Injection of youth: history of the development of VAZ injection

Already in the mid-eighties, when front-wheel drive Sputniks were rolling off the Tolyatti assembly line with might and main, it became clear to VAZ engineers that the future lay clearly in the so-called fuel injection: a power system devoid of an archaic carburetor. They started developing it - technological lag was definitely not part of the plant’s plans.

Not for the sake of boasting, but for the benefit

And the point here was not at all a matter of ambition or the desire to show off the consumer: the classical power system did not meet the two most important criteria - stability of settings and toxicity standards. Even Solex, which was quite modern at that time, could not be compared with the so-called “injector”, because it did not “know how” to prepare an equally balanced fuel-air mixture under different engine operating conditions, and it was not particularly reliable, requiring regular cleaning and adjustment . While in the West, the unspoken norm was considered to be at least five years and 80,000 km without intervention in the power system, not counting the routine replacement of filters.

Even a cursory analysis showed that it is the power system with an electronic engine control unit, and not a mechanical or electromechanical injector, that has the highest stability of characteristics and “exhaust purity”. At that time, there were many types of injection in the world, and without the proper experience, it was not easy for engineers to make a decision - which option to choose? However, they were inclined towards electronic control, as the most progressive and effective.

The promising power system was planned not only (and not so much) for the modernization of the still old cars of the eighth family, but for the future “ten” . Its production was planned to begin at the turn of the eighties and nineties, and it was simply impossible to remain with an outdated carburetor - especially considering the plans to target the Western market, where the “injector” had long ceased to be a curiosity, but had become commonplace on commercial vehicles.

In addition, VAZ even then considered a multi-valve head with four valves for each cylinder as the optimal solution for the VAZ-2110, and it was almost impossible to optimize the combustion processes in such an engine with a conventional power system. All in all, it came down to the fact that introducing electronically controlled fuel injection at the launch of the next model is one of the main tasks. Moreover, it was decided not only to switch to an “injector” version with a 16-valve head, but also to equip a conventional 1.5-liter eight-valve engine, known as VAZ-21083, with injection.

Do not forget that in those “golden” years, the export of VAZ cars sometimes reached 40% of the total output - and this, as you know, is income in the form of such a desirable currency for the plant, and the upcoming tightening of environmental standards in Europe would be easy for VAZ destructive. It’s not for nothing that since the mid-eighties, export modifications have been equipped with systems for reducing exhaust gas toxicity – including those with a catalytic converter. However, the “cat” itself was not very effective, because even with additional electronics, a conventional carburetor turned out to be the “weak link” of the system for a simple reason - it prepared the mixture less accurately and stably than required.

Collaboration

The leading players in the market for the development of injection systems at that time were three companies - Bosch, Siemens and General Motors. Preliminary negotiations ended with the conclusion of a contract with GM for a simple reason - GM had more experience and could offer the maximum range.

Lada Baltic was the first to try on the 2111 injection engine. GM components are distinguished by the distinctive design of the mass air flow sensor between the air filter housing and the intake manifold.

What were General Motors specialists supposed to do as part of the contract? Firstly, to develop and adapt fuel injection for VAZ engines that would meet Euro-1 and US-93 standards. Secondly, for export cars, “Dzhiem” had to supply more than half a million (!) sets of power systems. And, finally, the result of the work was supposed to be the acquisition of the appropriate licenses with the subsequent production of components at Soviet (and in the new realities, Russian) factories.

The type of power system on the Lada Baltic was emphasized by the original “injection” nameplate, located on the left rear door under the inscription “LADA”

Already in 1993, GM began supplying central injection kits (the so-called monoinjector) for Zhiguli and Niva, and subsequently, distributed injection systems for Lada Samara. Alas, for objective economic reasons, in a difficult time for the new country, in six years it was possible to put on the assembly line only 115 thousand sets instead of the initially planned 540 thousand.

At that moment, VAZ realized that it was impossible to rely on just one foreign partner and decided to sign a contract with Bosch in 1995. This made it possible to master both the development and production of another power system, later known as the “Boshevskaya”. Of course, work on a fundamentally new power system required long stays on foreign business trips for VAZ specialists leading on the project, some of whom worked on this topic in the United States for three or four years in a row.

