Modern cars cannot do without a large number of sensors. Some of them are responsible for security, others for the coordinated operation of all systems. There are devices that provide an acceptable level of comfort for the crew.

Of course, engineers and car designers know everything about these systems. How can a simple owner understand the purpose and, moreover, diagnose any of these devices?

For example, what is the rough road sensor for a Priora car needed for? Providing comfort is clearly not a priority in this class of car. There is no point in informing the driver about potholes; he will feel it himself. The true purpose of the device is ecology. It sounds a little strange, but it's true.

Operating principle of the device

With the introduction by a special commission of the European Union of mandatory parameters Euro-2 and Euro-3 in vehicle electronics, the use of an ignition misfire system has become mandatory as a function when programming the ECU.

Algorithms for its diagnostics were also integrated into the “brains” of the on-board computer. With its help, to prevent excessive toxicity of unspent fuel, a program was installed to turn off cylinders with defects in the injection system. This occurs by blocking the fuel supply through the injector system. With the help of preventive blocking of such a function, the release of unburned fuel into the environment is stopped, and the functionality of rather expensive oxygen sensors and a complex of catalyst elements does not suffer. On vehicles equipped with a set of additional electronic devices included in Euro-3 and subsequent generations, a VAZ rough road sensor is added to the ignition system interval control complex.

This indicator is positioned as the only device in the vehicle electronics that does not directly affect the management function of the Priora from the electronic on-board complex. With this question posed, Russian car enthusiasts often ask why a rough road sensor is needed in a car.

Such a device has the function of protection when moving along sections of the roadway with obvious unevenness (bumps, ruts, etc.). Based on the pulses emitted by the device, the controller can temporarily suspend the process of identifying intervals in the ignition system and turning off idle cylinders.

Many, even experienced drivers, often ask: where is the rough road sensor, where is it located, on what basis does it function, and how it makes measurements sent in the form of pulses to the electronic on-board control unit. If questions arise about where the rough road sensor is located, it must be taken into account that a device of this type must record body vibrations while being in a rigid connection with it.

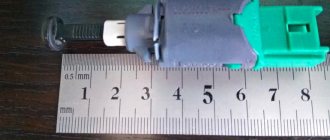

The standard device is located in the power compartment of the vehicle on the mudguard of the wing on the right side. As a rule, it is mounted on a special ledge and connected to the on-board computer via a three-pin contact. Finding the rough road sensor and replacing it is not particularly difficult.

It operates based on the use of a piezoelectric effect, similar to the knock sensor of a power plant, i.e. there is a transformation of acceleration signals that appear in the system when driving on a road surface with uneven surfaces. Such a pulse is converted into a DC voltage value that is in direct proportion to the previous signal. This is how the controller identifies the position when the vehicle is moving on a road with difficult terrain and gives the command to disable the combustion suppression function.

When moving on a road surface with unevenness and potholes, the variable load effect of a variable type significantly affects the angular speed of rotation of the crankshaft of the technical device. Frequency pulses transmitted during the rotation of the crankshaft of a technical device act as an analog signal that occurs during intervals of ignition of the air-fuel mixture.

How to check the functionality of a lambda probe

The electronic rough road sensor in Priora measures the amount of vibration of the vehicle body and transmits the received impulse to the controller. If the permissible level of pulse parameters is exceeded, the controlling detector disables the indicators of the combustion intervals of the injection system.

Options for crankshaft sensors on the VAZ-2114

Crankshaft position sensor

When considering the issue of crankshaft sensor malfunction, it is worth paying special attention to the possible options for this part. According to the technical data of the manufacturer, there are several products that can be distinguished by design features and operating principle:

- Inductive. Inside the product there is a metal rod, which is surrounded by a magnet. The entire product has a copper winding, which is connected to the connection wires. When a metal part is located next to the sensor, a pulse appears on the rod and goes to the ECU.

- The hall sensor is located inside the crankshaft sensor. When a metal product is attached to it, its state changes.

- Frequency. In this case, the electronic control unit sends a certain pulse, and when a metal part approaches the sensor, the frequency of this pulse changes, which gives a signal to the ECU.

Symptoms of a problem

Location of the crankshaft sensor near the flywheel

There are not many signs of a malfunctioning crankshaft position sensor. As practice shows, in many cases, problems with the product are caused by the fact that dirt or plaque adheres to it, which prevents the data from being read, or makes this operation incorrect.

