For proper and reliable operation of the VAZ 2110 engine, optimal fuel pressure must be maintained in it, and deviations in pressure seriously affect the operation of the entire engine.

Sometimes when a car starts poorly, jerks, or refuses to drive at all, one of the reasons for such malfunctions may be insufficient fuel pressure in the system.

In this article, we will look at ways to check the fuel pressure in the VAZ 2110 ramp, and we will also talk about the nominal pressure in the fuel system and much more.

Fuel pressure in the system

Fuel pressure is one of the important parameters in the car system; the reliability of starting and driving the car depends on it. The pressure is pumped up by a special fuel pump (gasoline pump), which pumps fuel into the rail, and a special fuel pressure regulator dumps excess fuel back into the tank, thereby regulating it.

Parts affecting fuel pressure:

- Fuel pump;

- RTD;

- Filter;

- Injectors;

These parts, if they fail, can reduce fuel pressure.

Stories from our readers

“Fucking basin. "

Hi all! My name is Mikhail, now I’ll tell you a story about how I managed to exchange my two-wheeler for a 2010 Camry. It all started with the fact that I began to be wildly irritated by the breakdowns of the two-wheeler, it seemed like nothing serious was broken, but damn it, there were so many little things that really started to irritate me. This is where the idea arose that it was time to change the car to a foreign car. The choice fell on the melting Camry of the tenth years.

Yes, I had matured morally, but financially I just couldn’t handle it. I’ll say right away that I am against loans and taking a car, especially not a new one, on credit is unreasonable. My salary is 24k a month, so collecting 600-700 thousand is almost impossible for me. I started looking for different ways to make money on the Internet. You can’t imagine how many scams there are, what I haven’t tried: sports betting, network marketing, and even the volcano casino, where I successfully lost about 10 thousand ((The only direction in which it seemed to me that I could make money was currency trading on the stock exchange, they call it Forex. But when I started delving into it, I realized that it was very difficult for me. I continued to dig further and came across binary options. The essence is the same as in Forex, but it’s much easier to understand. I started reading forums, studying trading strategies. I tried it on a demo account, then opened a real account. To be honest, I didn’t manage to start earning money right away, until I understood all the mechanics of options, I lost about 3,000 rubles, but as it turned out, it was a precious experience. Now I earn 5-7 thousand rubles a day. I managed to get the car buy after half a year, but in my opinion this is a good result, and it’s not about the car, my life has changed, I naturally quit my job, I have more free time for myself and my family. You’ll laugh, but I work directly on the phone)) If If you want to change your life like me, then here’s what I advise you to do right now: 1. Register on the site 2. Practice on a Demo account (it’s free). 3. As soon as you get something on the Demo account, top up your REAL ACCOUNT and go to REAL MONEY! I also advise you to download the application to your phone, it’s much more convenient to work from your phone. Download here.

I’ll make a small digression right away. The peculiarity of pressure gauges is that their initial scale values have relative inaccuracy. What does it mean ? If the air pressure gauge has a scale of up to 16-20 atm (when the measurement limit for fuel is 5-7 atm), then pressure measurements will not be accurate due to this error, which will fall within the initial values of the instrument scale. Therefore, it is correct to check the fuel pressure with a fuel pressure gauge with a limit of 6-7 atm.

Take a pressure gauge (in the photo a device for measuring tire pressure). We wind the foam (plumbing flax) under the pipe and put on an oxygen hose with an internal diameter of 9 mm. Secure with clamps. Place a rag on the generator (so as not to start a fire under the hood). Unscrew the plastic cap on the fuel rail.

Under the cap there is a hole with a nipple. Unscrew it from the wheel cap. Due to the residual pressure in the rail after removing the nipple, gasoline will splash out.

What is the pressure in the fuel system of the VAZ 2110

As you know, the VAZ 2110 was equipped with three types of engines: 8-valve carburetor, 8-valve injection, 16-valve injection. Each of these engines has its own pressure readings, except for the carburetor engine, its fuel is not supplied under pressure.

An 8- and 16-valve injection engine, with an aluminum receiver, that is, with a return line, has a fuel pressure of 2.8-3.2 bar.

