Today, I bring to your attention step-by-step instructions for replacing ball joints on a VAZ 2107, with a detailed description of the process supported by informative photos. The replacement of ball joints by specialists has been worked out to the point of automation and has changed only slightly over the years thanks to new tools and capabilities.

The VAZ 2107 ball joint is replaced using an inspection pit or a lift in my case. When starting any repair work, take care of your own safety. If you are going to work in an inspection hole, install wheel chocks, tighten the handbrake and engage second gear. Working on a jack alone without the safety measures described above is strictly prohibited.

So, if you are ready, I suggest you start.

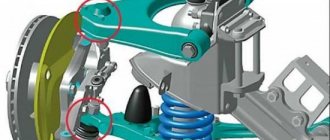

How to distinguish the upper ball from the lower

Today we will find out how the lower ball joint differs from the upper one using the example of VAZ 2107, VAZ 2106 , what are their visual differences. In the photographs we will clearly indicate how they differ from each other. I raised this topic for a reason; I was often approached about replacing ball joints on classics; it was not always indicated on their bodies where the top and where the bottom was. Often they brought me hinges in one box, four pieces each, so their location on the levers was not indicated. Knowing which one to install up and which one down is important, I’ll tell you why.

When we studied the design of the VAZ 2107 ball joint, it was mentioned that its design contains a ball tightly compressed with a plastic liner. Depending on its location on the lever, its strength level is different. The lower ball of the VAZ 2107 bears a greater load than the upper one, so it is structurally designed to take on greater forces during suspension operation.

If you mix up the supports, there is a high chance of “losing” the wheel on the road. The finger will be torn out of the body under heavy loads. For this reason, you need to clearly know how to distinguish the upper ball from the lower .

Checking the condition of the car suspension

To find out how the suspension is doing, you will need a jack. First, lift the front of the car. Grab the top and bottom of the wheel with both hands and rock it. If the ball joint needs to be replaced, it will make an unpleasant metallic sound.

For another method of checking, you will need an assistant. Adjust the hub nut and ask him to press the brake all the way, holding it for a while. Now swing the wheel. The rattling sound that appears will only confirm your suspicions.

Signs by which you can distinguish ball joints VAZ 2101-07

Let's start with a visual inspection. There may be several differences, they are all indirect, because different manufacturers do not always adhere to the same standard. Let's look at several signs, the totality of which can clearly determine the top and bottom of the ball joint. There are small guarantees that all of the listed differences will be on your copies, but knowing all the possible ones, you can accurately answer the question on today’s topic.

To clearly recognize the differences, you need to remove the protective boot. Now let's visually inspect.

- The lower part of the body near the upper supports is made in the form of a sphere, as if a ball was pressed into it. The lower ones have a flat bottom. This is done so that more lubricant can fit under the liner.

- A clear difference between the lower ball is the presence in the bottom of the body of a hole with a screwed-in plug bolt (look at the photo above). This is for the oiler to add lubricant and check for wear. Some manufacturers also have space for an oil nipple on the upper hinges. Therefore, this is not a 100% sign of difference

- Visually, the lower one looks more massive and has more weight than the upper support. This is an indirect sign. There were almost identical specimens.

- Having removed the boot, you can find a hundred percent difference - the housing cover, where the finger moves, has a certain shape.

- So on the lower support it is oblong, elongated. This is due to the fact that the lower ball pin moves in one direction, given by the shape of the support body. The upper one can “move” in all directions, so the hole for the finger has a round shape

- In some cases, markings are indicated on the back of the support body: “B” - upper, “H” - lower, or on the ball pin.

- The force with which the joint can be moved

Since the forces for which the supports are designed are different, when installing, try to move the ball pins. You can move your hand on the top one, and with a certain amount of effort it will begin to move. On the bottom, in most cases, nothing will work.

