The phenomenon, which car enthusiasts call jerking, occurs due to a sudden change in the crankshaft speed when the gas pedal is in a stable pressed position. If suddenly a VAZ 2110 jerks while driving, this causes anxiety and concern to the car owner.

We need to do something urgently, but first we need to understand the reason. We will talk about some features of jerks and signals that help you understand why they occur.

During the start

Most often, when starting from a standstill, the highest stage of the jerk is observed - failure, that is, a very significant delay in the engine’s response to the pressed gas pedal. It happens that the engine stalls. It’s especially unpleasant when you’re standing, for example, in front of a traffic light, and someone behind you is already honking, and you’re frantically starting the car again.

A jerk when starting off occurs when the ECU (electronic control unit) gives a signal to start opening the throttle valve, that is, when transitioning from the XX mode to the driving mode.

Throttle position sensor

Throttle position sensor

IN THIS WAY, THE QUANTITY OF FUEL SUPPLY THROUGH THE INJECTORS SHOULD INCREASE, WHICH DOES NOT OCCUR WHEN THE PRESSURE IS INSUFFICIENT IN THE FUEL LINE.

Potential culprits for the car moving jerkily when starting off:

- fuel pump , which is about to completely fail. This is evidenced by its peculiar periodic “howling” or an increase in its noise. The pump on an injection engine is listened to even before the engine itself is started - it is turned on initially from the battery, starting to pump fuel before turning on the starter. It is located inside the gas tank, so it becomes almost inaudible once the engine is running. In carburetor cars, the fuel pump is under the hood, you can hear it even when the engine is running;

- The fuel pump mesh is clogged with foreign particles that enter the gas tank along with low-quality gasoline at the gas station, or are formed in the tank itself due to condensation. This is why the gas tank should be flushed periodically;

- fuel filter , which is located under the hood. It also needs to be changed periodically;

- pressure regulator To replace it, you will need to remove and disassemble the fuel pump.

The first step is to check what pressure the fuel supply system produces. The check is carried out using a pressure gauge. It connects to a fitting located on the fuel rail (under the hood). We cannot give uniform readings, since it is different on different engines.

For some, a pressure below 325 kPa can be considered normal, while for others it is 400 kPa. That is, you need to look specifically at your instruction manual.

Engine power system

If the pressure gauge readings are too high, it means there is a malfunction in the fuel pressure regulator. If the readings are too low (less than 284 or 364 kPa, again, depending on the engine), replacing the fuel filter will help.

The car jerks when you sharply press the gas: why does this happen?

First of all, it should be understood that jerking and jerking when pressing the gas is most often associated with the quality of the fuel-air mixture.

The mixture can be lean or enriched. A fairly common situation during the operation of a vehicle is when failures occur when pressing the gas pedal, the engine stalls when over-accelerating, the power unit does not pick up speed, choke, etc.

Has your almost new car with a fuel-injected engine suddenly, for no apparent reason, started to jerk during acceleration? There can be many reasons for such a problem, but here we will consider mainly those that are related to the operation of an injection engine. This type of engine has a number of significant advantages over a carburetor engine. But at the same time, it is structurally more complex, and therefore there can be much more reasons for its malfunctions. In particular, the “injector” has an electronic control unit (“electronic brains”) that controls fuel injection, focusing on the readings of various sensors (controllers) of the engine condition. There are quite a few of these controllers, but jerking when accelerating the car can be primarily associated with a malfunction of the following of them:

- Throttle Position Sensor (TPS)

- Mass air flow sensor (MAF)

- Crankshaft position sensor (CPS)

Attention. The most unpleasant consequences occur due to improper operation, or - God forbid - failure of the DPKV

In this case, the injector will stall, and you will no longer be able to start it. Therefore, if you suspect that engine jerking is associated with DPKV, it is best to stop and check the operation of this sensor yourself

The most unpleasant consequences occur when the device operates incorrectly, or – God forbid – when the DPKV fails. In this case, the injector will stall, and you will no longer be able to start it. Therefore, if you suspect that engine jerking is associated with DPKV, it is best to stop and check the operation of this sensor yourself.

To do this, you need to connect a car oscilloscope to the output of the DPKV (located on the oil pump tide) and start the engine. If the DPKV is working properly, clear pulses of the injector operation will be visible on the oscilloscope screen. If the pulses are blurred (or not visible at all), then it is better not to risk it and immediately get to the service station, where you can carry out computer diagnostics of this and, if necessary, all other controllers. Such diagnostics can also reveal malfunctions in the operation of the oxygen sensor (lambda umbrella) or electric injector valve, which are also a common cause of engine jerking. The second group of causes of jerks in engine operation are malfunctions in the injector ignition system. These include improper operation of the ignition module, as well as spark plugs, ignition coil and high voltage wires. Therefore, experienced drivers always have a set of spark plugs and an ignition coil in stock, which most often fail.

