A modern car has an ECU that controls the main systems of the car, receiving information from various sensors. The article explains where the oil pressure sensor (OPS) and the oil level sensor are located on the VAZ 2109, their purpose, diagnostic features, and provides instructions for replacing these devices.

What you need to know about DDM?

If the indicator lights up indicating low oil pressure, this does not always mean that there is not enough lubrication in the system. It is possible that the DDM is faulty. In order to find the true cause, you need to know what the device is and how it can be checked.

Purpose and location

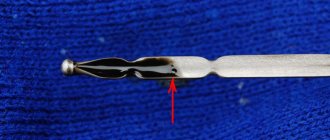

The DDM consists of a housing, a membrane and a transmitting device. The membrane becomes deformed when oil begins to press on it. Deformation of the membrane is reflected in the rheostat, whose resistance changes. The ECU records changes and reflects them thanks to an indicator on the instrument panel. The controller on the VAZ 2109 is located under the oil filter on the cylinder head on the side where the carburetor is located.

DDM location

Diagnostic features

Before diagnosing the DDM, you should check the oil level in the system using a special dipstick and an oil filter.

One of the simplest diagnostic methods is to check the presence of pressure in the lubrication system. To do this, you need to unscrew the DDM from the socket and manually turn the crankshaft several times. If grease flows or splashes out of the socket and the control light remains on, this means that the pressure is OK and the cause of the malfunction is in the controller.

The process of unscrewing the DDM from the socket

Next, you should visually inspect the device itself. If no mechanical damage is detected, it must be cleaned with gasoline and screwed into the old place. If after this the light does not go out, this indicates that the device is broken and must be replaced.

For the second method of checking, a pressure gauge is required. The controller is removed from the warm engine and screwed into the pressure gauge; the adapter from the pressure gauge is screwed into its place. The control LED is connected to the positive terminal of the battery and the controller contacts. Then the running engine should gradually pick up speed until the pressure gauge shows a value of 1.2-1.6 bar. If the controller is working properly, the LED will go out. Otherwise the device is faulty.

On a note

Don’t fall into a premature panic, draw too hasty conclusions, drive to a service station and pay money for faults that might not even exist! An emergency pressure lamp indicates a drop in lubricant pressure in the system, insufficient oil level in the engine, but it is not yet a fact that this is the reason. A fairly common malfunction is when the oil pressure sensor itself has failed and, accordingly, simply “lies.” If you don't notice this right away and don't understand the reason, you can really waste a lot of money or cause yourself more serious problems.

Important information about the oil level sensor

The health of the engine can be judged by various signs. One of them is the oil level. If oil consumption has increased, this means that there are some problems in the system that need to be corrected.

Purpose and location

The main purpose of the oil level regulator is to control the lubricant level so that the mechanisms and components of the engine function normally.

The VAZ 2109 oil level controller is located between the oil filter and the oil pan at the bottom of the engine. It is inserted into the hole intended for it in the power unit housing.

Diagnostic features

A sign of a malfunction of the device is the lighting of the indicator indicating insufficient oil level, despite the fact that in fact it meets the norm. You should regularly measure the oil level using a dipstick. If it is insufficient and the indicator does not light, this is also a sign of a sensor malfunction.

Diagnostics of the device is performed using a multimeter set to ohmmeter mode. One probe is connected to the controller body, the second to the output. By moving the float, we measure the resistance of the device. When the float is in the upper position, the resistance should tend to infinity, in the lower position it should drop to zero. If this is not the case, the sensor is faulty and must be replaced.

Replacement instructions

Replacing the regulator is easy and consists of the following steps:

- First, remove the negative terminal from the battery.

- Next, the plug with wires is disconnected.

- Then the fastening bolt is unscrewed with a “10” key and the controller is carefully removed from the crankcase.

- A new device is installed and the mounting bolt is screwed on.

- Then a block with wires is connected to it and the removed battery terminal is returned to its place.

Photo gallery “Replacing the lubricant level regulator”

Monitoring the health of the sensors ensures the correct operation of the vehicle, since based on their readings the ECU controls its systems.

How to replace the oil level sensor on a VAZ 2108-VAZ 21099?

Removal: 1) First, disconnect the battery by using a wrench to loosen the nut that secures the “-” terminal, and after loosening, remove the “-” terminal from the battery. (How to loosen the nut securing the “-” terminal and then remove this terminal from the battery, see on our website in the article: “Replacing the battery”, point “1”)

2) Next, go to the sensor that measures the oil level, and then disconnect the block with wires from it by hand.

3) After the block is disconnected, use a wrench and use it to completely remove the single bolt that secures the sensor.

4) And to complete the operation, carefully remove the sensor from the hole in the engine crankcase.

Installation: 1) First install the new sensor into the hole in the engine crankcase, and then tighten one single bolt that secures it.

