List of parts: Bearing of the upper strut support - 350 rubles/piece 11180-2902840-01

Ball pin (with fasteners) – 400 rubles/piece 21230-2904192-86

Front suspension arm – 980 rubles/piece 2190-2904020 Stretching joint “Daisies” – included with the arm. Estimated cost 200 rubles/4 pieces. 2190-2904046

Anti-roll bar struts “Eggs” - 360 rubles 11180-290650-00 Stabilizer pad (I mistakenly call it a bushing in the video) - 35 rubles/piece. 2190-2906040-10 And the article number of the bushing, so that you also have an understanding of what it is) 2190-2906040-10

Brake pads NiBK - 673 rubles PN-0223

In total, everything came out to 4,430 + 200 rubles I paid at the service center for a used rack support. An iron bushing popped out of the rubber on mine.

For the service work given: Replacement of the bearing of the upper support of the strut - 3200 rubles Replacement of the ball pin - 400 rubles Replacement of brake pads - 600 rubles Wheel alignment - 1800 rubles Total 6000 rubles.

Lada Granta is one of the cheapest and most affordable cars on the Russian market. The vehicle is built on a common platform with Kalina and has similar technical characteristics. However, as for the suspension, the Lada Granta has been slightly modified. Read more in our article about how the chassis on the VAZ 2190 is designed and what its malfunctions are.

Removing the Grant strut

If, during the process of repairing a strut on a Lada Granta, you come across the fact that your car’s brakes have an anti-lock braking system, be sure to remove the sensor responsible for the frequency with which they rotate.

Then proceed to disconnect the tie rod. This procedure must be performed in conjunction with removing the tip of the strut swing arm. To ensure that during the work there is no significant violation of the angles at which the Lada wheels are installed, be sure to mark where exactly the highest bolt and the same washer are located. The entire procedure can be performed using an ordinary marker. This action will help you in the future to achieve the correct position of the bolt relative to the racks so that the Lada does not start to move to the side when moving.

The nuts securing the racks must be unscrewed carefully to prevent them from falling.

Unscrew the nut from the bolt that attaches the Lada Grant strut directly to the steering knuckle. Once you have completed this procedure, begin removing it in such a way as to grab the eccentric washer at the same time. Now unscrew the lower nut securing the strut. It is located in close proximity to the steering knuckle. Once you have the mount loosened, remove the bolt. Disconnect the steering knuckle from the strut.

Next, look under the hood. In front of your eyes there are three nuts, thanks to which the support is attached to the body

They must be unscrewed sequentially and carefully, holding the stand so that it does not fall under any circumstances. All work is done using a 13 key

After unscrewing the nuts, we take out the stand.

We take the spring ties and install them on the spring, always opposite each other. After this, turn the tie screws evenly until the spring begins to dangle. When it stops pressing on the support cups, using a 22mm wrench, unscrew the rod nuts. Once the nuts are unscrewed, you can disassemble the stand itself. We take out the strut support along with the bearing, remove the metal cup and damper. What remains is the spring and the boot with the bump stop.

At least walk

In the city of Zlatoust, about 60% of the territory is occupied by the private sector, and the roads there are dirt, consisting of crushed stone mixed with earth. Driving on such a road is not much fun. If you have ever driven on a washboard, you will understand what I mean. It would be nice to “shake up” on such a path once again, but the specifics of working in a taxi forces you to ride over such potholes many times a day. If you add to such a shake the unbearable rattling sound that the car makes, you just want to walk. How to deal with this? I can’t “win” the road, so we will “fight” with the source of the chatter.

Photo 1: Lada Granta before starting diagnostics

This is interesting: Knock in the front suspension of Lada Granta

Removing the shock strut assembly with the steering knuckle

We remove the front door trim of the Lada Granta with our own hands.

We carry out the work on a lift or inspection ditch.

Loosen the front wheel mounting bolts.

We remove the hub cap, unscrew the hub mounting nut with a 30mm socket and remove the washer.

Remove the front wheel.

We unscrew the nine screws and two bolts securing the engine mudguard and remove the middle engine mudguard.

Using pliers, undo the cotter pin and use a 19mm wrench to unscrew the nut 3 (Figure 2) securing the ball pin of the outer tie rod end 1.

We press the ball pin out of the swing arm 2 of the front suspension strut.