The last large group of causes of car jerking are various malfunctions of its fuel system, for example, irregular operation of the fuel pump due to clogged fuel filters or the formation of air locks in the fuel hoses. A specific malfunction of the injectors, leading to jerking of the car during acceleration, is clogging of the fuel injectors. Having very small holes, when using low-quality gasoline, they often become clogged and require cleaning. You can do this yourself, using the tips of specialists, but it is better to clean the injectors with ultrasound at a service station.

A serviceable car is the key to traffic safety on the road. However, unexpected interruptions while driving can cause particular trouble. Such problems include a situation where the car jerks during acceleration, or interruptions occur when driving at low speeds.

The best way to get rid of surprises is prevention and correct diagnosis. With their help you can avoid expensive repairs.

It is difficult to carry out diagnostics with an unevenly running car that is idling. The correct solution would be to identify interruptions during its movement. To do this, select a straight section of road without heavy traffic.

While driving, we shift gears one by one. At each switched-on stage, sharply depress the accelerator pedal. The power plant must respond sensitively to all the driver’s efforts. In those cases when the car jerks when you press the gas pedal or does it without any effort, the vehicle needs a more thorough inspection of individual components. It all depends on the specific behavior of the car.

Why does the 16-valve VAZ-2112 stall when accelerating?

Repeatedly, many drivers were faced with the fact that the 16-valve VAZ-2112 began to become dull during acceleration or a drop in speed was felt. This may be due to various reasons that you need to know how to eliminate.

The video shows the process when a VAZ-2112 was tripping, did not pick up speed well, the check engine light came on periodically, and a solution:

Fuel quality

Adjusting valves on a VAZ 2110 8 valve injector

The use of high-quality gasoline or diesel fuel is the key to long-term engine life and obtaining maximum power indicators from it. But none of the drivers is completely immune from refueling with low-quality fuel, the use of which threatens not only a significant reduction in power indicators, but also the inability to start the engine. Regular use of low-quality gasoline manifests itself in intensive formation of carbon deposits on the cylinders, pistons, catalyst and exhaust manifold, as well as increased wear of the cylinder-piston group.

A car with a carburetor jerks at low speeds

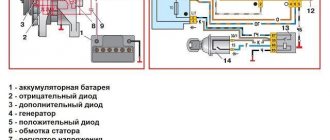

Wiring diagram of VAZ 2114 injector 8 valves with description

To reduce the length of the text, our editors omit standard checks of the transmission, lines and ignition. If all systems are functioning normally, but the jerking continues, reconfiguration and carburetor cleaning are required.

This is important, since a small speck that gets into the nozzle can completely upset the calibration of the unit. The unit is dismantled and wiped clean of dirt.

Next, you need to sequentially disassemble the entire system and thoroughly rinse it from possible debris with clean gasoline. After cleaning, all internal passages and inserts are purged with a compressor, which guarantees 100% cleanliness.

The last step is reassembly and installation on the engine.

VAZ 2109/08/99 and 21074 carburetors are especially sensitive to such “sores”.

Frequent malfunction: the engine does not gain speed and what should the driver do?

Lost engine thrust on VAZ 2114 (8 valves, injector)

If the engine has stopped gaining momentum, then the first thing you need to do is analyze when and how this manifested itself. In other words, the unit suddenly stopped spinning up or the problem with speed gradually progressed

You should also pay attention to the presence or absence of other symptoms

The fact is that the failure of a previously serviceable engine to gain speed after any repairs or other manipulations may simply be the result of assembly errors, a not connected sensor, etc. In such cases, the malfunction can be quickly and accurately determined after an independent inspection or immediate return of the vehicle to the service center where the car was previously repaired.

If you are faced with the fact that the engine stalls for no apparent reason, does not pick up speed, the car periodically stalls, etc., then in this case the engine needs in-depth diagnostics. The causes of such a breakdown can be divided into simple and complex, arising immediately or having received prerequisites.

The engine does not pull, where to look for the reasons

In the life of motorists, a situation often arises when, when driving out onto the road and trying to accelerate, it is noted that the engine does not pull.

That is, the acceleration dynamics are very “sluggish”, the car is reluctant to pick up speed, and it feels like something is holding it back.

This problem can arise with almost any car - domestic or foreign, gasoline or diesel, with a carburetor power system and injector.

Often, a drop in traction is accompanied by additional symptoms - extraneous sounds appear when the engine is running, the engine may stall in one of the modes (usually at idle), the crankshaft speed is not stable and “floats”.

But this is not always the case; it happens that the unit behaves perfectly in all respects, but does not develop power.

Fuel pressure regulator is faulty

It is impossible to achieve the desired speeds when accelerating a vehicle if the product does not correctly “perform” fuel return. The moment of release occurs provided that the pressure has exceeded the standard parameters. If the regulator is faulty, fuel will begin to flow back into the tank prematurely. That is, when accelerating a car, it will not reach the required speed, since the power of the propulsion system will drop.

Check the serviceability of the regulator using an air pump. For the control process, it is necessary to prepare a special rail and air blower. It can be not only a pump. It is recommended to use a compressor to speed up the action. While pumping air, monitor the readings of the rack. When the regulator operates, look at its readings. When it operates before reaching the control mark, it must be repaired or replaced with a new regulator.

