump drive

The VAZ 2107 mechanical fuel pump is driven by a pusher and an eccentric. Among drivers, it is customary to call the pusher a rod, although the rod is another part of the fuel pump. The eccentric is located on the intermediate shaft, which operates from the gas distribution mechanism.

The fuel pump drive includes (see figure):

- 1 - pusher;

- 2 — heat-insulating spacer;

- 4 — adjusting gasket;

- 5 - sealing gasket;

- roller (cam).

The pusher is driven by an eccentric located on the shaft of the auxiliary mechanisms

Device and principle of operation

The operation of the mechanical fuel pump drive is not based on the fact that:

- the oil pump shaft is driven through a timing chain;

- the cam (or eccentric) begins to press cyclically on the pusher;

- The pusher transmits force to the lever and the fuel pump begins to pump fuel.

Drive faults

Problems with the mechanical fuel pump drive lead to interruptions in the operation of the fuel supply system. Actuator malfunctions are most often associated with deformation or excessive wear of the pushrod or cam.

Fuel pump rod bends

The fuel pump pusher is often made of metal that is not strong enough. There are often cases when, after 2–3 thousand kilometers, such a pusher bends and flattens the constant impact of the cam. The length of the pusher should be 82.5 mm. If your fuel pump tappet does not meet this size and is flattened on the cam side, it will need to be replaced.

If the fuel pump pusher is flattened on the cam side, it needs to be replaced.

Performance check

Checking its performance will help make sure that the fuel pump has failed. For this you will need:

- screwdriver with Phillips bit;

- a piece of gas-resistant hose (50–80 cm) with a clamp;

- key to 17;

- empty 2 liter plastic bottle;

- a piece of insulated wire;

- stopwatch.

Performance testing is carried out as follows:

- We remove the back seat. We lift the carpet and find the gas tank hatch under it. Unscrew the two screws (diagonally).

- Once you remove the hatch, you will see the top of the fuel module. Using a 17 wrench, unscrew the nut of the outlet fitting. We put a hose on it and secure the connection with a clamp. We lower the other end of the hose into an empty bottle.

- Disconnect the pump power connector. Using a piece of wire, we supply power to the positive contact of the device from the corresponding battery terminal. We connect the negative one to ground.

- We begin counting the time from the moment the pump starts.

A working fuel injection pump for a VAZ 2110/2112 should pump 1.5 liters of fuel in one minute. If this indicator is lower, the pump must be replaced.

Gasoline pumps DAAZ vs Pekar

The other day I caught a vapor lock in the fuel pump. I was very surprised by this because I have a branded Pekar fuel pump in which there are no vapor locks. I decided to figure out what was going on. Having opened the fuel pump, I was somewhat shocked by its contents. which prompted me to write this article. So DAAZ vs Pekar.

First, some description of the pumps.

Left Pekar right DAAZ

Pekar - the words of the manufacturer. OPERATIONAL RELIABILITY — Oil- and gasoline-resistant membrane made from imported materials — Galvanic coating of parts protects gasoline pumps from the adverse effects of the environment REPAIRABILITY — For the first time in Russia, a modular design of gasoline pump units is used LEAK-TIGHT — Valve design that allows maintaining pressure and vacuum ensures quick engine starting ABSENCE OF VAPOR LOCK — Design fuel pumps, ensuring a minimum parasitic volume, eliminates the formation of vapor locks in the engine power supply system. PETROL PUMPS PROVIDE: - uninterrupted supply of fuel to the carburetor in various climatic conditions at temperatures from -40°C to +50°C

— performance of the car engine in accordance with technical specifications

Pressure at zero supply, at a camshaft speed of 2000 rpm, (kgf/cm2) 0.22 - 0.35 Vacuum created by the pump, at a camshaft speed of 2000 rpm, not less (kgf/cm2) 0 ,4 Capacity for free draining at a fuel temperature of 20°C, at a camshaft rotation speed of 2000 rpm, not less (l/hour) 60 Suction (time from the start of pumping to the start of fuel supply), at a camshaft rotation speed of 200 rpm /min, no more (sec) 10 Valve tightness (pressure drop over 10 min), no more (kgf/cm2) 0.05 Outer diameter of the diaphragm (mm) 70

Pump weight, no more (kg) 0.5

DAAZ - the manufacturer’s words here, I must say, the manufacturer turned out to be more modest.

A gasoline pump with a mechanical drive of a diaphragm type, size 70, is designed to supply gasoline to the carburetor in the vehicle’s power system.

The use of three diaphragms in the design, separated by a spacer, prevents gasoline from splashing out into the engine compartment if the integrity of one of the diaphragms is damaged.

Capacity for free drainage, l/h 60 If you look at both pumps externally, you will notice that the DAAZ gasoline pump has a much larger cavity for gasoline, this is Pekar’s main move. because The baker does not have a dome-shaped lid, and this is what the buyer is attracted to. Thinking that a vapor lock will form under this very lid. But no, the fact is that this cover is nothing more than an INLET sump. and even if there is somehow air there, it will not affect the operation of the pump in any way. Just as the air in the gas filter does not affect the operation of the pump. The DAAZ dome is essentially an additional gas filter.