So, let's look at the main signs of a DPKV malfunction:

Schematic designation of the location of the crankshaft sensor relative to the flywheel

- Unstable idle mode.

- The revolutions are floating. This will be visible from the tachometer reading on the dashboard. It will look like this: the car picks up speed, and then it drops sharply in the same operating mode.

- Loss of power.

- Acceleration failures.

- The car starts very poorly.

In this case, it is worth dismantling the sensor and diagnosing it. It can be done in a simple way - with a multimeter, or if you have an oscilloscope - with this device.

A clear example of the location of the sensor relative to the flywheel

Also, in addition to signs of malfunction, it is worth considering the reasons why the crankshaft position sensor may fail:

- Deformation or destruction of the housing.

- Short circuit that damaged the winding.

- Wear.

Diagnostic methods

With the sensor removed, diagnostic operations can be carried out that will accurately determine the condition of the product and its performance. So, let's look at the methods for diagnosing DPKV:

- Using a multimeter. In this case, it is necessary to close the power supply connectors to resistance. The normal value should be 500-700 Ohms.

- The second method also involves using a multimeter. A reading of 200 millivolts is set on it, and a metal object is brought to the sensor core. If the sensor is working properly, then a fluctuation in readings will be visible on the multimeter.

- Using an oscilloscope. This device shows the most accurate result from all diagnostic methods. The test is carried out in different modes: at 800 rpm (that is, at idle), 2000 and increasing up to 6000. Depending on the result on the screen, the cause of the malfunction can be determined.

Oscillogram for checking the crankshaft sensor

how to disable the rough road sensor ~ AUTOTEXNIKA.RU

Features of the functioning of the rough road sensor in Lada Priora

The emergence of such an electrical device in the electrical equipment system of a vehicle, as a rough road sensor, is justified by the development of the entire complex of the global automotive industry, traffic safety systems and vehicle environmental friendliness, namely.

Operating principle of the device

With the introduction by a special commission of the European Union of the mandatory characteristics of Euro-2 and Euro-3 in vehicle electronics, the misfire (ignition) system became mandatory for use as a function when programming the ECU. Methods for its diagnostics were also integrated into the “brains” of the on-board vehicle. With its help, to prevent unnecessary toxicity of unused fuel, a program was installed to turn off cylinders with deficiencies in the injection system. This occurs by blocking the fuel supply through the injector system.

With the help of preventive blocking of this function, the release of unburned fuel into the environment is stopped, and the functionality of the rather expensive complex of catalyst parts is not affected. On vehicles equipped with a set of additional electrical devices included in Euro-3 and subsequent generations, a VAZ rough road sensor is added to the ignition system interval control complex.

This indicator is positioned as the only device in the vehicle electronics that does not directly influence the management function of the Priora from the electrical on-board complex. When the question is posed this way, Russian car owners often ask why a rough road sensor is needed in a car.

Such a device has the function of protection when moving along sections of the roadway with obvious unevenness (bumps, ruts, etc.). Based on the pulses emitted by the device, the controller can temporarily stop the process of identifying intervals and turning off idle cylinders.

Reversing light

The standard device is located in the power compartment on the wing mudguard on the right side. Usually, it is mounted on a special protrusion and connected to the side panel via a three-pin contact. Finding a rough road sensor and replacing it is not particularly difficult.

Lada KalinaDND rough road sensor malfunction

the engine starts and stalls, elimination of error codes P1606/P1616/P1617, description of the cause of the error and its elimination.

It operates on the basis of the introduction of the piezoelectric effect by analogy with the knock sensor of a power plant, i.e. there is a transformation of acceleration signals that arise in the system when driving along a road surface with uneven surfaces. Such a pulse is converted into a constant current voltage value, which is in direct proportion to the previous signal. This is how the controller identifies the position when the vehicle is moving along a road with difficult terrain and gives a command to disable the function of stopping the ignition of a flammable mixture.

When moving on a road surface with unevenness and potholes, the variable load effect of a variable type significantly affects the angular speed of rotation of the crankshaft of the technical device. Frequency pulses transmitted during rotation of the crankshaft of a technical device act as an analog signal, which appear during intervals of ignition of the air-fuel mixture.