Experienced motorists claim that a cracking sound appears in the engine compartment due to a faulty fuel regulator.

Causes of poor speed gain

General view of the engine under the hood

So, let's look at what the problem is and where exactly you need to look for it:

- Fuel pump and pressure.

- Injectors.

- Fuel rail.

- Ignition system.

- Electronic control unit.

Now that all the causes are predetermined, you can begin sequential diagnosis and methods for solving the problem.

Options for solving the problem

To diagnose all of the above systems you will need a set of wrenches and screwdrivers, a tester, a little knowledge and hands growing from the right place. The main task remains to correctly distribute the sequence of operations. This is exactly what we will talk about next. So, let's look at where we need to go to remove the effect that has arisen.

Setting the OZ on carburetor engines

The simplest and most effective way is to use a regular 12-volt light bulb.

Algorithm of actions:

- Rotate the crankshaft pulley until the marks match (on the cover - this is the central mark) using a special spanner. If it is not there, turn on 4th gear and push the car until the marks match.

- From the ignition breaker (distributor), disconnect the thin wire going to the coil and attach a light bulb to it, the second contact of which is connected to ground.

- Loosen the nut securing the distributor (usually it is a “13” wrench).

- Turn on the ignition, make sure that the lamp is on, and slowly turn the distributor around its axis until it goes out.

- Now turn the distributor again until the light flashes, and immediately tighten the distributor fastening nut.

Signs of engine tripping

Regardless of the reasons, engine tripping is associated with the presence of various problems, which can be solved after finding out what caused the stoppage of one of the cylinders of the internal combustion engine.

The main signs of engine tripping include

Signs

Auto mechanics identify several reasons why jerking occurs and the engine begins to stall. The main ones are: incorrect ignition timing, faulty spark plugs and installed condenser, broken piston rings, piston and valve burnout, rocker wear, clogged air filter, and others.

The cause of the jerking must be sought in the cylinders

To reduce the search for the cause of engine tripping, it is recommended to determine which cylinders are not working correctly or have stopped functioning. To do this, you will need to remove the high-voltage wire from the spark plugs one by one.

This procedure must be performed carefully, as there is a risk of electric shock. Before performing this work, you will need to place a dielectric base in the form of rubber or wood under your feet.

It is recommended to remove by the wire. Then the engine speed increases to 1500 rpm. The valves are removed from the cylinders one by one. If the sound of the vehicle changes when removed, then the cylinder is working correctly. Otherwise, it must be replaced.

Carburetor cars

The first step is to disassemble and clean the carburetor itself. In this matter, you will be helped by instructions for the repair and maintenance of your car, which are very easy to find on the Internet.

Disassemble the carburetor with care so as not to lose small parts: springs, screws, nuts and washers

All metal parts needed:

- Collect in one container, preferably metal or glass;

- Fill with cleaner;

- Let it sit;

- Rinse them with water and wipe with a dry cloth.

The outlets in the carburetor must be cleaned using compressed air or a special aerosol. Do not try to clean these holes with metal tools, as this may cause them to become deformed. After cleaning and drying all parts, the carburetor should be assembled and adjusted using the same repair and maintenance instructions for your car or the almighty Google.

The next thing we check is the fuel system. We need to see if it is clogged:

- Gasoline coarse filter;

- Fine filter;

- Gasoline pump.

If there is visible contamination, the parts need to be cleaned or replaced with new ones.

Next, it is recommended to check the electrical circuit of the car:

- Ignition coils;

- Spark plug tips;

- BB wires and spark plugs at the time of breakdown.

If necessary, replace faulty parts. The candles, of course, can be cleaned, but this will not bring any tangible results. If it does happen, it won't last long.

Correctly set ignition is also of considerable importance. You can configure it yourself (if you know how). If you have never encountered this, you can read literature on this topic or ask your comrades for help, or again, the omnipresent and omniscient Internet will help you.

After carrying out the above steps, the problem should be resolved. If this does not happen, then you should contact professionals.

VAZ injection engines

In injection engines VAZ-2110, 2112, 2114, 2115, both 8-valve and with a timing belt with 16 valves, it is more difficult to identify the cause of the decrease in power due to the more complex design of the main systems.

Supply system

Any injector consists of a mechanical executive part and an electronic control part, and problems can arise in both of them, which will lead to a drop in power.

Let's look at the mechanical part first. Here, cravings can be influenced by:

- Severely clogged mesh filter on the fuel pump;

- Decrease in fuel pump performance due to wear;

- The fine filter is dirty;

- Malfunction of the fuel rail pressure regulator;

- Clogged injectors;

- Fuel filter dirty;

- Air leak in the manifold.

In general, almost every element of the injector executive part can be the culprit for a decrease in dynamics.

The situation is approximately the same in the electronic component.

The operation of the engine with the injector is controlled by an electronic unit, which constantly monitors the parameters through sensors installed on different systems.

Why does the car jerk when accelerating?

