The correctness and stability of the operation of all vehicle electronics depends on the serviceability of the generator, because it powers all devices after the engine starts. Therefore, it is important to maintain the generator in “combat” condition, which means servicing it correctly. Periodically checking the generator with a multimeter will identify possible malfunctions of the device and increase its service life. More details on how to check a car generator with a multimeter (with and without removing the device) will be discussed in this article.

Multimeter - what is it

A multimeter is a measuring device used to measure resistance, current or voltage. Also, using such a device you can check the wiring for breaks. Each of these measurements involves the use of separate measuring instruments, such as a voltmeter, ammeter or ohmmeter. Therefore, a multimeter is considered a universal tool (mulmeter = voltmeter + ammeter + ohmmeter). In practice, analog and digital multimeters are used.

What is a multimeter

Analog

This multimeter is equipped with a special hand, like on a watch, by the movement of which the measurements are read. The analog multimeter is also equipped with a measuring scale with resistance, current and voltage values. The device is inexpensive, so it is very popular. The disadvantages of an analog multimeter include measurement errors (this mainly applies to products made in China).

Analog multimeter

Digital

Unlike an analog multimeter, a digital multimeter has an LCD or LED screen that displays data. These devices are easier to use and also have high accuracy, which cannot be said about cheaper analogues.

Digital multimeter

Note! Some types of digital multimeters can work in conjunction with a computer, transferring data obtained as a result of measurements to it.

Video - How to use a multimeter

What elements does the stator of a synchronous generator consist of and the principle of operation?

- Package of stator windings;

- Stator core or package;

- Wires for connection output.

The stator itself is made of three windings, three different current values are formed in them, this circuit is a three-phase output. The ends of each winding extend from the generator body (they are connected to it), the second end is connected to the rectifier. To concentrate and enhance the magnetic field in the generator, a core made of metal plates is used.

The stator winding of a synchronous generator is located in special slots, usually there are 36 such slots. In each slot, the winding is held by a wedge. This wedge is made of insulating materials.

Possible generator breakdowns

All generator malfunctions can be divided into two types - mechanical and electrical. Mechanical breakdowns can be identified by visual inspection of the device (cracks in the housing, wear of the tension roller or belt, delamination, etc.). To identify electrical faults, special tools are needed.

Common generator problems

Table. Damage to the electrical part of the generator.

| Malfunction, photo | Description |

| Failure of the relay regulator | The relay is responsible for the battery, preventing the generator from recharging it. Failure of the relay-regulator leads to a complete lack of charge. In this case, diagnostics is required. |

| Brush wear | The graphite brushes moving along the generator stator tracks wear out quite often. They need to be changed periodically. |

| Winding burnout | The winding on the rotor or stator may burn out as a result of overloading the device. It can also short out when exposed to moisture. |

| Bearing jamming | During the operation of the car, the alternator bearings wear out, as a result of which the generator begins to jam. This leads to a rupture of the belt and, as a result, to failure of the generator. |

Some faults are difficult to notice, so drivers come to the service center with a generator that is no longer working and a “tired” battery. Therefore, it is important to periodically diagnose the generator using a multimeter.

How to test a generator with a multimeter

Causes and solutions to the problem

If you have the opportunity to borrow someone else’s battery for testing, you can try installing it in the car instead of yours. Of course, this battery must be fully working. Actually, in this way you can find out what the cause of the problem is - in the battery or in the generator. Below we will consider the reasons for this malfunction.

Internal condition of the battery

Typically, the reason why the generator cannot charge the battery is due to sulfation of the battery plates. In this case, the surface of the plates may be covered with salts - partially or completely - which prevent the battery from charging. If the degree of plate coverage is small, then, in principle, you can always try to restore the functionality of the battery. However, if the destruction process is no longer reversible, it will be necessary to replace the device.

As for restoring the battery structure from sulfation, this process can take more than one day, and the result and quality of restoration cannot be guaranteed. This means that you may eventually need a new battery anyway. The resuscitation procedure, as a rule, begins when the battery shows no signs of swelling, mechanical damage, cracks, etc. That is, the device body must be intact.

Installing battery terminals to terminals

But it should be borne in mind that the external state is not always a guarantee that the result will suit you. Inside the structure there are banks in which plates can break off, which ultimately leads to a short circuit. If this is the case, then there are no other options other than buying a new battery.

Terminals

Sometimes the indicator light may appear while driving a car. At this moment, you should not panic, as the reason may be quite banal. If you hit a bump or a hole, the contact may simply fall off the battery, especially if the terminal was not screwed on properly. If this is the case, then you just need to put it back in place and tighten it harder.

Problems with terminals can occur if they become oxidized at the point where they connect to the terminal. To solve this problem, the oxidation simply needs to be cleaned up. To do this you will need fine grit sandpaper. You need to be as careful as possible during the process, since you can accidentally cut off the lead part of the terminal, and this is unacceptable. If you erase more layers than necessary, the terminal will not hold well and will begin to fall off on every bump (video author - Avramenko Garage).

Generator belt

What charge should the generator provide and for what reasons does the battery overcharge or fail to charge? Quite often, the problem lies in the strap of the unit - if the tension is weak, the belt will begin to slip on the shaft, at this moment the unit will not be able to supply voltage to the system. The battery is switched and the charged battery turns from an energy consumer into a source of consumption, which is gradually discharged.

Diagnostics of the degree of belt tension can be carried out with the engine turned off. If the internal combustion engine is disconnected, you can try to tighten it if necessary. But it should be borne in mind that slippage can be caused not only by poor tension, but also by profile wear. This problem can only be solved by replacing the strap.

A wet or damp shaft can cause the impossibility of transmitting rotation - the strap will slide over the surface without effort. In order for the battery to charge normally, the pulley must be dry, so it will only be enough to dry it. It is quite difficult to determine slippage; in this case, the strap may break.

The cause of the problem may be oxidation of the wires on the generator unit at the connections. If you notice a white coating, then, as stated above, it can be removed with sandpaper. Carry out a visual check for possible broken wires or burnt contacts. If the wire is burnt out, this may be indicated by a characteristic smell (the author of the video is VAZ 2101-2107 REPAIR AND MAINTENANCE).

Checking the generator without removing it

Step 1: Set the parking brake and raise the hood.

Lift the hood

Step 2 . Connect the multimeter to the battery terminals (do not mix up the “+” and “-” terminals). Place the device itself on the battery, as in the photo. When the car is not running, the battery charge should be about 12.5-12.6 V.

Connect the multimeter to the battery

Step 3: Start the engine.

Start the vehicle

Step 4: Monitor your metrics. 1-2 seconds after startup, the voltage should increase to 14.3-14.4 V.

Monitor your multimeter readings

Step 5. Give maximum load to the generator. To do this, you need to turn on all the car's consumers: lights, heater, heated windows and mirrors.

Turn on the light Turn on the stove

Turn on the heated seats

Step 6. Monitor the battery voltage. If the indicators have changed slightly (14.1-14.2 V), then this indicates normal operation of the generator. If the voltage drops significantly when the devices are turned on (to 13-13.5 V), then diagnostics of the generator is needed.

Monitor the voltage coming from the generator

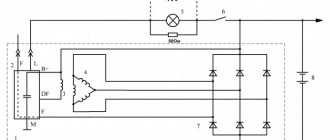

Diode bridge functions

For charging and normal operation of the battery, direct current is required, but the generator produces only alternating current. To make the desired conversion, a diode bridge is used. The electronic components included in this unit conduct current in only one direction, rectifying it. The resulting voltage drops are smoothed out by the battery, “replacing” the capacitor. The functions of valves are most often performed by silicon diodes. However, it is possible to use other types of rectifiers - for example, selenium pillars.

Check with removal

No preparations or preparatory steps are required for testing. You just need to remove the generator itself and prepare a multimeter. A full check of the device consists of diagnostics of the relay regulator, diode bridge, stator and rotor windings. Let's consider the procedure for checking each of these elements separately.

Checking the generator with a multimeter and removing

Checking the relay regulator

Step 1. Remove the relay regulator and prepare a multimeter.

Remove the relay regulator

Step 2. Prepare a light bulb with two wires (as in the photo).

Connect a light bulb with two wires

Step 3. Connect the wires from the light bulb to the brushes ( See Replacing generator brushes ) of the relay regulator.

Connect the wires to the brushes

Step 4. Now you need to connect an regulated power supply to the “+” and “-” relays.

You need to connect the power supply to the plus and minus

Step 5. Connect the negative of the power supply to the negative of the relay. Secure the wire using a metal crocodile clip.

Connect the minus of the power supply to the relay

Step 6. Connect the second terminal of the power supply in the same way.

Now connect the plus

Step 7. The finished design should look like this.

This is what the design looks like

Step 8. Now connect the multimeter to the terminals of the relay regulator. Everything is the same: “minus” to “minus”.

Connect the negative of the multimeter to the relay regulator

Step 9. Connect “Plus” to “Plus”.

Connect the positive terminal of the multimeter

Step 10: Turn on the power supply to supply voltage to the relay. The multimeter shows 3.8 V after switching on.

Turn on the power supply

Step 11. Gradually increase the voltage, look at the light bulb and the meter readings. The brightness of the light bulb gradually increases.

Slowly increase the voltage on the power supply

Step 12. At around 14 V, the light should go out suddenly. If this happens, then the relay regulator is working properly. Otherwise, replacement of this element is required. At this point, testing the relay-regulator under load can be considered complete.

When the voltage increases to 14 V, the lamp should go out

Checking the diode bridge

Step 1. To work, prepare a multimeter with a ringing function and a diode bridge, which must be removed from the generator in advance.

Prepare the diode bridge and multimeter

Step 2: Check the first diode. It has positive polarity. The resistance of a working diode when tested in one direction should be from 400 to 700 Ohms.

Check the first diode with positive polarity

Step 3. In the other direction the resistance should be infinity. If this is the case, then the diode is fully operational.

Test the diode in the other direction

Step 4. Test the second negative diode in the same way.

Check the second negative diode

On a note! The resistance of the diodes can vary within certain limits and depend on the ambient temperature. When heated, the resistance decreases, and when cooled, it increases.

Step 5. Using this diagram, check all the remaining diodes. A burnt-out diode will have a resistance of infinity.

Repeat the procedure for the remaining diodes

Step 6. Small diodes are tested in the same way as large ones. The resistance of these diodes will be slightly lower than that of larger ones. A slight difference in the resistance of these diodes is considered normal. This completes the check of the generator diode bridge.

Check the small diodes on the bridge in the same way

Stator check

Step 1. Prepare the generator winding for testing. It is advisable to do this in a well-lit place.

Prepare the stator for diagnostics

Step 2. Take a multimeter and set it to test.

Set the ringing mode on the multimeter

Step 3. The winding has three outputs and they should all “ring” with each other.

The winding outputs should be directed upwards for convenience

Step 4. Connect the first terminal of the multimeter to one output, and touch the second terminal to the other two outputs in turn.

Connect the multimeter terminal to the winding output

Step 5. Check the stator for any holes in the metal. To do this, press the multimeter terminal to the edge of the winding, and the second one to the second edge.

Check the stator for metal damage

Step 6. Connect the second probe in turn to the winding outputs. If there are no signals, then the winding is intact.

Connect the terminal to the winding outputs one by one

Rotor check

Step 1. Prepare the generator rotor for further diagnostics.

Prepare the rotor for diagnostics

Step 2. Take a multimeter and set it to dial mode. The black probe should be in its original place, and the red one should be for measuring voltage.

Set the dialing mode on the multimeter

Step 3. Check the device for serviceability by connecting the black and red probes.

Connect the probes of the device to check its functionality

Step 4. Attach one feeler gauge to one rotor ring and the other to the other. In this way you can check for a break.

Attach the probes to the rotor rings

Step 5. Check the rotor for breakdown. To do this, one probe must be pressed against the ring, and the second against the body. If there is no breakdown, then the multimeter shows infinity.

Check the rotor for breakdowns

Step 6. Set the multimeter to resistance measurement mode in the 200 ohm range.

Set the resistance measurement mode on the multimeter

Step 7. Place one feeler gauge on one rotor ring, and the second on the other (as done previously). If the winding is intact, then the resistance should be around 3 ohms.

Reattach the probes to the rotor rings

Possible problems

Is your car battery not charging from the alternator even though the car is used regularly? There are many reasons for this. Let's take a closer look at those that motorists most often encounter.

The generator works but does not charge the battery

The battery icon, glowing red on the dashboard when the car is moving, indicates that due to a combination of circumstances, the battery has stopped receiving energy from the generating device. That is, the generator works, but for some reason does not charge the battery. The root cause may be hidden both in the generating device itself and in the battery. Initially, you should determine the reason for the current leak, and in addition, measure the voltage at the terminals, check the level and density of the electrolyte, which in most cases will allow you to identify the culprit of the malfunction. Usually the reason is as follows:

- Burnt fuse. When this happens in the battery circuit, charging will not go directly to the battery; the remaining electrical consumers of the car will operate as normal. In addition, the voltmeter will show the presence of voltage in the on-board network.

- The generator belt is broken or its tension is loose. In such a situation, under load, the generating device will “slip”: the belt slips on the pulley, making whistling sounds. When the headlights are turned on, the indicator on the panel indicating that the battery is low will light up. Eliminate the cause of the malfunction by replacing the belt, adjusting its tension.

- Damage to contacts or wiring. Oxidized battery terminals contribute to current leakage and do not allow the battery to accept charge from the generator. The condition of the contacts should be checked not only on the battery itself, but also on the generating device, as well as on the vehicle’s ground. The oxide is removed by cleaning or with a special lubricant. The generator is connected directly to the battery with a thick wire. If it is damaged or has manufacturing defects, the battery will not be charged.

Charging "jumps"

Sometimes the generator charging current can fluctuate over a wide range. This affects not only the full supply of energy to the battery, but also other consumers: dim headlights, the interior light bulb blinks, the radio operates intermittently. The main reasons for the instability of the amount of incoming charge:

- The generator regulator is faulty. The device, which is a relay, must ensure the voltage of the on-board network is within acceptable limits, regardless of the load, temperature conditions, and shaft speed. The sensor device is nothing more than a conventional electronic circuit with outputs to graphite brushes. Equipment malfunction may be caused by:

- poor contact between wires or a break in the electrical circuit;

- incorrect adjustment;

- short circuit between contacts;

- sintering of contacts, breakage of the armature spring. Damage to the device usually manifests itself in a regular lack of battery charge or, conversely, its excess. You can check the device's functionality using a tester set to voltmeter mode.

- Failure of the diode bridge. The structural element of the generator performs the functions of a collector, replacing it. A bridge circuit is necessary to equalize the ripple of alternating current and convert it to direct current. The main factors leading to failure:

- problems with the battery - low electrolyte density or short circuit of its cans;

- incorrectly performed “lighting” from another car;

- dirt or moisture that has penetrated inside the generator housing.

Signs of malfunction:

- instant discharge of a fully charged battery;

- the appearance of whistling sounds from under the hood when starting the engine or while driving;

- a steering fault is displayed on the display and the power steering stops working;

- headlights dim quickly when driving;

- The car radio and air conditioner turn off.

In addition, there are several situations when the battery will be discharged intensively, but this is not associated with malfunctions in the generator-battery system:

- The battery is reaching the end of its factory life.

- Rare trips over short distances with a full electrical load - the maximum number of consumers is turned on: headlights, radio, air conditioning, and so on.

- Standing idle in traffic jams for many hours with the engine running.

Additional recommendations

Before starting the test, you need to familiarize yourself with the type of generator set, because the relay regulator can support different values depending on the car model. We are talking about the range from 13.6 to 14.2 V. All these subtleties need to be learned before starting the test, because the final result may depend on them.

Checking the car generator

Otherwise, the process of checking the generator is simple, so even without experience, the driver can do it on his own. Of course, you need to start by checking the generator without removing it. Only by its results can you determine whether the device needs to be dismantled or not. Also, during the test, you can identify other faults related to the generator or other electrical devices of the car.

Generator diagnostics will help prevent serious malfunctions