The car has long become an integral part of our lives. It is quite difficult for many of us to imagine life without him. But sometimes there comes a time when the car stops starting at the most inopportune time.

Faced with such a problem, many car owners have no idea what to do in such a situation. We will try to help solve the problem when the Priora does not start and the starter does not turn the engine and what actions should be taken first.

The starter is silent when you turn the ignition key - causes and methods for eliminating them

Failure of one or another vehicle component/device forces the owner to take measures to eliminate this problem. Prompt troubleshooting largely depends on the effectiveness of such measures. In order not to aggravate the situation and save time and money, diagnostic measures in this case should not be spontaneous and unreasonable.

Any malfunction has a number of characteristic symptoms and manifestations. They should serve as a starting point in solving a specific problem. Let's consider a comprehensive diagnostic procedure in the case when the starter does not respond to turning the ignition key.

Stator problems

Staters of modern starters are mainly made using permanent magnets, but there are also units with classical windings. Insulation breakdowns, breaks and interturn short circuits are possible in it. To check the absence of the listed problems, it is recommended to use the diagrams presented in the image below.

The permanent magnet stator has virtually no problems. Despite this, in domestic units, poles may peel off or cracks may appear.

The battery is low

The vehicle's power supply system largely depends on the health of the battery. To keep it in working order, you must comply with a number of requirements and instructions. If, for some reason, the battery was not taken care of, then sooner or later such negligent attitude will come back to haunt the owner.

The most pronounced symptoms of a faulty battery are:

- low brightness of running lights;

- sound signal attenuation;

- presence of a red/white indicator on the battery cover;

- deflection of the on-board ammeter needle towards the charge when the starter circuit is closed;

- presence of sulfation at the battery terminals.

All these signs, one way or another, indicate that the battery needs diagnostics. First, you should check the level and density of the electrolyte. After this, the battery must be charged using a charger. If the battery is old, charging should be done at extremely low charging current values.

During this procedure, the battery can caps must be removed. During the entire charging time, you must ensure that the battery does not self-discharge. It happens that during charging one or more cans begin to “boil” before the rest. This phenomenon indicates that the battery, due to improper care, has exhausted its resource.

Ignition switch problem

The operation of some devices involves frequent movement of working elements. This functional feature leads to increased mechanical wear. Such devices include the ignition switch.

During long-term operation, its working elements may at some point cease to perform their functions. This malfunction is caused, first of all, by poor pressing of the contact group. This results in the engine not responding at all when the starter circuit is closed.

A problem with the ignition switch can be expressed as follows:

- interruptions in the operation of control indicators;

- The steering shaft does not come out of the lock.

Repairing a contact pair does not require highly professional skills. You can produce it yourself. As a rule, a layer of tin is soldered onto a worn surface, and the lock still serves faithfully for quite a long time.

Brush unit

If interruptions in the starter operation are observed even at idle, then there is a high risk of problems in the brush assembly. The presence of unstable electrical contact leads to slow rotation of the armature, as a result of which the motor does not catch and does not enter the independent operation mode.

Unreliable contact often occurs due to brushes getting stuck in the guides. Therefore, first of all, it is important to check their free movement.

A large current flows through the brushes. It causes thermal damage such as melting. Therefore, it is important to inspect all elements for defects.

Particular attention should be paid to surfaces in contact with the collector. They are most often damaged. Minor defects require sanding. If it is impossible to eliminate the damage, the brush must be replaced.

Brushes are the most susceptible to wear. You can determine the remaining life by measuring their length. Further decisions should be made by referring to the table below.

Table - Brush wear

| Wear level | Action |

| Complete erasing down to the wires | Mandatory replacement. Even test starts of the starter are prohibited during repairs. There is a risk of damaging the anchor. |

| Less than 30% of original size left | Mandatory replacement before assembly |

| There is half a brush | The need for replacement should be determined by the condition of the remaining elements |

| More than 70% of original size left | It is recommended to reuse the brush |

Wiring

Often, difficulties with starting the engine are caused by mechanical or electrical damage to individual sections and associated wiring elements in the starter circuit. This leads to the fact that the starter is “silent”, no matter how diligently the driver closes the starter circuit with the ignition key. To identify such failures, you should use a tester and a test lamp.

