Article number and price for the original ball joint

On the Lada Largus car, two types of ball joints are used. Until June 2013, the knot had a finger with a diameter of 16 mm. An annular groove was made on the support. The article number for the old-style ball is 401604793R. The price of the part ranges from 680 to 850 rubles.

In the 2014 model range, new types of supports began to be used. The diameter of their finger was increased to 18 mm. The groove has also changed. It became lateral, which, according to the designers, increased the reliability of the unit. The catalog number of the new ball is 40160-2523R. The cost of the support is 500-1400 rubles.

Despite the fact that ball joints of different years of manufacture are successfully pressed into seats instead of each other, experienced car owners do not recommend doing this. Using a “foreign” support may cause a knock in the suspension, and a number of difficulties will arise during installation.

The balls are fixed using a bolt with an increased diameter inside. The old and new type support mounts are not interchangeable. When purchasing an unsuitable unit, car owners have to bore a groove for the bolt, which does not have the best effect on the reliability and safety of the suspension.

Troubleshooting solutions

After carrying out a visual inspection, which has made it possible to determine the causes of sounds uncharacteristic of the car, you should proceed to dismantling the failed elements. Although sometimes they can be quite successfully repaired.

If, during the diagnosis of a new type of ball joint, looseness of the bolts securing the stabilizer bar was identified, then they need to be tightened.

When the above-mentioned part has to be replaced, especially together with the lever, it is considered an expensive pleasure. That is why today the services of restorers involved in their comprehensive repair are in great demand. Two technologies are used here:

- reworking the ball joint with changing plastic inserts and polishing the pin;

- filling the housing under pressure with liquid polymer, followed by removal and replacement with non-original parts.

If there is excessive or insufficient resistance to turning the ball joint pin of the front suspension arm, it can only be eliminated by completely replacing it.

Article number and cost of analogues of original ball joints

There is no clear opinion among car owners about which supports are best to purchase. Some drivers advise purchasing original ball joints. In this case, there is 100% confidence that they will fit optimally into the seat. However, other Largus owners believe that the quality of the originals does not match the cost. For a comparable price you can buy an analogue that will last much longer. The best alternatives for original ball joints are presented in the tables below.

Table - Good analogues of ball 401604793R.

| Manufacturer | vendor code | Approximate cost, ruble |

| Glober | 615127 | 250-300 |

| Rider | RD993529469 | 255-300 |

| Teknorot | R585 | 275-325 |

| Profit | 23010322 | 330-400 |

| Lemforder | 3780901 | 780-900 |

Table - Recommended Support Alternatives 40160-2523R.

| Brand | Catalog number | Approximate price, ruble |

| Renault | 40160-2523R | 500-650 |

| TRT | RS8018 | 330-350 |

| At program | AT 2523-200BJ | 340-350 |

| Quartz | QZ1602523 | 400-420 |

| LYNXauto | C1341LR | 580-600 |

Diagnostics of the ball joint condition

Symptoms of the need to pay attention to the Largus ball joint are:

- there was a need to apply additional force when turning the steering wheel;

- driving over bumps, for example, a speed bump, is accompanied by a knocking sound from the front suspension;

- Uneven tire wear was detected;

- entering a turn is accompanied by extraneous sounds coming from the wheel arches;

- the steering wheel turns with a creaking or grinding sound;

- the car has become less obedient when entering a turn;

- When driving over bumps, controllability partially decreased and the car became unstable.

If you have the above symptoms, it is recommended to use the following algorithm for finding a ball fault.

- Hang it in front of Largus.

- Take the tire from above and below.

- Check that there is no play. To do this, you need to shake the wheel in a vertical plane. It should be borne in mind that the cause of movement may be not only the ball joint, but also worn steering tips or stabilizer links.

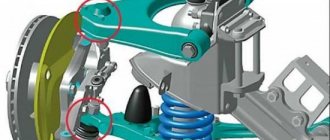

The main load-bearing element of the ball joint is the pin. It is made of high carbon steel. On one side of the finger there is a sphere, which is located in a metal case. It is filled with polymer or grease. To prevent moisture, dirt and dust from entering, a protective cuff is placed on top.

Abrasive particles and water pass through the boot freely if it is damaged. The sphere and its seat are subject to intense wear, and the lubricant dilutes and ceases to perform its functions. Therefore, when diagnosing a ball, it is important to pay attention to the condition of the boot. If cracks, punctures, holes or other holes are found, the support must be replaced.

Remove the support from the lever

Now that the element has been removed from the car, we begin to disassemble it. Using a screwdriver, pry the support under the collar. We press the ball out of the lever, leaning on its edge. Next, we look at the state of the element itself. The hole in the lever should not have cracks or any breaks. If everything is in order, we clean it from dirt with a rag soaked in gasoline or white spirit, and proceed to pressing in the new support.

To do this, we need to insert the part into the hole and place a piece of pipe of a suitable diameter under the lever. Using light blows of a hammer, press the element into the grooves. Make sure there is no distortion. After this, the lever assembly with the ball can be installed in place. The assembly procedure is carried out in the same way in reverse order.