Well, let's talk about everything in order.

Let's study the design of the Pekar fuel pump. So, the first thing we see in the Pekar fuel pump upon closer examination is that the outlet fitting is not flush with the pump, but is simply inserted into it. Of course, it fits tightly, but on the Internet you can find stories about how this fitting simply flew out of the pump. For example, here is a man’s story about how a fitting fell out of a baker and this led to a car fire

https://www.azlk-team.ru/forum/viewtopic.php?t=17726&highlight=%E1%EE%EB%F2%E0%E5%F2%F1%FF

Opening the pump Yes, the chamber is really small, but the trace left on the diaphragm washer from the exhaust valve immediately catches your eye, this can be seen in the photo. There is only one diaphragm in the baker

If the diaphragm ruptures, gasoline will flow through the pusher hole straight into the engine crankcase!!! Under the diaphragm there is a spring whose quality simply shocked me

that’s actually the whole design of the baker fuel pump

The fuel pump itself was purchased by me from the official dealer of TD Pekar and has a halographic sticker confirming its authenticity. Now let’s look at the design of the native Zhiguli DAAZ fuel pump. Both fittings on the DAAZ are tight, so you don’t have to be afraid that one fine day this fitting will come off.

Under the top cover of the pump there is a mesh filter with a sump that additionally filters gasoline at the inlet to the fuel pump. Once again, I want to note that the myth that steam locks form under the top cover of the DAAZ is complete nonsense. The top cover is an INPUT filter to the pump, so even if there is air in it, it cannot affect the operation of the pump.

filter

here we see the inlet valve at the top, the recess of the sump in the wall of which can be seen the hole of the inlet fitting

We disassemble the fuel pump in half and see that the working cavity of the pump, like that of a baker, is minimal. but the exhaust valve does not stick out and the diaphragm washer does not touch anything. The DAAZ diaphragm itself consists of three diaphragms and a plastic spacer.

disassembled diaphragm assembly

two operating diaphragms, a plastic spacer, a safety diaphragm and washers. Why is the knot made this way? for reliability. If the first working diaphragm breaks, the pump will work on the second one. Even if the second diaphragm breaks, the distance between the diaphragms = 0 and the probability that the second diaphragm will break in the same place as the first one also tends to zero. So even with two torn diaphragms, gasoline leaks will be minimal. The safety diaphragm prevents gasoline from entering the engine crankcase in the event of a breakdown of two working diaphragms. And in the plastic spacer between the working and safety diaphragms there are drain holes through which gasoline will drain towards the manual fuel pumping handle when the working diaphragms break through. (under this handle there is ground and draining gasoline is safe)

spring under the diaphragm

This is the entire design of the DAAZ pump. Now let's move on to tests and comparisons. Pump working chambers

the baker's working chamber is a little less than 10 cubes versus 12 for the Daaz (measurements were made using a syringe. But it is worth considering that the baker's spring is smaller and less rigid than that of the Daaz; hence we can conclude that the Daaz's chamber is a little larger because it has a larger stroke diaphragms, especially considering that the lower parts of the pumps are identical, and completely identical.

I could not measure the pressure created by the pumps due to the lack of a suitable pressure gauge. But the performance of the pumps was measured as follows. I used a 0.5 liter jar of white spirit. filled to the very neck. The pump was first pumped with water from another can to eliminate the difference in volumes. And then the pump, using a manual pumping lever, sucked water out of the can to the first lower line, while counting the number of presses on the lever that would be required to pump out this amount of water.

As a result, the baker needed 72 presses on the lever and the DAAZ needed 64, which again indicates the greater productivity of the DAAZ and the greater stroke of its diaphragm.

Both fuel pumps passed the test for purge (tightness) of valves without any complaints

Bottom line. Parameter Daaz Pekar fuel filter + — Diaphragm breakthrough protection system + — Displacement 12 10 Diaphragm stroke more less Pump capacity by 0.5 l 64 pumping 72 pumping Workmanship + —

Manufacturer's honesty + —

Regarding the honesty of the manufacturer, everything that was stated by DAAZ about its pump turned out to be true

Baker's statements - For the first time in Russia, a modular design of gasoline pump units is being used - not true

— The design of the valves, which allows maintaining pressure and vacuum, ensures quick engine starting. When I removed the fuel pump from the car, the inlet hose was completely dry. Before this, the car stood for about 14 hours.

NO VAPOR LOCK - The design of gasoline pumps, which ensures a minimum parasitic volume, eliminates the formation of vapor locks. Two days before writing this article, I caught a vapor lock on the baker 4 times.

— uninterrupted supply of fuel to the carburetor in various climatic conditions at temperatures from -40°С to +50°С; the temperature that day was no more than +30

As can be seen from all of the above, the Pekar is structurally worse than the DAAZ, and I absolutely do not understand why the Pekar costs twice as much, and even the manufacturer lies so blatantly.

You can discuss the article and ask questions on the forum https://www.semerka.info/forum/viewtopic.php?p=44845#44845

Mr.Ice for www.semerka.info