Early “injectors” had imported GM controllers

During the work on the “injector”, they tried to convert such exotic modifications as the 1.1-liter VAZ-21081 engine . However, subsequently it was decided that small-capacity modifications should not be touched, and VAZ designers, together with foreign specialists, focused on engines with a volume of 1.5-1.6 liters - both Zhiguli and chisel engines. And the 16-valve engine 2112 was supposed to be the first in the history of VAZ, a design that was initially “tailored” only for an electronic power system with distributed injection.

Even during early experiments on classic engines, it turned out that the installation of a catalytic converter greatly worsens the engine’s performance in terms of power and torque, so the power system had to provide maximum efficiency in order to minimize “environmental” losses of power supply, inevitable in any case.

In Samara, with the so-called low panel, the injection controller was placed on a shelf under the glove compartment

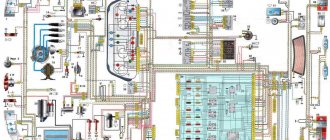

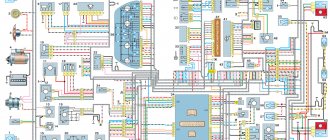

Electronically controlled fuel injection was a common (yet modern) concept. The electronic control unit received information from a couple of dozen sensors, on the basis of which the correction of the fuel-air mixture was based, as well as other parameters - the opening time of the injectors, the ignition timing, the amount of air and fuel supplied to the cylinders, and so on. The main “work” was done by several important sensors - for example, the crankshaft position sensor (without it the engine will not start at all!) and the mass air flow sensor.

The most important advantage of VAZ injection, like most similar systems, is “survivability”. If the electric fuel pump or the “strategic” DPKV sensor has not failed and the ECU controller or ignition module has not burned out, then the system, at the very least, will work even if several sensors fail, going into emergency mode and working according to alternative control algorithms using some “averaged” » indicators built into the program.

Difficulties

But it was smooth only on paper. Mastering such a complex system, when the industrial giant of the USSR had already fallen asleep, became a difficult task for VAZ. However, with the intellectual support of foreign partners, they completely coped with it - at least, by the end of the nineties, the “injector” had become not just a workable, but also a completely serial power system for VAZs.

The mass air flow sensor is one of the most expensive components of a power supply system with distributed injection.

Of course, a lot went wrong. Attempts to attract the defense industry to production ended in nothing, and the work in the States was completed back in 1994 - before injection was put on the assembly line. In addition to the injection version of the 1.1 liter engine, in the end it was not possible to master the 16-valve version of the Samara, although the adaptation of the 2112 unit to the 21093 body was carried out in the early stages of the injection work. Only much later did the multi-valve engine fit under the hood of Samara in a factory version - more precisely, “near the factory”, from.

A special device is provided to absorb fuel vapors - an adsorber.

Some components had to be left imported - for example, the oxygen sensor, injectors and mass air flow sensor. Blocks were produced to order at Bosch, and over time, domestically produced controllers were also introduced. The remaining components (sensors, intake, exhaust and fuel supply system from the tank) were mastered almost independently.

Rework

To replace a carburetor with an injector yourself, be sure to arm yourself with the following components:

- Cylinder head from VAZ 2112 with receiver and manifolds;

- Knock sensor;

- Throttle pipe with throttle position sensor;

- Mass air flow sensor and a number of other elements.

Replacement kit

When everything is ready, you can get to work.

- Remove the old cylinder head. Plus, remove all attachments in the fuel assembly, gas tank and ignition system.

- Remove the alternator, thermostat, pulleys and belts.

- Install a new gas tank with a pump, borrowed from a donor - an injection VAZ.

- Remove the carburetor and ignition system components that need to be replaced.

- Disconnect the cooling system pipes and hoses. Here, install a completely new kit from the injector.

- Remove the pan.

- Install new pistons from an injection donor and connecting rods at 10. Standard carburetor components are not designed for an injection compression ratio. Plus there are special recesses for other valves.

- Install a new unit with an underflow on the cover for the DPKV, replacing the standard oil pump. If you can remove the cover, then only that will be replaced.

- After removing the old cooling system pipes, install new ones. The best solution is to replace the entire set. Buying it won't really impact your overall budget.

- Prepare everything necessary to mount the 16 valve head. The fasteners match, only the bolts from the old head are long and need to be shortened. Plus, don’t forget to make a size 12 hole in the new head.

- Install new fuel lines from the donor.

- Connect your new gas tank to the lines.

- Route the wiring from the control unit to the fuel pump. You can use old fuel level regulators from a carburetor car.

- Cut a hole in the wall of the engine compartment through which the wiring will be routed. This way you won't have to make the standard wires longer.

- Install the knock sensor by drilling a hole in the block and tapping a size 8 thread.

- Be sure to replace the water pump using a unit from donor 2112.

- Get a new crankcase breather and oil dipstick. Install them instead of the previous ones.

- Install a new cylinder head. Just don't forget to change the gasket, which corresponds to a different head.

- Install a thermostat borrowed from a VAZ 2112.

- Connect the coolant pipes.

- Remove the rear timing cover and rollers. The pulleys from 2112 are dismantled. The belt must be installed in accordance with the marks.

- Install the new generator along with the drive. For the new generator, the upper fasteners will remain intact, since they are not provided for by the design of the carburetor VAZ 2109. Therefore, fasten the pair of lower mounting bolts as securely as possible.

- Place all the sensors in their new places.

- Seal the valve covers with a good quality sealant.

- Assemble the ignition module, wires, spark plugs and other components.

- Install the air filter.

- Get your exhaust system back to normal. The muffler is often left stock, but the resonator and other components are taken from the donor.

- The wiring is connected to the dashboard and the lock.

- Fill in new oil, refuel the car with high-quality fuel.

- Start the engine and take it for a test drive.

Article on the topic: Installing Euro handles on a VAZ 2114 with your own hands

( 1 rating, average 4 out of 5 )

History of the VAZ 21093 - how did a domestic car with an injector appear?

Serial production of VAZ 21093 cars began in the late 80s. At that time, the VAZ was produced only with a carburetor engine. The main difference between this car model and its predecessor, the VAZ 2108, was the presence of 5 doors, which is why it began to be considered a family car.

The production of the VAZ 21093 with an injector began in 2000, when the so-called electronic brains appeared - primitive on-board computers that control all electronic processes in the operation of the car. The presence of connectors allows a car service center to diagnose the car and determine faults without delving into the insides of the car. The on-board computer can see malfunctions of sensors, turn signals, headlights, ignition systems, and problems with engine operation.

Since 2012, the VAZ 21093 has received another advantage - an electronic gas pedal, which is a pleasure to press! The driver does not need to make almost any effort - just put his foot on the pedal for the car to start.

Diagnosis of sensor failure

Let's consider deviations in engine operation and the corresponding possible causes. Unstable operation at idle, difficult starting or stopping the engine after driving in high power mode can be caused by malfunctions of the mass air flow sensor (MAF) - it will give the controller at low speeds readings that are 15–25% higher. If there is excessive fuel consumption or the engine response has decreased, the mass air flow sensor gives underestimated readings.

Jerks and dips when switching from idle to operating speeds, even in the case of light loads, means that the operation of the sensor that reads the throttle position has been disrupted. Difficulty starting a warm engine or slight excess fuel consumption - the coolant temperature sensor has failed.

The engine picks up speed poorly and does not develop the required power, or there is a large excess fuel consumption - the knock sensor has failed or the wire from it has broken. In the event of a noticeable overconsumption of fuel with a simultaneous increase in the amount of harmful emissions in the exhaust gases, the oxygen sensor has failed.

A slight decrease in throttle response and deterioration in other engine performance characteristics means a failure of the speed sensor or oxidation of the contacts of its wires or connector. Limiting engine speed or stopping it indicates a failure of the crankshaft position sensor. Large excess fuel consumption - the phase sensor has failed. Minor deterioration in engine performance or difficult starting means the temperature sensor of the air entering the engine has failed.

If all of the above devices and sensors have been checked, but the injection VAZ-2109 does not start, then the processor may have failed and it does not properly control the entire starting system. In this case, diagnostics at a car service center is required.

Characteristics of VAZ 21093 - not a single injector

Car 21093 with an injector has proven itself very well in the domestic market, primarily due to its affordable price. It is superior in comfort to previous models and has a brighter design. The car has front-wheel drive and, due to its shape, has increased durability on the highway. The engine in the fuel-injected car is four-cylinder, with 8 valves, volume 1.3–1.5 liters and engine power 75 hp. With.

Compared to carburetor cars, injection cars consume less fuel on the same stretch of road. With good quality gasoline and an average speed of 90–110 km/h, the consumption of the VAZ 21093 is 6.5–7.5 liters per 100 km. This fuel consumption is achieved not only due to the presence of an injector, but also due to the weight of the car, as well as the reduced energy consumption of various car devices.

The speedometer of this car brand shows 160 km/h, but it is not recommended to accelerate it more than 140 km/h - the car is blown out, causing unpleasant vibration and rattling. The injector in a car is one of the most key devices. This part consists of a fuel rail, injectors, an intake manifold, as well as electronic sensors that carry out commands sent from the electronic brains. The principle of operation of the injector is to uniformly supply fuel to each of the cylinders.

This work is performed by supplying fuel through the injectors, which are responsible for fuel injection. The intake manifold is a device through which air from the environment passes. The throttle valve controls the air supply to the manifold; it opens when the gas pedal is pressed.

Fuel system

If there is a spark in a carburetor or injection engine, it should be assumed that the car does not start due to problems in the fuel supply system.

First make sure that gasoline is flowing into the injectors. If not, then look at the VAZ fuel pump. It is equipped with an electric motor and is located directly in the tank. Normally, when the ignition is activated, it starts to make noise.

It is advisable to find out whether the pressure in the ramp is normal. Measure it with a pressure gauge - there is a special fitting for it. Connect the device to it - if the reading is 4 atmospheres, then everything is in order. Low pressure appears due to a clogged fuel filter; this element will have to be removed and cleaned.

If there is no positive result, move on to the injectors. When they become clogged, gasoline either stops flowing altogether or its volume noticeably decreases. Moreover, it does not spray, but only drips. This problem does not make itself felt while the engine is hot. In frosty weather, the car, even if it starts moving, will still not be able to develop normal power.

In addition, fuel atomization does not occur when the computer does not open the injectors. Make sure they have all the wires and are securely attached.

Car injector breakdowns

Quite often a situation arises when a fuel-injected car starts poorly or does not start at all. The reasons for this operation may be dirty spark plugs from low-quality fuel, problems in the operation of the generator, starter, or insufficient current in the battery. The main malfunction is the low fuel supply to the injector frame; accordingly, an insufficient amount of fuel is sprayed by the injectors.

The fuel pump is responsible for supplying fuel to the injector; it may not produce the pressure necessary for normal operation of the car engine. In this case, it is best to replace the pump. If the reason is not a pump failure, then it will be enough to replace the filter in it. Another common cause of malfunction is the failure of one or more injector nozzles. Low-quality fuel, which sometimes, against our will, enters the system, contains various additives that are deposited on the injectors and interfere with proper operation.

When the injectors become dirty, the vehicle's fuel consumption increases noticeably and the vehicle's traction decreases. If fuel is not supplied in the amount required for engine operation, then the speed on the tachometer begins to fluctuate. In all injection VAZ cars, the average engine speed at idle should not exceed 900 rpm.

Candles

First of all, find out if there is a spark at all. The weakness of the latter allows you to start the engine while it remains hot, but it does not work when it is cold.

Unscrew the spark plug, place it against ground and crank the starter. If there is a spark, then there is probably a problem in the fuel system. We will tell you about it later.

It is necessary to do otherwise when the unscrewed spark plug works properly, but it turns out to be wet. Here you should check the timing belt. The latter sometimes jumps off, which disrupts the correct gas distribution and, accordingly, the VAZ engine does not want to start.

If you see that the spark plugs are filled with fuel, then perhaps this very circumstance is preventing you from starting the engine. Dry them with a burner or on a gas stove burner. When they turn out to be wet again during the next attempt, you will have to find out why this happened.

If there is no spark, the cause is sought further. It often lies in problems:

- crankshaft pulley or sensor that controls its position (DCPV);

- computer.

In most cases, the VAZ model 2109 injector does not want to start precisely because of the failure of the DPKV. Failure of other sensors does not prevent the engine from starting, it will simply not work correctly.

First, check whether the connector leading to it is intact and whether the wires are in good condition. It is the destruction or contamination of these elements that most often interferes with the normal operation of the DPKV, while the device itself is reliable.

To test the sensor, just hold a piece of metal close to it and measure the output voltage. It will fall if the piece of iron is taken away, and rise when it is brought close.

Another reason why a VAZ may not start is the crankshaft pulley. The disadvantage of this unit is that its teeth are partially made of rubber, which means they can come off or even scroll. This affects the sensor readings, and the computer, guided by them, does not want to supply voltage to the spark plugs. It’s not difficult to check - remove the casing from the timing belt (inspect it at the same time), and then examine the pulley.

There is a high probability that there is no spark due to a faulty ignition. First you should make sure that the connector leading to it is intact. Installing a known-good module on a Lada that does not want to start will allow you to confirm your suspicions.

It is imperative to inspect all wires. A break in them, even with working devices, often leads to the inability to start the engine.

VAZ injector repair

Cleaning a car injector is not a complicated or long process. Partial cleaning of injector nozzles can be done at home, armed with some tools and washing liquid. Such cleaning is more than enough at the initial stage; it is recommended to be carried out for prevention and preferably once every 10,000 km.

More complete cleaning can be done at a specialized car service center. At the stand, they will wash your injectors and also conduct computer diagnostics of your car as a whole.

If you decide to clean your car's injector yourself, then buy a chemical liquid that is available at any auto store. When purchasing, you should pay attention to the instructions for use. It is also recommended to replace the rubber O-rings on the injectors when cleaning. A repair kit for such rings is inexpensive and available to everyone.

Before removing the injector, remove the terminals on the battery, then take the necessary keys and unscrew the intake manifold. In some car modifications, it is not always necessary to remove the manifold to clean the injectors. After this, disconnect the electronic chips that are attached to the injectors, shaking them left and right. Pull out the fuel rail with injectors and carefully disconnect them.

Next, follow the instructions indicated on the can of flushing liquid; after completing all the procedures, reassemble everything in the reverse order. In some cases, it is necessary to replace the filters inside the injectors. To completely clean the injector, do not forget to clean the throttle valve. It is advisable to perform it once every 5,000 km.

Modifications of VAZ 2109

At the end of 2014, AvtoVAZ stopped producing cars of the Samara family, thereby ending an entire era in the history of the domestic automobile industry. The VAZ 2109 turned out to be one of the most popular and popular cars. Over the years, more than 1,500,000 nines were produced. And the design began back in 1979, but the release of the first VAZ 2108 car was only in 1984. The Eight was a hatchback with two doors, had a completely new design and was radically different from everything that had been produced by VAZ before. But it was the nine that was most popular, because four doors are more rational for a car owned by a family man with a wife and children.

VAZ 2109

So, the history of the production of the VAZ 2109 is the VAZ 2109 - it was initially equipped with a 1.3 liter engine and was produced from 1987 to 1997. VAZ 21091 is a carburetor model with a reduced engine capacity of 1.1 liters (1987-1997), produced in smaller volumes than the VAZ 2109. VAZ 21093 is a model with a carburetor engine of 1.5 liters (1988-2006). Starting in 1994, trial models of the VAZ 21093i appeared, which had a new product - an injection power system. It is noteworthy that global automakers began to mass produce cars with injection engines back in the late 70s. Well, in Russia this happened only almost 20 years later. There is a classification of the VAZ 2109 according to the type of wing: - with a short wing;

VAZ 2109 with a short wing

-with a long wing.

VAZ 2109 with a long wing

Initially, the nine was produced with a short wing and a beak-like radiator grille. Later, designers developed a refined radiator grille and began to use a long wing. For special-purpose services, the VAZ 2109-90 model with a rotary engine was produced.

History Edit

The car began production in 1987. At first, the car was equipped with in-line 4-cylinder 8-valve carburetor gasoline engines with a volume of 1100, 1300 and 1500 cm³.

VAZ 21093 “Samara” (1990-2004)

In 1991, the newest design of the “front” of the car was developed. Cars with such a front design began to be produced immediately after the start of production of the VAZ-21099 sedan. Since 1994, these cars also began to be equipped with 4-cylinder, 8-valve VAZ-2111 1500 cm³ gasoline engines, which used a fuel injection system with distributed fuel injection.

In the Finnish version of the VAZ-2109, it may also have been optional to install air conditioning, electric windows, power steering, and a sunroof.

The VAZ-2109 has two doors on each side, which makes it easier for passengers to get in and out compared to the two-door version; The central pillar of the body separating the doors has been shifted forward, so the distance between the pillar and the rear seat cushion has increased; The position of the upper fastening points of the safety belts has also changed - they are less restrictive when traveling.

A total of 1,615,995 units were produced. Then it was replaced by the VAZ-2114 model.

What year did the injection VAZ 2109 start?

Since 1987, production of VAZ-2109 models in the 5-door hatchback began. Compared to the task from the eight tribe, the Sputnik/Lada Samara VAZ-2109 was considered the best home car. Moreover, the presence of 5 doors and, as a result, the least expressive appearance.

Since 1988, the ninth model, as well as modifications of this car (VAZ-21091 and VAZ-21093) have become the most common models of front-wheel drive VAZs. A much more successful modification of the ninth model was the VAZ-21093, released in 1990.

By folding the rear seats, the car can simply become a cargo and passenger version. This can be used as a van. Basic versions of the VAZ-2109 are equipped with transversely mounted carburetor 1.3-liter four-cylinder engines producing 65 horsepower. With these capabilities, a fully loaded car accelerates to 100 km/h in 18 seconds. The maximum possible speed is 156 km/h. The VAZ-21093 model was armed with 1.5-liter engines (VAZ-21083) with a capacity of 72 horsepower. VAZ 21093i comes with 1.5-liter injection engines. In addition, a modification of the VAZ-21091 appeared, which was equipped with 1.1 liter engines. Since the development of 90 years, the "Svita" vehicles have been equipped with a new instrument panel with tachometer and on-board computer. And the most recent development was an engine with a distributed fuel injection system.

READ How to Adjust Headlights on a VAZ 2112

In 1995, the body was restyled. Over time, the radiator grille stopped melting. The last cosmetic modernization was carried out in 1997, but at the same time the car’s equipment remained virtually unchanged.

The VAZ-2109 model and its modifications were completed in 1997. This was justified by the cessation of production of engines of the predecessor VAZ-2108.

VAZ 2109 16V

When the VAZ-21099 appeared on the conveyor belt in 1990, the production process for the Samara family of models was completed. The rear canopy has been increased, which significantly expands the car compared to the principles of a family car. This model featured a radiator trim that was completely unique, and the front fenders and hood were made without a plastic mask. In particular, the car's interior was equipped with the latest panel, with a tachometer. A little later, these solutions were used for this family of models. "Samara",

VAZ 21099 car with front-wheel drive. Body. car. The car is equipped with 1.5 liter engines and, as a rule, a 5-speed manual transmission. VAZ 21099i comes with 1.5-liter injection engines. Since the release of these cars, modifications have been made in different years to both carburetor and injection engines with a volume of 1.3 liters VAZ-210993 and 1.5 liters VAZ-21099.

READ How to Remove the Box of a Lada Granta

The following options were provided: for cars with carburetors. “norm” (VAZ-210992-01), “catalog” VAZ-21099-00 and “luxury” VAZ-21099-02; For cars with injectors. “norm” VAZ-210992-21, “catalog” VAZ-21099-20 and “luxury” VAZ-21099-22.

Specifications

| Layout | Front engine, front wheel drive |

| Wheel formula | 4×2 |

| Number of seats | 5 |

| Dimensions, mm | |

| Length | 4006 |

| Width | 1650 |

| Height | 1402 |

| Wheelbase | 2460 |

| Curb weight, kg | 945 |

| Load capacity, kg | 425 |

| Engine | |

| Model | VAZ-21081 (1.1), VAZ-2108 (1.3), VAZ-21083 (1.5), VAZ-2111-80 (1.5i), VAZ-11183-20 (1.6i) |

| Type | Petrol |

| Number of cylinders | 4 |

| Transmission | Manual, 4-speed or manual, 5-speed |

| Brakes | |

| Front | Disk |

| Rear | Drums |

| Fuel tank volume, l | 43 |

What year did the injection VAZ 2109 start?

Since 1987, production of VAZ-2109 models in a 5-door hatchback body began. Compared to the task set by its fellow eight, the Sputnik/Lada Samara VAZ-2109 was considered a better home car. This matter was affected by the presence of 5 doors and, as a result, a much less expressive appearance.

Since 1988, the ninth model, as well as modifications of this car (VAZ-21091 and VAZ-21093) have become the most popular front-wheel drive VAZ models. A much more successful modification of the ninth model was the VAZ-21093, which was produced in 1990.

If you fold the rear seats, the car could simply transform into a cargo-passenger version. It could be used as a station wagon. In the basic versions of the VAZ-2109, transversely mounted carburetor 1.3-liter four-cylinder engines with a power of 65 horsepower were installed. With such features, a one hundred percent loaded car accelerated to 100 km/h in 18 seconds. The maximum possible speed is 156 km/h. The VAZ-21093 model was armed with 1.5-liter engines (VAZ-21083) with a power of 72 horsepower. The VAZ-21093i model came with injection engines with a working volume of 1.5 liters. Additionally, a modification of the VAZ-21091 was carried out, which was equipped with engines with a volume of 1.1 liters. Since the development of the 90s, Luxury cars have been equipped with a newer device panel, which had a tachometer and a route computer. And the newest development was a motor with a distributed fuel injection system.

In 1995, the front of the body was restyled. During the process, the radiator grille no longer melted. The last cosmetic modernization was carried out in 1997, but at the same time, the car’s equipment remained virtually unchanged.

The VAZ-2109 model and its modifications were discontinued in 1997. This was justified by the cessation of production of the engines of the predecessor VAZ-2108.

VAZ 2109 16V

When the VAZ-21099 model in the body of a car appeared on the assembly line in 1990, the production process of the Samara model family was completed. The rear overhang was increased, which significantly lengthened the car compared to the family cars. This model had a radiator lining that stood out, which was quite unique, and the front fenders and hood were made without a plastic mask. Specifically, the interior of the car was equipped with the latest panel, with a tachometer. A little later, these solutions were used for this family of Samara models.

VAZ 21099. car with front-wheel drive. Body. automobile. The car is equipped with engines with a volume of 1.5 liters, and of course 5-speed manual transmissions. VAZ-21099i came with injection engines with a volume of 1.5 liters. Since the production of these cars, modifications have been produced in various years, both with carburetor engines and injection engines with working volumes of 1.3 liters VAZ-210993 and 1.5 liters VAZ-21099.

The following options were provided: for cars with carburetors. “norm” (VAZ-210992-01), “standard” VAZ-21099-00 and “luxury” VAZ-21099-02; for cars with injection. “norm” VAZ-210992-21, “standard” VAZ-21099-20 and “luxury” VAZ-21099-22.

About LADA 2109 engines 1st generation (1987 - 2011)

VAZ 2109 (Lada Samara), popularly known as a nine, is a 5-door hatchback, a continuation of the Samara line. It was developed in 1987 using the 3-door hatchback VAZ 2108 as a base. The nine itself became the basis for the creation of the VAZ 21099.

The car gained wide popularity thanks to its fast design, good engines for those times, and a convenient 5-door body. All this, coupled with the low cost, and a wide selection of spare parts, made the VAZ 2109 very attractive. This attractiveness was passed on to its successor, the VAZ 2114. In contrast to the eight, the injector was installed as standard on the 2109 engines (unit 2111).

In addition to the injector, the 2109 was equipped with a carburetor with a displacement of 1.1 l, 1.3 l and 1.5 l. Such engines can be seen if you look under the hood of the 2108.

In the article we will look at the engines themselves for the VAZ 2109, their properties and weak points.

ENGINE VAZ 2108

The 1.3 engine is the basis for the eight, it was developed from scratch, and is structurally similar to the 21011 1.3 liter engine. there is nothing in common. This engine became the basis for the development of power units for installation on the Samara family with a working size of 1.1 liters, 1.5 liters. This is an in-line carburetor type engine, has 4 cylinders and an overhead camshaft. The timing drive uses a belt.

Regarding the service life of the engine, it is fair to say that careful and measured operation, correct and consistent service will allow you to exceed the official 120 thousand km and the service life can be 180-200 thousand km.

As for the disadvantages, the following are more often noted. The parts of the cooling system wear out quite quickly. Frequent oil filter changes and valve adjustments will be necessary. Oil leaks often occur due to unreliable valve cover seals, fuel pump and distributor sensor. It is necessary to emphasize that Solex carburetors are completely unreliable, and EPHH specifically.

VAZ-2109

A distinctive feature of the VAZ-2109 compared to the G8 was its 5-door body with narrower front doors. One of the features is that the VAZ-2109 received a plastic gas tank, unlike the metal VAZ-2108, and its strength was no worse than the metal one, but the weight was much less. Otherwise, the unification of cars was colossal. Almost all body panels were identical. If you put both cars side by side, it is impossible to distinguish them from the front.

It has become much easier to fit inside the VAZ-2109 car. Compared to the VAZ-2108, the front doors of the Nine have become narrower, and the central pillar has been moved forward, thereby increasing the distance from the pillar to the back of the rear seat. Another advantage of the 5-door body was that due to the displacement of the central pillar, it became easier to put on a seat belt, now there was no need to reach for it, and it did not constrain the driver and passenger when driving.

Reliability

VAZ 2109 was considered a reliable and safe car. And thanks to the availability of spare parts, it was not difficult to repair it. This workhorse easily overcame any difficulties even when fully loaded. After all, at the time of its appearance, not everyone could afford a car, and therefore relatives with personal cars were mercilessly exploited. And add here the poor quality of roads and we get an ideal workhorse that overcomes any difficulties.