Using a 19mm socket, unscrew nut 3, Figure 3, securing the ball pin to the lower arm of the front suspension and press ball pin 2 out of lever 4 (article - Repair, removal of the ball joint).

Using a TORX E8 socket, unscrew the bolt securing the speed sensor (if the car has ABS) to the bracket on the steering knuckle and remove the sensor from the bracket.

We remove the sensor harness from the guide bracket on the front suspension strut.

Unscrew and remove the pad guide with the caliper and cylinder assembly.

We tie the bracket to the brake hose bracket (Figure 4).

We remove the outer CV joint from the wheel hub and fix it in a suspended state using a wire or a technological hook.

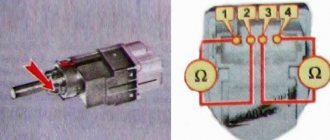

If after removing the shock strut you need to disassemble it, then use a 22mm spanner to loosen the tightening of the rod nut (Fig. 5), holding the rod from turning with a 6mm hexagon.

Using a 13 socket, unscrew the three nuts 2, Figure 5, securing the upper support of the telescopic strut 1 to the mudguard 3 of the body and remove the washers.

Remove the strut assembly with the steering knuckle and ball pin.

Remove the lower support from the upper support 1, Figure 6.

Installing the shock strut assembly with the steering knuckle

Install the speed sensor bracket onto the steering knuckle and secure it with a bolt. Bolt tightening torque 7 – 15 Nm.

We install the lower support on the upper support of the rack.

When installing the lower support, the direction of the arrow on it must coincide with the arrow on the upper support. On the left support to the right of the hole, on the right - to the left.

When installing the rack into the car body, the arrow on the support should be oriented in the direction of travel of the car.

We install the strut assembly with the steering knuckle, brake and ball pin into the car body, install the washers and tighten the three nuts securing the strut to the body mudguard. Nut tightening torque 20…24 Nm (2.0…2.4 kgf.m)

We insert the splined part of the outer drive joint into the wheel hub, put on the washer and tighten, without tightening, the new wheel hub nut.

We press the ball pin into the suspension arm and tighten the nut securing the ball pin. The tightening torque of the nut is 67…82 Nm (6.7…8.2 kgf.m).

We thread the front wheel speed sensor harness into the guide bracket of the front suspension strut, install the sensor in the sensor bracket and secure it with a bolt. The bolt tightening torque is 6…9 Nm (0.6…0.9 kgf.m).

Before installing the speed sensor, apply lubricant (LSTs-15 lubricant) to the surface of the mating hole.

We press the ball pin of the tie rod end into the swing arm of the front suspension strut and tighten the nut securing the ball pin. The tightening torque of the nut is 28…34 Nm (2.8…3.4 kgf.m).

We tighten the nut. If the cutout of the nut does not coincide with the hole in the ball pin, retighten the nut to an angle of no more than 60˚ to ensure cotter pinning.

Install the wheel and tighten it without tightening the front wheel mounting bolts.

We lower the car, tighten and lock the front wheel hub fastening nut, deforming the locking belt of the nut into the grooves of the shank of the outer drive joint housing. We install wheel caps. The tightening torque of the nut is 230 - 250 Nm (23 - 25 kgf.m).

Tighten the front wheel mounting bolts. The tightening torque of the bolts is 76 – 92 Nm. Install the engine splash guard.

Granta 38 4 new size

We make sure there is no play (knock). If there is a knock on the front wheel, ask an assistant to press the brake pedal. If the knocking noise disappears, it means the wheel bearing is faulty, and if the knocking noise remains, then the ball joint is most likely worn out.

The hub bearings of the front and rear wheels are not adjustable and must be replaced if there is play.

To check the serviceability of the ball joint, insert a mounting blade between the suspension arm and the ball joint housing. Be careful not to damage the ball joint boot.

Preparatory procedures

Repair of the front suspension (arms, balls, hubs) of VAZ 2114

Many car owners are interested in which racks are best to install, as well as how to do everything correctly. Before you repair the front struts, you will need:

- We stop the LADA Granta car using the handbrake and place wheel chocks under the stern wheels.

- Under the hood we find a shock-absorbing support rod, into the hexagonal recess of which, located at the end, we insert a key of the corresponding profile.