All passenger cars with gasoline engines in use today are equipped with either injection or carburetor power units. The second type of internal combustion engine is now considered almost “rare”, but in Russia (especially in the provinces) there is still quite a lot of such equipment “on the move”. Therefore, considering the possible reasons why passenger cars can jerk and accelerate jerkily, it makes sense to start with them.

Carburetor engines

These power units, compared to more modern, injection ones, are simpler in design, all their “weak points” have been well studied, and therefore it is not so difficult to find the reason for their unstable operation at the stage of starting and accelerating the car. Experienced engine specialists with knowledge of the matter claim that cars with carburetor engines most often jerk due to problems such as:

- Dirty fuel or air filter;

- Problems with the fuel pump;

- Malfunction of the fuel pressure regulator.

Thus, those owners of cars with carburetor engines whose cars began to twitch when starting the engine and accelerating should, first of all, check exactly those parts, components and assemblies that are listed above.

If it turns out that everything is in order with them, then you need to pay close attention to the ignition system. In carburetor engines, its malfunctions are also often the causes of jerking

Practice shows that in cases where, when you press the accelerator pedal, the car refuses to accelerate (as drivers say in their professional slang, it “fails”), it makes sense to thoroughly check the ignition coil, as well as the high-voltage wires connected to it.

In fact, it often turns out that these parts begin to “punch through”, and therefore the engine “troubles”. The solution to the problem in this case is to replace the faulty part.

Another fairly common problem is banal carbon deposits in candles. It leads to the fact that the spark does not occur when it should (and sometimes does not occur at all), which leads to jerks during acceleration. The way out of this situation is to clean or replace the spark plugs.

Injection engines

Gasoline power units of this type have significantly better operational and technical characteristics than carburetor units, but their design is much more complex. Accordingly, there are much more reasons why a car may jerk during acceleration.

The main feature of an injection engine is that a special electronic unit regulates the flow of the fuel mixture into its combustion chambers. Several sensors are involved in this process, namely:

- Throttle position;

- Mass air flow;

- Crankshaft positions.

A malfunction of any of them may cause the car to jerk when starting the engine and accelerating. It is interesting that if serious problems arise with the crankshaft position sensor, the injection system is often turned off completely, and then it is impossible to start the engine at all.

It goes without saying that the reasons for jerking during acceleration of cars equipped with injection engines can be the same as for carburetor engines, that is, clogged filters, problems with spark plugs, ignition coils and high-voltage wires, as well as fuel system elements (including and clogged fuel injectors).

It should also be noted that one of the common reasons for a car to jerk when starting the engine and accelerating is the use of low-quality fuel. As a result, a lean fuel mixture is formed, and the engine begins to operate very unstable, in particular, jerks appear during acceleration. This applies equally to both carburetor and injection power units.

Power drop on a VAZ carburetor engine

To begin with, let's take VAZ cars with a carburetor power system and an 8-valve timing system - VAZ-2109, VAZ-2110, VAZ-2114, VAZ-2115.

The same power plant is installed on these cars, so the reasons are identical.

Let's go through those components, due to malfunction of which a drop in dynamics may occur.

In general, the main reason that the engine does not pull is a change in the processes in the combustion chambers - a mismatch in the proportions of the air-fuel mixture, the combustion process is disrupted, the filling of the cylinders and the removal of exhaust gases does not occur as required.

Supply system

Very often, a drop in traction occurs due to the power system. Structurally, the carburetor fuel system used on cars from VAZ-2109 to VAZ-2115 is very simple and is almost completely mechanical, so identifying the cause is not particularly difficult.

A decrease in power can occur due to:

- Severely clogged fuel filter (its throughput drops and the pump is simply not able to pump the required amount of fuel);

- Contamination of the carburetor channels (the jets and fuel channels in this element have a small cross-section and debris often clogs them);

- There is air leakage in the area from the tank to the pump (because of this, the performance of the fuel pump drops sharply);

- Damage to the fuel pump membrane (a small crack in it leads to the fact that the vacuum required for pumping fuel is not created in the pump chambers);

- The fastening of the carburetor or intake manifold is loose (due to this, air leaks around the carburetor and the proportion of the air-fuel mixture is greatly disturbed);

- The hole in the fuel tank cap is clogged (because of this, a vacuum is created in the tank and it is much more difficult for the gas pump to pump gasoline out of it);

In addition to the elements responsible for supplying fuel, a drop in power also occurs due to severe contamination of the air filter element.

Ignition system

This system also takes part in the combustion of the mixture, which means a failure in its operation can affect power.

In carburetor engines VAZ-2110 and others, a decrease in traction can occur due to:

- Faulty spark plugs or changes in their thermal gap;

- Excessive wear of the contacts and the central electrode of the distributor;

- Voltage losses in high-voltage wires;

- Violations of the ignition timing.

Irregularities in the power supply and ignition systems most often cause a drop in power, so testing to identify the cause should begin with them.

If the operation of these systems does not raise suspicions, other components of the engine should be diagnosed.

Exhaust system, timing belt and crankshaft

Loss of traction can also occur due to the exhaust gas removal system, although problems with it rarely occur on carburetor engines.