Diagnosis of this kind of problem requires a certain sequence of actions:

- inspection of contacts and connecting terminals for contamination/oxidation/poor contact of surfaces;

- checking the wires for breakdown using an ohmmeter;

- inspection of wires for damage to the integrity of the insulating coating.

A test lamp can be useful if there is a high probability that the stator winding of the electric motor has failed, or the brushes have become unusable.

Bushing wear and damage

The appearance of wear or damage to the bushing is indicated by a characteristic grinding noise when starting the engine. If you do not pay attention to this symptom for a long time, the starter will start turning too slowly. A gasoline engine is less critical of reducing speed, while a diesel engine may refuse to start at all.

To diagnose, rotate the armature shaft. If it turns tightly, there is a high risk of damage or wear to the bushings. For a more accurate check, you should disassemble the assembly and visually inspect the contacting surfaces.

Starter malfunction

As practice shows, most of the problems associated with starting the engine are directly related to the breakdown of the starter.

If, when you turn the key to the “Start” position, the starter does not manifest itself in any way, the reason for this may be:

- break in the coil of the solenoid relay;

- loss of elasticity of the relay return spring;

- failure of the starter relay (if present);

- mechanical damage to the solenoid relay;

- jamming of the Bendix drive fork.

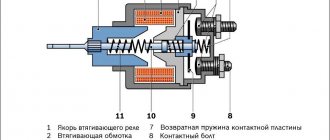

Eliminating each of the presented reasons requires dismantling the starter, followed by disassembling and replacing the corresponding elements. The further sequence of assembling the device should be done in reverse order. It is important not to confuse the location of the underwater terminals.

A thick wire is connected to the starter power contact terminal, a thin wire is connected from the ignition switch to the “retractor” windings. The second “nickle” is connected to the stator winding of the motor.

Problems with the starter armature

Problems with the armature are also common during starter operation. One of the main troubles is a breakdown on the body. It is easy to identify it by performing a “diagnosis” with a multimeter or ohmmeter.

In the absence of measuring instruments, the test can be performed using a light bulb, wires and a power source. You need to assemble the circuit shown in the image below. If current flows through the circuit and the light comes on, this means that the armature has become unusable and has a breakdown in the body.

Problems with the starter occur due to damage to the commutator. The reasons for this can be different, but most often associated with improper operation or exhaustion of the starter's resource.

Starting for too long leads to overheating of the plates. Small thermal defects can usually be removed by grinding. In case of significant damage, restoring the collector plate is impractical, so the armature must be replaced.

Other reasons

In addition to the malfunctions presented, there are a number of factors that can cause such a malfunction.

- fuse break;

- starter relay failure;

- bad mass.

It is worth noting that the starter relay and the traction or retractor relay are two different devices. The starter relay is an auxiliary device that allows you to convert the current permissible for the ignition switch contacts into a high-power current necessary to start the starter.

Engine starting methods

If such a nuisance takes a car enthusiast by surprise on the road, there are a number of practice-tested methods and techniques that will allow you to start the engine in extreme conditions. This will require a minimum of tools and a maximum of dedication and dexterity of the driver.

- direct impact on the starter contacts and solenoid relay;

- mechanical manipulation using a hammer handle;

- changing the position of the starter power contacts;

- impact on the drive axle of the car.

The first option is considered if the ignition switch has failed or power is not supplied to the “retractor” winding.

Its essence is as follows: the car is put in neutral, the handbrake is “cocked”, the ignition is turned on, and with the help of any metal object, be it a screwdriver or a pry bar, two power contacts are closed. Their role is played by the power contact from the battery and the underwater contact going to the auxiliary relay terminal.

What to do if something happened to the Bendix drive elements? A proven patented tool that has no analogues in the whole world will come to the rescue - the “hammer”.

How to remove the electric starter

The procedure in this case is as follows:

- remove the terminals from the battery;

- the “plus” connector is removed from the starter;

- removed from the relay block;

- The nuts securing the faulty unit are unscrewed.

Then you can safely remove it.

Next you will need to check the functionality of the relay. To do this, take emergency wires to start from another car. The negative one is installed on the battery and on the starter housing. “Plus” is connected to the relay. The latter in this case (if it works properly) is triggered and moves the gear. The absence of this reaction indicates a breakdown of this element.