- Using the second wrench, we loosen the tightening torque of the nut securing the suspension element to the body. In the meantime, we use a hex wrench to keep the rod from trying to turn in conjunction with the nut.

- We “dive” into the wheel arch of the LADA Granta and find a bracket that holds the brake hose on the strut body.

- We unscrew the specified fastening unit, removing the hose itself from the holding bracket. This will provide space for unscrewing the lower point of the shock absorber strut. You will have to work in tandem with a key “17” size.

You should dare to replace the struts in cases where a leak of working fluid from the shock absorber is detected, as well as if there is a knock, deformation of the rod or destruction of the silent block.

You should remember the rule that implies replacing the struts as a whole on one axis, even if the second shock-absorbing element is in good condition.

Checking status

Video: Replacing VAZ silent blocks. Do it yourself!

The main sign that a rubber element is worn out and requires replacement is a decrease in vehicle controllability, the appearance of vibration on the steering wheel, and the sound of impacts while driving over potholes and uneven surfaces.

You can visually determine the degree of wear of the hinge by driving the car onto an inspection hole or overpass. If upon inspection it is noticed that there are any cracks on the visible rubber part of the hinge, then it requires replacement.

Additionally, a regular mount will help check the condition. With its help, it is necessary to forcefully rock the components of the suspension where the hinges are installed. If, for example, the lever has a significant oscillatory amplitude under such influence, or knocking noises are heard, then the hinges should be replaced. Note that they are changed in pairs, even if the elements are worn out on only one half of the suspension.

Lada Vesta

How to tighten the handbrake on a Lada Granta with your own hands

A steel protective screen 0.8 mm thick with zinc coating is installed at the bottom. As in the case of Granta, it has technological holes for draining oil and monitoring the tightness of the box. It is attached at 12 points along the perimeter.

The Vesta suspension is technically more advanced with modern solutions at a fundamentally different level compared to the Granta. A huge advantage of the Vesta suspension is the subframe.

It is composite, the spars come separately. A subframe is a cool thing because it gives the car a number of beneficial advantages. For example, it contributes to the structural rigidity of the entire vehicle, allows it to more evenly distribute the load from the suspension onto the supporting body and prevent local overloads of the power elements. This also simplifies the process of installing the front suspension and steering. The subframe also guarantees the accuracy of the location of the suspension elements.

Advantages of a subframe

Firstly, due to the subframe, or rather the steering rack mounted on it, in the Lada Vesta we get informative and clear “steering”.

Secondly, at Vesta’s wheel alignment post, only one parameter will be adjusted – wheel alignment. The camber is determined by the geometry of the subframe and levers.

Thirdly, when driving on an uneven road in Vesta, shocks will not be transmitted to the steering wheel. The Granta will have this because the steering rack is mounted on the front panel. Accordingly, the impacts go to the body, through direct communication they are transmitted to the rack and directly to the steering wheel. In general, I think that the subframe has a lot of advantages.

Front suspension

L-shaped levers are used, the design of which replaces the longitudinal brace and wishbone of the Granta.

The lever comes complete with a ball, but if desired, it can be replaced separately. This is somewhat more difficult, since it is secured with rivets. But it will be much cheaper. The ball joint costs about 1,000 rubles, and the lever assembly costs more than 3,000.

In front of the lever there is a rigid silent block, which provides the lateral rigidity necessary for precise response to steering inputs. At the rear there is a rubber-metal joint, which allows the wheel to move slightly backward, which has a beneficial effect on the smoothness of the ride.

For Lada Vesta cars of the first years of production, there were several characteristic defects regarding the suspension. The first and most basic thing that 99% of owners of these cars have encountered is the creaking of stabilizer bushings. The point was that with large suspension strokes, the stabilizer bar began to rotate in the bushings, and a creaking sound appeared. There were many complaints; AvtoVAZ sent dealers several methods for correcting the suspension.

At first it was recommended to put a special grease into the stabilizer bushings. Then polyurethane bushings appeared, they were also installed on foreign cars. But even if all this had a positive effect, it was for a short time. As a result, this problem was completely overcome by installing a new stabilizer with vulcanized bushings that were non-removable.

After this the problem completely disappeared. The second problem associated with the suspension of these cars in the early years of production is the stabilizer struts, or rather their hinges. They began to play already at short runs. The play produced creaking and knocking noises when driving over uneven surfaces. This problem was solved quickly, and in recent years the stabilizer links have been running for a long time without causing any problems.

There were also some problems with the front struts for some time. When driving on uneven roads, they made a characteristic knock and were loud. This problem was especially pronounced on Vesta SV Cross cars. Some installed racks from another manufacturer, or simply put up with the malfunction.

But AvtoVAZ has carried out corrective measures, and on cars of recent years of production there are no problems with struts. They serve more than 100 thousand km.

Rear suspension

The Lada Vesta, like the Grant, has a semi-independent rear suspension. The arms are also connected by a cross beam, but there are some design differences. For example, the springs are installed separately from the shock absorbers. This provides more comfort, as shocks from the road are evenly distributed throughout the body. In addition, this design is easier to maintain.

Double-acting shock absorbers provide good ride comfort. Structurally, the rear suspension of Vesta is also simple, there are no problem areas. All units last for more than 100 thousand km.

FakeHeader

Comments 10

In my case, the knocking from behind on a rough road was due to a fallen trunk ventilation valve, which was stuck between the bumper and the body.

1) My silencer was knocking in the last suspension rubber band, which was cured by replacement. 2) The knock was due to a weakened clamp for the handbrake cable in the rear beam - it was cured, I bent it and put an elastic band on it. 3) Trunk lock - adjusted, put an elastic band under the loop and unscrewed the rubber bumpers more. 4) there is something else rattling slightly, I think the pads are in the drums. I still don’t know where to dig myself.

For me it turned out that I just tapped the trunk lid lock on the hinge in the closed position, rewound the bracket with electrical tape and unscrewed the stop rubber bands on the lid more.

For me it turned out that I just tapped the trunk lid lock on the hinge in the closed position, rewound the bracket with electrical tape and unscrewed the stop rubber bands on the lid more.

Exactly. Now I was driving, turned onto the gravel road and opened the trunk with the button. The knock is gone. Now I will eliminate it. Thanks to all.

It was the same bullshit. I unscrewed the rubber bands a little, lubricated the lock and that was it.

Maybe the handbrake cable will hold it together. I haven’t tried bending the eyes

I defeated the creaking of the handbrake cable a long time ago. There's just a dull knock. It's as if something in the trunk is moving and knocking. On the previous Mazda it was similar, when the upper mount of the strut became loose. But everything is fine here. I'm starting to complain about the ventilation valve under the bumper. I read that it often flies out and rattles. It's just hard to get to it. Maybe someone else can tell me something. If not, you'll have to remove the bumper...

Rear independent suspension – Kalina, Granta, Kalina 2

1. Management

- Stable contact with different road surfaces and clear control of the vehicle during maneuvers and turns, even without changing the characteristics of the shock absorbers.

- High information content when driving a car at high speeds.

- High directional stability.

- Changing the kinematics of the rear suspension.

- Reduced longitudinal roll during acceleration.

- Reducing the rate of roll development.

- Reducing the car's reaction time to turning the steering wheel.

- The suspension characteristics are adjusted to the zone of slight understeer, which improves the predictability of the car's behavior when maneuvering.

2. Comfort

- Independent right and left suspension parts increase comfort when operating on poorly paved roads.

- Reducing the unsprung mass of the rear suspension.

- Improved comfort due to more silent blocks.

- By increasing the rigidity of the rear of the car, deformations of the body floor when driving over uneven surfaces are reduced.

3. Reliability

- Factory production. Patented solution for LADA cars.

- Computer modeling was used in the development and testing of suspension components.

- Life tests were carried out on different types of surfaces (the suspension easily withstood rally special stages and did not require adjustments after that).

- The design uses high-quality silent blocks from LEMFÖRDER.

4. Body rigidity

Increases the torsional resistance of the rear part of the body due to the ZNP beam.

5. Advanced settings

- Possibility of adjusting wheel angles in a wide range (alignment/camber).

- Possibility of individual adjustment when raising/lowering the suspension.

- Possibility of customizing individual suspension parameters to suit the necessary conditions in amateur sports.

Warranty: 12 months.

Installed on serial cars, with an overestimation of +15 mm, with an understatement of up to -50mm (the size from the center of the hub to the edge of the car arch must correspond to the following range: from 305 mm to -370 mm).

Installed only in conjunction with a direct-flow muffler.

Attention! For vehicles without ABS, you must purchase an additional pressure regulator bracket. For installation you will need: - Black nylon clamp 5x350 mm - 2 pcs.

For installation you will need: - Black nylon clamp 5x350 mm - 2 pcs.

We recommend using it with disc brakes (with a set of ZNP spacers for the ZDT) and “STT”.

The following is usually installed with the suspension: - Subframe.

Silent blocks

By 100 thousand, the silent blocks of the cross member and lower arms fail. Signs of a malfunction are a dull knock from the front suspension of the Lada Granta. Motorists recommend replacing these elements with polyurethane ones.

They are characterized by higher strength and good service life. At the factory, rubber silent blocks are installed that do not withstand the impacts of our roads. To replace, we need to press out the old element. First, the bead is cut off from it, and then knocked out using a mandrel or chisel. Pressing is done using a vice. It is important to maintain alignment and not mix up the installation side. For easier pressing, it is recommended to use lubricant.

The silent blocks of the anti-roll bar also fail. These bushings are also replaced with polyurethane ones.

Lada Granta Liftback Orange › Logbook › Suspension 21928 (Part 4)

Hi all. Finally we come to the final stage of replacing the suspension. Left just a little bit.

In the previous part, the front struts and steering tips were replaced. Now all that remains is to change: levers, balls, front arm extensions, extension brackets (Crabs) and install anti-roll bar 21928 (24mm). All this will be discussed here. Well, let’s sum it up at the end.

To replace levers and everything else, it would be more convenient to hang both sides of the car at once

First of all, I unscrewed the stabilizer from the levers. To do this you need to take 2 keys for 17

Next, we proceed to removing the levers assembled with a brace, a ball joint and a crab. For removal, we will need the following tools: 2 19mm wrenches (It is better to take a long wrench and a head), a 13mm wrench for unscrewing the crabs from the body, and a Torx E12 socket for unscrewing ball joint from the steering knuckle (had to buy it in a store).

The lever is attached to the body with 1 bolt and nut, 19 keys. To unscrew the nut, I had to use an extension on the knob, since everything was tightened very tightly.

The ball joint came off quite easily, and the extension brackets (Crabs) too.

Let's look at the condition

But the condition of the ball joints after 115 thousand km leaves much to be desired

Now that everything has been removed, you can prepare new parts for assembly and installation.

It is very convenient to put everything assembled. And the design is so simple that sometimes you are even surprised at the Granta’s maintainability.

Now a few words about the anti-roll bar

After assembling the suspension, we immediately go to the wheel alignment

The numbers turned out to be as follows

Now about the sensations:

As soon as I assembled everything, the first thing that was noticed was that there was no significant sagging of the car body when entering the cabin. Previously, if I sat in the driver’s seat, the left side would noticeably drop down (even though I’m not heavy). Now everything is tough, and there is no such thing.

Then I went out and first of all checked the suspension on a dirt road with holes. Fortunately, in our dacha there are a dime a dozen of such roads. I immediately noticed that small pits and nervousness in the suspension began to go through a little softer. The installation of new rubber elements has a greater impact here. Still, the new silent blocks provide some softness.

Now asphalt. At low pit speeds, the suspension moves elastically, but at the same time, if you accelerate a little, it becomes a bit harsh. Especially if you fall into a hole of medium depth at a speed of 40 km/h. Driving quickly on a bad road on this suspension is very uncomfortable. Yes, and on oil, original racks, too, by the way. Yes, it’s a little softer there, but still there. This is already a design feature of this car, which, in my opinion, must be accepted.

But the advantages of the 928 suspension showed themselves in completely different ways:

1) I noticed almost no squealing noise when braking. The car stops hard, while the muzzle does not go much down, but seems to move forward and come back. This is already a plus.

2) There is less roll in corners! You can really feel it. For comparison, before I took the same turn on an oil suspension at a speed of 30 km/h and the car fell on its side. Now, at the same speed, the car is screwed into it without strong rolls. Moreover, it behaves more stable.

3) At high speed, over 100 km/h, on a highway with patches, the car throws less. It feels like the car clings to the road surface more confidently. He is less tossed from side to side. This is because the suspension is stiffer and feels more collected. But at the same time, every joint, and especially the height differences, became very noticeable. The profile of the road in particular. The car even wobbles on small bumps. But this is a price to pay for increased rigidity.

4) When overtaking, at a speed of 120 km/h, lane changes are more confident. Also, returning to your lane occurs more clearly, without unnecessary steering.

5) Sharp lane changes at a speed of 30-40 km/h, or avoiding a sudden obstacle also feel different. If you turn the steering wheel sharply to the side, the body follows the steering wheel clearly, without unnecessary swinging. I like it. Of course, you shouldn’t think that the car immediately turned into a sports car, but if you compare it with stock oil, there is a difference.

Pendant 21928 can be described as:

But here you need to understand that I am comparing the new one with the old one, which ran 115 thousand km. But in any case, there is a difference, and it is noticeable.

As a result, I came to the conclusion that of the factory suspension options for the Grant, only suspension 21928 will provide more confident behavior of the car. This is a good choice for those who want to maintain the factory ground clearance, while improving driving characteristics. Well, if that’s not enough, you can go further...

To take or not to take?

As you can see, purely structurally, the Granta is an excellent car. Durable, simple, as cheap as possible. The disadvantages have already been mentioned above: poor quality of parts, assembly flaws and poor service culture. In 2022, the chances of finding a well-maintained Grant are very high, and maintaining it in decent condition for many years is not at all burdensome. Of the configurations, oddly enough, all other things being equal, cars with automatic transmissions are more reliable, especially those with hydromechanics. The unit may be more complex, but it is significantly stronger than the VAZ mechanics, designed for the 70-horsepower engines of the old Samaras. So, if the spartan situation and the prospect of solving many cheap but annoying problems don’t bother you, a used Grant is an excellent option for an anti-crisis car.

Source

Downloading a book

After successfully completing the payment (by any method) and returning to the KrutilVertel store from the payment system website, you will be taken to the successful payment page:

The book you purchased will be in your personal account, from where you can always download it.

Please note that after making the payment, you need to return back from the payment system website to the KrutilVertel website. If for some reason you did not return back to the site and closed the payment system tab with a message about the successful completion of the payment, please let us know - we will send you a letter indicating access to download the book

If for some reason you did not return back to the site and closed the payment system tab with a message about the successful completion of the payment, please let us know - we will send you a letter indicating access to download the book.

Article number and cost of analogues of original ball joints

The lack of stable quality of original ball joints forces car owners to search for good analogues from third-party manufacturers. At the moment, the market is filled with a lot of alternative spare parts options. The price for non-original supports is comparable to the original. The best brands of balls are presented in the table below.

| Manufacturer | vendor code | Approximate cost, ruble |

| BelMag | BM.0033 | 370-400 |

| Hofer | HF815503 | 300-350 |

| Pilenga | TS-P 3142 | 380-420 |

| Stellox | 52-00840A-SX | 400-430 |

Purpose of the front strut support bearing

Let's take a specific technique - the VAZ-2110 car. This model has independent front suspension with hydraulic struts.

The main purpose of the strut is to dampen vibrations that occur when the spring moves.

How does this happen? For example, a wheel of your car falls into a hole. This, in turn, causes one side of the vehicle to sway. In the absence of a stand, such vibrations could continue for a long time.

Fastening is of particular importance. In the upper part the rack is fixed directly to the body, and in the lower part - to the rotary cam.

To ensure a movable connection between the body and the shock absorber, a special transition element is provided - a support bearing.

The name “support” reveals the essence of this unit and its location - at the junction with the car body.

Structurally, the device must withstand maximum radial and axial loads.

Overview of the main shock absorber manufacturers

By default, hydraulic ones from SAAZ (Skopovsky Automobile Plant) are installed from the factory. They are not particularly distinguished by their quality, but with moderate use they can last up to 60,000 km.

- Kayaba : Japanese, characterized by high quality, reliability, and long service life. When purchasing, be careful, as some of the products are made in China.

- ASOMI: domestic manufacturer for GAZ, VAZ, LADA models. One year warranty from the date of installation. Judge the quality for yourself.

- SS (SS): also a domestic manufacturer of racks for VAZs. Quality guarantee for two years, according to the owners' reviews, they are not bad, a little harsh.

In general, all shock absorbers are divided into three categories:

- Highway;

- Standard;

- Sport.