A 16-valve engine (124) with a plastic receiver, has no return, the fuel pressure in it is 3.6-4.0 bar.

Pump replacement

Here you will need to initially buy a high-quality pump. It is recommended to buy one that was previously installed . You can also buy a part from BOSH.

You will need:

- The key is "17".

- Head at "10".

- Screwdriver.

- Pliers.

Before carrying out work to remove the pump, it is worth reducing the pressure in the system and disconnecting the battery. Next, you will need to remove all the pipes that fit the pump and unscrew the bolts securing it to the motor.

The work should be carried out carefully, as a certain amount of fuel may remain in the system.

Remove the gas tank flap under the rear seat.

Disconnect the block and fuel hoses.

Unscrew the pump mounting nuts.

After removing the pressure ring, pull out the fuel pump.

Assembly work is carried out in reverse order.

Checking fuel pressure

To check, you need to prepare a special tool, a pressure gauge for measuring air or liquid pressure; connect a hose with a diameter of 12 mm to the pressure gauge through a clamp.

It is advisable to cover the generator with a rag so that fuel does not get on it.

The process of measuring fuel pressure:

- We relieve the fuel pressure by removing the connector from the fuel pump in the system and starting the engine, letting it run until it stops.

- We unscrew the fuel rail cap near the timing belt drive.

- We unscrew the spool.

- We connect the pressure gauge to the fuel rail and tighten it with a clamp.

- Turn on the ignition to activate the fuel pump.

- We check the pressure on the pressure gauge and compare them with the nominal readings.

Troubleshooting

The main symptoms of a malfunction of the VAZ 2110 fuel pump are engine interruptions in various operating modes, lack of pressure in the fuel system, loss of acceleration dynamics, increased fuel consumption, or complete failure when trying to start the engine.

The first step is to check the functionality of the pump. When you turn on the ignition, you should hear a slight whirring sound from the pump under the rear seat for a few seconds.

If the engine is running, it is necessary to check the fuel supply pressure using a pressure gauge; the fuel supply pressure to the injector should be 3.5 - 4 atmospheres. If the sound of the fuel pump is not heard, if you have an electrical tester, you can check whether power is being supplied to the pump.

To do this, you need to remove the back seat of the VAZ 2110, the decorative cover, and the terminal from the fuel pump housing, turn on the key to crank the starter, if the tester does not receive power, you need to check the relay, fuse or wiring trace for a break! If there is power, the fuel pump needs to be replaced.

The serviceability of the relay can be checked by replacing it with a working one from the fuse box, for example the high beam headlight relay. When replacing a new relay, you need to pay attention to the manufacturer and the recommendations of a spare parts specialist in the store; it is better not to save on the cost of the relay.

Messages 16

1 Topic by denisby4kov.77 2015-06-22 23:57:56

- denisby4kov.77

- New member

- Inactive

- Registration: 2015-06-22

- Messages: 6 Thanks : 0

Topic: no pressure in the fuel rail (filter, pump and regulator replaced)

Hello. Such a problem - I was driving and began to tune the engine. I got to the garage and that was it. It starts, just under the throttle it stalls. I made a mistake on the fuel pump, I bought a pump motor and a filter. everything has been replaced. the problem has not gone away. I suspect a pressure regulator. purchased and replaced. the same. on the fuel rail there is a fitting for a pressure meter - so, I press the nipple on the fitting, three drops splash from there and that’s it. I suspect the injectors. who can tell me what?

2 Reply from 7491cm3x 2015-06-23 04:45:36

- 7491cm3x

- Connoisseur

- Inactive

- From: Norilsk

- Registration: 2015-01-29

- Messages: 467 Thanks : 119

- Car: VAZ 2112 1.5l 16v

Re: no pressure in the fuel rail (filter, pump and regulator replaced)

Connect the pressure gauge, turn the ignition key and measure the pressure. I don’t remember how much there should be, but Google will help. If below normal, look for a leak. If the injectors are pouring so much pressure that the pressure drops below normal, you will hardly start the engine, because the spark plugs will be flooded to the very top. Is there a smell of gasoline anywhere? Has the fuel filter been changed recently? Mesh in the tank?