The electrical rough road sensor in Priora measures the amount of vibration of the vehicle body and transmits the acquired impulse to the controller. If the permissible level of impulse characteristics is exceeded, the controlling sensor disables the characteristics of the combustion intervals of the injection system.

What blocks the knock sensor from working?

The operation of the sensor is based on the piezoelectric effect. It reacts only to vertical vibrations. This allows you to effectively detect the passage of an unevenness and promptly report it to the controller. Because of this, many motorists make a mistake. If you disconnect the sensor, no changes in engine operation will occur. But after some time, fuel consumption will increase, and “shots” into the muffler will periodically be observed. And as a result, the destruction of the catalyst will occur with all the ensuing consequences. From all of the above, it becomes clear that its correct operation is very important.

For those curious, here are some technical data:

- Operating voltage 5 V (nominal);

- Mains current maximum 20 mA;

- Temperature values at which operability remains from -40° to 105° C;

- Resistance of the output connector is maximum 0.3 Kom;

- Acceleration limits range from -5g to 5g.

Article on the topic “How to check the knock sensor and what it affects.”

What to do with a non-working lambda probe

Why do you need a rough road sensor and how does it work?

Good afternoon. In today's article I will tell you why a rough road sensor is needed, how its malfunction manifests itself and why it appeared on all cars several years ago.

Short answer.

The rough road sensor is needed to temporarily disable the cylinder misfire diagnostic system so that the check engine light does not come on again.

How does the misfire check mechanism work?

Any injection engine equipped with a distributed fuel injection system has self-diagnosis for misfires.

It works very simply - the engine rotation speed per revolution remains quite stable in any case.

The engine rotation speed is checked using the crankshaft position sensor. It generates impulses at the moments when the teeth on the pulley pass by it.

If the sensor detects that the engine is not rotating evenly, a check is made for random or persistent misfires in a specific cylinder and based on this ignition, a warning lamp is displayed and an error code is recorded.

How does the rough road sensor work?

The rough road sensor, depending on the specific car model, is attached to the side member, frame or suspension elements. It works on the principle of a piezoelectric element - when deformed, it generates electrical impulses, i.e. just like the knock sensor.

If the level of deformation of the piezoelectric element is higher than the permissible level, a signal about driving on an uneven road appears at the sensor output.

Why do you need a rough road sensor?

Everything is extremely simple - when driving on an uneven road, a situation where the wheel may momentarily lift off from the surface is possible; naturally, this will instantly lead to a change in the engine rotation speed. Since the accuracy of determining the engine rotation speed is very high, the slightest deviation leads to a misfire error.

If there is a signal from the rough road sensor, the error control is temporarily turned off, and on some cars, the ignition timing is shifted towards a retardation, for more reliable ignition of the mixture.

When and why did rough road sensors appear on cars?

With the tightening of environmental requirements, especially after the massive introduction of the Euro 2 standard and exhaust gas converters (catalysts). All cars received a rough road sensor.

The thing is that unburned fuel very quickly renders the catalyst unusable. Accordingly, if the engine detects a misfire in a particular cylinder, the fuel supply in it is turned off, and this is done precisely to preserve the catalyst.

If misfires are detected randomly in different cylinders, the “check engine” warning light comes on.

If misfires are detected in different cylinders, but there is a signal from the rough road sensor, the warning light does not light up.

Conclusion.

That's all for me today. I hope the article, “Why is a rough road sensor needed, and how does it work?” fully answered the question.

If you have comments or if you want to add to the article, write comments.

Diagnostics

Checking the operation of the sensor can be carried out in 2 stages. To begin with, a regular system scan is performed using conventional equipment (car scanner or laptop with the program installed). On AvtoVAZ cars, the following errors can be seen when the sensor malfunctions:

- P1616

– low pulse value; - P1606

– the pulse has left the limited interval; - P1617

– increased pulse value.

In principle, this is already enough to determine the cause of the “check” that lights up. But in order to fully understand the cause, it is necessary to conduct a more in-depth diagnosis. To check, you will need a DST-2M

. You can use others that are similar in operating principle. Essentially, this is a scanner with advanced functions. It can also evaluate the response of the rough road sensor.

If this sensor is subjected to influence, for example, by knocking on it, it will react, and the scanner will display the acceleration value -g. It should be noted that the sensor is quite sensitive, so it should respond even to slight rocking of the car.