2) Then connect the wire block to this sensor.

3) And at the end of the operation, install the “-” terminal on your battery, using the same article that describes “Replacing the battery”.

Replacement

So, the check showed that the oil pressure sensor is the culprit and it needs to be replaced. There is definitely no need to go to a car repair shop for this. The work is easy to do with your own hands, even for beginners in the field of self-repair of a car. Especially when it comes to repairing a car like the VAZ 2109.

Dismantling works

To replace the sensor, you first need to remove it and install a new one in place of the old device. Step by step it looks like this.

- Disconnect the negative terminal from the battery. All work related to the electrical component of the car must begin with this step.

- Disconnect the power cable with protective cover from the sensor by hand. They are connected together, so there is no point in trying to disconnect the cover separately.

- Using a wrench, you must completely unscrew the oil pressure sensor from its mounting socket.

- Finally remove the regulator from its seat.

- Arm yourself with a new sensor, insert it into the appropriate socket. An aluminum O-ring should be included with the new device. Check this at time of purchase. You should not use the sealant from the old DDM.

- Screw the sensor until it stops using a wrench. A mistake many people make is to simply screw in the device by hand. This contact may not be sufficient, causing the oil pressure regulator to provide incorrect information.

- Return the wire combined with the protective cover of the sensor wiring to its place.

- Connect the negative terminal back to the battery and check to see if the light on the instrument panel stops lighting.

Does the VAZ-2109 oil pressure sensor work?

To determine if it is correct, you need to check the engine oil level. To do this, you need to open the hood and pull out the dipstick. In order to check more accurately, you need to do this:

- drive into a pit and remove the protection;

- get close to the sensor;

- turn on the ignition;

- disconnect the power cord;

- Use a voltmeter to measure the voltage between the block and ground. It should show 12 volts.

If there is no voltage, then there may be a problem in the contact or a broken wire.

VAZ-2109 owners check the sensor in different ways:

First.

Remove the DDM located above the oil filter, turn the starter, the engine cannot be started during such a check. If all is well, oil should flow out. Then visually check the condition of the sensor. If there is no damage, then wash it with gasoline. They are installed in place. The light will go off. If it continues to burn, then it needs to be changed. Second. Check the oil level. If it’s low, add lubricant, then check again whether the light is on or not. Next, warm up the engine and then turn it off. Then connect to a pressure gauge. This adapter from the pressure gauge is screwed into place of the sensor and grounded through the ground of the car. Connect the signal LED to the battery positive and the sensor, start the engine and step on the gas. When the pressure gauge reads 1.2-1.6 bar, the LED goes out. If it lights up, then the DDM is broken.

The car owner must always monitor the condition of the DDM. After all, he also has problems. And these problems can affect the technical condition of the machine. You should not allow breakdowns, because if the engine jams, this will lead to large financial expenses.

Examination

The sensor has an elastic membrane that deforms when oil pressure is applied to it. The amount of membrane deflection is reported to the rheostat when the resistance changes. This change is recorded by the car's electronic system and reported to the pressure gauge. That, in turn, shows the corresponding data on the dashboard.

Brand new device

Today, VAZ 2109 owners use two main ways to check the functionality of the oil pressure sensor. Decide for yourself which one to use.

Verification method

Your actions

The second method is more detailed and allows you to find out not only whether everything is okay with the sensor. You need:

- Check oil level. If it is low, add the necessary amount of lubricant, and then check again to see if the lamp has turned off. If it doesn't burn, everything is fine;

- Warm up the engine to operating temperatures and then turn it off;

- Unscrew the sensor and connect it to the pressure gauge;

- Screw the adapter from the pressure gauge into place of the sensor;

- Ground the pressure gauge through the vehicle ground;

- Connect the control LED to the battery positive and the sensor contact. This is where the extra wiring comes in handy;

- Start the engine and step on the gas. The speed should increase smoothly;

- When values of about 1.2-1.6 bar appear on the pressure gauge, the LED should turn off. If this does not happen, the DDM is broken.

If after the second test method the LED goes out and the sensor turns out to be working, but the lamp on the dashboard still continues to light, the reason is different. She needs to be found. This is done like this:

- Gradually increase engine speed to reach 2000 units per minute;

- If the engine temperature is about 80 degrees and the pressure gauge shows less than 2 bar, the crankshaft bearing is worn out and requires replacement;

- If the pressure gauge shows more than 2 bar, the problem is not with the bearing. Let's move on;

- Increase the speed of the power unit. If the pressure gauge shows above 7 bar, the bypass valve has broken down. Its replacement is carried out together with the replacement of the oil pump cover.

Even if, after all the above operations, the light on the dashboard stubbornly refuses to go out, you will have to contact a car service center so that you can have a comprehensive diagnosis of the car’s condition.

Location