The hinge pin will not move by hand. For these purposes, you will have to use a lever to break it and move it apart. Because it is the lower ball that takes on the greatest load, so its design is made to “digest” shocks when driving over uneven roads. This is not a 100% sign. Some will have the same ones. You can move the upper and lower ones freely with your hand - this is an indicator of the poor quality of manufacturing of the hinges .

Important! Such signs of differences in supports are not suitable for all cars. They are relevant only for VAZ classics. For example, the Niva boasts identical supports installed on the upper and lower suspension arms.

This is due to the design features of the chassis. In the Zhiguli VAZ 2101-07, the lower ball is installed in the lever with the finger up. Therefore, the wheel, moving over uneven roads, tries to “rip out” the pin from the joint body, so it must be reinforced to withstand the impacts of the wheel. It is the classic VAZ models that can most often be found with the wheel turned outward.

On Niva they got rid of such a miscalculation in the suspension. The supports are mounted pin down on the upper and lower arms. Therefore, the cone where the ball pin is pressed does not hit the pin, tearing it out of the cracker, but rather the lever. The lower joint does not experience such stress, so there is no need to install a reinforced ball joint down. On Nivas, the suspensions have identical upper supports in a circle; there is no need to learn to distinguish them.

Parts selection

The main enemies of the upper and lower ball joints are not only water or dirt, but also low-quality materials. It is best to purchase spare parts made of steel, as they are the most durable and wear-resistant. Any auto store will tell you which companies produce such parts. Also, reviews of other VAZ 2107 car owners can help you in your choice. Most of them recommend paying attention to domestic manufacturers, since cheap Chinese analogues can fail at any time.

- pressure plate;

- ball pin cover;

- upper ball pin.

Purpose of ball joints VAZ 2107

A ball joint (BJ) is an ordinary hinge built into the VAZ 2107 suspension and allows the wheel to move only in a horizontal plane. At the same time, it limits the possibility of wheel movement in the vertical direction.

Ball joints of the VAZ 2107 are very short-lived, so they have to be changed often.

Design of ball joints VAZ 2107

Previously, passenger cars did not have ball joints. They were replaced by bulky king pins that had to be lubricated frequently. The mobility of such compounds left much to be desired. This, in turn, negatively affected the car's handling. The designers of the VAZ 2107 abandoned the kingpins and installed ball joints. The first SHO consisted of:

- housings;

- ball pin;

- springs;

- anther

The finger was pressed into a fixed eye, fixed with a powerful spring and covered with a boot. This structure also needed to be lubricated periodically, but quite rarely (about twice a year). The lubricant on the pins had to be changed every week.

Subsequently, the VAZ 2107 SHO was constantly improved:

- the spring disappeared from the structure;

- the steel boot was replaced with a plastic one;

- the fixed eyelet in which the finger was fixed became more compact and received a plastic external finish;

- SHOs have become non-separable, that is, practically disposable.

One driver I know assured me that he had found a great way to extend the life of plastic boots. Before installing new ball joints, he always applied a thick layer of silicone ointment to the boots, which car owners use to prevent the rubber bands on car doors from freezing in winter. From his words, it turned out that the anthers after such a procedure become practically “indestructible.” When I asked how an ointment intended for rubber could improve the quality of plastic, I was recommended to just try it and see for myself. Unfortunately, we never got around to it. So I leave it to the reader to check this driver’s find.

Reasons for failure of VAZ 2107 ball joints

The main reasons for SHO failure are as follows:

- Alternating shock load. As a result, the ball pin pressed into the suspension eye is destroyed. The support is designed in such a way that the shock loads on the pin ball are very high. When the quality of roads is poor, these loads increase manifold. In such conditions, even a high-quality SHO will not be able to fully exhaust its resource.

- Lack of lubrication. Under the influence of shock loads, the lubricant is gradually squeezed out of the SHO. In addition, over time, the lubricant loses its original properties.