What is a rough road sensor used for?

There are also many misconceptions on this issue, and on the Internet there are simply tons of not entirely correct information on this topic about the need to use this sensor - from cruise control to ecology.

In fact, the rough road sensor initially had nothing to do with either cruise control or the environment.

Although it was still aimed towards ecology, it was not to protect the ecology itself, but to protect the catalyst that protects the environment.

So why and how does the rough road sensor protect the catalyst?

This has already been mentioned on the page How to remove a catalyst, but I will repeat it here.

The fact is that the catalyst is not a cheap thing, and according to statistics, most cases of its failure are associated with its overheating. Why does the catalyst overheat? It overheats not from exhaust gases, as many people think, but from misfires in the engine cylinders.

Note! A misfire is when, for some reason, the fuel-air mixture in an engine cylinder fails to ignite. This phenomenon is popularly called “engine trouble” and “misfire.” From my point of view, it is preferable to say “misfire” rather than “misfire,” since the mixture in the cylinder may not ignite not only due to ignition, but also due to the fault of the fuel system and engine hardware.

So how does misfire overheat the catalytic converter?

The fact is that the unburned mixture in the cylinder enters the catalyst and, as a result of catalytic neutralization, burns in it. In simple words, the mixture burned not in the cylinder, but in the catalyst.

Naturally, the more misfires, the more mixture burns in the catalyst and the more it overheats. I think this is clear.

Therefore, automakers were forced to find some way out.

Replacement

Installing a new sensor is not a difficult job. To carry it out you will need a minimum of tools, as well as a little time:

- The battery turns off;

- The spring clamp of the sensor is compressed;

- Remove the wire block from the sensor terminals;

- A pair of mounting screws is unscrewed;

- The sensor is removed and a new one is installed in the reverse order.

Thus, work to replace the sensor is carried out on Lada Kalina and Lada Priora.

On machines of other brands and models, this work may be performed differently. Manufacturers

.

If you have a foreign car, then it is better to purchase an original sensor from official suppliers. Even the most expensive models will cost relatively little. You shouldn’t save money and buy a Chinese “pig in a poke”; no one will guarantee the service life of the part. Several of our companies produce DND for domestic production. The most famous are Kaluga sensors and those produced in Zelenograd. Connoisseurs of German quality can purchase a device manufactured by BOSCH. Conclusion . There are many different control devices in a modern car. All this allows you to make the engine operate as optimally as possible. But not all devices are immediately accepted by car enthusiasts. Many, for example, do not know what a rough road sensor is needed for. But, despite its not very obvious operation, it allows the motor to maintain normal operation in any conditions.

What is a rough road sensor used for?

There are also many misconceptions on this issue, and on the Internet there are simply tons of not entirely correct information on this topic about the need to use this sensor - from cruise control to ecology.

In fact, the rough road sensor initially had nothing to do with either cruise control or the environment.

Although it was still aimed towards ecology, it was not to protect the ecology itself, but to protect the catalyst that protects the environment.

So why and how does the rough road sensor protect the catalyst?

This has already been mentioned on the page How to remove a catalyst, but I will repeat it here.

The fact is that the catalyst is not a cheap thing, and according to statistics, most cases of its failure are associated with its overheating. Why does the catalyst overheat? It overheats not from exhaust gases, as many people think, but from misfires in the engine cylinders.

Note! A misfire is when, for some reason, the fuel-air mixture in an engine cylinder fails to ignite. This phenomenon is popularly called “engine trouble” and “misfire.” From my point of view, it is preferable to say “misfire” rather than “misfire,” since the mixture in the cylinder may not ignite not only due to ignition, but also due to the fault of the fuel system and engine hardware.

So how does misfire overheat the catalytic converter?

The fact is that the unburned mixture in the cylinder enters the catalyst and, as a result of catalytic neutralization, burns in it. In simple words, the mixture burned not in the cylinder, but in the catalyst.

Naturally, the more misfires, the more mixture burns in the catalyst and the more it overheats. I think this is clear.

Therefore, automakers were forced to find some way out.

And they found a way out by teaching the engine control unit to detect misfires in each cylinder.