Even now it is recommended as a first car or a car for a summer residence, since the latest generation of the “Nine” costs the money for which, even if you can buy a foreign car, but it’s absolutely dead and then you still have to look for spare parts for it.

“Nine” took a whole milestone in the history of Avtovaz and the whole country. They sang songs about it on stage, and participated in races and international car rallies. This car was the cherished dream of many and could be seen in films more often than other domestic cars. The legendary VAZ 2109 was replaced by the no less stylish VAZ 2114, and then by the Priora. But the “nine” will forever remain in the hearts of the 90s generation as the best car of that time. And despite the fact that production of the “nine” has long been discontinued, it is still on the list of leaders on the secondary market.

Modifications of VAZ 2109

At the end of 2014, AvtoVAZ stopped producing cars of the Samara family, thereby ending an entire era in the history of the domestic automobile industry. The VAZ 2109 turned out to be one of the most popular and popular cars. Over the years, more than 1,500,000 nines were produced. And the design began back in 1979, but the release of the first VAZ 2108 car was only in 1984. The Eight was a hatchback with two doors, had a completely new design and was radically different from everything that had been produced by VAZ before. But it was the nine that was most popular, because four doors are more rational for a car owned by a family man with a wife and children.

VAZ 2109

So, the history of the production of the VAZ 2109 is the VAZ 2109 - it was initially equipped with a 1.3 liter engine and was produced from 1987 to 1997. VAZ 21091 is a carburetor model with a reduced engine capacity of 1.1 liters (1987-1997), produced in smaller volumes than the VAZ 2109. VAZ 21093 is a model with a carburetor engine of 1.5 liters (1988-2006). Starting in 1994, trial models of the VAZ 21093i appeared, which had a new product - an injection power system. It is noteworthy that global automakers began to mass produce cars with injection engines back in the late 70s. Well, in Russia this happened only almost 20 years later. There is a classification of the VAZ 2109 according to the type of wing: - with a short wing;

VAZ 2109 with a short wing

-with a long wing.

VAZ 2109 with a long wing

Initially, the nine was produced with a short wing and a beak-like radiator grille. Later, designers developed a refined radiator grille and began to use a long wing. For special-purpose services, the VAZ 2109-90 model with a rotary engine was produced.

VAZ 2109 with Wankel engine

The dynamics of this engine were excellent, accelerating from 0 to 100 km/h in just 8 seconds. However, it had too low a service life, only about 50,000 km. It was also very expensive to operate and maintain. As the mechanics used to say, “gasoline by the ton, oil by the barrel.” The engine had high fuel consumption and took oil. But in special operations it was indispensable; the Wankel engine was unrivaled in its dynamic characteristics and power. After the collapse of the USSR, the VAZ 2109 was also produced in Finland, the model was called VAZ 21093-22 (Lada Samara Baltic).

Lada Samara Baltic

The export version featured voluminous bumpers and a radiator grille. The quality of assembly and painting was much higher than that of cars produced in Russia, so the cars were very much appreciated.

Lada Samara Baltic

Interestingly, this Lada model was also produced in an export modification for England. The model was called VAZ 21096 and was right-hand drive. Otherwise, it was exactly the same nine, well, maybe the build quality was better for export.

VAZ 21096 right-hand drive

There was also a modification of the VAZ 2109 with a diesel engine. It was produced by the French importer Vasa. In Europe, the production of diesel cars was supported and a diesel engine was installed in the Lada Samara Diesel GLX. This model was not brought to Russia because they were afraid of problems with maintenance. Also produced in Belgium was the VAZ 2109 Carlotta.

VAZ 2109 Carlotta

About the car in general Edit

- The VAZ-2109 assembly is front-engine, front-wheel drive.

- The body of the VAZ-2109 is two-volume, hatchback type.

Lada Samara Baltic GL (21093-22) (1996-1998)

The engine – VAZ-2109 was equipped with a four-stroke in-line 4-cylinder petrol engine VAZ-2108.

- Box – VAZ-2109 was equipped with a manual gearbox, which included:

- Chassis - The front suspension of the VAZ-2109 is completely independent, MacPherson type, so-called. "floating candle" The rear suspension is semi-independent with a torsional transverse support, similar in design to almost all other front-wheel drive cars of those years.

single disc clutch; five-speed gearbox; cylindrical main gear; bevel differential; drive shafts with CV joints.