3 Reply from denisby4kov.77 2015-06-23 07:59:06

- denisby4kov.77

- New member

- Inactive

- Registration: 2015-06-22

- Messages: 6 Thanks : 0

Re: no pressure in the fuel rail (filter, pump and regulator replaced)

The fuel pump, mesh and filter are new + pressure regulator. After turning off the ignition, the sound is like a Kamaz is leaking excess air. from under the hood

4 Reply from v258 2015-06-23 12:46:02

- v258

- Participant

- Inactive

- From: Krasnodar region

- Registration: 2015-05-14

- Messages: 171 Thanks : 37

- Car: VAZ 2111, 1.5 8V

Re: no pressure in the fuel rail (filter, pump and regulator replaced)

5 Reply from kuler_78 2015-06-23 13:01:06 (2015-06-23 13:07:35 edited by kuler_78)

- cooler_78

- Experienced

- Inactive

- Registration: 2014-10-22

- Messages: 142 Thanks : 57

Re: no pressure in the fuel rail (filter, pump and regulator replaced)

And this is not clear yet. It seems like there was no pneumatic compressor on the top ten. Is it possible that this is poisoning gasoline? Author, check the fuel line carefully. There can be no miracles. Maybe the line itself is clogged somewhere. I’ve seen this happen. The fuel rail was completely clogged. Yes and until you check the pressure in the rail, it’s not worth changing everything. Maybe the reason is elsewhere. You decided that it was the fuel pump based on indirect signs. And the fact that you press the nipple and three drops of gasoline flows out is not an indicator. I have the same situation. and the problem here is in the fuel pump valve, but it works fine even without it, only the pressure immediately drops and does not start the first time.

What devices are used

Converted tire pressure gauge

Several instruments can serve as devices for taking pressure readings.

- A special device purchased from an auto parts store. It comes complete with an adapter, drain hose and pressure gauge. Costs about 1.5 thousand rubles.

- Converted tire pressure gauge. The instrument scale and tube are subject to modification. As you know, the air pressure gauge shows a value of up to 20 atm, and the fuel measurement limit is around 5-7 atm. For this reason, reading errors may occur, and the device is modified to take this into account. Regarding the tube: you need to change it to a gas-resistant version.

Features of the fuel rail design

What is the importance of this element? As already mentioned, a fuel rail or rail is used in engines with distributor fuel injection, that is, in diesel engines and modern engines.

The part is a hollow metal tube with closed ends. Bends are attached to the ramp for connecting small tubes connected to the nozzles. Also, there is a hole on the rail for installing a pressure regulator.

Purpose of the fuel rail

Most often, the ramp is attached to the intake manifold of the power plant. Its direct purpose is to distribute fuel to the injectors. At the moment of fuel supply, high-power pressure is created inside, which can destroy the ramp structure. To prevent this from happening, the manufacturing material is a single piece of metal pipe.

Since the fuel mixture contains various additives, the injectors attached to the ends of the outlet pipes often become clogged.

Cleaning and dismantling injectors

To clean the injectors, they must be removed, this must be done carefully, as the connectors and nozzles can be damaged. When dismantling the ramp, you must make sure that no dirt from the injectors gets inside the tubes, otherwise the entire cleaning operation will have to be repeated. We recommend washing the injectors every 20 - 30 thousand mileage.

Determination of RTD performance

An RTD is a sensor that, if faulty, affects pressure readings in the entire system. To determine the performance of an RTD, 2 main methods are used.

- Close the nearby contacts on the diagnostic block near the gearshift lever if the pressure with the engine stopped is below 2.8 atm. A short circuit will allow the fuel pump to bypass the engine.

- Stop the fuel pump. Measure the pressure, which under normal conditions should drop to 0.7 atm and remain at this level, without varying. On the contrary, if the indicator instantly drops to 0, either the sensor is faulty or there is a problem in the pump return system. Fuel leaks, poor condition of injection elements, etc. are also possible.

How to determine the condition of the fuel pump?