- Anther destruction. The boot protects the hinge joint from dirt. If a crack appears in it, the dirt that gets into the joint turns into an abrasive material and grinds down the surface of the ball pin.

Signs of malfunction of VAZ 2107 ball joints

The main symptoms of a VAZ 2107 SHO malfunction include:

- Extraneous sounds. While driving, a knocking or grinding noise begins to be heard from the wheel. This is especially pronounced on uneven roads at a speed of about 30 km/h and is usually a consequence of partial destruction of the ball on the support pin.

- Wheel rocking. When accelerating, the wheel begins to sway slightly in different directions. This happens due to the backlash that occurs in the SHO due to its wear. The situation is quite dangerous, and the backlash must be eliminated quickly. Otherwise, the wheel may turn at a right angle to the body at speed.

What is a shock absorber

A shock absorber is a component of the suspension that acts as a damper for vibration impulses. The scope of work tasks for shock absorbers includes the following:

- elimination of vertical swing;

- ensuring vehicle stability while driving;

- ensuring good grip on the road surface.

As you can see, this part is very significant, and when it fails, it has the most negative impact not only on driving comfort, but also on driving safety, because faulty shock absorbers invariably lead to an increase in braking distance and worsen traction, which becomes very dangerous along the way.

In addition, when worn out, they cause rapid wear of other parts and systems, in particular the brake system components.

That is why it is so important to carefully monitor the condition of the suspension, and, after the working period has expired or in the event of a malfunction, replace the defective part with a new one.

We'll talk about this later, but for now let's figure out what kind of shock absorbers there are, and, since we decided to talk about such a domestic model as the VAZ 2107, which of the existing components are suitable for this car.

Types of shock absorbers

Today, three types of shock absorbers are used for VAZ cars:

- Oily. This type of unit is suitable for calm, comfortable driving for drivers who primarily value order and regularity. They work well on city roads, where traffic speed is limited and there are no treacherous potholes or potholes. But, if you prefer speed or extreme driving on country roads, then you need to look for something else.

- Gas-oil classic option. This option is ideal for speed lovers. The design of the device itself provides better protection against impacts falling on the lower part of the car during high-speed driving. True, such units are thirty percent more expensive than just oil ones, but the quality is much higher.

- Gas-oil with variable hardness coefficient. When you want to drive on the roads of distant provinces without worrying that the road will turn into a nightmare, then you should give preference to a gas-oil shock absorber of increased rigidity.

It is also worth noting that both versions of gas-oil units guarantee better controllability and the ability to maneuver on sharp turns than oil units.

The quality of the components also depends on the manufacturer’s brand: each company tries to introduce technical innovations into one or another option that significantly improve the characteristics.

So, having decided to replace shock absorbers in order to improve the technical characteristics of the VAZ-2107 car, you can turn your attention to:

Diagnostics of ball joints VAZ 2107

You can make sure that the cause of the grinding or squeaking is the ball joint in various ways.

- Aurally. An assistant will be needed for this. Two people rock a car with the engine turned off, simultaneously pressing on both sides of the car's hood. If at the same time an uncharacteristic sound is heard from one of the wheels, the corresponding wheel is worn out or needs lubrication.

- Detecting the backlash of the sho. The wheel, on which the support has most likely failed, is raised with a jack by about 30 cm. An assistant from the interior presses the brake pedal as hard as possible. After this, you should forcefully rock the wheel, first in a vertical plane up and down, then to the right and left. When the brakes are locked, play will immediately appear. Even if it is insignificant, the SHO still needs to be changed.

Replacement

Tools:

- spanners;

- spring tie;

- jack;

- hammer;

- mount;

- a device for removing the nuts securing the stand;

- mechanism for removing the steering tip.

Work order

- You need to remove the hub cap and rip off the CV joint nut while an assistant presses the brake using a wrench or socket.

- Raise the car using a jack and remove the wheel. The factory stand should also secure the vehicle.

- With the steering wheel turned in the opposite direction from the support being repaired, you need to release the cotter pin. To do this, use a hammer, a pry bar and a steering rod puller.

- Remove the 2 ball joint mounting bolts.

- The brake hose is removed from the holder.

- Next, the 2 caliper bolts are also loosened. It must not be allowed to hang on the brake hose; it must be taken to the side and hung on a wire.

- To make it more comfortable to work with the stand removed, the nut needs to be removed, but there is no need to unscrew it completely. Then the 3 support nuts are unscrewed.

- Unscrew the CV joint nut completely and simultaneously remove both the CV joint and the strut.

- Use the device to compress the spring evenly on both sides.

- You can easily disconnect the support from the compressed spring. A new support is installed.

- Assembly is carried out in reverse order.

Selection of ball joints for VAZ 2107

The main element of any SHO is a ball pin, the reliability of which determines the operational life of the entire assembly. A high-quality ball pin must meet the following requirements:

- the finger should be made only of high-alloy steel;

- the ball of the finger must necessarily undergo a cementation procedure (surface hardening), and the body of the finger must be hardened and then cooled in oil.

Other support elements are produced by cold heading followed by heat treatment.

This technology for manufacturing SHO is quite expensive. Therefore, there are only a few companies that produce high-quality supports for the VAZ 2107. These include:

- Belebeevsky;

When choosing ball joints for the VAZ 2107, you should beware of fakes. There are quite a lot of such products on the market. Some of them are made so well that they can mislead even a specialist. The only criterion to distinguish a fake from the original is the price. Low-quality SHOs cost half as much as real ones. However, saving on details on which the driver’s life literally depends is unacceptable.

Replacement

Replacement is quite simple if you follow the step-by-step instructions below. To make the work easier and more trouble-free, you need to prepare the necessary tools in advance.

Required tool:

- Socket wrench or socket for 17 and 19 mm;

- Ratchet or crank;

- Hammer and pry bar (it is better to use a puller);

- Puller;

- Jack;

- Penetrating lubricant WD-40;

Step-by-step instruction

First of all, put the car on the handbrake and put the stops under the rear wheels of the car.

Raise the car with a jack and remove the front wheel.

Unscrew the two bolts securing the ball joint with a 17mm head;

We unscrew the pin securing the ball joint to the steering knuckle with a 19mm socket;

Replacement of ball joints VAZ 2107

Ball joints on the VAZ 2107 cannot be repaired. On the first “sevens”, collapsible ball joints were installed, from which a worn ball pin could be removed and replaced. Modern supports cannot be disassembled. Moreover, even if we allow for the possibility of disassembly, it will still not be possible to repair the SHO, since ball pins for the VAZ 2107 have long been discontinued.

To replace the SHO you will need:

- a set of new ball joints;

- jack;

- a device for squeezing supports out of the eyes;

- set of open-end and socket wrenches;

- hammer;

- flat blade screwdriver.

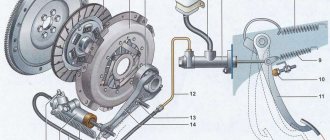

Procedure for replacing ball joints

Replacing ball joints on a VAZ 2107 is carried out as follows.

- The wheel on which it is planned to replace the wheel is jacked up and removed.

- Using a 22mm open-end wrench, unscrew the nut securing the upper ball pin.

Requirements for a new ball

Make sure that the new ball joint boot is in good condition - there should be no cracks or damage. The new ball joint should have a grayish color to the finger. There should be no defects on the clip. The ball pin is not allowed to rotate freely - this indicates that the element is of poor quality.

For good elements, it either does not rotate in the cage at all, or does so very tightly. Try to purchase products from domestic manufacturers - “BelMag”, “Trek”, “Trial”, “Kedr”, “Nadezhda”, “BZAK”. You should not trust manufacturers from China or Turkey - practice shows that such elements are very unreliable and have a short lifespan.