Print this article Font size 16

The generator's task is to ensure the functionality of the entire electrical circuit of the car. In this case, we are talking about the VAZ 2114 model. The system facilitates the distribution of electricity. It cannot be called perfect and trouble-free, so sometimes certain problems may arise.

Device elements

Main malfunctions of the VAZ 2114 generator

- The fuse has blown. To fix this problem, you just need to change the fuse. But first you need to find out the reason.

- The circuit supplying the devices is broken. Be sure to check the connection of the neutral wire with other contacts.

- Damage to the ignition switch. Make sure the ignition switch circuit board is in good condition.

- Indicator lamp malfunction.

- Brush malfunction. To eliminate the problem, it is necessary to replace the brush holder and the brushes themselves; it is enough to clean the oxidized slip rings with gasoline, or treat them with WD-40.

- Malfunction in the voltage regulator.

- Damage or malfunction of the alternator belt.

- The bearing is faulty or broken.

The described malfunctions are very common, if you ignore them and do not make the necessary repairs in a timely manner, the generator will be permanently damaged, and subsequently it will have to be completely replaced. Which in monetary terms is much more expensive than repairing minor problems.

But don't rely on yourself if you don't have the appropriate training. The best solution would be to contact a service station for qualified assistance.

Why change brushes?

If signs of brush breakage are detected, they should be replaced. If repairs are not carried out in a timely manner, there is a possibility that you will soon need to purchase a new generator, and this is a completely different expense. The battery can only hold the ignition without brushes for a few minutes, which means it will have to be constantly charged. And soon it will be replaced. You can check the condition of the brushes by the size of their protrusion from the seat. If the protrusion size does not reach five millimeters, then they should be replaced immediately to avoid possible problems.

It is recommended to replace it every 50,000 km or every season, which is the key to safe operation of the vehicle. It is better to have a spare set of spare parts so as not to get into an unpleasant situation on the road and then call a tow truck.

For a set of brushes you will need to pay from 150 to 200 rubles, depending on the store. The cost of repairs at a car service center will cost 200-300 rubles, inexpensive, of course, but why pay for something that you can do yourself?

Checking the serviceability of the generator

Defects in the operation of the generator can have unpredictable consequences. If there is insufficient charge coming from the alternator, the consequence will be that the battery will die and as a result the car will simply stall. But the most dangerous thing is that if the alternator produces high voltage, the entire electrical system of the vehicle will be damaged as a result.

We check the power of the VAZ 2114 generator using a tester:

- After turning on the ignition key, make sure that the instrument panel lights are on, only then the engine starts. If the battery icon is lit or blinks dimly, this indicates damage to the generator circuit.

- The engine must be warmed up to 90 degrees, only after that all energy-consuming devices must be turned on.

- We connect the tester directly to the battery. The assistant accelerates, keeping the rpm at approximately 3200 - 2500. If the voltage is 13V, the generator is working.

- We turn off the devices consuming energy, and again take measurements, also at engine speeds of 3200 - 3500. The generator is operational if the voltage is 14.7V.

On a note! The main reason why the generator produces low voltage, below the level of 13V, may be due to malfunctions: insufficient tension of the generator belt, the generator circuit is damaged, the voltage regulator is damaged, the brushes are completely worn out, the generator must be replaced.

While the car is running, you need to pay attention to the sounds coming from the generator; if you hear a hum, this is an indicator of bearing wear, in this case it needs to be replaced.

Basic problems

There are several main problems specific to a generator. If you study them, it will be quite possible to carry out repairs even on your own.

We will list them and also tell you about the necessary additional actions to eliminate them.

| Breaking | Your actions |

| Fuse blown | To fix this problem, simply replace the old fuse with a new one. But be sure to determine the reason why the problem arose |

| The circuit supplying the devices has broken | In this situation, be sure to make sure that the neutral wire is connected securely to the other contacts |

| Having problems with the ignition switch | Check if the ignition switch board is working |

| The control lamp has failed | Just change the device to a new one if the lamp just burns out |

| The brushes are out of order | You will have to change the brushes themselves, as well as their holders. Check the contacts for oxidation. They can be treated with WD40 or cleaned with gasoline |

| Voltage regulator does not work | This unit must be replaced. It is impossible to repair it |

| The alternator belt is damaged or faulty | You can try to adjust the belt tension if this is the problem. If the unit is damaged, it must be completely replaced. |

| The bearing has failed | Only its complete replacement will help here. |

Such breakdowns occur quite often, so they cannot be ignored at the first sign. Having understood the structure of the generator, solving problems with its malfunction becomes much easier.

In some cases, it is not possible to resolve the issue by replacing or repairing individual elements of the generator, so the only correct solution is to completely replace the unit.

Where is he located

Before removing the generator, you need to at least figure out where this device is located.

This unit is located in the engine compartment to the left of the engine. Look in relation to the interior in the area near the front right headlight.

This is exactly where the desired element is located.

Location

Functionality check

If the generator does not work correctly, the consequences can be unpredictable. If the charge coming from the device is low, the battery will quickly run out and your VAZ 2114 will simply stall. High voltage is even more dangerous because it damages the entire electrical circuit of the car.

The power indicators of the generator can be measured using a tester.

- Turn the ignition on and make sure all the lights on the dashboard come on. After this, start the power unit.

- If the battery icon lights up on the panel or blinks dimly, there is damage to the alternator circuit.

- Warm up the engine to approximately 90 degrees, then turn on all volatile devices.

- Connect the tester directly to the battery. The second person at this moment will press the gas pedal and keep the speed in the region of 3.2-2.5 thousand revolutions.

- When the tester reads 13V, the generator is working properly.

- Now turn off all power consumers and take measurements again. The revolutions are kept the same. If the generator is working properly, the tester readings will be 14.7V.

- At the same time, we recommend paying attention to the sounds that come from the generator. If there is a hum, there is a high probability of bearing wear, which should be replaced.

Low voltage can be caused by one of several reasons:

- The timing belt tension is not strong enough;

- The generator circuit is damaged;

- The voltage regulator is faulty;

- The brushes are worn out;

- The generator is worn out and needs to be replaced.

What causes the battery sign to light up on the dashboard?

When you turn the ignition key, the system turns on all the lights on the dashboard, allowing you to check that the systems are working properly. After this, the engine starts and all these lamps go out. But only if the car is in good working order.

If one of the lamps remains on, there is a problem with the car.

As for the battery icon, its glow when the engine is running indicates that the voltage generated by the generator is too weak or completely absent.

Replacing brushes

Replacing generator brushes is not difficult if the need arises. Such work is carried out if natural depreciation occurs.

There can be several reasons for depreciation:

- The battery is not receiving a charge;

- At night, the headlights do not generate enough light;

- Reduces tension, etc.

Typically, service stations do not pay much attention to minor generator malfunctions, so discovering failed brushes is often a complete surprise.

To replace, you will need to disassemble the assembly along with the voltage regulator.

- Disconnect the negative terminal from the battery.

- Disconnect all wires.

- Remove the cap from the plus terminal wiring system, unscrew the nut that holds this bundle in place, and remove it from the block.

- Remove the plastic casing. To do this, you must first disconnect the clamps.

- Now unfasten the regulator fasteners.

- When you remove the regulator, be sure to disconnect the wiring harness.

- The brushes are replaced in a similar way, but with a changed sequence.

- All disassembled elements are returned to their places.

The brushes are replaced as they wear out. The rod should be less than 0.5 millimeters in length, which indicates the need for replacement. If the rod length is normal, the cause of the malfunction may be a damaged regulator.

Regulator check

The regulator is checked together with the brush holders. This will allow you to immediately detect damage in the circuit of the regulator and brushes, if any.

Three-level voltage regulator

To check you will need:

- Wires;

- 12V light bulb;

- AA batteries;

- Car battery.

- If the regulator is working properly, the voltage will be 14.7V. If the supply is higher than the norm, the voltage supplied to the brushes will have to be stopped.

- If there is a problem with the regulator, the lamp is on, the device is most likely damaged.

- If the lamp is not lit, the contact that connects the brushes to the regulator may be broken. Or there is a break in the circuit.

- If the voltage is less than 13V, the regulator must be replaced with a new one.

- The job of removing and replacing the voltage regulator is similar to replacing the brushes, since both devices are removed together.

Belt tension

In many ways, the functionality of the generator depends on how correctly the timing belt is tensioned. If the tension is too weak, problems will occur in the on-board system. You can identify the problem by a whistle coming from under the hood and a flashing battery icon on the dashboard.

When the tension is too strong, there is little good in it either. Because the service life of the bearings is significantly reduced, and they soon fail.

The timing belt must be replaced after every 15 thousand kilometers. Be sure to periodically check its condition for signs of peeling or tears. If they are found, be sure to replace the unit.

The tension indicator depends on the timing belt model used.

- Model 37.3701 provides tension with a permissible deflection of 10-15 millimeters;

- Model 9402.3701 allows deflection within 6-10 millimeters with a pressure of 10 kilograms.

The tensioning procedure directly depends on the type of engine used in your VAZ 2114. Therefore, we will tell you about each type of engine separately in our table.

| engine's type | Tension procedure |

| 1.5 liter engine | — Loosen the generator fasteners; — Use the adjusting screw to adjust the tension; — To increase tension, the screw moves clockwise; — When the tension is weakened, we move counterclockwise; — After adjustment, secure the generator and check the belt. |

| 1.6 liter engine | — In a similar way to the 1.5-liter engine, we loosen the generator fasteners; — Using a crowbar, the generator is slightly moved away from the motor, which allows you to tighten the belt; — By moving the generator towards the engine, you loosen the tension; — Tension the belt, secure the generator and check for proper operation |

If this method does not resolve the problem, you should look for other causes of the problem.

Device from Priora on VAZ 2114

It is not uncommon for VAZ 2114 owners to think about installing a more efficient, powerful generator on their car.

Regulator from Priora

In this case, experts recommend using a device from Priora or Kalina, which these models receive with air conditioning.

The power of the units is 115A, while a regular factory generator has only 80A. The difference is significant, as you can see.

In this case, you will definitely have to change the pulley on your VAZ 2114. The task is simple, and it will cost a small amount of money.

Also pay attention to the Eldix generator. Its power is 115A, perfect for the “fourteenth” model. The only, but serious, disadvantage is that it is very difficult to find spare parts for it.

Why does the battery icon light up on the dashboard?

When you turn the ignition key, the system displays all icons on the instrument panel to check the vehicle’s serviceability, i.e. All system lights are fully functional. Then the engine starts, so the lights should go out when the machine is in full working order. But if one of the lights does not go out, this indicates an existing problem.

Accordingly, if the battery icon does not go out, this is a consequence of the fact that the generator supplies too little voltage, or it is completely absent.

How to check a generator with a multimeter - do-it-yourself repair and maintenance

There are only two devices that ensure the functionality of the car's ignition system. Battery and generator. They function in pairs, complementing each other.

Any of these devices can operate separately from the second for a short time. It is allowed to drive for some time with a faulty generator until the battery is discharged. Also, a spark in the ignition can only be maintained by a generator, but the problem arises when starting the engine for the first time - without a battery, the crankshaft cannot be cranked.

Moreover, coordinated work will be disrupted not only if the generator breaks down. If the voltage produced deviates from the norm, the battery will not charge, and the vehicle's electrical systems will either not start or fail.

Replacing generator brushes after their natural depreciation

Reasons for depreciation of generator brushes:

- Voltage drop.

- At dusk, there is insufficient illumination from headlights.

- The battery is not charging.

- and etc.

During normal maintenance, no one pays attention to small problems of the generator; for this reason, worn brushes are always a surprise. Do not rush headlong to change brushes if primary symptoms of problems occur. Find out the source of the problem, then disassemble the generator housing.

How to dismantle the generator brushes:

Before carrying out work on replacing the generator brushes, it is necessary to remove the assembly together with the voltage regulator, so we unfasten the minus terminal and disconnect the wires from the casing.

- Disconnect the wires.

- We remove the cap from the output wire system to +, disconnect the nut securing this bundle and remove it from the block.

- We remove the plastic casing, having first disconnected the clamps.

- Disconnect the voltage regulator fasteners.

- When removing the regulator, do not forget to disconnect the wire block.

- We change the brushes using the same method, but the sequence changes; we install everything in its original place.

Just a note! Be sure to check the wear of the brushes; they change when the length of the rod wears down to less than 0.5 mm. If the brushes are of normal length, a possible reason for the lack of charge is a malfunction of the voltage regulator or brush regulator circuit.