In order to determine a fuel pump malfunction, you need to check the fuel pump “at the wall” (zero supply pressure or “at the plug”). In simple terms, this is the pressure that the fuel pump develops.

It is by this parameter that the service life of the fuel pump can be determined. As the pump wears out, this parameter gradually decreases. When the pressure is “into the wall”:

- about 3 atm - the car stalls

- 4 atm - the pump will still serve

- 5-7 atm – the state of the new pump (the Czech gas pump produces 7 atm)

Checking the fuel pump “for a plug” is quite simple; you need to pinch the return line with pliers (for 2-3 seconds) with the car running and watch the pressure gauge readings. Another way to check the fuel pump: smoothly raise the engine speed to 3000 rpm. If the pressure gradually drops, then this is a sign of a “dead” pump.

Separator design

The VAZ 2114 gasoline vapor separator is a small, completely sealed tank made of metal or impact-resistant plastic. It is installed in the right rear part of the car on a special bracket. Using a hose system, it is connected to the gas tank (from where vapors flow through drain pipes) and to a two-way valve. The total volume of this device is 7 liters.

Once in this tank, the vapors accumulate in it and, due to increased concentration and cooling, condense. Drops of condensation settle on the walls and bottom, after which they gradually flow back into the gas tank. The same vapors that did not have time to condense flow towards the two-way valve. From its name it is easy to guess that it works in both directions at once - “for the intake” of atmospheric air into the tank and “for the release” of fuel vapors outside.

Despite the obvious simplicity of the fuel ventilation system and the minimum of parts located in it, it still breaks down, leading to rather unpleasant consequences.

So, signs of a vapor separator failure may include:

- smell of fuel inside the cabin;

- the smell of fuel near the car (and a lot of time has passed since refueling);

- gasoline stains near the neck of the tank;

- drops of fuel on the ground after a long stay.

Injection pump pressure on a Mercedes

This is a high pressure pump installed on diesel cars and some gasoline cars.

This is how pressure is measured.

- Motor 4g93 starts.

- Take a multimeter, which is connected with one probe to the middle connector of the RTD chip. The second probe must be connected to the negative terminal of the battery.

- Indicators are taken.

The normal value should vary within 3 volts. If it is less, you need to raise the speed of the power plant and keep it within 2000 rpm. Adjust the pressure bolt in this mode by rotating clockwise. At the same time, you need to look at the device to stop rotation as soon as the pressure reaches the standard value of 3 volts.

If the pressure does not want to return to place, you can draw conclusions about a fuel leak or a malfunction of the fuel system elements, including the pump.

The process of removing the fuel rail (+photo)

General view of the fuel rail

Before proceeding directly to the dismantling process, you need to understand that you will have to remove the injectors, and therefore you can simultaneously diagnose and clean this unit. So, let's consider the sequence of actions that are aimed at removing the fuel rail:

- Remove the minus terminal from the battery.

- We are dismantling the receiver.

Unscrew the clamp and remove the crankcase ventilation hose

Unscrew the oil circulation pipes

Removed the oil dipstick

Having disconnected the connectors, we disconnect the ramp from the on-board network

After unscrewing the fastening screws, we dismantle the fuel pipe bracket

Unscrew the screws by 5 and remove the ramp

Unscrew the fastenings of the fuel supply regulator and remove it

Reasons for withdrawal

There are several reasons for removing the fuel rail from the car:

- Cleaning injectors.

- Replacement or repair of the ramp itself.

- Removing the valve cover.

- Carrying out diagnostic and repair operations that involve engine disassembly.

- Other operations where removal of the ramp is required.

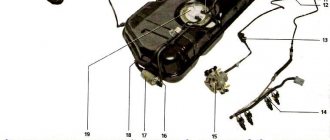

Fuel rail mounting diagram

Fuel pump drive

The VAZ 2107 mechanical fuel pump is driven by a pusher and an eccentric. Among drivers, it is customary to call the pusher a rod, although the rod is another part of the fuel pump. The eccentric is located on the intermediate shaft, which operates from the gas distribution mechanism.

