WHAT GASOLINE TO POUR IN THE VAZ-2114?

This topic has become overgrown with various conjectures and speculations, but we will try to put everything in its place.

The technical data sheet of the fourteenth indicates that the car engine requires AI-95 gasoline, and there is no reason not to trust the manufacturer’s recommendations.

Another thing is that many car owners, over their long driving experience, have accumulated rational doubts about the existence of any serious differences between 95 and 92 gasoline. Adding fuel to the fire was the recent statement by the chief engineer of the Moscow oil refinery, A. A. Abrosimov, that we do not make 95-grade gasoline in our country, and everything that is sold under its guise is either 92-grade or unknown fuel brought from somewhere.

As evidenced by reviews from VAZ 2114 owners who use exclusively 92-octane gasoline, there were no problems with the car during its service life due to fuel, and they see no point in using a more expensive analogue. However, the final decision about what to pour into the fourteenth is yours.

Why is this device needed?

The regulator, responsible for maintaining normal fuel pressure in the system, is in direct interaction with the power unit. According to its location, it can be located in the fuel tank or in the rail (this is where you will be able to find the regulator if you have an injection VAZ-2115). The reason for the failure of this element is often the low quality of gasoline. If you fill up at gas stations with greatly reduced prices, then it is not surprising that very soon the regulator will fail.

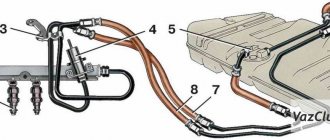

The fuel flows through the injectors to the intake manifold, and it is important that its pressure does not change at this moment. The regulator measures the volume of fuel required for engine operation, and also monitors the pressure in the fuel rail and intake manifold.

The main task of the RTD is to maintain the pressure difference at the same level, as well as monitor the indicators.

How to properly check RTD

In order to independently check the pressure in the system, and therefore the correct operation of the regulator, you need to take a pressure gauge, the maximum pressure in which is up to 10 atmospheres. You should not use a device with a larger scale, as its readings will have a serious error. It connects between the fitting and the fuel pipe:

- first turn off and cool the engine;

- locate the fuel rail under the hood;

- remove the plug from the fuel pressure fitting;

- unscrew the fitting nipple using a spool valve;

- wipe the surfaces if fuel splashes appear under the influence of residual pressure;

- pull a hose with a diameter of up to 9 millimeters onto the fitting and secure it with a clamp;

- Connect the second hole of the hose to the pressure gauge.

Next, you will need an assistant, because the readings from the pressure gauge need to be read at one of four moments:

- when the ignition is turned on, the pressure should be 3 atmospheres;

- at idle speed - 2.5;

- when squeezing the fuel outflow hose - 7;

- with the hose removed on the RTD – 3.3.

If on your VAZ-2115 the measurements show different indicators, then you need to replace the regulator with a new one. To do this, it is enough to detect it in the system, dismantle it, and then return the fuel line to its original state. In the VAZ-2115, the engine of which has 8 valves or another system, the RTD is mounted at the very end of the fuel rail.

Lada 2115 Samara 2 Sport › Logbook › Fuel system and extending the life of the gas tank

After installing the power unit on the car, it came to a complete revision and replacement of some elements of the fuel system.

The first thing I decided to do was repair the fuel tank. It was removed from the body back in the summer of 2013, and had the following appearance: After washing the tank and visually inspecting its condition, a slight deformation of the bottom in the area of the fuel pump module was revealed. By its appearance, we can confidently say that it was formed when a car collided with a road obstacle. Straightening out the dent was not difficult; for this I used a metal rod, a hammer and a copper block used in plumbing.

In addition, I paid attention to the condition of the metal in the area of the weld along the entire perimeter of the tank. Crevice corrosion was present almost everywhere. This upset me a little, since this problem had to be fixed, and in the first minutes I didn’t even know how to do it. But, after further thinking about this issue, I came up with an idea.

The manufacturing technology of the fuel tank involves joining the parts of the body with an overlap, and applying one weld with through penetration, as shown in the following figure.

The described development of events is confirmed in practice and has the following picture:

To avoid adverse consequences and extend the life of the gas tank, I decided to get rid of the potential source of corrosion by cutting off all the metal from the outside after the weld.

The procedure was performed with extreme caution in order to avoid breaking the seal of the tank. I cut off the main part of the unnecessary metal using an angle grinder, trying to cut at the edge of the weld or with a slight indentation from it. Then, where the use of an angle grinder posed a danger of violating the integrity of the seam, I, armed with a file with a large notch, finally removed the remaining metal until the metal overlap was completely removed. The result is a solid face without any cracks or cavities.

To check the tightness of the tank after the modification was completed, I poured a small amount of kerosene into it and installed it in a vertical position for some time, carrying out this control on each of the four faces.

The next problem I discovered, and not only with my gas tank, is the fastening of the fuel pump module. We are talking about earlier versions of tanks that use M4 threaded studs. In most cases, such a small thread, if used carelessly, quickly becomes unusable. The main reason here, in my opinion, is nuts with insufficient height, which involves too few threads. Negligent use of threads also means excessive tightening torque of a threaded connection, which is the case in our country. As a result, the threads are cut off at the place where the nut has its final position when tightened, which is what I found on several studs on my tank.

I saw the local solution to this problem as making nuts with an increased height in order to involve more threads of the fastening joint threads.

The last thing left to do was paint the tank, and this should have completed its restoration. Places where the old paint had peeled off and bare metal was visible were cleaned and primed. I did not completely remove the old coating, I just gave it a matte finish for better adhesion of the new paint.

The welded bracket for fastening the filling pipe had to be cut off, as crevice corrosion had formed between it and the pipe. After removing it, the bracket was welded back. To prevent a relapse in the future, after painting the pipe, I filled the crack with molten gun fat from Oilwright.

To power the engine with fuel, I planned to install something more efficient. I looked towards the well-known Masuma MPU-103. I already wanted to order it from the EXIST online store through my friend CHUJOYYA, but he convincingly dissuaded me from doing so.

The essence of the belief is that there is nothing more reliable than “made in Japan”, even from a landfill. Considering the quality of the new current spare parts, I easily decided on a pump from disassembly, and CHUJOYYA placed an order in my name and address. Thanks again to him!

Having installed the tank and connected the supply and discharge lines, all that remained was to install the filler neck, deal with the gasoline vapor separation system and the separator itself, since a crack was discovered on the old one, so it definitely required replacement. To study its design, it was divided into two parts:

I would also like to draw your attention to rubber goods installed on a metal shield located under the separator: - bushing of the outboard bearing strip (2101-2202106

) 4 things.;

— sealing ring for the gas tank filler neck ( 2108-1101085

) 1 pc.

The parts are irresponsible, they are quite rare in stores, few people bother looking for them. But still, out of necessity, some car owners acquire the desire to find them and buy them. I even came across a blog post asking for help in purchasing the O-ring mentioned above.

Source: www.drive2.ru

Main symptoms of a malfunction

Problems with the regulator can manifest themselves in various ways:

- reduction in engine power (you can notice this when driving downhill or during acceleration);

- problems with starting the power plant (the starter rotates, but the engine does not start);

- Unstable engine operation at idle (you may often stall at intersections).

Even an inexperienced car user can notice these failures. It is important to diagnose your car in a timely manner so as not to spend money on fixing more serious breakdowns later. If you detect these signs in time, you will be able to carry out the repair yourself. Otherwise, you will have to evacuate the car to a service station.

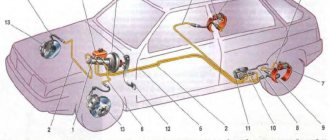

What does the VAZ-2114 fuel system consist of: device and diagram

A whole complex of devices combined into one fuel system is responsible for supplying fuel to the VAZ 2114 engine. This article is dedicated to it, by studying which you will learn what the power supply system of the VAZ 2114 injector consists of, what is the principle of its operation, and what preventive measures must be taken in order for the system to work out its resource to the fullest.

The fuel supply system is the main artery of the car

Scheme of work

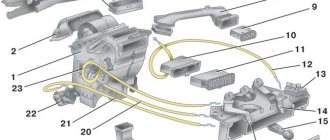

Essentially, a fuel pump is an electric motor that pumps fuel and creates the pressure necessary for the operation of the entire system. It, as noted above, is one of the components of the fuel module. The latter is a block, inside of which there are also:

- intake chamber;

- fuel level sensor;

- float;

- filter mesh.

The fuel pump is powered from the car's network. The engine is installed so that it is freely washed by gasoline. This ensures its cooling. In this case, the fuel also lubricates the working surfaces of the pump.