The battery is the only source of voltage during engine starting. As you might guess, if it is not working, starting the engine will be problematic. In this article we will tell you why a car alternator does not charge the battery and what to do in such cases.

No charging process

The fact that the generator is not charging the battery can be indicated by a diode indicator located on the instrument control panel. As a rule, this icon is depicted in the form of the battery itself, and when the electrical part of a functioning engine is working normally, it usually does not light up. You can see this indicator on the dashboard after you turn the key in the lock to position I. At this moment, diagnostics of all devices is carried out, so the appearance of the indicator at this moment is a completely normal situation. If the indicator continues to light while driving, this may indicate that the generator is not charging the battery.

Accordingly, the driver needs to solve such a problem as quickly as possible, since otherwise it can lead to more serious consequences than just an indicator appearing on the dashboard. Sometimes the generator unit does not charge the battery due to its inoperability. Moreover, there is no way to solve such a malfunction except by replacing the battery. But sometimes this may be due to improper operation of the generator.

The charger does not see the battery

If the battery does not charge when you connect an external charger, you should measure the voltage at the battery terminals. To supply current to the battery, many chargers need to register a certain minimum voltage at the battery terminals. In other words, the power supply does not see that its terminals are connected to the battery, and therefore does not start the charging process.

To get out of this situation, you will need an additional battery (charge not lower than 10 V) and two wires. To start the charging process, with the device connected, it is enough to connect the positive terminals of the batteries with one wire, and the negative terminals with the second. The charger will register the load and begin charging the battery, after which the wires can be disconnected.

Causes and solutions to the problem

If you have the opportunity to borrow someone else’s battery for testing, you can try installing it in the car instead of yours. Of course, this battery must be fully working. Actually, in this way you can find out what the cause of the problem is - in the battery or in the generator. Below we will consider the reasons for this malfunction.

Internal condition of the battery

Typically, the reason why the generator cannot charge the battery is due to sulfation of the battery plates. In this case, the surface of the plates may be covered with salts - partially or completely - which prevent the battery from charging. If the degree of plate coverage is small, then, in principle, you can always try to restore the functionality of the battery. However, if the destruction process is no longer reversible, it will be necessary to replace the device.

As for restoring the battery structure from sulfation, this process can take more than one day, and the result and quality of restoration cannot be guaranteed. This means that you may eventually need a new battery anyway. The resuscitation procedure, as a rule, begins when the battery shows no signs of swelling, mechanical damage, cracks, etc. That is, the device body must be intact.

Installing battery terminals to terminals

But it should be borne in mind that the external state is not always a guarantee that the result will suit you. Inside the structure there are banks in which plates can break off, which ultimately leads to a short circuit. If this is the case, then there are no other options other than buying a new battery.

Terminals

Sometimes the indicator light may appear while driving a car. At this moment, you should not panic, as the reason may be quite banal. If you hit a bump or a hole, the contact may simply fall off the battery, especially if the terminal was not screwed on properly. If this is the case, then you just need to put it back in place and tighten it harder.

Problems with terminals can occur if they become oxidized at the point where they connect to the terminal. To solve this problem, the oxidation simply needs to be cleaned up. To do this you will need fine grit sandpaper. You need to be as careful as possible during the process, since you can accidentally cut off the lead part of the terminal, and this is unacceptable. If you erase more layers than necessary, the terminal will not hold well and will begin to fall off on every bump (video author - Avramenko Garage).

Generator belt

What charge should the generator provide and for what reasons does the battery overcharge or fail to charge? Quite often, the problem lies in the strap of the unit - if the tension is weak, the belt will begin to slip on the shaft, at this moment the unit will not be able to supply voltage to the system. The battery is switched and the charged battery turns from an energy consumer into a source of consumption, which is gradually discharged.

Diagnostics of the degree of belt tension can be carried out with the engine turned off. If the internal combustion engine is disconnected, you can try to tighten it if necessary. But it should be borne in mind that slippage can be caused not only by poor tension, but also by profile wear. This problem can only be solved by replacing the strap.

A wet or damp shaft can cause the impossibility of transmitting rotation - the strap will slide over the surface without effort. In order for the battery to charge normally, the pulley must be dry, so it will only be enough to dry it. It is quite difficult to determine slippage; in this case, the strap may break.

The cause of the problem may be oxidation of the wires on the generator unit at the connections. If you notice a white coating, then, as stated above, it can be removed with sandpaper. Carry out a visual check for possible broken wires or burnt contacts. If the wire is burnt out, this may be indicated by a characteristic smell (the author of the video is VAZ 2101-2107 REPAIR AND MAINTENANCE).

What charge goes from the generator to the battery?

You should also understand the voltage from the generator going to the vehicle battery.

To draw any conclusions regarding performance, you need initial data, indicators that are considered the norm. The primary task is to find out what kind of charge generally should be from the generator to power the battery.

Motorists often make the same common mistake. They replace the battery with a more powerful battery, the parameters of which go beyond those recommended by the automaker. But at the same time, the old generator is left running. The latter, in turn, may simply not cope with the increased load. That is, it does not provide the necessary charging.

Now to the question of how much a standard generator under the hood of a car normally produces to charge the installed battery. The norm is considered to be a voltage of 13.5 to 14.5 V. This is how much the generator transfers to the starter battery so that the latter can replenish its lost charge.

To avoid such undercharging problems, it is better to check the car manufacturer’s recommendations in advance and select components based on these data.

Understanding now what kind of charge the generator should normally provide to the battery, we can give one useful piece of advice. To avoid difficulties starting your car, even in winter, focus on generators capable of delivering a charging current of approximately 10% of the battery capacity. Relatively speaking, if you have a 75 Ah battery under the hood, then the generator should supply 7.5 A. But do not forget that in addition to the battery itself, the generator has a number of consumers that it must also power. And the device should not operate at its maximum capacity. That is, the unit should be purchased with a certain power reserve. The automaker initially calculates this, and therefore the parameters of the factory generator are usually sufficient. It is better to change it if the battery is replaced with a more powerful one, and additional powerful consumers are installed that are not included in the standard configuration of the car.

Control of other elements of the charging system

To determine why the alternator is overcharging or not charging the battery at all, you may need a multimeter. Using the tester, you can measure the battery voltage in two modes. With the engine turned off, the charge parameter should be in the range of 12.5-12.7 volts, and with the engine running - 13.5-14 volts. If these indicators are lower when the internal combustion engine is switched on, this may indicate problems in the operation of the diode bridge or brush assembly. By the way, brushes can wear out, so they need to be changed periodically.

If the cause of overcharging or lack of charging is a relay, it can be eliminated by replacing or resoldering the diodes. If the diodes will be soldered, it is necessary to select devices that are closest in technical characteristics. Otherwise they may overheat.

Insufficient contact

Please note that if the brushes and rings on the rotor become oily or dirty, contact may be lost for a short time or permanently. It is possible that the springs in the brush holder have deteriorated. With their help, the brushes are pressed against the rings on the rotor. Consequently, the total resistance of the excitation winding increases, or the electrical circuit is completely broken. In this case, the generator gives a weak charge or stops working altogether. To get rid of this problem, sometimes you can simply wipe the brushes with a lint-free cloth. It is advisable to moisten it in solvent or gasoline. Of course, if the brushes are very worn, they need to be replaced. In the event that oxidation of the rings has occurred, it is necessary to clean them using glass sandpaper.

Generator check

The reason why the battery is not charging may be that the generator is not working. If the car has a high mileage, this can lead to wear out of the rotor or wear of the rotating elements. As a result, this can lead to misalignment of parts inside the structure and lack of rotation. If the generator is jammed, it will need to be replaced; repairs in this case will not yield results. In addition, the reason may be a broken circuit inside the mechanism. Such a malfunction can only be identified with the help of an electrician.

In general, most problems associated with lack of charge can be solved on your own. To do this, you just need to properly monitor the operation of the unit and devote time to diagnosing the battery and generator if the corresponding indicator appears on the device.

Number of amperes from the generator to the battery

Also, many are interested in the question of how many amperes a car generator normally produces for a standard battery. It is important to understand here that the current strength is individual for each electrical system of the machine. It is directly related to how many energy consumers are in the car, and how much is needed for full operation. Additionally, the current must be sufficient to charge the battery.

Amps appear only when a load is formed in the electrical system and the battery is being charged. When the engine was started, the current averaged from 6 to 10 Amperes. But gradually this figure will fall as the process of charging the battery takes place, which takes on the main energy consumption. If you turn on the headlights, audio system, heated seats or mirrors, then the charging current parameters will begin to increase.

Video “How to properly test a generator unit”

You can learn more about diagnosing a generator at home from the video below (the author of the video is AutoHandMade).

The battery and generator are the two sources of electricity in any car. The battery starts the engine and powers the on-board network. The battery loses charge when starting and powering electrical equipment, and the generator recharges the battery and maintains the required voltage in the network.

When operating a car, sometimes a situation arises when the battery does not receive a charge from the generator or does not receive enough of it.

Why is the battery not charging?

If the generator does not charge the battery when the engine is running, it quickly discharges to the minimum permissible values. When the alternator is not charging the battery enough, it is more difficult to detect. Most modern cars are equipped with indicators that show that the battery charge is insufficient. If the icon lights up on the dashboard, this is a sign that the generator is not supplying current to the network, and the vehicle's electrical equipment is powered by the battery.

If we exclude a malfunction of the battery itself, then there may be several breakdowns due to which the generator does not charge the battery.

Fuse burned out

Check to see if the indicator on the dashboard showing the battery charge is faulty. Read the technical description for your car for information about the fuse. Check its suitability with a special device. Start the car. If the indicator icon goes out, that's good. This means there are no problems with the car generator.

Broken alternator belt

A common case is when there is no voltage coming from the generator. Even a high-quality alternator belt wears out and breaks over time. It needs to be changed after a certain mileage (manufacturers indicate this figure), and not when you discover a malfunction in the car.

Alternator belt tension is loose

This is the second reason why the generator does not fully charge the battery. The belt blade may be in good condition, but its tension weakens over time. The generator does not provide sufficient voltage to charge the battery. The reason why the battery drains quickly not only when the car is moving, but also when it is stationary is precisely because the belt tension is insufficient.

Adjusts the tension. This work will take a little time. In the future, do not forget to check the belt tension. From the car manual you will learn about the frequency (in engine hours) when you need to check this parameter.

Some time after replacing the belt, it is recommended to check the tension again. The characteristic whistle that is heard when the engine speed increases sharply will tell you that it needs adjustment. You can adjust the tension yourself. You will need a pry bar and an open-end or socket wrench.

Damaged contacts or wiring

The battery often does not receive a charge from the generator due to oxidation of the contacts or defective wires. Therefore, periodically check the integrity of the insulation and power cable connecting the generator and battery. If you find a defect in the wires or cracks in the insulation, then it is wiser to immediately replace the entire wire.

Clean the contacts from carbon deposits and oxide. When the generator operates under load, a spark appears between the brushes and the commutator, causing ionization of the air. In such an environment, the terminals oxidize and a coating appears on them, which makes it difficult to transmit voltage.

If you see oxide, remove it with fine-grained sandpaper or a soft iron brush. Carry out the work carefully so as not to damage the surface of the terminals. Otherwise, due to deep scratches and dents, the contact area will decrease, which will lead to heating at the joints. As a result, sparks will appear and the charging current will be unstable.

Generator voltage regulator faulty

The engine speed is constantly changing, so the generator voltage fluctuates widely. To stabilize the voltage, a regulator is installed on the generator. A faulty generator voltage regulator is a serious problem, but it is rare.

How to check the network voltage on a car?

To measure charging, use a multimeter in DC current (DCV) mode. To find out exactly why the battery failed to charge, several methods are used to measure the voltage of the on-board network. Types of checks by connection type:

- measuring the voltage at the battery terminals. The multimeter probes are connected directly to the positive and negative terminals of the battery. The test shows the actual voltage of the on-board network;

- measuring the voltage at the generator output. The negative probe (COM) is connected to the negative terminal of the battery, and the positive one to terminal 30 of the generator (the wire with the largest cross-section is suitable for it). This connection allows you to measure the charge level without taking into account the losses due to overcoming the internal resistance of the positive wire from the generator to the battery, the connection point between the unit housing and the negative terminal of the battery.

The difference in readings should not exceed 0.1-0.3 V. A significant difference indicates parasitic resistance in the generator connection circuit.

To find out the cause of the difference, you need to connect one of the multimeter probes to terminal 30 of the generator, and the second to the positive terminal of the battery. The multimeter reading is the actual voltage loss at the ends of the conductor. If the readings are equal or very close to the voltage difference when measured at the battery terminals and from the output, it means there is a loss at the connection between terminal 30 of the generator and the battery. Otherwise, the problem should be looked for in the connection of the negative wire from the battery to the car body, as well as in the section of flexible mass from the body to the engine.

Do not forget about the possible loss of voltage at the battery connection terminals. Oxides on the inner surface, as well as loose terminals, will cause the battery to not charge completely.

Verification steps

Generator diagnostics are carried out in two stages.

- Measurements with switched off consumers. Test conditions: fully charged battery, vehicle idling. The voltage should be between 14-14.8 V.

- Measurements with consumers turned on. Test conditions: fully charged battery, the car is idling, the maximum number of powerful electrical consumers is turned on (heater fan, wipers, high beams, heated rear window, etc.). The purpose of the test is to load the generator as much as possible to check the charge level at peak consumption. The voltage should not drop below 13.8-14.3 V.

Reasons why your car battery does not charge

Below we will discuss the reasons why the battery may not charge. Diagnosing a lack of charging is not difficult, since this will immediately affect the condition of the battery. If during a trip the generator does not charge the battery, then the charged battery will completely drain. If the generator charges the battery, but not enough, it will be more difficult to immediately understand. The battery will simply drain faster than usual. But most cars have a battery charge indicator. There is an indicator on the dashboard that lights up if there are problems charging the battery. If the indicator is on, this means that no current is supplied from the generator and the power supply to consumers in the vehicle network comes from the battery.

If this is your case, then let’s move on to the reasons for the lack of charging from the generator. You can also read about the reasons for battery overcharging. It is also necessary to rule out problems with the battery itself. How to check your car battery for performance, read the article at the link.

Fuse burned out

First, it’s worth checking whether the battery charge indicator on the instrument panel itself is lying. Otherwise, you will look for a reason where there is none.

The first thing to do is check the fuse.

Find the appropriate fuse in your vehicle's manual. This information is usually contained in the electrical section. Find the fuse, check its condition and replace it if necessary. You start the engine and if the indicator goes out, then everything is fine with the generator and no repairs are required. Return to content

Broken alternator belt

This is probably one of the most common reasons for a generator not charging. The alternator belt, no matter how high-quality it is, wears out and periodically needs to be replaced.

It is better to carry out scheduled replacement of the alternator belt

It is better to change the belt after a certain mileage, as indicated in the car manual, and not wait until it breaks somewhere along the way.

Alternator belt tension is loose

Another reason why the battery may not be fully charged from the generator. Even if the alternator belt is in good condition, its tension may simply weaken, and the alternator will not produce enough voltage to charge the battery. This can cause the car's battery to drain quickly while parked.

Other causes of non-charging or poor battery charging

Where is the VAZ 2115 fuel pump fuse where is the injector located

? If, when trying to charge a dead battery from a charger, the car owner does not get the desired result, or the charging was not complete within a certain time, and the above tips did not help, then your actions will depend on the specific situation. Let's consider each case in detail.

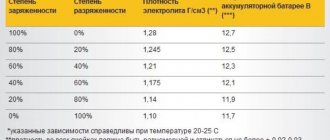

In a discharged battery, the electrolyte density does not correspond to the norm

The density is checked with a hydrometer in each jar. For temperate regions, it should be 1.27 g/cm 3, at +15 0 C. At a normal level, the density increases during charging. If the density does not increase in a bank or several banks, the battery does not take a charge. The fact that not everything is in order with the electrolyte is indicated by its cloudiness - in its normal state it is transparent and colorless.

Proceed in the following sequence.

- Observing safety precautions, drain the cloudy liquid.

- Rinse the desired jars with distilled water.

- Fill in new electrolyte, bring the density to normal.

- Recharge until normal density is achieved in all banks.

- Monitor the optimal electrolyte level and add distilled water if necessary.

It is better to wash the cans by an experienced specialist to prevent short-circuiting of the positive and negative electrodes.

Short circuit in plates

Difficulties with charging from the charger can occur when the plates short-circuit, which occurs when they fall off. In this case, lead particles settle to the bottom and come into contact with the lower ends of the electrodes.

Another possible problem is wear of the separators, in which case the positive and negative electrodes come into contact and a short circuit occurs. In addition, the positive and negative electrodes can become deformed for various reasons and short out the circuit.

If the battery design allows, the banks are repaired. Otherwise, the power supply must be replaced.

Sulfation of battery plates

The phenomenon when a white coating covers the electrodes is called sulfation. It appears if the battery has not been recharged for a long time, the water has evaporated, and the density of the electrolyte has increased. As a result, it is possible that the battery is not fully charged.

The battery may not take a charge even if the seal of the case is broken. If its integrity is violated, distilled water evaporates and the density of the electrolyte increases, with all the ensuing consequences. What to do in this case? To identify a possible defect, if it is minor, it is possible to restore the tightness by gluing or soldering with plastic. Restoring the integrity of the case is carried out without electrolyte, with a dry container.

It is possible to keep your car battery in working condition without it reaching the point where it won’t take a charge if you strictly follow the rules in the owner’s manual. Requires periodic recharging and keeping it clean.

After purchasing a new battery for a car, the owner has many questions regarding charging time and operating conditions. In some cases, car enthusiasts do not know how to prepare an electric current source for operation and whether there is any need for such an event at all. In the article we will talk about whether it is necessary to charge a new car battery, how long it takes.

Despite the apparent simplicity of a car battery, it requires periodic maintenance. Timely diagnostics and maintenance of the battery can extend its service life by several years and reduce the risk of malfunctions in the operation of on-board devices. We'll tell you how to properly service a car battery with your own hands, and what signs can be used to identify current ones.

The problem of battery discharge in the winter season is quite common. Therefore, knowing how to start a car if the battery is dead will be useful to every car enthusiast. Indeed, often the cause of a dead battery is its wear or the appearance of a current leak after unqualified installation of additional electrical equipment. Is the problem really in the battery? Winter mode of vehicle operation - .

A car battery not charging is a common problem faced by many drivers. Novice motorists, as a rule, get rid of such a power source and allocate funds for a new device. Additional costs can be prevented by identifying the true cause of the discharge.

We cut off the obvious causes of battery discharge

The battery, oddly enough, may be discharged even on a new car.

And the reason for this will be an elementary reason: short trips with frequent stops and starts of the engine. It takes time for the battery to recharge. In winter, to resuscitate the power source after one cold start, at least 30 minutes of continuous driving are required. In such matters, it is important to know the age of the battery being used. In the material on the service life of a car battery, we noted that sulfated plates and crumbling grease are encountered already in the third year of intensive use. Such a battery is physically unable to accept a charge, even if the on-board network is fully operational.

What to do if undercharging on the generator side is detected untimely

The battery is the first to suffer from failure to be diagnosed in a timely manner. The battery loses capacity due to sulfation of the plates. If this is not noticeable in the summer, then with the arrival of the first frost the engine may not start, since cranking a cold engine requires much more energy.

As a preventive measure, you can organize battery desulfation. The best tool for this is a desulfating device. If there is none, then charge-discharge cycles can be organized with a conventional charger with adjustable current and a low-beam headlight bulb. The process looks like this: we charge with minimal current and slowly discharge with a load (lamp).

Be carefull! Some batteries do not tolerate deep discharges, for example calcium batteries. A couple of deep discharges and such a battery becomes completely inoperable.

How to choose a replacement generator

When purchasing a new generator with a warranty, this item will be unnecessary. But most often it will be cheaper and more practical to purchase a used part from disassembly. When purchasing a generator secondhand, there is a risk of receiving a faulty part.

When purchasing, you need to check the generator using the following algorithm:

- Visual inspection . Dents, cracks on the body, broken seats and broken fasteners are a reason to bargain or refuse to purchase.

- Pulley rotation. The shaft should not jam and rotate silently; radial and axial play is unacceptable.

- Inspection of the plate. It is better to choose a generator that is completely identical to the standard one in voltage and speed.

- Inspection of slip rings and brushes. If there are deep grooves from brushes on the copper tracks of the rotor, then the generator has served for a long time.

- Checking the functionality of the generator. You will need a battery and a 3-volt control lamp. We connect the minus of the battery to the body of the part, the plus to the excitation terminal, marked with the number “30”. We connect one wire of the light bulb to ground, the second to the “+” terminal of the generator. We sharply turn the generator pulley by hand. If it is working properly, the three-volt light bulb will flash brightly.

- Checking the generator for breakdown of the windings. The technology is described above.

How to avoid serious damage

To minimize the risk of generator and wiring failure, scheduled maintenance should be carried out on time.

- Replacing generator brushes.

- Timely tension of the belt.

- Bearing inspection and replacement.

- Be careful when carrying out repair work.

- High-quality insulation of contacts and twists.

- The use of crimp terminals and terminal contacts when repairing wiring.

To carry out routine maintenance, it is advisable to contact a specialized service that can check the condition of the electrical wiring and promptly carry out maintenance.

Malfunctions of the generator or electrical wiring can cause many unpleasant moments for the car owner. Difficulties with starting, dim headlights, slow wiper blades... Gasoline engines cannot go very far without a generator - it takes a lot of energy to form a spark on the spark plugs. At the first signs of malfunctions, it is better to carry out a full diagnosis and maintenance of the vehicle’s electrical systems.

Algorithm for finding the cause

We looked at typical faults. But it is important to find the main reason. If the car has standard equipment and there are no abnormal energy consumers, then you can begin to diagnose the generator directly. If there are additional consumers, it is better to turn them off. In this case, it must be disconnected physically, from the on-board network.

Next, all consumers are connected and the leakage is measured in the same way with a multimeter. If it is large, then the reason should be sought not in the generator or battery, but in one of the devices in the on-board network. If no leakage currents are detected at rest, then most likely the VAZ generator is not charging. We have already discussed the reasons.