The fuel pump drive includes (see figure):

- 1 - pusher;

- 2 — heat-insulating spacer;

- 4 — adjusting gasket;

- 5 - sealing gasket;

- roller (cam).

The pusher is driven by an eccentric located on the shaft of the auxiliary mechanisms

Device and principle of operation

The operation of the mechanical fuel pump drive is not based on the fact that:

- the oil pump shaft is driven through a timing chain;

- the cam (or eccentric) begins to press cyclically on the pusher;

- The pusher transmits force to the lever and the fuel pump begins to pump fuel.

Drive faults

Problems with the mechanical fuel pump drive lead to interruptions in the operation of the fuel supply system. Actuator malfunctions are most often associated with deformation or excessive wear of the pushrod or cam.

Fuel pump rod bends

The fuel pump pusher is often made of metal that is not strong enough. There are often cases when, after 2–3 thousand kilometers, such a pusher bends and flattens the constant impact of the cam. The length of the pusher should be 82.5 mm. If your fuel pump tappet does not meet this size and is flattened on the cam side, it will need to be replaced.

If the fuel pump pusher is flattened on the cam side, it needs to be replaced.

How to buy a quality device?

The price for a VAZ 2110 fuel pump in market conditions will be 2 times lower than in a specialized store. The equipment is in durable and sealed packaging. Inside the package is purified gasoline. If you smell gasoline, then the seal of the packaging is broken and there is a possibility of corrosion forming inside the gasoline pump. Submerged equipment is lubricated and cooled by fuel. When using low-quality additives and gasoline, internal electrical mechanisms are corroded. If additional substances are not used in the operation of the device (dry), then the brushes wear off and it overheats. The service life of the equipment is longer. Some car owners are planning to replace the VAZ 2110 Bosch fuel pump, the characteristics and pressure of which are not normal only due to long-term use. Its pressure can be 6-7 atmospheres. It was amazing to hear from an experienced driver his method for testing the fuel pump. To do this, he took a jar of water, turned it on on the battery, and by the flow of liquid he realized that the power of the gas pump had decreased.

Checking the electrical circuit

Unlike a carburetor engine, where the fuel pump is mechanically driven, on the injection VAZ 2110/2112 a special relay and fuse are responsible for the operation of this device. Therefore, before moving on to diagnosing the pump itself, it is necessary to check the indicated elements. If any one of them is faulty, the pump will not work at all.

Turn on the ignition without starting the engine and listen. When the fuel pump is running, it emits a characteristic “whistle” when started. If it is not there, it means that either the pump itself has failed, or one of the elements of its power supply circuit has failed.

The pump relay and fuse are located in an additional mounting block located inside the vehicle's center console. It can be accessed by removing the plastic trim (near the front passenger's left foot). It is secured with several screws. Under the cover you will find three relays and three fuses. Typically, the fuel pump circuit protection elements are located centrally.

The relay and fuse are located in an additional mounting block under the cladding

To check the fuse, remove it from its socket and “ring” it with a tester. If necessary, replace it, observing the rating (15 A). It is unlikely that it will be possible to check the relay for functionality without special equipment. But you can take another relay, for example, the radiator fan (far left), and install it in place of the one being diagnosed. Turn on the ignition and listen to see if the fuel pump starts working. If yes, buy and install a new relay. If the problem persists, continue diagnostics.

To check the fuel pump relay, you can install the radiator cooling fan relay in its place.

Spark Plug Inspection

If the spark plugs are wet, then gasoline flows. Dry? In this case, you need to check the signal at the harness connector of the mechanical liquid or gas atomizer (injector) with a probe (as shown in photo 6).

Did you do it, but the spark plugs are still dry? Then you will have to unscrew the screws securing the ramp and lift it under the intake manifold so that the injector nozzles can be seen. We turn on the ignition and turn the engine crankshaft with the starter. If there are no streams of fuel, you need to remove the injectors and most likely replace them with new ones. True, almost every serious service will recommend that you wash them.

If the price of a new set of injectors is slightly higher than flushing, then you should choose a replacement. Injectors also experience age-related problems. Also read: