Reasons for failure of one of the cylinders

The engine can begin to trouble for several reasons and it is quite difficult to immediately diagnose the problem; it is recommended to start checking with the most harmless parts, following the list below.

The engine on a VAZ 2107 may triple for the following reasons:

- Worn spark plugs;

- Wear of high-voltage wires;

- Clogged filters;

- Problems with the fuel supply (clogged carburetor or injectors);

- The ignition has gone wrong (relevant for carburetor engines);

- Failure in the ignition module or DPKV (relevant for fuel-injected cars);

- Air leak in the system;

- Valve clearances are off;

- The cylinder head gasket was blown;

- CPG wear;

As you can see, this list contains problems of increasing severity. If your car shows signs of shaking, then checking and searching for the cause must be carried out using this list.

Incorrect operation of injectors

If your car has distributed or direct injection, then the cause of the engine tripping may be a malfunctioning fuel injector. It may overflow or not inject gasoline into the intake manifold or directly into the combustion chamber.

You can check the performance of the injectors at the stand. In the garage - just swap them and watch the scanner readings for errors.

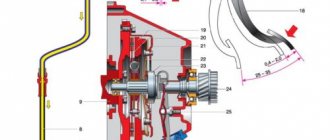

A stand for testing the performance of fuel injectors when searching for the causes of engine tripping

Solutions to the problem

To solve the problem on your own, a motorist needs to have not only a mechanic’s tool, but also a little skill in car repair. Below is a list of all possible methods for eliminating the problem of a VAZ 2107 engine stalling.

Spark plug

When tripping occurs (failure of one of the cylinders), first of all it is necessary to check the spark plugs, since they directly affect the performance of the cylinders. Quite often it happens that one of the spark plugs fails, thereby not supplying a spark to the cylinder, which leads to misfire of the fuel mixture and, accordingly, engine throttling.

If the engine on a VAZ 2107 starts to fail, the first thing you need to do is check the spark plugs, and if they have not been changed for a long time, then it is recommended to replace them with new ones; this will never be a bad idea.

High voltage wires

After spark plugs, it is necessary to check the high-voltage wires from the distributor or ignition module (depending on the type of engine - injector or carburetor). The wires are made of special silicone with high insulation resistance, inside which there is a conductor with low resistance, through which an electric current flows, having a high voltage reaching 15 kV.

When the wires wear out, abrasions appear due to friction against the engine body, their insulation is damaged and a voltage breakdown on the engine body is possible, which will lead to misfire in the cylinder to which this wire is connected and, consequently, to engine misfiring.

Filter

To ensure long engine operation, the car uses various types of filters that help purify the air and fuel that enters the cylinders. It happens that clogged filters can affect the operation of the engine; this, of course, will not cause a failure of the cylinders, but will significantly reduce the number of engine revolutions at idle, which can be confused with the failure of one of the cylinders.

If there is any suspicion of engine trouble, it is necessary to check all the filters of the car and, if necessary, replace them with new ones.

Fuel supply

Due to poor quality fuel or clogged filters, a fuel supply interruption may occur. If the engine is carburetor, then the engine will not work steadily and the speed will drop, but this will not cause the failure of any of the cylinders, since the carburetor is responsible for the operation of all 4 cylinders at once, but in the VAZ 2107 injection engine, a blockage in the fuel system can cause the engine to trip.

The 7's injection engine has injectors installed on each cylinder; it happens that debris with fuel gets into the injectors and clogs them. If one of the injectors is clogged, this can seriously affect the operation of the cylinder into which the clogged injector supplies fuel.

To determine whether the injectors are clogged, you need to measure the fuel pressure, then turn on each of the injectors one by one using diagnostic equipment and see how much the fuel pressure drops; on all 4 injectors, the diesel fuel pressure should drop by an equal number of divisions.

If the readings on one of the injectors vary less, this indicates that it is clogged.

Clogged injectors simply need to be washed and replaced.

Ignition problems

This problem is relevant only for carburetor engines, since in an injection engine the ignition is set automatically using special sensors.

Quite often, the ignition on the distributor goes wrong, or the distributor (runner) breaks through, which leads to engine failure. But when the ignition timing is lost and then the spark may not be supplied at the right moment, but late or, conversely, earlier than expected, this will lead to improper combustion of the fuel mixture and misfires.

Ignition module and DPKV

This problem only occurs on injection engines, since carburetor engines do not have an ignition module (IM). A module is a part that produces a spark to operate all 4 cylinders of a car. Inside the module there are two coils responsible for the operation of a pair of cylinders (1-4), (2-3). It happens that one of the coils may fail, then two cylinders fail at once and it turns out that the engine “doubles”. If two cylinders fail at once on your car, then 80% is a breakdown in the ignition module.

Air leak

For the engine to operate properly, the proportions of fuel and air must be maintained; when these proportions are violated, the engine begins to operate unstably and incorrectly. A violation of the proportions can be caused by air leaks in the system of one of the cylinders, then this will cause the engine to trip.

The suction can be:

- Near the intake receiver at the junction with the cylinder head;

- After DMRV;

- On the sealing rings of the injectors;

- On the throttle assembly;

All answers

In fact, Volodya seems to have said everything and already asked. The only thing is that since the vehicle says that replacing the spark plugs/wires helped for a while, it means that gasoline is most likely being supplied, but either not as needed, or the problem is already in the cylinder (valve/ring).

Watching the operation of the injector, measuring compression, and the appearance of the spark plugs has not yet been canceled as a diagnostic sign.

Oh, yes... and in the future, it is advisable not to reveal an inoperative cylinder by pulling off the explosive wires, because that’s exactly what I understood from the text.

The computer will only show the time of its opening, while it may well not spray gasoline, but literally pour it. Accordingly, such a mixture will burn poorly, and the candle will quickly fail. The last spark plug change didn't help at all?

PS What kind of “hog” is this? Merc in the 140th body or what?

Good day everyone. The problem is that cylinder 4 is not working. I found out by removing the caps from the spark plugs. From 1 to 3 cylinders, the speed drops, and on 4 it does not respond at all. I measured the compression. 10; 9.5; 10; 9.5. Here. I measured the wires with a tester, resistance 4-6 kOhm. (normal) I changed the spark plug with the third cylinder, the result was the same. I haven’t yet checked the spark on the unscrewed spark plug; I was confused by the fact that when removing the cap from the spark plug, a couple of clicks were heard, as I thought it was from a spark breaking through, but I’ll check it one of these days to ease my conscience. Worth BSZ. I tried to change the cover from the old contact one. I started it, heard a crackling sound, turned it off, it turned out that the contact of the slider was hitting the contacts on the cover. Do not have another one. But visually, there is deposits on contacts 1, 2 and 3 of cylinders, it is across the entire width of the contact, in the plane of rotation of the runner, and on contact 4 of cylinders such deposits are only half the width of the contact. Visually the contacts are uniform, well, in the sense, identical. by size.

So, you press the brake, the engine holds the speed for a couple of seconds and it drops by about 200. You pump the brake pedal, the revolutions jump from 800 to 1500. This happened before, but they jumped to a maximum of 1200. I checked the VUT (pressed the pedal, started it, the pedal went further.).

My plans for now are to pull out the VUT hose that goes to the engine intake manifold, turn it off, start the engine and also pull off the cap from the spark plug. there will be changes or not.

Anyone who may have had a similar problem, please tell me what else can be checked.

And the gas consumption of 16 liters in the city and 12 on the highway is not at all pleasing. Previously it was 12 and 9.5, respectively.

Even when releasing the gas, you can hear dull pops in the muffler.

Cylinder failure: causes and diagnostic methods

Issues discussed in the material:

- Why does cylinder failure occur in an engine?

- What is the danger of cylinder failure?

- How to independently identify the cause of cylinder failure

While driving a car, did you feel that the power unit was vibrating, while its power dropped, and it began to consume more fuel? Does the car start only the second or third time? These signs indicate that a cylinder failure has occurred. In our article today we will look at how to fix this problem.