The main reason here is the reduction in throughput due to large deposits in the muffler. Because of this, exhaust gases, without having time to escape from the cylinders, “choke” the engine.

The reasons for the drop in thrust are also often the gas distribution mechanism and the cylinder-piston group.

Here the reduction in power occurs due to:

- Violations of the thermal clearance of valves.

- Heavy carbon deposits on the valve plates and seats, or their burning.

- Occurrence of rings.

- Limit wear of the CPG.

- Cylinder head gasket failure.

In general, problems with the timing belt and CPG cause a drop in power in any engine - carburetor, injection, diesel. Therefore, we will not mention these mechanisms further.

Recommendations

Comments 14

In general, 2 weeks ago I had the same song... And the car is also 2003. In general, yes. I thought the worst too. I was looking for a diagnostician. But first I checked the marks, everything is ok. And the same crap. not noticeable on the first one. Perfect at idle. It doesn’t move until 2000 rpm, but from 2000 it pulls it out from under you. I'll go to the diagnostician. Luckily I got a normal guy. I didn’t bother to pull my mu by the front. I immediately removed the armor wires, took out a tester and measured the resistance. It wasn’t on two wires at all, but on two wires it was 7th. I couldn’t believe my ears. For the New Year, I changed the spark plugs and wires. They're still new. And the dick is there. They sell a lot of shit in stores. changed the wires. bought for 1000 rubles. The problem went away immediately. So far it's driving fine. But I immediately gave up the candles as a preventive measure. Check the resistance on the wires.

Thank you. Let's check it out. what should the resistance be?

well...I have 7 ohms. showed. And there, who the hell knows what the ideal is.

Why does the car jerk when driving at low speeds?

If the defect is noted when the vehicle is driven at low engine speeds, the reasons can also vary greatly. More often we are talking about failures of the fuel supply system, but the breakdown may lie in other components.

Supply system

This unit most often suffers when the wrong air-fuel mixture is supplied. If the car jerks when driving at low speeds, you will need to check the following:

- Condition of the throttle body: there may be cracks in it.

- Serviceability of idle speed sensors.

- Tightness and cleanliness of injectors.

- Condition of air ducts, percentage of wear.

If the diagnostic steps reveal that there are problems with these parts, it is recommended to immediately install new parts. After servicing, it is necessary to check the quality of connections, tightness, and pressure level in the fuel unit.

Ignition system

The malfunction may lie in premature ignition of the air-fuel mixture, or less often we are talking about low voltage on the spark plug elements. During diagnostics, the following is checked:

- Serviceability of the ignition coil.

- Condition of the candle set.

- No mechanical defects in wiring.

- Distributor functionality.

- The camshaft and crankshaft sensors are correct.

- Switch health.

Often twitching is caused by installing candles of the wrong size or by violating the installation technology. Replacement will help get rid of the unpleasant phenomenon.

Transmission

If the owner performs gearbox maintenance too rarely and does not observe the lubricant change interval, the car begins to twitch when driving at low speeds. The malfunction is especially typical for cars with automatic transmission and robotic gearbox. With a total mileage exceeding 150–200 thousand, noticeable jerks often appear. As a result, the oil in the gearbox begins to foam, the solution becomes thicker or, on the contrary, thinner. It is better to restore the gearbox at a service center; it takes an average of 3–4 hours. It’s better not to carry out the work yourself: you don’t always have the right tool at hand, and besides, this task is not an easy one, especially if the box has an automatic design.

Accelerator

When a driver quickly presses on the gas, the number of revolutions of the power unit immediately increases, which can cause a decrease in the efficiency of the vacuum regulators. After this, if the engine starts to operate at low speeds, its distributor falls, and the vehicle moves jerkily. With continuous combustion of fuel, the driver strives to increase the speed of the internal combustion engine; this cannot be done quickly if the regulators malfunction or fail completely. As a result, if the oxygen flow is not supplied synchronously and the damper is opened, the fuel does not burn immediately, which can damage the advance angle bearing.

During repairs, the regulators are first diagnosed: the hoses with pipes are removed, covering them manually. If there is no vacuum during engine operation, the reason is a damaged throttle valve. The part should be replaced, and then the car should be tested.

Sensors and their malfunctions

Separately, it should be said about the VAZ-2110-2112 sensors. Their number has increased significantly after the use of an injection power supply system for power plants. Each sensor must be reported separately. Crankshaft position sensor.

This sensor is quite reliable and rarely fails. But if it does, there are a number of signs indicating this. If the sensor is not working, the power unit starts poorly, operates unstably, the unit itself loses power and detonation occurs during operation. Problems with the performance of the sensor are eliminated by replacing it.

What does the manufacturer say about the roar of the engine?

Hyundai automotive power plants are installed on imported cars. The engines are not equipped with anachronistic carburetors, but with electronic fuel injection systems.

The manufacturer has prepared a list of possible malfunctions of injection engines:

- Malfunctions occur when the performance characteristics of the fuel mesh filter are reduced.

- Reduced technical characteristics of the gasoline pump.

- The engine injection nozzles are faulty.