If the control unit detects repeated misfires in a cylinder, it completely shuts off the fuel supply through the injector of that cylinder. Thanks to this, the unburnt mixture no longer enters the catalyst and does not overheat it.

How does this process happen? Let's imagine in slow motion how the engine works. While the engine is running, the flywheel does not rotate evenly, but in jerks. That is, the first piston makes its push and the flywheel accelerates at this moment. Then it slows down a little until the third piston gives its push. Then the fourth and after the fourth - the second. This happens in a circle, but our eyes cannot catch it and it seems to us that the engine flywheel rotates evenly.

But the control unit is able to detect these shocks from each cylinder. And, let’s say, the third piston fails to push several times in a row, then the ECU will see this and shut off the fuel supply to this cylinder.

Everything is very simple and reliable. But…

Let's say the wheel of our car fell into a hole and slowed down/accelerated its rotation for a split second. What will happen?

And the following will happen. This wheel, through the transmission system, will transmit this deceleration/acceleration to the engine crankshaft, disrupting the cyclic rotation of the flywheel. The engine control unit may mistake this for a misfire! What to do?

It's simple - you need to inform the control unit that the car is moving on an uneven road.

It is for these purposes that a rough road sensor is installed! When the sensor signals a rough road, then the ECU does not detect misfires, but ignores irregularities in the cyclic rotation of the flywheel.

In simple words, on a rough road the ECU does not monitor misfires. And the rough road sensor informs him about a rough road!

brief information

In fact, not all motorists know about the true purpose of the rough road sensor. So if you are one of them, don't be discouraged. In fact, this strange device is surrounded by many rumors and even legends with which car owners try to explain its presence in the design of their vehicle.

Most often, motorists consider the main task of this sensor to be limiting speed while driving on uneven roads. But in fact, this opinion is completely wrong and is not at all related to the real purpose of the device. Remember: this device has absolutely nothing to do with the speed of movement on bumpy surfaces.

https://www.youtube.com/watch?v=ytadvertiseen-GB

Then why do you need a rough road sensor? You might be surprised by the answer to this question. However, in reality it is necessary to temporarily stop the cylinder misfire diagnostic system. In simple terms, it disables certain functions of the car so that the check engine light on the dashboard stops systematically lighting up.

Malfunction and solutions

The reasons for the occurrence of tripping and blinking “Check” are almost identical for all power units. The root cause may be improper formation of the air-fuel mixture or a breakdown in the ignition system. But, everything is in order.

Poor quality fuel

Low-quality gasoline, or in common parlance - “bad gas”, leads to the fuel supply elements becoming clogged, and the injection system itself forms a lean mixture. To diagnose and troubleshoot the problem, it is necessary to test the injectors. It is better to carry out this entire operation on a special stand. If it turns out that the elements are clogged, then we can say that the vehicle was operated on low-quality fuel.

Another reason could be a clogged fuel filter, which is recommended to be changed every 20,000 km. Also, it is worth examining the performance of the fuel pump, which may fail.

Ignition system

Breakdowns in the ignition system, namely malfunction of spark plugs, high-voltage wires and ignition coils, can lead to a tripping effect. So, you need to unscrew the spark plugs and inspect them for defects. Also, using a simple tester, measure the resistance of the high-voltage wires, which is 5 ohms.

Air supply

The formation of the air-fuel mixture is influenced by the state of the air supply. A clogged air filter element or throttle valve can cause a rich mixture, which can cause a tripping effect. To eliminate the malfunction, it is necessary to dismantle and inspect the elements.

If the air filter is clogged, it is recommended to replace it, but the throttle valve must be cleaned with a special product or liquid for cleaning carburetors.

Software problem

Repeatedly, the cause of the tripping and blinking “Check” is a malfunction of one of the sensors or accumulated errors inside the electronic engine control unit. So, it is necessary to diagnose the condition of the elements and replace damaged ones.

When and why did the sensor appear?

This device, unknown to many car owners, is found on most modern cars. All cars began to be equipped with a rough road sensor after stricter environmental requirements, and especially after the mass introduction of exhaust gas catalysts and the Euro 2 standard.

And all this is because unburned fuel quite quickly provokes failure of the catalyst. If the engine detects a misfire in a certain cylinder, the supply of fuel to it is stopped, and this is done to preserve the integrity of the catalyst.