When you turn the key there is a spark, but there is no spark with the starter.

- To the beginning of the forum

- Forum Rules

- Old design

- FAQ

- Search

- Users

I turn the ignition key and the starter doesn’t make a single sound.

— The instrument room is on fire. — I tried a new ignition switch. — I changed the retractor - the same thing.

It just starts from the pushrod.

help the people!

I turn the ignition key and the starter doesn’t make a single sound.

— The instrument room is on fire. — I tried a new ignition switch. — I changed the retractor - the same thing.

It just starts from the pushrod.

help the people!

What to see. 1. DPKV. 2. Weight on the engine. 3. If the signal is on a break in the Starter circuit and goes off, this is from what I had in such a situation

The brushes may have worn out. Try changing the brush assembly. The collection costs 150 rubles. When you remove the starter, inspect it. Very often, in case of brush wear, the brush springs lift up the armature commutator. If the damage is minor, trim the nicks with a file and put everything back together

If at least one contact of the commutator is knocked out, then the entire armature must be changed - the old one will still quickly break the brushes.

I turn the ignition key and the starter doesn’t make a single sound.

If there is a starter disable relay, then check it. It is worth paying attention to the separate wire that runs from the generator to the relay - the terminal from the generator often jumps off, if everything is fine with it, pull out the relay, put a jumper on the power contact and try to start it.

[/quote] 1. DPKV. 2. Weight on the engine. 3. If the signal is on a break in the Starter circuit and goes off, this is from what I had in such a situation[/quote]

And what does the DPKV have to do with when it starts from the pusher??

Take two wires from the battery directly to the starter. It turns. Does the retractor click??

1. DPKV. 2. Weight on the engine. 3. If the signal is on a break in the Starter circuit and goes off, this is from what I had in such a situation[/quote]

And what does the DPKV have to do with when it starts from the pusher??

Take two wires from the battery directly to the starter. It turns. Does the retractor click??[/quote]

don’t bother, put the car in neutral, engage the handbrake, turn on the ignition, open the hood, take a screwdriver with good insulation and... touch the positive bolt of the starter and the terminal on the retractor, and if there are no glitches with the wiring, everything will be fine, it means the power is lost in this red wire, you’ll figure it out later.

I turn the ignition key and the starter doesn’t make a single sound.

— The instrument room is on fire. — I tried a new ignition switch. — I changed the retractor - the same thing.

It just starts from the pushrod.

help the people!

Something like this happened to me over the weekend. I decided to park the car, turned off the engine, a better place became available - I decided to rearrange it, but the car was silent and did not turn over. I opened the hood, and because of the air cover the starter was not visible (Saturday evening) I thought - I’d better go and drink beer. In the morning while I was drinking coffee I looked at the diagram - everything is just 50, 30 and “+” contact. I open the hood - off “-“, open. Mass air flow sensor, remove the pipe, pull out the air cover from the mass air flow sensor. I put the “-” key on “to start” and put the “+” key on the retractors with a screwdriver and turn it - it eases up - no starter. I see some twists. In short, there is an additional relay, which died. I connect it as per the standard - everything works - I assemble it. For everything about 15-20 minutes. left (with the condition that I didn’t know what to look for) I try to do everything myself, from a penny a habit is an economical habit.

Why was it necessary to change the LOCK(?) - after all, the tidy is on, but why change the solenoid relays(?) - it was necessary to close it to “+” and check whether it works or not. and then unscrew it - establish the cause and then repair it.

Why does the starter not respond to turning the ignition key?

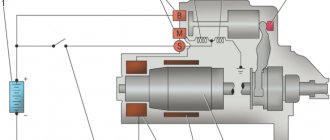

After turning on the ignition, power from the battery is supplied to the on-board electrical systems and the computer (if equipped). If there is an immobilizer (standard or an installed security system), this occurs only after the tag is recognized. When the key is turned to the start position or the start button is pressed, the contacts of the solenoid relay are closed, resulting in power being supplied directly to the starter. At the same time, the starter overrunning clutch (Bendix) engages with the flywheel crown, setting it in motion and ensuring the engine starts. Often, switching is carried out through an additional starter control relay, which removes the load from the lock.