- Poor tightness of the lines allows excess air to enter the combustion chambers of the cylinders.

- The ECU and ECM sensors are not precise in their actions.

- The ignition system was damaged.

These other faults can create problems when accelerating cars. In some cases, the propulsion system growls, thus signaling a problem.

If the diesel engine doesn't work

A decrease in traction can also occur in diesel engines. If we look at old cars that have completely mechanical power systems, then the most common cause is depressurization of the system.

As a result, air enters the fuel, which is why the fuel injection pump is unable to provide the required pressure.

- clogged filters;

- weakly pumping fuel priming pump;

- damaged plunger pair;

- Coking of injector nozzles.

And if we also add possible problems with the timing belt and CPG, then identifying the cause will not be so easy.

In modern diesel installations, where an additional electronic component is used, the search range will increase.

For example, the Common Rail system uses all the same sensors as the injection engine. And if at least one of them breaks, this will certainly affect the operation of the control part.

Causes

There may be several reasons for the lack of proper speed gain:

- There are problems with the air supply;

- The ignition has failed;

- Fuel system malfunctions have occurred;

- There were problems with the exhaust system.

Fuel system problems are common in gasoline engines. They are the most common. Therefore, you should start with checking it.

Fuel system

If problems arise when accelerating the car, start checking by inspecting the fuel system.

- Most often, the engine stops gaining momentum because the fuel pump fails. At first, this may have a slight effect, sometimes unnoticed. Over time, as the pump wears out, the speed and power will begin to drop, and the acceleration dynamics will decrease.

- If the fuel pump is partially damaged, it still partially performs its functions, but is no longer capable of delivering the same volumes of fuel. This results in fuel starvation and power loss.

- The best solution to a problem with the pump is to replace it. It is better to trust repairs to specialists.

Ignition

If the ignition fails, you will have to conduct a comprehensive check of all system components that may cause a drop in engine power and speed.

What to check

Peculiarities

Checking timing marks

If the marks are installed incorrectly, fuel will not be injected in a timely manner, and the correct frequency of spark supply will be disrupted.

You will have to check all the sensors that take part in the operation of the ignition system

Pay special attention to the crankshaft and camshaft position sensors. A regular test allows you to quickly determine whether the sensors are really to blame

If the belt has been in use on your vehicle for a long time, it may be at the end of its service life. Or it was installed incorrectly when replacing it. After all, it is enough to make a mistake by one tooth, and the performance of the car will be impaired, the car will not be able to accelerate properly

In some cases, they do not allow the car to start at all if there is a malfunction, but sometimes they lead to a noticeable drop in power. Remove them, check their condition, clean them, measure the distance between the electrodes. If they fail, simply replace them with new ones.

Chassis and transmission

The chassis of the 10th family did not show its best side. Problems with it arise after about 40 thousand km.

Shock absorbers on a car, approaching this mileage mark, are already beginning to fail. Moreover, they don’t just sag, they begin to flow.

The next chassis elements that require replacement at 40 thousand km are ball joints. Next to the bearings, the hub bearings will require replacement.

After replacing the shock absorbers, supports and bearings, you should not relax; a little later, at about 55 thousand km, the external constant velocity joints - CV joints - will begin to make themselves felt and require replacement. The main element of the transmission, the gearbox, as a whole, did not cause significant problems. However, such a nuisance often arose as the difficulty of engaging second gear.

Not everything is in order with the gearbox control drive either; the weak link of the drive was the plastic bushing of the rocker. Well, in general, the owners note a slightly increased noise level of the box. The brake system, in addition to replacing consumables, often “pleased” with the weakening of the handbrake cable tension, but otherwise there were no serious problems with this system.

Main reasons

Many owners are scratching their heads, inventing reasons for the drop in engine power. Unfortunately, it is not immediately possible for even experienced specialists to make a correct diagnosis as to what caused the drop in engine power. This malfunction should be corrected as soon as possible to avoid even more serious consequences and costly repairs.

The main reasons for the deterioration of ICE traction include:

Air filter clogged

– it is worth noting that for replacing the air filter, regulatory periods have been established, calculated for the average operating conditions of vehicles. In the summer, many motorists quite often go out of town, where, as a rule, dirt roads predominate. If you are on the road, looking in the rearview mirror, and periodically notice a plume of dust accompanying your car, then be prepared for an emergency filter replacement.

Electrical interruptions

– the control unit is responsible for the electrical part of the machine. It controls the injection of the fuel mixture, is responsible for its ignition at the right moment, and monitors the performance of all sensors. One of the common cases when a car loses its power is when either a too lean or too rich fuel mixture gets into the engine cylinders. It is obvious that one or more sensors are not working properly. Engine diagnostics will help deal with the problem, as a result of which the mixture parameters will become known, and based on them, conclusions will be drawn about the causes of the malfunction.

If there is a drop in power when the engine heats up, then diagnostics will also help make the correct diagnosis.

Difficult operation of the intake and exhaust system

– various obstacles encountered in the path of the intake and exhaust systems inevitably lead to a drop in power. So, in addition to a clogged air filter, damage to the catalytic converter can “choke” the engine.