If misfires are detected in different fragments, the “check engine” light on the dashboard lights up. But if the same thing happens, but with the participation of a rough road sensor, the light does not turn on.

Masses: Gazelle and UAZ (Part III)

I. N. Skrydlov, aka Aktuator

Masses. Part IMass. Part II

Attention! The article contains a large amount of graphic material. UAZ Patriot with Mikas 11 E2

UAZ Patriot with Mikas 11 E2

The negative battery is screwed to the body on the left mudguard, between the battery and the left headlight, onto a welded pin:

Copper braided engine grounding harness, screwed to the body onto a welded pin at the bottom of the left mudguard:

The harness is attached to the engine under the left engine mount, by one of the oil sump mounting bolts (bottom view):

The ECM ground is taken from the front bolt that holds the intake manifold halves together, next to the throttle pipe.

The ECM controller itself is mounted under the hood, in the rear of the right mudguard. The OBDII standard diagnostic block is located next to the controller.

Gazelle with engine 405, 406

The negative battery is screwed to the cabin mass, onto a welded pin on the platform, above the right side member, under the overhang of the engine shield. A braided grounding harness for the internal combustion engine is screwed onto the same stud. In some versions, there is a ground switch between the welded pin and the battery negative.

The second end of the braided engine grounding harness is screwed to the rear stud of the intake manifold halves, together with the ECM grounding:

The jumper grounding the frame is attached at one end to the cab under the left headlight, with an M6 bolt (together with the masses of the left part of the engine compartment harness),

and the second end to the frame, vertically from the first, on the left side of the frame with an M8 bolt.

The bolt goes through a hole in the frame, so to securely tighten the bolt connection, you must hold the head of the bolt from inside the frame, in front, through the tow hole. In practice, turnkey bolts of 10, 11 and 12 mm were encountered. The nut is always 13mm wide.

Gazelle with engine 4216

The minus of the battery is similar to the version with internal combustion engines 405 and 406. But the fastening of the braided grounding harness of the internal combustion engine is somewhat different. On the 4216 engine, the internal combustion engine grounding is attached to the head cover mounting stud on the rear of the engine. To avoid burns, it is advisable to tighten this fastening on a cold engine. 13mm key.

Frame grounding is similar to engines 405, 406:

The weight of the ECM (before 2010) is taken from the mounting pin of the internal combustion engine transportation eye, in its left front part. Wrench nut 15mm.

The photo also shows an additional braided harness from the frame to the indicated eye, but in my opinion, it would be more correct to secure it by analogy with the 405 engine.

Since 2010, the mass of the ECM is taken directly from the negative terminal of the battery:

Since in Gazelles the negatives on the EBN and rear lights are taken from the frame, unreliable grounding of the frame can cause the fuel pressure to depend on the number of external lighting lamps turned on (dimensions, stops, reverse, etc.).

And further:

Since 2010, a new type of fuse block began to be used on Gazelles:

And on the ICE 4216 there is also a new type of ignition coil, externally reminiscent of the VAZ ignition module for the ECM January 5.1.

The rough road sensor on vehicles with internal combustion engine 4216 is located in the front right part of the frame.

If the harness going to the DPM is not secured with ties to the generator belt tension bracket and the cooling pipe, it can be damaged by moving engine parts and ultimately cause a failure of the DPM signal processing channel in the ECM.

Let me give you an example of a mechanic's carelessness when replacing a generator.

The DND harness got caught between the tension bar and the generator pulley, which caused its damage and failure of the DND, MAP_a and TPS. In this case, the controller survived.

Volga, ICE Chrysler, ECM Motorola.

Jumper Minus battery - body and ground of the front engine compartment harness, mounted on a stamped protrusion, below and to the right of the left headlight

A thick grounding wire for the internal combustion engine is attached with an M8 bolt, key 13, to the left side of the engine block, under the intake manifold.

The controller masses are attached two to three centimeters above, with a bolt securing the oil dipstick mounting bracket. Bolt M8, key 13.

Volga, ICE Chrysler, ECM Mikas 11CR.

The difference from the Motorola ECM is the presence of an external generator regulator relay. The relay regulator is attached to the right mudguard.

The diagnostic connector of the OBDII standard on such Volgas is located at the bottom of the dashboard, near the driver’s left knee.