Modernization of suspension systems

1. For front suspension:

2. For the rear suspension, the springs were strengthened and gas-filled shock absorbers were installed. It is worth noting that factory tuning of the suspension is combined with improved sound insulation of the car. With this modification, the car feels quite comfortable on the road up to 150 km/h, while coping well with cornering on almost any road surface.

A detailed analysis of the reliability of the suspension for the Lada Granta liftback is quite difficult to carry out. This is due to the short life of the car. Life tests of the machine are still ahead. However, based on reviews from owners and the results of warranty and service maintenance of these cars, we can characterize the main faults:

- loosening the anti-roll bar fixing bolts;

- failure of hydraulic shock absorbers (after 60-80 thousand km), leakage of shock absorbers;

- wear (increased clearance) of the front wheel bearings, which causes accelerated wear of the silent blocks of the levers;

- loss of spring stiffness (especially for springs with a smaller diameter);

- wear of the ball joints of the front suspension.

- the appearance of squeaks in the place where the shock absorber strut is attached;

- shock absorber failure;

- violation of wheel alignment angles, including due to violation of the adjustment of the clearance of the hub bearings or their destruction;

- Damage to the shock absorber protective covers.

This approach can easily be justified by the increased costs of deferred repairs. Worn bearings will place increased load on ball joints, rubber bushings of levers, and cause disruption of the alignment angles of the front wheels. Over time, the tires will begin to wear out faster. A sagging spring will not only lead to possible damage to the bumper on the first high curb. The shock absorber will wear out faster, and the car will lose comfort at high speeds.

Removing the rear suspension shock absorber strut on a Lada Granta car is done to replace a sagging or burst spring, as well as to replace the shock absorber itself or repair it if it is dismountable and you have the appropriate repair kit.

Prepare a standard set of tools and perform the following sequence of actions:

Inside the car, fold down the back of the rear seat and use a flat screwdriver to pry off the rubber plug of the shock absorber strut cup.

We remove the rubber plug, then use a socket and a regular open-end wrench to unscrew the nut of the upper fastening of the shock absorber rod to the car body.

- We install stops under the front wheels and hang the rear part of the body, remove the wheel from the side being repaired.

- Unscrew the nut of the bolt securing the lower shock absorber to the rear beam bracket.

- We remove the lower end of the rack from the bracket and remove it along with the spring.

Remove the spring from the shock absorber along with its rubber spacer. Next, remove the bushing and lower cushion along with the boot from the rod. All rubber elements must be replaced if the rubber has lost its elasticity, is severely cracked, or has other defects. Don't forget to remove the rubber compression buffer from the boot.

Having completed the necessary repairs or replacement of worn elements, we proceed to install the rack. The installation sequence is carried out in the reverse order of removal

First of all, using insulating tape, fix the rubber spacer on the upper end of the spring.

We put the spring on the strut so that its end fits neatly into the corresponding groove of the shock absorber support cup.

When installing, make sure that the lower end of the spring faces the wheel. At this point, the repair work on removing and installing the rear suspension shock absorber strut on the VAZ 2190 has been completed

At this point, the repair work on removing and installing the rear suspension shock absorber strut on the VAZ 2190 has been completed.

Sources

- https://vashalada.ru/mashiny/lada-granta/podveska-lada-granta.html

- https://1ladagranta.ru/harakteristiki/podveska-osobennosti.html

- https://remladavaz.ru/snyatie-i-ustanovka-stojki-amortizatora-zadnej-podveski-lada-granta

Chevrolet Niva ball joints - what are the differences from a regular Niva?

A logical continuation of the topic would be to search for an answer to the question: “Which ball joints are better for the Niva Chevrolet (2123)?!” Chevrolet Niva supports are another matter. The usual part from the Niva differs from them in the different distance from the rod to the mounting bolts on the support body.

Replacing the top with the bottom support and vice versa will not work. Just as it won’t work to install the part from a regular Niva. The wheel will not stand straight, and when the steering wheel is in the extreme position, it will cling to the A-pillar. In this case, tire wear will be uneven, and operating the car will not bring proper driving pleasure.

Troubleshooting in the rack

Basically, the strut can make a knock and transmit impacts from uneven roads only when the entire structure is severely worn. Moreover, this element of the car suffers the most when the front pair of wheels falls into a deep hole - the rebound strut does not work, but the spring undergoes a sharp straightening. As a result, the wheel will go sharply down, stretching the spring to the maximum possible length. Thus, it turns out to be 2 hits - the racks against the support and the racks with the bottom of the pit.