Its internal structure resembles a honeycomb, which becomes clogged over time and impedes the passage of exhaust gases. The situation can be corrected by replacing the neutralizer.

Failure of the ignition system

– often a decrease in engine power occurs due to the fact that the spark plugs do not supply a spark in a timely manner. Ignition delays or advances inevitably lead to interruptions in the operation of the internal combustion engine. If you notice not only a deterioration in the car's power when accelerating, but also strong engine vibration at idle, then the first thing you should do is check the condition of the spark plugs.

If one of them turns out to be non-working, you need to replace it. However, this does not always solve the problem. Installing a spark plug can only temporarily eliminate the problem, which will appear again after a few days. Then it becomes obvious that the issue is not the candles. The next element that comes under suspicion is the high-voltage wire connecting to the non-functioning spark plug. It is probably partially burnt out from the inside and returns to service only when working with new spark plugs, without ceasing to spoil them. A new set of high-voltage wires will help correct this kind of breakdown, after installing which the cause of the interruption should be eliminated.

Violation of valve timing

– it happens that the camshaft pulley jumps one tooth of the timing belt, and the valve timing is confused, and this causes a sharp deterioration in the traction of the internal combustion engine.

Air conditioner operation

– loss of power can be observed when the air conditioner is turned on. This disadvantage is typical for many vehicles and is especially noticeable in cars equipped with liter engines. If, with the air conditioner turned off, the car demonstrates good dynamics and rapid acceleration, then you have no reason to worry.

Engine problems

– this could be a malfunction of the hydraulic compensators, burnout of the valves, or violation of the gaps between them.

A drop in power that occurs gradually can be caused by a decrease in compression in the cylinders. This is a reason for a more detailed inspection of the motor and its internal components.

Power plants

Let's start with the “heart” of these models – the engines. These cars were equipped with several engines with different technical equipment and performance. The first models that rolled off the assembly line had power plants that were not much different from the engines of previous models - VAZ-2108-2199. It was a 4-cylinder 8-valve unit with a carburetor power system. Later it was replaced with the same one, but with an injection system.

There were also 16-valve engines, and there were even models with an Opel engine. In general, all engines performed well and their reliability was good.

Weak points of motors. The main weak point was the timing belt. He rarely covered the 60 thousand km specified in the maintenance regulations.

Therefore, on VAZ cars it is necessary to promptly replace the timing belt. Moreover, the difficulty of restoring the latter’s performance directly depended on the type of engine.

If 8-valve engines survived belt breaks without problems, then 16-valve engines caused a lot of trouble for owners. For models with these power plants, when the belt broke, the pistons collided with the valves, causing the latter to bend.

The injection power system was relatively reliable, like the carburetor system; it only required timely replacement of the fuel filter and refueling with more or less high-quality fuel.

VAZ 2110 car owners also note that the engine mount is easily loosened, in particular the rear engine mount. Even if the car was purchased from scratch, after a year many noted problems with the cooling system, which is already recommended to be flushed.

Also, the clamps securing the pipes become loose and coolant leaks appear. Over time, the rubber pipes also lost their elasticity, which led to the appearance of cracks in them.

Another weak point of the cooling system was the expansion tank. The appearance of cracks on it is a matter of time.

Exhaust system and EGR

A malfunction of the exhaust gas recirculation system, as well as deterioration in the throughput of any elements of the exhaust system, can also affect engine power and speed. Due to the deterioration in the flow of exhaust gases, the pressure in the exhaust system increases, the engine literally begins to “suffocate”, as a result of which it significantly loses power, and in more advanced cases is not able to develop high speeds, or even start at all.

The first thing to check in the exhaust system is the condition of the catalyst or particulate filter. Their function is precisely to filter car exhaust. Therefore, you should not be surprised that they often become clogged. To check the catalyst, you can try unscrewing the spark plug, starting the engine and pressing the gas pedal several times. If there is a sharp increase in speed, the problem is in the catalyst. To learn more about a car catalyst, what it is, signs of failure, methods for checking the converter, as well as other information related to it, follow this link.

Also, one of the reasons why the car does not pick up speed when you press the gas pedal may be a layer of carbon deposits on the walls of the exhaust manifold. This can happen due to excessive oil consumption by the engine. In this case, its remains will end up in the collector and burn out there. Over time, carbon deposits, gradually accumulating, actually reduce the diameter of the pipe, in some cases by up to 3-4 centimeters.

The car does not pick up speed - what to do?

Having discovered that the car does not gain speed when you press the gas pedal, it does not matter whether it is a VAZ 2110 injector or another, you need to immediately determine the reason. To do this, just look at the instrument panel, and also use your hand to determine the selected speed by the position of the gearshift lever.

Gear lever

There are 4 indicators that are important to you on the instrument panel:

- speedometer;

- tachometer;

- engine temperature indicator;

- Check Engine icon.