Conclusion

I wrote a lot. I wanted to cover as broadly as possible the topic of the reasons for the “uneven” operation of the power unit when it is tripping. As you can see, many vehicle systems may be to blame for this. Therefore, a comprehensive, sequential check of all nodes should give a positive result.

Did you find the article useful? - rate it. Write comments whether you agree with me or not. Good luck to everyone on the roads.

Sources

- zen.yandex.ru/media/id/59ab872ae86a9e96d63241ad/pochemu-dvigatel-nachal-troit—samyi-polnyi-razbor-prichin-5f13f65010f41130e8b84ac9

- 7vaz.ru/remont/troit-dvigatel.html

- drive2.ru/b/528965974225847925/

- avtodvigateli.com/neispravnosti/troit-inzhektor-vaz-2107.html

Why does the engine troit?

Some car owners do not know why the engine idles at idle. If you are an inexperienced driver, you need to identify this malfunction and then find the reason why it occurred.

Cylinder failure is a good reason for the engine to misfire. The cylinders may stop functioning alternately. Moreover, you don’t even need to search for a breakdown, because it will immediately become clear that a cylinder failure has occurred. The engine will shake and vibrate, the speed will begin to jump, it will be difficult to start the car, and the car will begin to consume more fuel. It is simply impossible to ignore such symptoms. For example, if one cylinder fails in an engine that has only 4 of them, the speed will drop by 25%. Even an inexperienced driver will notice this malfunction.

Ignition module or coils

Some vehicles may use an ignition module or individual coils for each spark plug. Their failure also leads to tripping of the power unit.

There is no spark - the air-fuel mixture in the cylinder does not burn.

How to check

If the engine starts to leak, remove the caps from the spark plugs one by one. We move it a little away from the central contact of the spark plug and observe whether there is a spark between them. If there is sparking on all spark plugs, the ignition module is working.

The malfunction of individual ignition coils can be checked with a multimeter, but this is the topic of another article, or using a scanner. Diagnostics will show misfire on one cylinder. In this case, the coils can be rearranged. If the misfires “move” to another cylinder, then it is she who is to blame.

It happens that at idle speed or low loads the coil works properly, it manages to ignite the mixture efficiently. At maximum, misfires may occur, it does not have time to produce a spark.

Signs of engine tripping

How to determine if a cylinder has failed:

- After a cylinder failure, the power unit will shake at idle speed. Unfortunately, an inexperienced driver is unlikely to notice this immediately after a breakdown. The fact is that this symptom occurs over time. And if you notice that the engine is shaking, it means that the problems started a long time ago. And after the cylinder failed, the engine worked for a long time and became worn out.

- The spark plug became dark, smoked, and carbon deposits formed. This sign indicates that the spark plug should be replaced. But this is at best, and at worst, such a symptom means that the machine is not working properly. Even though spark plugs can be used for quite a long time, they should not be sooted. A slight change in shade is allowed.

- The exhaust system began to sound differently. This also indicates a cylinder failure.

- If the car picks up speed poorly, both at low and high speeds, then the engine is not functioning properly. The reason could be either a cylinder failure or another engine failure.

- The car began to consume more fuel. In this case, you should definitely check the operation of the engine. This symptom indicates a serious problem with the motor.

We recommend

Valve clearances

Many may argue that this cannot be the cause of tripling. But there was a case in my practice when a car arrived to us, without an ECU, an on-board computer with a carburetor - a VAZ 2107. The power unit was severely troubled only when “cold”. After warming up the engine ran smoothly.

All systems were checked and no comments were found. We were the same skeptics. But we still decided to check the gaps - the dipstick did not want to fit in. We set the correct gap, the engine began to run smoothly in any condition - cold, hot.

What to do

If the engine is not equipped with hydraulic compensators, then you need to check the thermal clearances of the valves. For the future, in such power units it is necessary to adjust the valves after 15-20 thousand mileage.

This is especially true for the use of HBO.

In this case, you can get a burnt valve and repair the cylinder head. In case of engine tripping, you need to check the thermal clearance of the valves. On VAZ 2107 engines, the gap is checked with a feeler gauge

What does driving with an inoperative engine cylinder lead to?

When a cylinder fails, the fuel mixture entering it does not burn. The fuel is mixed with oil, removing it from the cylinder bore. The mixture will then penetrate into the crankcase. Due to the fact that the surface of the cylinder is dry, scoring occurs on it. In addition, oil mixed with fuel does not lubricate healthy cylinders well.

As a result of the failure of the first cylinder, the others will also stop working normally. Where will all this lead? The car owner will be forced to spend a large sum on boring the cylinder block or even on lining.

The next problem that will happen if the cylinder fails is that the engine will overheat. The change in its operating temperature is due to the fact that the lubricant does not perform its functions. And, as you know, motor oil not only lubricates surfaces, but also removes heat.

All of the above is sufficient reason to declare: under no circumstances should you operate a car after a cylinder failure!

Misfires - what is it?

Let's start with what is a cylinder misfire? This phrase means a situation where in one of the cylinders the ignition of the fuel mixture occurs late or slow. Simply put, the “acceleration” of the piston in some of the cylinders is slower than in the others. As a result, there is a violation of the synchronization of the engine, the engine runs unevenly, jerking occurs, fuel consumption increases, and the dynamics of the car decreases so much that even a small hill becomes a big test. In addition, in cars equipped with an ECU, a corresponding error appears on the display in the form of a code, for example “P0304” - misfire in the fourth cylinder. The last digit in the code corresponds to a specific cylinder.

Where to look for the cause of cylinder failure

Important!

You will have to look for the cause of engine cylinder failure in a garage. There are two possible ways here: check the mechanics or the electrical, that is, the ignition. Let's start with the simplest thing and diagnose the electrical system.

- Spark plug . Let's use a proven method to check their functioning. Look at the side electrode and insulator, their color should be light brown, not black. There should also be no soot. If there is soot, it means the mixture is over-enriched or there is oil on it. Now let's start checking sparking. Place the spark plug on the high-voltage wire, and then bring it to the cylinder block, the distance between them should be 1-2 cm. Turn the starter. Did the spark travel that distance? This indicates that the spark plug is working properly, otherwise it should be replaced.

- BB wires . They may be damaged. How to check this? Pay attention to the tip of the high-voltage wire. Did you see a light gray coating on it? This means he is operating at the limit. Use a special multimeter to check the resistance of the high-voltage wire. Please note that depending on the motor, the wire length and resistance may vary. When there are no additional instructions, 20 kOhm is taken as a constant resistance value. If this value is exceeded, then the problem is in the high-voltage wire.

- Ignition distributor . When the spark plug does not work properly, a breakdown occurs in the ignition distributor cap. In this case, it is necessary to diagnose the ember; stretching the spring will also help.

- High voltage wires are mixed up . If a cylinder failure occurs, the cause may be in the explosive wires.

We recommend

Now let's check the mechanics.

- Injector . A malfunction in its operation may be one of the reasons for the failure of the cylinder. For example, an injector is broken, or the injector is clogged with a poor quality fuel mixture. Note! Damage can result from the use of the latest fuel purifiers, which can be purchased at any specialized auto store. It is best to diagnose and clean the injectors at a trusted service center.

- Gas distribution mechanism . The fuel mixture enters the cylinders in the wrong quantity and quality. This can happen for various reasons. For example, the timing belt was installed incorrectly, the tensioners or oil seal became unusable. The camshaft may also break, or the hydraulic lifters may need to be replaced.

Because the engine constantly overheats, the cylinder head gasket may burn out. This happens because the car owner does not monitor the antifreeze level or drives the car at high speed.

All of the above can cause the cylinder to fail. By the way, not everything that can lead to such a breakdown is listed here. Only by understanding why one cylinder in the engine failed will you be able to eliminate the problem. You can do this yourself or by visiting a specialized service center.

Timing marks

If the camshafts are incorrectly aligned relative to the crankshaft, the engine will triple. The opening and closing timing of the intake and exhaust valves will not coincide with the engine strokes.

For example, at TDC of the piston the valve may be closed, so a flash will occur not only in the cylinder, but in the intake or exhaust manifold, depending on which valve is not closed.

This may occur due to a stretched timing drive. As the chain or belt is used, it stretches. Therefore, the opening or closing angles may shift. This leads to engine tripping.

What to do

If you have checked everything: the spark plugs are in order, there is a spark everywhere, the quality of the mixture is at the right level, you need to check the timing marks. We look at the degree of belt tension. In the case of a chain, how “out” the tensioner is. If the marks are knocked down, then we set them as needed.

Correctly set marks on the camshaft of a 16-valve engine

After troubleshooting, we fix the problem. If the motor stops running, the cause has been found and eliminated.

Diagnostic methods

When you find out that the motor is not working, you should diagnose it. This is the only way you can find out which cylinder failed and why. You can do this yourself, or go to a car service center. There the engine will be checked using a computer. However, most often you will be able to find out on your own why the engine is tripping. However, if there is a cylinder failure, and the reason is a decrease in compression, you should find a competent specialist who will solve your problem.

Act one. We find the cylinder that failed. To do this, we diagnose the engine after it starts. Be extremely careful when performing this work. Turn the ignition key, the hood should be open. Let's listen to the sounds coming from the engine compartment. Pay attention to how the engine works. Now, one by one, we disconnect the explosive wires that go to the spark plugs.

If you disable a cylinder that is working properly, the engine will run rough. If a cylinder fails after the spark plug is disconnected, the power unit will operate without changes.

How else can you perform diagnostics? We do not touch the explosive wires. We simply turn off the chips one by one that control the fuel supply from the injectors to the cylinders. If you disconnect the chip, but the motor runs without changes, it means that this cylinder has failed.

Act two. We carry out diagnostics of explosive wires, as well as spark plugs. First of all, you should disconnect the wire and carry out an inspection. Is the insulation damaged? This indicates that the problem is in the BB wire. Then we check whether the conductive core is intact. Did you find that it has kinks or is burnt out? This means that a breakdown or internal resistance may occur. To measure it, use a multimeter. The data obtained must satisfy the acceptable readings. Otherwise, current will not flow normally to the spark plug.

Did you find out that everything is fine with the wire? Then we unscrew and diagnose the spark plug.

Is the spark plug base or its electrodes deformed or do they have carbon deposits on them? A new spark plug needs to be installed. If everything is fine with it, then the reason for the engine tripping is not a cylinder failure.

High voltage wires

The tips and the wires themselves are suspect. Due to harsh operating conditions, they may lose elasticity and dry out. I have witnessed more than once when they were changed, they did not align, lying on the table, they remained the same shape as on the car.

Plus, poor manufacturing quality leads to microcracks appearing on them. The high discharge penetrates them. In such places, a light spot with black dots or soot streaks forms. It is best seen in the dark with the engine running. You can observe sparks at the breakdown sites.

There is another way to check high-voltage wires, it is shown in the video:

This is fraught with poor sparking. The spark will be weak or absent altogether. The cylinder will stop working and the engine will stall.

What to do

Only replacement of armored wires with new ones. They cannot be repaired. If you have successfully done this, write in the comments how you did it and what the result was.

How to prevent the engine from stalling

After you check the motor and find out why it is misfiring, you should fix the problem. When spark plugs or explosive wires fail, it will be easy to solve the problem: just replace them. We take exactly the same actions if the ignition coils or switch are broken. However, when the fuel or air system is clogged, it will not be possible to quickly eliminate the breakdown. To clean the injectors, you will have to use a cleaning compound, such as Injection System Purge. It may also be necessary to replace the lambda probe, because it most likely functions incorrectly.

Have you cleaned the injectors, but this did not help fix the problem and the fuel mixture is flooding the spark plugs? Then we replace them. If the engine fails, the fuel pump and other components of the fuel system should be removed and new ones installed. It is not recommended to repair or install old elements. It may also be necessary to replace the air filter and parts of the air supply system if depressurization occurs.

At the very end, we remove errors in the electronic control unit; this may also be the reason that the motor is not working.

Rich mixture

The engine began to stall and stopped developing maximum power. When cold it may start and stall. In this case, the air-fuel mixture is to blame, where there is a lot of fuel and little oxygen.

It floods the spark plugs with gasoline and they refuse to work. From this you can judge the quality of the fuel mixture. If there is black soot, it is rich, if it is light, it is poor. I wrote about this in detail in other articles, go to the channel, everything is written there, the link was above.

What to do

Look for the reason. There are several possible sources of problems:

- Mass air flow sensor

. It fails and the ECU receives incorrect readings for preparing the mixture. I wrote how to check it here. - The second lambda was covered with a “copper basin”

. There is also a separate article about it. - In the case of a carburetor, a high level in the float chamber

.

And so on. There can be many reasons for a rich mixture. If you are interested, I will write a separate article on this topic. Let me know about it in the comments.

Solution methods

When the reasons for the throttling of the injection-type VAZ 2107 engine have been determined, you can proceed directly to analyzing options for eliminating the problem. Before you begin, you need to understand that you need to know the design features of the motor.

Fuel pump and filter

The first place to look for the cause begins with the fuel supply. First, you should check the fuel pump for functionality and whether there are any malfunctions. If this element does not show visible signs of damage, then it is recommended to disassemble it and check it.

Many experienced car enthusiasts advise, after the fuel pump, to start replacing the fuel filter element, since this is where fuel can poorly pass to the injectors. The fuel filter, according to the service documentation, must be changed every 30-35 thousand kilometers.

Injectors

The next place to look for trouble is the injectors themselves. They may be clogged due to the use of low-quality fuel or defective due to their service life, in other words, worn out.

The elements are checked using a special stand, which not only diagnoses the condition, but also cleans the elements. If there is a damaged or worn part, it is better to replace it with a new element.

Spark plugs and high voltage wires

Loss of spark can also lead to engine malfunction. The next unit that needs to be examined is the ignition. First of all, it is recommended to diagnose the spark plugs. To do this, you need to pull them out from the block head and visually inspect them for cracks. Next, it is recommended to clean the spark plugs from accumulated dirt.

The next stage of diagnosis is to ring the contacts using a multimeter and measure the gap. In most cases, such diagnostics show that the spark plugs are not suitable for further use and should be replaced.

Another element of the ignition system that directly affects the ignition of the air-fuel mixture is high-voltage wires. How well and economically the motor will work will depend on their condition. Therefore, it is recommended to inspect them for damage and also test them with a multimeter.

Air filter

A dirty air filter can lead to the engine not receiving enough air into the combustion chamber, and accordingly the formation of the air-fuel mixture will be disrupted. Therefore, it is recommended to inspect the element, and if it is found that it is dirty, it must be replaced.

Throttle

A dirty throttle valve also prevents the normal flow of air into the engine. To diagnose the unit, it is necessary to dismantle it. If you find that dust and other foreign objects have accumulated on the walls, you should clean the part. To do this, you will need a special product or liquid for cleaning carburetors. This operation can be performed by any car enthusiast without any problems.

valves

Burnt-out valves can cause the engine to start to misfire, since a gap is formed between the seat and the exhaust valve, through which exhaust gases flow back into the combustion chamber, thereby disturbing the balance in the air-fuel mixture.

To diagnose the unit, it is necessary to dismantle the block head. Often, already burnt-out valves are the first sign of wear on the piston group, and accordingly everything leads to a major overhaul.

Comparative fault characteristics

If we compare the reasons why the engine troits. You can notice some features in different VAZ models. Unlike the classic VAZ 2107, version 2114 has additional sensors and an electronic control unit. In this car, the reasons that the engine is misfiring may be expressed a little differently, namely:

- Electronics supplies an overly rich fuel mixture to cooled gasoline when the engine warms up;

- Despite the fact that the spark plug reacts to starting, in fact, it may be faulty;

- A malfunction may cause moisture to enter the ignition coil or high-voltage wires;

- Wear of piston assembly elements.