Ignition switching circuit

If a problem arises at any of the above stages, the car will not start: you turn the ignition key and the starter is silent. As a rule, the reasons for this behavior lie in:

- ignition switch contact group;

- alarm and immobilizer;

- control relay;

- wiring from the control relay to the starter;

- starter solenoid relay.

More information about why the starter does not work with the ignition key can be found in the table.

The starter does not work from the ignition key: reasons

| Problem | Cause of malfunction |

| Starter motor faulty | The electric motor fails due to overheating, short circuits in the windings, wear of the brush assembly, and jamming of the gearbox. |

| The circuit from the ignition switch to the starter solenoid relay is faulty | Wiring break or short circuit. Often occurs after repairs, installation of additional equipment, or as a result of mechanical wear during long-term use. |

| Damage to the ignition switch (deformation of the cylinder) | Deformation due to overheating, which in turn occurs due to poor contact. Damage is also possible due to the mistaken use of an inappropriate key. |

| Electrical malfunction of the ignition switch contact group | The layer of oxides formed on the contacts prevents the flow of current. Also, the contacts may move away due to deformation of the rotary sleeve on which the mating parts are attached. |

| Start blocking by installed alarm | A voltage surge in the on-board network or loss of power (disconnection of a terminal or discharge), failure of a transistor or microrelay responsible for turning on the start line in the base unit of the security system. |

| Immobilizer malfunction/decoding | Voltage drops and sudden loss of power (battery discharged or terminal removed), software failure, failure of microelements. If the immobilizer does not recognize the mark, the starter does not turn after turning the ignition key, and the immobilizer symbol usually lights up or flashes on the indicator panel - an image of a car with a key or lock. |

| Failure of the solenoid relay | Burnout or short circuit of the winding as a result of overheating due to the flow of increased current or being under load for an extended period. The root of all problems is usually oxidation of the internal and external contacts of the solenoid relay. |

| The limit switch for the automatic transmission selector position, the brake pedal for an automatic transmission or the clutch for a manual transmission is faulty | Sensors fail due to mechanical wear, and their wires and terminals can oxidize or fray. Because of this, the ECU does not allow the starter to start. |

| Starter relay failure | If the starter control relay is stuck or shorted, it cannot supply power to the control terminal of the solenoid relay. |

| Poor “+” contact from the battery on the starter | The power contact terminal oxidizes under the influence of moisture and heat. The nut that holds it to the starter stud can come loose due to vibrations. |

| Poor ground contact at the battery terminal, car body or engine | Due to oxidation, the contact of the ground wire deteriorates; the same thing happens when its nut is unscrewed under the influence of vibration. In this case, the passing current may be enough to turn on the on-board network and the ECU, but not enough to drive the starter electric motor. |

What to do if the starter does not turn the engine from the ignition switch

If when you turn the ignition key the car does not start, and nothing happens at all, in some cases you can correct the situation by supplying power to the starter, bypassing the lock. This solution is suitable for cases where the electric motor itself and the solenoid relay are in good working order. In this case, you need to proceed according to the following algorithm:

Control wire terminal

- Turn on neutral gear and ignition.

- Find two terminals on the starter: a thick power wire from the battery positive and a thin control wire from the control relay.

- Using a metal object (screwdriver, key, wire), close the power and control contacts.

- After the starter operates and the engine starts, immediately open the contacts.

An alternative to the same method is to supply power to the starter control terminal directly from the positive terminal of the battery. This can be done using any insulated wire, for example from a cigarette lighter wire kit.

The lack of response of the starter to direct power supply indicates its breakdown, failure of the electric motor or the solenoid relay. To diagnose the starter, you need to disassemble the starting unit, inspect the brush assembly, armature and stator windings. This is not easy to do in the field and without a multimeter, so you need to push the car and get to the garage or service station.

When the starter turns directly, but not from the key, then the starter itself is fully operational, and the problem lies in the electrical circuit from the key to the starter. To determine the location of the breakdown, you need to follow the instructions given below.

Lada won't start when cold

Check how fast the crankshaft spins on your Priora. Too low a speed indicates:

- dead battery;

- hardening of the lubricant.

The absence of any reaction from the motor suggests that the problem lies in:

- fuel system - sometimes condensate freezes there;

- a sensor that monitors the temperature of the antifreeze;

- loss of tightness of nozzles;

- weak compression in the cylinders;

- failure in the on-board computer.

If the car starts unstably in winter, then perhaps there is low-quality gasoline in the Priora tank or a lot of condensate has accumulated. It would also be a good idea to look at the spark plugs and the cables leading to them from the distributor, the ignition unit itself, and the sensor that monitors the oxygen level.

Frequent malfunctions on popular cars

In most cases, the starter does not turn when the ignition key is turned due to oxidation and mechanical damage to the wiring. If there is poor contact with the “+” terminal of the battery, the control relay or ground, the starter does not receive enough current to crank the engine . Therefore, first of all, you need to look at the contacts in the engine compartment and check for voltage at the terminals with a tester. The most common malfunctions of specific car models, due to which the starter does not respond to the ignition key in the table.

| Why does the starter not work from the ignition key on popular car models? | |

| Auto | Weakness |

| VAZ 2110, 2111, 2112 | Wires of the central locking and ignition switch, which melt due to power surges. |

| VAZ 2108, 2109, 21099, 2113, 2114, 2115 (Lada Samara) | Oxidizing contacts of the control relay located in the engine compartment above the VUT, as well as the wiring extending from it. |

| VAZ 2101, 2102, 2103, 2104, 2105, 2106, 2107 (Classic) | The contact “nickels” of the solenoid relay often burn or oxidize. The contact group of the ignition switch fails. On later models, for example, 2107, problems with the control relay are similar to Samara (see above). |

| Niva | On old Nivas (before 21213), the ignition switch contacts burn and oxidize. On newer ones (after 21214), the starter control relay, located under the hood near the brake fluid reservoir, often fails. There is a drainage tube located nearby that drains water from under the glass, moisture from which gets onto the relay, which leads to oxidation of its contacts. |

| Lada Priora | Immobilizer problems due to which it does not see the key. |

| Lada Kalina, Lada Granta | Failure of the immobilizer, blocking the start, malfunctions in the contact group of the ignition switch and failure of the additional starter relay K3 in the fuse block. |

| UAZ | Malfunction of the 5-pin starter control relay and solenoid relay. |

| Gazelle | Poor contact of wires and failure of the starter relay. |

| Peugeot 307 | Solenoid relay fuse F8 blows, poor ground contact. |

| Kia Sid | The limit switch of the automatic transmission selector, which determines the P and N positions, is faulty. There may be poor contact at the starter terminals or at the point where the ground wire is attached to the body. |

Answers to frequently asked questions

How can you tell if the starter relay is not working?

To determine whether the starter relay is working, apply power from the positive terminal of the battery directly to the control contact of the relay. After this, a click should sound; if it is faulty, there will be no sounds.

How to check whether the starter is working or not?

To check the serviceability of the starter itself, you need to apply current to it directly by connecting the power wires of the retractor relay (thick wire from the battery) and the electric motor (stud with a thick wire from the retractor to the starter). A working starter should start moving.

What to do if the starter does not work after turning the ignition key?

First, make sure there is voltage at the battery terminals. If you don’t have a tester, this can be done using a 12 V lamp. Then try to apply voltage directly to the starter: use a screwdriver to close the pin to which the wire from the battery goes and the control contact located nearby. If there is no reaction, check the quality of the contacts of the terminals on the battery, the ground contacts (with the body and the engine) and the contacts of the starter itself by cleaning and tightening the terminals. If the battery is discharged or the starter is faulty, you need to start the car with a pusher (manual transmission) or tow it to the repair site.

Planetary gear

If the starter shaft is difficult to rotate, a common cause is thickening of the lubricant in the planetary gear. At the same time, when the engine is cold, the electric motor turns the crankshaft worse than when the engine is hot. This is due to the fact that the lubricant changes its viscosity depending on the temperature. When hot, it liquefies and interferes less with the rotation of the shaft.

To solve the problem, you need to disassemble the planetary gearbox and clean out all the contents. After this, new lubricant should be applied.

The reasons why the starter does not work well and turns weakly are often related to the condition of the planetary gearbox gears. Therefore, it is important to inspect them for signs of wear and broken teeth.