Required tools and materials for DIY replacement

To replace the ball joint on Largus with your own hands, you will need the tools that are listed in the table below.

Table - Tools and materials required to replace the ball joint.

| Name | Note |

| Jack | Not required with a lift |

| Shoe | 2 pcs. For placing under the rear wheels. |

| Key and head | It is advisable to have a set |

| Balloon wrench | For mounting and dismantling wheels |

| Screwdriver | With a flat tip and definitely durable. As an alternative, a thin chisel is ideal. |

| Support | It is prohibited to carry out any operations on a car without a wheel, which is held only by a jack. |

| Hammer | Medium or large sizes. You can use a sledgehammer. |

| Vise | Necessary if you don’t have a hydraulic press |

| Mandrels | Two pieces of pipe. The first should have a slightly larger diameter compared to the ball, and the second should have a smaller support. |

| Pliers | Can be replaced with snap ring pliers |

| Penetrating lubricant | To simplify the analysis of stuck joints |

| Grease | Required if there is insufficient amount of lubricant under the boot |

| Rags and wire brush | To remove dirt |

We change ball joints, steering ends and silent blocks of front levers in the service

A note about what investments in the chassis await the future owner of Largus at 70-80 thousand mileage; how much will it cost to replace ball joints, steering ends and silent blocks of front arms; what is the cost of wheel alignment? Real prices for Yaroslavl

Greetings to all future Largus breeders!

By the end of spring, the mileage on my Larick was approaching 70 thousand. The snow has almost melted. And one day an unpleasant rubber squeak appeared from the suspension. It was heard especially clearly when turning the steering wheel in place and when driving at low speeds (up to 20-30 km/h). In traffic jams you could hear it in neighboring cars.

It was not a squeak in the area of the upper shock absorber mount, which occurs between the cup and the rubber washer. In my case, everything was quiet there.

A little later I went for suspension diagnostics. I called several car services in advance. In one of them, they asked for 700 rubles to check the Largus chassis. Most offered a free check. The calculation is simple - the person will choose further repairs from them. In my case it worked. Where I did the diagnostics, I went there for repairs.

Ball joint Lada Largus: causes of malfunction and replacement rules

The ball joint is the most important element of the front suspension of a car. It allows you to perform basic control functions, turns and provides stable movement in a straight line. The design of the part ensures that the wheel is fixed in the vertical plane and rotates freely in the horizontal plane when turning. The ball joint was invented 40 years ago by an Italian engineer from the Fiat corporation, and its design has remained almost unchanged all this time.

Changing the oil in “mechanics” “tens”

Procedure for changing oil in manual transmission:

It is better to replace the lubricant immediately after operating the vehicle, when all units maintain operating temperature conditions. We place the car on a level area, set the parking brake and turn off the power to the vehicle. For convenience, we place the “front” of the car on a stand. Check the oil level with the vehicle standing horizontally. Clean the filler plug and inspection hole. Install an oil drain tank under the gearbox housing and unscrew the plug

Take measures to prevent burns from hot aggregate oil. After draining the waste, thoroughly clean the hole plugs, paying special attention to removing metal particles from the inserts with magnets. Wait until the oil has completely drained and place the car in a horizontal position. Fill the unit with oil and test the lubrication level in the unit. Tighten the inspection plug, take a short trip and check the oil level in the gearbox, if necessary, add the missing amount

Tighten the plug with the recommended torque.

Technical characteristics of the ball joint on Largus

The ball joint consists of a main load-bearing element - a pin made of high-carbon steel. On one side there is a sphere, and on the other there is a groove for mounting with a steering knuckle. The spherical part of the finger is located in a metal case filled with polymer, which dampens vibrations and shock loads when the car is moving. The support body is pressed into the suspension arm, and a boot is placed on top of it to prevent dirt and dust from entering.

The ball joint on Largus models produced before June 2013 had a pin with a diameter of 16 mm and an annular groove. In the supports that are installed on new models, the pin diameter is 18 mm, they have a side groove.

In fulfilling their purpose, ball joints are subjected to heavy loads, so stringent requirements are placed on their design and manufacturing technology. The support pin must withstand a force of up to 5 tons to be pulled out of the body. To ensure the high quality of this important unit, GOST 52433-2005 “Ball joints. Technical requirements and test methods”, which should guide both Russian and foreign manufacturers.

There is a wide variety of ball joints on the aftermarket market. The most reliable and best-selling brands are:

- Febi, Germany;

- Monroe, USA;

- Ruville, Germany;

- Delphi, USA;

- Mapco, Germany;

- Meyle, Germany;

- Tork auto, Türkiye.

With the same quality of supports, their cost on the market can differ by up to 40%. The choice of one brand or another depends on the personal preferences of the car enthusiast.

Lada Largus 7 seats equipment 02D › Logbook › Changed the ball joints

Automatic transmission for Lada Largus

I haven’t written anything for a long time, I don’t like to write banal things, but something brilliant doesn’t come to mind, the car is three years old, the warranty has expired, I insured for the next year, but who cares?