Anti-lock braking system

ABS (ABS) - the sensor is installed on each of two brake circuits: front left (right), as well as rear. In addition to the mechanical part, a block with electrical power is connected to the sensor. If the sensor malfunctions, it displays an alarm notification.

The price of each sensor is specified at the time of purchase. Often other parts and assemblies necessary for repairs are purchased

Always check the catalog numbers with the factory ones, pay attention to the cost. Original products are never cheap

In the maximum configurations of the Chevrolet Lacetti or on an individual order, the following installations are carried out: parking sensors, a shock sensor, and a rain sensor on the windshield. As well as other options that are not included with the basic models.

Problems when paying with bank cards

Sometimes difficulties may arise when paying with Visa/MasterCard bank cards. The most common of them:

- There is a restriction on the card for paying for online purchases

- A plastic card is not intended for making payments online.

- The plastic card is not activated for making payments online.

- There are not enough funds on the plastic card.

In order to solve these problems, you need to call or write to the technical support of the bank where you are served. Bank specialists will help you resolve them and make payments.

That's basically it. The entire process of paying for a book in PDF format on car repair on our website takes 1-2 minutes.

Source: krutilvertel.com

What blocks the knock sensor from working?

The operation of the sensor is based on the piezoelectric effect. It reacts only to vertical vibrations. This allows you to effectively detect the passage of an unevenness and promptly report it to the controller. Because of this, many motorists make a mistake. If you disconnect the sensor, no changes in engine operation will occur. But after some time, fuel consumption will increase, and “shots” into the muffler will periodically be observed. And as a result, the destruction of the catalyst will occur with all the ensuing consequences. From all of the above, it becomes clear that its correct operation is very important.

For those curious, here are some technical data:

- Operating voltage 5 V (nominal);

- Mains current maximum 20 mA;

- Temperature values at which operability remains from -40° to 105° C;

- Resistance of the output connector is maximum 0.3 Kom;

- Acceleration limits range from -5g to 5g.

Article on the topic “How to check the knock sensor and what it affects.”

Electronic engine control unit

The unit is installed in the engine compartment and secured with special brackets. AC power supply. The main function of the ECU is diagnostic, monitoring the operation of the power unit, identifying faults, and notifying on the central dashboard. To avoid negative consequences, the ECU transfers faulty units to emergency operation mode.

When you start the Chevrolet Lacetti engine, a number of indicators on the center console light up, after two seconds they go out, which indicates that all vehicle systems are working properly. If any of the indicators does not go out, it is obvious that the mechanism is faulty; prevention and diagnostics are required. After switching to emergency operation mode, engine power decreases, fuel consumption increases, the accelerator pedal becomes uninformative with periodic dips when pressed. Emergency exit is possible using software or automatically after the third trouble-free trip.

All system errors, even those that have already been eliminated, are recorded in the memory of the control unit. If necessary, they are read by a diagnostic scanner connected to a block under the steering wheel, to the right of the hood release lever.

Checking the ignition module with a multitester

Checking the ignition module in car services is carried out using an oscilloscope. The device allows you to accurately identify part faults. But if you suspect its breakdown, it is not necessary to contact a service station. You can diagnose the device yourself.

For diagnostics, it is recommended to use a multimeter and a test light. The first thing you need to do is check the fuse. To do this, you can connect a known-good element to replace the installed one or use a tester. The device should be set to voltmeter mode. The check is done like this:

- Disconnect the block with wires from the fuse;

- Place one terminal of the measuring device on terminal “A”, and attach the second to the ground of the motor.

If the fuse element is working, the multimeter will show a value of 12 V. If the voltage is different, it must be replaced. A broken fuse can also be noticed visually. The wires should also be tested. To check, the test light must be connected to contacts “A” and “B”. When the engine starts, the control indicator should light up. If this does not happen, there is probably a break in the wiring.

If diagnostics of the fuse element and wires do not reveal their damage, it is necessary to test the module. Checking the VAZ 2114 ignition coil with a multimeter is performed according to the following algorithm:

- Set the multimeter to ohmmeter mode.

- Connect the measuring device to the high-voltage wires of the first and fourth cylinders, then to the wires that go to the 2nd and 3rd cylinders.

If the part is in good condition, the device will show a resistance of 5.2 - 5.5 Ohms. If the values are different, it has failed and requires replacement.