Repair of generator components

Most often the voltage regulator breaks down. This device is connected to the brush holder. When there is a lot of wear on the brushes and the voltage regulator does not work, the entire unit is replaced. It is bolted to one of the generator covers. Replacement is carried out with the negative terminal removed. In this case, the VAZ generator is not disconnected. When the belt fails, it must be replaced. Replacing the VAZ alternator belt is done in the following sequence.

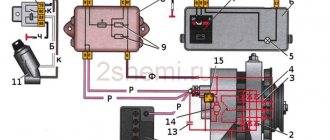

Connection diagram for testing the generator on the stand: 1 – generator; 2 – control lamp 12 V, 3 W; 3 – voltmeter; 4 – ammeter.

- The adjusting bar is unscrewed, for which the fixing nut is released.

- The generator is moved towards the engine, the old belt is removed.

- A new alternator belt is installed, after which it is tensioned. The generator moves away from the engine, the belt stops sagging. Sagging is allowed no more than 8 mm.

- The position of the element is fixed by tightening the nut.

Repair of the rectifier unit is done in case of failure of the diode bridge. To carry out such an operation, the generator must be removed and completely disassembled. New diodes are soldered. All work must be carried out with the utmost care, as there is a risk of damage to the unit body. Soldered diodes are filled with epoxy resin. After it dries, the block is installed in place and the entire assembly is assembled.

Checking the voltage regulator

As we have already found out, the voltage regulator is checked together with the brush holders, so that if the circuit between the brushes and the regulator is damaged, we can immediately see this problem.

First, we check the brushes to see if they are broken or worn out; therefore, on your VAZ 2114, replacing the generator brushes is inevitable.

We prepare the necessary parts for testing, these are wires, a car battery, a 12V light bulb, AA batteries, to build two circuits:

Checking the voltage regulator

Checking the voltage regulator

If the voltage regulator is working properly, then the voltage is 14.7 V. If the supply exceeds the norm, it is necessary to stop the supply of voltage to the brushes.

If there is a problem with the voltage regulator, if the lamp is on, the cause is damage to the regulator. If the lamp does not light up at all, the reason is that there is no contact connecting the regulator and the brushes, or the circuit may be broken.

The regulator must be replaced if the voltage is less than 13V when the on-board system devices are turned on. An increased voltage of more than 14.7V may also be a consequence of damage to the regulator.

The process of removing and reinstalling the voltage regulator completely coincides with the process of removing the brushes from the generator, because they are removed along with the voltage regulator.

Useful video

You can get additional information on this issue by watching the video below:

- replacing speed sensor VAZ 2114 injector 8 valves

- Installation and connection of fog lights for VAZ 2114

- Coolant level sensor for VAZ 2114: device, check and replacement

One day the car stopped starting from a dead battery, I charged the battery and drove it for 3 days after which it was discharged again. At that time I was still just a novice motorist, so I immediately thought that the battery was faulty, I bought a new one in the store, brought it and installed it, literally 5 days later the car would not start again because the battery was dead. I went to the store and demanded a replacement, after much persuasion from the manager, they finally agreed to replace the battery. Well, history repeated itself, then I realized that I had to go to a car service center; they didn’t tell me about the generator malfunction. This is how I unknowingly killed a lot of nerves and time.

Source

Alternator belt tensioning procedure

An important factor is the tension of the alternator belt. If its tension is weak, the voltage in the on-board system can be reduced. In this situation, a whistle is heard, and the battery icon on the dashboard begins to flash.

Strong tension also has a negative effect, since it negatively affects the life of the bearings in the generator.

Important! The alternator belt must be replaced every 15,000 km. When visually checking the belt, pay attention to its structure; it should not peel off or tear, otherwise it should be changed urgently.

The permissible belt tension depends on the generator: for model 37.3701, when tensioning, the permissible deflection is 10 -15 mm, for model 9402.3701, the deflection is allowed 6 - 10 mm, when pressing 10 kg.

Step-by-step instructions for disassembling the generator

1 - Pulley; 2.4 - Thrust washer; 3 - Front cover; 5 - Rotor; 6 - Stator; 7 - Back cover; 8 - Plastic cover; 9 - Diode bridge; 10 - Brushes;

- Remove the plastic back cover of the generator (8);

- Unscrew the brushes, remove the chip from the diode bridge and take them out (10);

- Unscrew the capacitor from the generator housing;

- Unscrew the bolts holding the stator winding to the diode bridge;

- We bend the leads of the stator winding and take out the diode bridge (9);

- Unscrew the 4 bolts securing the rear cover of the generator and use a puller to remove it (7);

- We clamp the generator rotor (5) through a rag (be careful not to split the armature) into a yew and unscrew the pulley (1);

- Remove the pulley and use a puller to remove the front cover of the generator (3);

- The disassembly process is complete;

We tighten the belt

The tensioning process itself depends on the engine size of 1.5 or 1.6, since the VAZ 2114 model.

1.5 L engine:

- We loosen the fastening of the VAZ 2114 generator.

- Using the adjustment screw, we adjust the belt tension; if we need to tighten it, we act clockwise; if necessary, loosen the direction of movement counterclockwise.

- When we have reached the required belt tension, we strengthen the generator and be sure to check the belt.

1.6 L engine:

- In the same way as in the first case, we loosen the fastening of the VAZ 2114 generator.

- Using a crowbar, we move the generator slightly away from the engine and tighten the belt; if it is necessary to loosen the belt, we move the generator in a different direction, i.e., towards the engine.

- After completion, secure the generator and check the belt tension.

Important! After the work was done, the problem did not disappear, the voltage drop process continues, so the problem was not identified, be sure to check the generator.

Causes of malfunction

Photo of the VAZ 2114 generator

Electrical faults:

- the unit produces too low voltage;

- the installation is heating up;

- no battery charging voltage;

- The charging voltage exceeds the required values.

Mechanical failure causes increased noise in the unit when the engine is running. The cause of noise may be wear of the bearings. First, the bearings in the front cover wear out. They are subject to increased load, so they wear out faster and may fail.

Generators for VAZ 2114 and Priora in comparison

Many car enthusiasts want to install the most powerful type of generator in their car. In this case, the best option would be a generator with air conditioning used for installation on models such as Priora and Kalina. The power is 115A, while the power of the factory copy is only 80A.

But there is a small nuance: you will have to replace the pulley; this is an inexpensive and fairly easy procedure.

Many car owners recommend the Eldix model generator, with a power of 115 A. It is a good model, but it has a huge disadvantage: it is impossible to get spare parts.

How to identify electrical problems in a car?

The first step is to understand whether your car really has power problems. There are two groups of problems in this regard; roughly, all problems can be divided into problems during startup and strange operation of the electrical network after starting the engine

It is important to distinguish this because different modules are involved in these processes. It’s worth figuring out what symptoms of the car you should look for if the electrical network is not working well after starting the engine:

- the operation of all the lamps in the cabin, as well as the headlights, side lights and brake lights is too dim; this may not be very noticeable, but in reality the difference in brightness is noticeable;

- turning off some elements of the electrical network without permission under fairly heavy loads, for example, when the fan in the cabin is turned on, the music may turn off;

- when revving up at idle, the brightness of the interior lighting noticeably increases for a second, but when other equipment is turned on, the brightness decreases;

- perhaps a barely noticeable or annoying blinking of the light, uneven illumination of the road, rapid failure of light bulbs in various modules of your car;

- a decrease in fan speed is noticeably felt when optics, music or other power consumers are turned on; there may be an incorrect connection in the network.

The problem is that a car owner can easily get used to many such manifestations. And in this case there will be no surprises. You can get used to dim light, poor airflow and other troubles. But in general, this mode of operation is very harmful to your car. Sudden failure of the fuel pump, climate system, poor operation of the automatic transmission and other components is possible.

Signs of a faulty generator diode bridge

The bridge is an electrical circuit of diodes that process signals from alternating current flows into direct current. Problems with the generator directly depend on problems in the diode bridge.

Problems that can completely leave the battery without a charge or charge the battery more than normal ultimately have huge negative consequences with the internal electrical system of the car.

The function of the diode system is not only in the process of converting current pulses, but also in its unipolar transmission from the generator to the battery. Accordingly, if the diode is faulty, the current is directed in both directions, or the current supply is completely stopped. The cause of damage and malfunction of the diode bridge is poor-quality contacts, or as a result of moisture penetration.

To check the diodes, the bridge must be dismantled using fairly light manipulations.

We dismantle the diode bridge of the generator:

- Disconnect the “-” terminal from the surface of the battery and detach the wiring system from the casing.

- Unscrew the wires.

- We remove the rubber cap from the wires + terminal, disconnect the nut securing these wires and remove them from the generator block.

- We remove the plastic casing, having previously unfastened the fastening system.

- Disconnect the mount for the regulator.

- When removing the voltage regulator with brushes, do not forget to unfasten the wire block.

- Use a wrench to remove the bolts securing the bridge.

- Having bent the leads directed to the stator winding, we unscrew the capacitor mount.

- We take out the diode bridge. We unscrew the 2 nuts of the contact bolt, remove the bushings from it, and also remove the bolt from the bridge. That's all, now you can change or check the diode bridge.

- We repeat the installation process in reverse order.

Removing the diode bridge

Problems with the brush assembly

The performance of the brush assembly directly depends on the electronic controller and the brushes themselves. By the way, it is possible to replace the brushes without dismantling the generator, however, this is quite inconvenient.

In order to check whether the brush assembly is working, you need to take a 12-volt light bulb and an regulated power source. Connect the light bulb to the brush, and the power regulators “+” and “-”. Thanks to this action, the light bulb should light up immediately. If the input voltage is increased to 15 Volts, the light should go out. But if it continues to burn at 16 Volts, the electronic regulator should be replaced.

The wear of the brushes themselves can be determined by the following parameters:

- complete lack of battery charge;

- The charging voltage constantly fluctuates;

- The on-board network voltage is lower than specified.

How to remove a generator on a VAZ 2114

We remove the VAZ 2114 generator:

- In order to remove the VAZ 2114 generator you need a pit or a lift.

- The protection must be removed from the engine.

- The tension roller for the drive belt needs to be loosened.

- Disconnect the top bolt securing the generator.

- Then remove the bottom bolt securing the generator.

- Disconnect the air conditioning compressor mount.

- The drive belt is removed and the VAZ 2114 generator is removed from its seats and subsequently shifted to the right closer to the battery.

- Then simply unscrew the top bolt securing the air conditioning compressor.

- We simply take out the compressor and hang it up; the tubes are strong enough and can easily support its weight.

- The generator holder bolts must be unscrewed.

- After disconnecting the terminal, the generator and its holders can be pulled down.

- Installation follows the same method but in reverse order, and be sure to adjust the drive belt.

As a result, if the winding is shorted, it is necessary to find out the reason. If any contact ring has become unsoldered, this problem can be eliminated by unwinding the defective turn back, then removing the broken end and soldering the unwound drive. If desoldering occurs, it is also enough to simply solder the wires.

Relay problems also occur due to a sufficiently strong or weak charge; it is changed during repair of the generator. If the generator is working properly and the signal on the panel is flashing, this indicates a malfunction of the diodes. Since these elements are located in the generator, their necessary replacement is carried out when the VAZ 2114 generator is disassembled.

Excessive noise is the result of wear on the rotor bearing. If it is completely worn out, it must be replaced; if the violations are related to the lack of play in the bearing, it is enough to fill it with oil.

You can repair a generator yourself if you know and follow the procedure. If possible, check the operation of your vehicle in a timely manner and carry out the necessary replacement of parts.

Mechanical breakdowns

If there is a mechanical breakdown of the generator, loud noise appears during its operation. But it also happens that this equipment begins to make unusual noise due to the fact that the bearings are worn out too much. Most often, the bearing located on the front cover requires replacement. It is he who takes on the highest radial loads, and therefore his service life is significantly shorter than the others.

By the way, if the drive belt is tightened too much, the load increases, which means the bearing will last much less.

What is this?

A generator is a device that produces electricity from mechanical energy to power equipment in a car. Thanks to this device, the wipers function, the battery is maintained in good condition, the headlights and side lights shine normally.

The generator is constantly under heavy load. This leads to it breaking over time. The following signs indicate that it is time to start looking for a unit:

- Light fixtures began to emit dimmer light.

- The sidelights and headlights dim as the speed increases.

- The low battery light flashes or stays on.

- The car stalls in the middle of the highway.

- The battery recharges spontaneously.

- The wipers do not function.

If one part of the autogenerator fails, the situation can be corrected by repair. If there are too many faulty elements, then it is more advisable to replace the device completely.