The presented nuances are not the entire list of problems that cause the engine. For example, at idle speed, the list of reasons why a VAZ 2107 carburetor engine may stall is replenished with the following options: poor adjustment and excessive compression of valves, installation of a timing belt without matching the marks, piston burnout, disturbances in the cylinder head or ECU system.

Checking the distributor

And then we will check the VAZ 2106 distributor. The first thing you need to pay attention to is its cover. We remove it and inspect it for damage, cracks, etc. Through cracks, along the path of least resistance, current can flow to ground

Thus, a small voltage will already come to the spark plug or nothing at all will come, and the spark will either be weak or not exist at all

Through cracks, along the path of least resistance, current can flow to ground. Thus, a small voltage will already come to the spark plug or nothing at all will come, and the spark will either be weak or not exist at all.

Next we will talk about the remaining parts of the distributor. And they need to be considered in the event that you do not have a spark at all, or if you have one, but it is very weak. Those. if there is no spark in only one cylinder, then there is a 99% chance that the problem is not in the distributor.

After the lid, we immediately pay attention to the slider. The runner must also be intact and not have any damage. Moreover, you need to inspect it both from above and from below.

And the best way to do this is to unscrew it

Moreover, you need to inspect it both from above and from below. And the best way to do this is to unscrew it.

Next we move on to the breaker contacts. First you need to check the cleanliness of the contacts. If there is any plaque or carbon deposits, it naturally needs to be removed. It would probably be better to do this with zero sandpaper or a needle file. Next, after cleaning, you need to check the gap between the contacts. It should be 0.35-0.45mm

We take a set of probes, find a 0.35 probe and check... We also pay attention to the cams that move the contacts - they should not have significant wear and the existing wear should be the same for all cams

Next you need to pay attention to the wire that is connected to the breaker contacts. It is advisable to move it, tug it in different directions, and make sure that the wire has reliable contact. It may happen that over time, due to vibration and other things, this wire breaks off and, naturally, the contact will either be very weak or disappear altogether

And this is not often paid attention to

It may happen that over time, due to vibration and other things, this wire breaks off and, naturally, the contact will either be very weak or disappear altogether

And this is not often paid attention to

The next logical step is to check the capacitor. The simplest thing is to measure its capacity. It should be within 0.25 µF. But for this, of course, you will need a tester with a capacitance measurement mode. I don’t have this, so I’ll tell you about the second method. We disconnect the capacitor wire and the wire coming from the coil from the distributor breaker and connect a light bulb (12V) between them. Afterwards, turn on the ignition and look at the light bulb - if it is on, it means the capacitor is broken and needs to be replaced. If it doesn’t light up, then everything is fine with the capacitor.

In the same way you can do without a light bulb. Instead of connecting the light bulb, we simply short-circuit the wires with each other, with the ignition on, of course. If it sparks, the capacitor is broken.

Ignition adjustment

The injection modification of the VAZ 2107 does not require adjustment of the ignition timing. The electronic control unit, using a sensor, determines the optimal ignition timing. The participation of the car owner in adjusting the operation is limited to setting the engine timing belt to the marks.

To check the performance of the ECU and the functionality of the sensors, it is necessary to connect a computer with specialized software. In this way, the cause of most electronic ignition system malfunctions can be determined.

It is also worth checking the operation of the throttle position sensor yourself. When the throttle is closed, the voltage on the sensor should be no higher than 0.55 volts, and when fully open - 4.5 volts. Measurements must be made with a voltmeter with the ignition on.

The engine is the heart of the machine, which, if not properly maintained, can break down and cause failure of other systems and components. There are often situations when the car loses power, vibration appears, and the equipment stalls at idle. The cause of this phenomenon can be various engine breakdowns, including misfires, which reduce engine efficiency and can lead to failure of the fuel and exhaust systems.

Almost every motorist has encountered the problem of flammable mixture ignition. There can be many reasons for problems when igniting a combustible mixture, but they all lead to a drop in engine power and the shutdown of one or a pair of cylinders. On cars with an ECU, when the engine malfunctions, errors appear that indicate problematic parts of the unit. If misfires occur, you should urgently contact a service station to troubleshoot the problem.