Checking the functionality of the support pillar is carried out in a standard way - the vehicle is swung vertically or a partner presses forcefully on the central part of the hood. If the rack is in good condition, the body of the machine should return to its original state once without sharp straightening.

If the case falls sharply, you will hear a dull thud. This indicates a malfunction of the element due to a loose lock nut, which makes noise inside the support post itself. Repair of the rack should only be carried out at a car service center, since special equipment will be used to secure all elements in a high-quality manner.

If a knock occurs on small bumps due to the strut, the car sways strongly when moving and loses control. This may result in an accident on uneven roads.

Also, problems may lie not in the strut itself, but in the shock absorbers. A malfunction of the shock absorber system is primarily due to improper treatment with oil. Drivers often pour an oil solution with incorrect viscosity characteristics inside. This value is affected not only by the purchased oil, but also by the ambient temperature at which the solution is poured. Too low a temperature does not allow the oil fluidity to increase to the required value.

Reviews

| № | Positive |

| 1. | Mikhail, 36 years old : I’ve been using the car for two years now, no comments. The chassis and suspension work properly, everything is original, nothing has been changed. I've heard some negative things about the racks, but I don't agree. |

| 2. | Kirill, 33 years old : recently carried out maintenance, the master recommended replacing the rear struts. I didn’t invent anything, I bought my native SAAZ. |

| 3. | Vasily, 41 years old : the car is old, since 2011, I repair it myself. The other day I replaced the suspension - all four shock absorbers and springs. Since the old ones lasted a long time, I bought similar ones from SAAZ. |

| 4. | Gennady, 32 years old : I’m leaving my positive review on the original racks for Grant. Those who spoke negatively may have gotten into trouble, but everything is fine with me. My advice. |

| Negative | |

| 1. | Martin, 39 years old : after the first 50,000 km. The original shock absorbers fell off. I didn’t make a mistake the second time, I bought a HOLA SH22-270G. I ride, enjoy, no problems. |

| 2. | Victor, 34 years old : I don’t trust standard shock absorbers, I replaced them immediately after buying the car. I heard negative things and decided not to try it. Installed Trialli AH01510. |

| 3. | Vitaly, 29 years old : I work as a taxi driver, driving a car day and night. Two months ago I replaced the racks with the same original ones. Already dissatisfied, they began to rattle, no quality. I will change to Pilenga. |

| 4. | Konstantin, 27 years old : on the advice of a friend, I replaced my original shock absorbers with BOSCH ones. I didn’t try my luck; I heard a lot of negative things. |

What to do about the knocking?

If you do not pay attention to the problem and do not change the silent blocks on the grant, the knocking will become increasingly stronger. Therefore, it’s time to drive the car into the pit, remove the engine protection, and look at all the details. You can swing the car from the desired side, whether you hear a knock or not, but it will happen if the silent block on the grant has become completely unusable. If the problem is in the stretcher, then you need to pull it too, the resulting knock will be proof that the cause of the breakdown has been found.

You can replace the silent blocks with grants, the price of which seems reasonable, right in the pit, without the need to remove the levers.

Tools required:

1. 2 keys for 24. 2. Extension tubes. 3. Head 17. 4. Thin screwdriver. 5. Punch, it is better to give preference to the canonical one. 6. A hammer, it will hardly be possible to do without it in work when the silent blocks of the grant need to be replaced.

Top brands

For domestic equipment

Number one among manufacturers of ball joints for Russian cars is the Kedr company, which focuses on the production of solid forged parts. The declared service life reaches 75 thousand kilometers, depending on the specific model. Customer reviews show that such figures are quite justified. Only a few motorists claim that they changed the Kedr ball joints after 30–45 thousand kilometers. There are also reviews about a service life approaching 100 thousand kilometers.

If you need to find out which ball joints are better for a Chevrolet Niva

For fans of extreme driving, ball joints from the Trek production association are offered. The “Champion” model is made from the most durable materials and has a unique design that prevents damage to the part under the highest impact loads. Thanks to this, the manufacturer specifies a service life of the support of 60 thousand kilometers, regardless of operating conditions. Consumers claim that the high price of such components is completely justified - they really do not create any problems during operation. However, the problem with counterfeits is also relevant for ball joints from this manufacturer.