All engines that were installed on the VAZ 2108–2115 are high-speed, that is, their maximum torque is achieved at 3–4 thousand rpm. If you are driving up a mountain and the revs on the tachometer are noticeably lower, then you have found one of the reasons for the weak traction. If you have a car without a tachometer, then learn to determine engine speed by ear or install this device as an additional device.

Remember, direct (fifth) gear is only for smooth driving on flat roads at speeds over 100 km/h; if you are driving uphill or about to overtake, engage a lower gear.

Perhaps the engine will pull the car in fifth place, but this will negatively affect the engine and will also significantly bring its overhaul closer. If you are going to overtake at a lower speed, go to third or second gear.

After making sure that there are enough revolutions and that the weak traction is not due to them, look at the thermometer, which should show approximately 95 degrees; if it does not have numbers, then its needle should not enter the red zone or be below the 50 degree mark. Remember, if you accelerate too much on a cold engine, its service life will sharply decrease, but even short driving in overheating mode damages the cylinder head.

Instrument panel VAZ 2114

If the readings of all sensors are normal, including the Check Engine icon and the gear is selected correctly, and the car does not gain speed, it does not matter whether it is a VAZ 2114 or another, the reason is something else.

If the Check Engine light comes on, then on your own or using a tow truck, get to the nearest car service center and conduct computer diagnostics to determine the problem.

What to do if everything is normal according to the instruments

After making sure that the instruments show normal values and the car is moving without overload, stand on the side of the road, then put up a warning triangle (triangle) and turn on the hazard lights. Then follow these steps until you find the reason why the car is not picking up speed well, it doesn’t matter whether it’s a VAZ 2109 injector or some other one.

- Check the air filter, it should be clean and white, if it is very dirty, remove it and try driving like this, increased traction will confirm that the problem is there.

- Ask an assistant to sit behind the wheel and press the gas pedal sharply and all the way several times, immediately releasing it, while you watch the movement of the throttle valve. If it does not open completely, then there is a problem with its drive, which means that the cable needs to be replaced or the drive mechanism needs to be repaired.

- Unscrew all the spark plugs (be sure to remember the order in which the wires are connected) and carefully inspect them - black contacts indicate either a malfunction of the spark plugs or serious engine problems. Replace them and see if the car's behavior changes - an increase in speed will confirm that the problem is in the spark plugs, and if the car still does not gain speed when you press the pedal, it doesn’t matter whether it’s a VAZ 2110 injector, or any other model,

- If there is a car shop nearby, buy a compression gauge and measure the compression in the cylinders; 10 atm (bar) or below when hot means that the engine cannot pull because it is badly worn out and needs urgent major repairs. If it is impossible to buy a compression tester, take a clean white rag and place it next to the exhaust pipe so that the smoke goes directly to it. Then ask your assistant to start the engine and press the gas pedal firmly and sharply several times, immediately releasing it. Blue or white smoke, as well as oil stains on a rag, indicate that the engine needs urgent repairs.

- Do you remember if you recently filled up with gasoline? If yes, then the reason may be bad fuel; ask the nearest car service center to drain it and fill it with normal fuel. Improving the behavior of the car will confirm that the car does not gain speed, no matter whether the VAZ 2110 has an 8-valve injector, or any other, due to low-quality fuel.

What can carburetor car owners do?

If you are the owner of a carburetor car, you can check the amount of fuel in the float chamber. With the cover with the floats removed, the distance from the plane to the fuel should be 22 mm; if you find a difference in any direction, adjust it by pressing the tongue of the floats, and then, after removing excess fuel, reassemble the carburetor. Pump up the fuel 5–10 times, then remove the cap again and measure the level - a strong excess indicates that the needle or floats are faulty. If you know how to change them, then replace them and check the operation of the engine - an increase in power will confirm that you have found the reason why the VAZ 2110 car does not gain speed.

conclusions

Determining and eliminating the causes of poor speed of the 16-valve VAZ-2112 engine is quite a difficult matter. It is necessary to go through each node step by step, which may be the cause of the malfunction. Well, if the motorist was unable to diagnose the problem on his own, then it is recommended to contact a car service center, where specialists will quickly determine what the problem is and fix it.

Hello. I have a Lada 2112 1.5 16 valve problem. I was driving from the garden and at the very end of the journey the car stopped responding to the gas pedal (it didn’t pick up speed) (it was idling), after stopping, I turned it off and stood for a while, started it up again and revved it up There are revolutions, I drove for 50 seconds and again it does not react. The next day I tried to replace the fuel filter. Everything seemed to work. But I literally drove for 1-1.5 hours, the car started again and does not respond to gas. Tell me what could be the reason. There are assumptions that this only occurs when the car is hot, 90-97 degrees .The speedometer also suddenly failed and the check light does not light up.

Why the 16-valve VAZ-2112 began to accelerate poorly - slow acceleration and poor dynamics

Poor acceleration of the 16-valve VAZ-2112 is a consequence of a malfunction in the ignition system or fuel supply. It is difficult to eliminate the causes of such a failure, but it is quite possible to do it yourself. To do this, a considerable amount of work will have to be done.

Lost power on the VAZ-2112 - many symptoms and reasons, more details in the video below: