The braking system of a car as a whole is one of the most important elements that allows you to protect the driver and passengers from many troubles. For this reason, it is extremely important to maintain it in working order and carry out regular maintenance.

In this article we will talk about how the brake system works on the VAZ-2115 car (injector).

Operating principle of the rear brake cylinder

Rear brake cylinders are elements of the brake system that are directly responsible for acting on the pads, pressing them against the inner surface of the drum.

The main working parts of the rear brake cylinder are a body, two pistons, and two rings - a sealing ring and a thrust (adjusting) ring. When you press the brake pedal, the pistons move out of the housing, pressing the pads against the surface of the drum. They return back under the action of the tension spring of the pads. The purpose of the thrust ring is to limit this movement, so that the gap between the friction linings and the drum is maintained at the same level. The O-ring, in turn, prevents brake fluid from leaking through the cavities in which the pistons are located.

1 — block stop; 2 — protective cap; 3 - cylinder body; 4 - piston; 5 - seal; 6 - support plate; - 7 - spring; 8 - crackers; 9 — thrust ring; 10 - thrust screw; 11 - fitting; A - slot on the thrust ring

Thus, it is the rear brake cylinder that is responsible for transmitting braking force to the pads and for maintaining the distance between the surface of the drum and the friction linings as the latter wear out. Below you will learn how to check the rear brake cylinder.

VAZ 2109 injector stalls at idle.

I have a computer on board. who knows how to dry candles. So after drying the spark plugs it usually starts. From this I conclude that the spark plugs are still flooding despite the normal operation of the injectors.

Recently I was told to check the vacuum booster. They say sometimes the membrane in it bursts and begins to poison the air. I checked the hoses and tightened them - no relief.

This is a plus to the problem. BortComp periodically displays the error “Voltage loss on the ECU.” After talking with an electrician, I found out that the ECU is powered directly from the battery by one terminal. Why the voltage is lost is not clear.

In general, the engine behaves poorly; when accelerating hard, the speed rises twice. That is, with one press the speed rises, then drops slightly and then rises again. It knocks shamelessly. Can you tell me how realistic it is and whether it is possible to adjust the valves yourself in makeshift conditions and what you need to have for this, which initial set of adjusting washers.

In general, people, save me from trouble, don’t drive cars. Thanks in advance for advice on repairs. Or maybe someone can tell me smart men in Yekaterinburg who I can contact.

Only 2 errors appear on the BC. 1 - Voltage loss on the ECU 2 - Low signal level on the mass air flow sensor - (occurred 2 times) I think a consequence of a drop in speed.

As soon as I find someone to swap with, I’ll try to twist the sensors and install ones that are known to work

I don't think he is. Now I'm stalling less often. Sometimes I’ve been driving for 3-4 days now, and it’s never been capricious. They recommended cleaning the fuel pump screen. I think this procedure won't hurt in any case. But there is still a problem. The body hatch for access to the gas tank is offset relative to the hatch in the gas tank itself, and removing the gas pump without removing the gas tank (or modifying the body with an angle grinder) is a very hectic task. I don't think that's the problem.

The main problem of owning a VAZ is that you can buy a new part that is already dead in a store and spend a very long time thinking about the cause of the malfunction. Not to mention that the parts are sometimes half-dead. Either they work or they don’t. In the meantime, I will look for a person with the same mass air flow sensor.

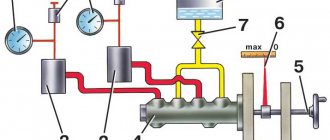

I haven’t written on this topic for a long time, and yet the problem is still urgent. Traveled about 1000 km. The car only messed up a couple of times. Light frosts have set in in the Urals; today it started for the first time at -13C°. After analyzing my arguments and methods, I came to the conclusion that, as an option, the wrong mixture may be to blame. Throws out the candles. I found an article with a similar problem https://avto-remont.com/catalog/stat/8/1/31.html (I also noticed the dependence on the amount of gasoline. Indeed, there are no problems with a full tank.) I decided to check the whole thing. I bought a German (Chinese-made) pressure gauge, a hose from a vacuum booster and a couple of clamps. I cut off 5 cm of the hose and connected it to the fuel rail fitting. Turned on the ignition. The fuel pump turned on, the pressure gauge showed 2.5 bar. 3 seconds and the fuel pump turned off. within a second the pressure dropped to zero. I started the engine, the pressure gauge showed 2.5 bar at idle, warm. The pressure norm according to the book, as far as I understand, is 2.8-3.2 bar. I don’t know how quickly the pressure should drop when the fuel pump is turned off (I also cleaned the mesh). And I don’t know how critical the low blood pressure is either. After the measurements, I removed the pressure gauge. It's a pity I can't get to purge the fuel system yet. Perhaps all the delights begin during prolonged use. THEN when you pour 30 liters of gasoline into the tank and forget about it, a vacuum gradually begins to accumulate in it, then the pump cannot cope with gasoline? When I sell the fuel line I will report the results. I hope for a favorable resolution of the problem and that this topic will be useful to someone else.

The BC takes readings from the speed sensor, the readings are true.

I haven’t written on this topic for a long time, and yet the problem is still urgent. Traveled about 1000 km. The car only messed up a couple of times. Light frosts have set in in the Urals; today it started for the first time at -13 degrees. After analyzing my arguments and methods, I came to the conclusion that, as an option, the wrong mixture may be to blame. Throws out the candles. I found an article with a similar problem https://avto-remont.com/catalog/stat/8/1/31.html (I also noticed the dependence on the amount of gasoline. Indeed, there are no problems with a full tank.) I decided to check the whole thing. I bought a German (Chinese-made) pressure gauge, a hose from a vacuum booster and a couple of clamps. I cut off 5 cm of the hose and connected it to the fuel rail fitting. Turned on the ignition. The fuel pump turned on, the pressure gauge showed 2.5 bar. 3 seconds and the fuel pump turned off. within a second the pressure dropped to zero. I started the engine, the pressure gauge showed 2.5 bar at idle, warm. The pressure norm according to the book, as far as I understand, is 2.8-3.2 bar. I don’t know how quickly the pressure should drop when the fuel pump is turned off (I also cleaned the mesh). And I don’t know how critical the low blood pressure is either. After the measurements, I removed the pressure gauge. It's a pity I can't get to purge the fuel system yet. Perhaps all the delights begin during prolonged use. THEN when you pour 30 liters of gasoline into the tank and forget about it, a vacuum gradually begins to accumulate in it, then the pump cannot cope with gasoline? When I sell the fuel line I will report the results. I hope for a favorable resolution of the problem and that this topic will be useful to someone else.

Symptoms of rear brake cylinder failure and checking them

To check the operation of the rear brake cylinder, you need to identify the symptoms. Symptoms of rear brake cylinder failure can vary. Indirect reasons for concern may be:

- a slight but stable drop in the level of brake fluid in the reservoir;

- insufficient braking force on the rear axle or uneven braking of the left and right rear wheels.

However, the above may also be caused by other problems. The “well-being” of the cylinders can certainly only be assessed by visual inspection. This is usually done when replacing rear brake pads.

Damage to the sealing ring may be indicated by leaks of brake fluid on their surface. A fairly serious reason for concern about the condition of the cylinders may be their excessively oxidized surface. In this case, the pistons may no longer move so quickly in the housing. You can check this with an assistant, who should smoothly press the brake pedal or monitor the stroke of the pistons and hold the pads while you do this. You need to “brake” very carefully, otherwise the pistons may come out of the cylinder completely.

Source

Why the wheel mechanisms are not fully released

Most likely, this malfunction will cause the brake pedal to stick. In this case, you will have to adjust it.

In addition, the disappearance of the gap between the piston in the master cylinder and the vacuum booster adjustment bolt may also be the cause. The problem is eliminated by increasing the lumen.

If fuel or oil gets into the brake fluid, the gaskets in the master cylinder sometimes swell. You will need to flush the entire system with new brake fluid and replace seals that have become unusable.

What does the VAZ 2114 brake system consist of?

The brakes of the VAZ 2114 are a vital system of the car. These are not loud words and every driver will agree with this. Also, every driver knows that timely, high-quality repair of the VAZ 2114 brake system is the key to its trouble-free operation.

The brake system on the VAZ 2114 consists of two main parts:

- Wheel mechanisms - directly affect the elements rotating with the wheel and slow down its rotation.

- Drive – a system for transmitting force from the pressed pedal to the wheel mechanisms.

Choosing mirrors

We decided to purchase and install heated mirrors ourselves, but the choice is not an easy one, since today a huge number of different models are sold on the markets, which differ in appearance, price and technical characteristics. To help with the choice, we will not describe or list unnecessary details, but rather consider the points that will be important to pay attention to when purchasing.

Visual characteristics

An important characteristic is the reflection coefficient, in other words, reflectivity:

- You can see this value for your car in its passport

- According to the standard, the reflectance coefficient (reflectivity) for a car mirror must be more than 40 percent

- Otherwise, you run a high risk of not seeing what’s going on behind your car and getting into an accident.

The second equally important characteristic is the correctness of the transfer (without distortion) of the shape of objects:

- It is difficult to evaluate this characteristic

- All you have to do is look at your reflection in the sample being tested.

- And if your reflection resembles the reflections in the funhouse mirrors, then you should not purchase such a product

In addition, you should pay attention to the presence of an anti-reflective coating on the mirror element:

- Only high-quality “tinting” will protect your eyes from being blinded by reflected light.

- However, it is worth considering the fact that excessive darkening further reduces reflectivity and can lead to incorrect color rendering

Mechanical characteristics

When purchasing heated side mirrors, you need to pay close attention to the position adjustment present, as well as on what principle it is implemented:

- For example, if you take standard mirrors from a VAZ 2110, they have a lever adjustment mechanism, which has a number of disadvantages

- Therefore, a cable mechanism is more preferable, since it is smoother and has better adjustment accuracy compared to a lever mechanism.

- However, the ultimate dream of every car owner, without any doubt, is electrically controlled elements

- In this case, a joystick is located inside the car, with which you can easily set the location of the side mirrors as you prefer.

It is worth recalling a point that applies not only to the choice of mirrors. Rather, this is a general recommendation that everyone needs to remember when purchasing any spare part:

- Immediately pay attention to the quality of the mirror element, carefully inspect all the details of the case

- The parts must have cracks, scratches, chips, or other mechanical damage

- In addition, you should pay attention to the complete set and branded packaging.

- Any self-respecting manufacturer supplies its products exclusively in branded packaging, which usually indicates the address and telephone number, and also contains detailed information about the model

- Therefore, feel free to open the box to make sure there are instructions inside in your native Russian language, as well as an installation diagram

- In addition, an important factor is the presence in this kit of the necessary fasteners, a set of wires and seals

- This will allow you, if you install it yourself, to reduce additional costs, and also significantly reduce the time it takes to complete the work.

Heating efficiency

Another parameter that interests us, for the sake of which all the actions were done:

- Because ultimately you need a mirror that will be able to work effectively under adverse conditions

- We need to evaluate the heating rate and quality of the heating element and how quickly moisture, snow and icing will evaporate from the surface

- You won’t be able to evaluate such phenomena on your own without special sensors and a computer program, so all you have to do is connect and test in real conditions, observe visually and record the time

This concludes, additionally watch the video on this topic, good luck in installing the heating.

Front brake mechanism

The design of the front brake mechanism on the VAZ 2114

The front brake mechanism consists of the following components:

- Brake disk. Directly connected to the wheel hub and rotates with it. Slowing down the rotation and stopping the disk leads to the slowing down and stopping of the wheel.

- Pad guide. Serves as a holder for the pads and a base for the guide pins.

- Caliper. It combines the pads, cylinder, and piston into a single unit and ensures uniform transmission of force from both pads to the disc.

- Brake pads. They directly act on the disc, squeezing it on both sides and slowing down the movement.

- Cylinder. A sealed cavity in which the piston moves.

- Piston. Under the influence of hydraulic fluid pressure, the pad is pressed against the disc. Thanks to the “floating clamp” system, the second block is pressed simultaneously. This ensures uniform wear of their linings and discs and guarantees effective braking.

- Seal ring. Prevents fluid leakage and ensures system tightness

- A cover to protect the guide pin from dirt, allowing for unhindered movement of the pads.

- Guide finger. Allows the pads to move evenly and adhere to the disc with their entire plane.

- Protective cover. Protects the disc from road dirt.

Engine operating principle

The VAZ 21099 is equipped with a carburetor and injection engine with distributed fuel injection. The engine volume is 1.5 liters. Each of the four cylinders has a separate injector that delivers fuel.

Using a neutralizer, the engine monitors the composition of the exhaust mixture and independently regulates it in order to create the most optimal mixture.

Several components are required for proper engine operation.

Neutralizer

Determines the composition of the mixture in the exhaust system to use fuel as efficiently as possible. Adjusts the fuel mixture when it detects unburned hydrocarbons and carbon monoxide. By adjusting the fuel mixture, harmless water vapor and carbon dioxide appear in the exhaust system.

It receives information from various sensors and issues commands to regulate the mixture. The ECU receives these parameters as information:

- internal combustion engine air consumption;

- position, as well as crankshaft speed;

- fuel supply;

- detonation;

- engine cooling system temperature;

- the speed at which the car is moving;

- battery voltage.

Memory device

It stores information about mixture ratios, operating algorithms, and also stores information about errors.

Only when all units are working properly will the engine function smoothly.

Rear wheel brake

Rear wheel brake on VAZ 2114

- Hub nut

- Hub flange. The brake drum is attached to it

- Lower tension spring

- Left pad

- Thrust spring

- Cylinder

- Upper tension spring

- Guide bar

- Eccentric

- Right pad

- Pad cover

Tip: when driving through deep puddles or fording a river, the brakes get wet. This dramatically reduces braking efficiency. Immediately after overcoming a water obstacle on a straight section and at low speed, brake several times. The pad linings, discs and drums will become hot and dry. The system's efficiency will be restored.

In general, the braking system of the VAZ-2114 is simple and reliable. For a person who has experience driving cars of other brands, servicing it on a “fourteen” will not be a problem. But even those drivers who got behind the wheel of a car for the first time can easily understand the operating principle and operating features of the VAZ-2114 brake system. But remember: it is better to service the brake system at warranty service stations from experienced technicians.

Source

Braking of one of the wheels is observed when driving

Most often, such a breakdown is caused by the destruction of the tension spring on the rear brake. The damaged one will have to be removed and a new one put in its place.

It is also common for pistons in wheel cylinders to not function properly if dirt has gotten inside or they have begun to rust. Cleaning and rinsing will eliminate the problem.

Sometimes braking occurs due to loosening of the bolts that secure the guide pads directly to the steering knuckle. If they are re-tightened or replaced with new ones, the problem will be eliminated.

And finally, this can happen because the parking brake system has not been adjusted correctly.

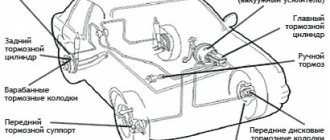

VAZ 2114 brake system diagram

The design of the VAZ 2114 brake system is very simple and understandable. The system is dual-circuit, equipped with a hydraulic drive. When you press the pedal, pressure is generated which activates the cylinders. Dual-circuit structure - this means that when you press the pedal, the force is transmitted to each pair of wheels along its own contour. Its distribution occurs diagonally. In this case, the right rear wheel works together with the left front, and the left rear - with the right front. This principle ensures effective braking of the machine, even if one of the circuits fails. The diagram of the brake system on the VAZ 2114 looks like this:

- Main brake cylinder VAZ 2114 (GTC).

- Metal pipes of the 1st circuit.

- Flexible hose for front mechanisms.

- Liquid reservoir.

- Vacuum brake booster.

- Metal pipes of the 2nd circuit.

- Rear wheel cylinders.

- Brake pressure regulator drive lever.

- Flexible hose for rear mechanisms.

- Pressure regulator.

- Pressure regulator bracket.

- Pedal.

The GTZ is responsible for creating pressure in the entire system. It is distributed along the contours and transmitted through them to the wheel brake mechanisms of the car.

Injectors

Fuel is injected into the cylinders through electromagnetic injectors. Due to poor quality fuel, they can become clogged and not allow enough fuel into the cylinder. Hence we have the fact that the car stalls when the gas is released. The injectors are installed on the fuel rail. Everything can be easily removed, and you can carry out the injector cleaning procedure yourself in your garage. You just need to first buy new rubber gaskets for the injectors and carburetor flushing fluid. We put the wires from the battery on the nozzle and supply liquid from a can of cleaner into it under pressure through a standard tube. It is necessary to achieve good atomization of the liquid coming out through the nozzle; when voltage is applied from the battery, the nozzle should click. If this does not happen, then it must be replaced. But it’s better to contact a service center that has the necessary equipment and will do the washing procedure much better.

Front brake device for VAZ 2114

The front brakes of the “four” consist of the following parts and mechanisms:

- Brake disk. It is connected to the wheel hub and rotates with the car wheel.

- The pad guide is a holder for the pads and a base for the guide pins.

- Caliper. Responsible for uniform transmission of force from the pads to the disc.

- Brake pads. When you press the pedal, the disc is compressed on both sides. This results in slower movement.

- Cylinder. A sealed cavity in which the piston moves.

- Piston. Hydraulic fluid pressure presses the pads against the disc during braking.

- Seal ring. Serves to seal the system.

- Cover to protect the guide pin from dirt.

- Guide finger. Ensures uniform movement and adhesion of the pads to the disc with the entire plane.

- Protective cover. Protects the disc from contamination.

The front brakes of the VAZ 2114 are disc. They provide automatic adjustment of the gap between the pads and the disc.

The relationship between the engine and car subsystems: theory

To understand the theory of the occurrence of such a situation, it is necessary to imagine how exactly the power unit of a car functions. It is worth understanding that the operation of the internal combustion engine in any mode depends on factors such as:

- fuel assembly composition;

- serviceability of the fuel injection pump and pump;

- UOZA or UOVT (for diesel engines);

- compression;

- state of spark-forming elements;

- timing belt work and much more.

Why is the injector difficult to start when cold?

If disturbances occur in one of the car engine systems, this will automatically lead to a change in the operating mode. For example, if compression decreases, the proportion of gases appearing during the process of chemical decomposition will not participate in the overall work, but will only interfere. As a result, the pressure force on the piston will decrease, the speed will drop, and the engine will stall.

The same can be said about the lubrication system and generator. If the gene voltage drops for any reason and the lubrication efficiency decreases, the engine speed drops below the required level. And vice versa, if the speed goes down, the voltage decreases. All this leads to an increase in the amount of energy required to rotate the crank.

If engine operation stabilizes after pressing the accelerator pedal, whether in idle mode or on the road, it means that there is a slight malfunction of one of the engine systems (if an injector) or a malfunction of the idle system (if a carburetor). If this does not help, the engine should be taken for professional diagnostics.

Rear brake device for VAZ 2114

The design of the rear brake system of the VAZ 2114 is as follows:

- Hub nut

- Hub flange. The brake drum is attached to it

- Lower tension spring

- Left pad

- Thrust spring

- Cylinder

- Upper tension spring

- Guide bar

- Eccentric

- Right pad

- Pad cover

The car has drum brakes at the rear. This design has been time-tested and is considered very effective. In addition to the above elements, it also includes a parking brake. It ensures reliable fixation of the car even on an inclined surface while stopping or parking. The handbrake on the VAZ 2114 has the following structure:

The braking system of cars of this model is quite reliable and durable. But it also needs regular maintenance. To ensure effective braking, it is necessary to change pads and discs, as well as drums and other elements in a timely manner. System parts require regular inspection to identify external damage and defects. When they are identified, broken elements are replaced, even if their scheduled replacement period has not yet arrived. Particular attention should be paid to the serviceability of the handbrake; you need to monitor the condition of the cable. If the handbrake does not provide reliable fixation of the car on an inclined surface, then the cable needs to be tightened or replaced. It is wrong to leave a car in a parking lot in gear. The parking brake is used for this. Driving with a faulty brake system is illegal and very dangerous. Sudden brake failure can cause a serious accident with unpredictable consequences. Therefore, the system requires regular inspection, maintenance and repair when faults are identified. You can usually check and repair your brakes yourself. Contacting a car service is required in difficult cases and when the owner is unsure of his own abilities.

Ways to prevent breakdown

To avoid this, it will help to completely flush the injector and diagnose your vehicle after 30 thousand kilometers. But it is necessary to take into account that the problem may be hidden simply in a malfunction of the sensor itself for measuring speed.

Everything here, of course, is very simple, you need to go to the store and buy it, it costs about 200 rubles and the process of replacing the sensor is not very difficult.

There are countless stories about the complete assembly and disassembly of the legendary “nine”, followed by the normal functioning of the unit, taking into account the remaining “extra” parts.

If it is not possible to fix the problem yourself, it is better to contact specialists, they will definitely help, do not forget that poor-quality car repairs can only lead to new, often more serious, breakdowns. And then you will definitely have to contact the service, paying much more money than you could have paid before. Take care of your lives and cars.

Conversion of 2108 to 2113, Question about documents.

Posts: 5,093

The question is why? Well, you put plastic on it, well, change the wings. But why, it won’t go faster, and it won’t become more comfortable. It’s better to make a noise with this money, and the rest will remain. And do you need this hemorrhage? Standing in the traffic police, repairs, searching for the necessary spare parts. I don’t know.

The answer has already been written that the floor of the muzzle needs to be changed. And in the topic there is a question about documents. and not speed, comfort and noise. I could also advise selling the car and buying a moped

Post edited by tab

— May 26 2013, 16:23

Well, wouldn’t it be easier to sell it? Half the face needs to be replaced, how much money will he do it for, or will he do it all himself? That is, both plumbing work and painting.

What difference does it make to you? Look at the topic title!

Post edited by tab

— May 26 2013, 16:46

And you run around the services, maybe someone will write you a certificate for a ruble and it will be good for them and for you. I just don’t remember if a certificate is needed at all, if people register a 16 cl head without any certificates, then there will hardly be any problems with the bodywork. And I don’t think I’ll dissuade you, only then you’ll still remember your 08 bumpers.

I’m just advising the person. I think he understands that a good restoration costs good money, that is, in order to weld well, you need to be able to do it correctly, and even paint it. 40-50 thousand for this.

Well, if he does everything himself, then there are no questions.

Post edited by sporky

— May 26 2013, 18:09

Posts: 5,494

Posts: 5,494

Forever Young Forever drunk

Why paint something, now they sell painted ones too. The quality is certainly not very good, but it will last for 2 years. Painted parts: Hood 14-15th - 5600 rubles Wing 14-15th - 2500 rubles*2=5000 rubles. Front bumper 14-15th - 1500 rub. Rear bumper — 1500 rub. Headlights? (I think at least 1500 rubles * 2) Moldings - 900 rubles. (I think you can put 08s on old doors, just drill a few holes.) Thresholds - 800 rubles.

If you take black iron, then it costs about 2 times less than painted iron, but painting work costs 3,000 rubles per item, without materials (paint, primer, varnish). Usually the warranty on painting is half a year.

Now someone will say that painted ones don’t shrink. The familiar fenders and hood changed and became excellent. A friend who sells iron says these are the same parts, some are simply painted, others are not.

Post edited by KorbenDallas

— May 27 2013, 07:24

The prices are like for a Bentluha. Friend converted a nine-wheeler into a cap, a hood for 700 rubles, wings for 300 rubles, 2 bumpers for 1500, 2 headlight units for 1000, etc. and so on. There’s a ton of these broken pieces everywhere, and so too are body parts

Forever Young Forever drunk

Not everyone’s religion allows them to put something on their broken car, but the vehicle is already damaged. My father-in-law with his old 7 (Camry hit him in the side) doesn’t even want to change the radio, he says, come on. You'll have to look for a used one in color, but the prices were for new painted iron.

Post edited by KorbenDallas

— May 27 2013, 08:55

Subscribe to topic

Notification by e-mail about replies to a topic during your absence from the forum.

Subscribe to this forum

Notification by e-mail about new topics in this forum during your absence from the forum.

Download/Print theme

Download the theme in various formats or view a printable version of the theme.

Noise when braking

High-frequency noise, squealing, and whistling can occur both during braking and, sometimes, during normal movement. The reason is the off-design mode of friction of the friction material on the working surface of the brake disc. Extreme wear on the brake pads and severe corrosion of the brake disc (often on the inside, “invisible” side) may be to blame. It happens that the brake pad lining has peeled off from the base. The list of possible causes continues with contamination of the pads, warping of the disc due to local overheating, improper fastening of the pads in the caliper, left pads or discs, etc.

Compare doors of VAZ 2108 and 2113

- Registration

- Entrance

- To the beginning of the forum

- Forum Rules

- Old design

- FAQ

- Search

- Users

- List of forums AUTOLADA.RU

- Family "Samara"

- 1

- 2

- >

The left (driver's) door

in the 8th has no holes for the molding. And so - identical.

Left side of the body.

Left (driver's) door

08 does not have holes for attaching modling.

Left side of the body.

should stand up like a native from 08.

In theory, you can also take the eighth door and just glue the molding with 3M tape and it will hold tight. Although if it’s smart, then the door should be original from 13.

“Poke your nose on me” is the VAZ-2113 in the catalogue.

I don’t just poke, I dip with my head! https://acat.autodealer.ru/index.php?mark=1_1

Yes, almost everything fits from 08, I have 2108 written on the rail

The main thing is that they only put it on 15, and the marking is 14. You surprised me, brother, with this news

And how surprised I was when I saw this marking, so it’s worth guessing how Vaz decided to give such a marking.

Of course, I knew that creative individuals sat on the Vase, but to such an extent

There are complete idiots sitting on the Vase, brother, and there is more and more evidence of this

Damn brother, off topic, I remember you hinted to me about installing a cross member from Avtoprodukt (two crabs and a pipe between them) that they say I don’t have it yet, I’m thinking about installing it here, but damn we can’t find any options at all, I thought we could put TM fish , you’ve actually stirred up something in this direction.

Dranik

By the way, I read that they wanted to make a cap and a sweatshirt in the spirit of the tag, and then they cut the budget, maybe the headlights have remained since then, but I still don’t understand how they imagined it.

No, my brother hasn’t stirred up anything in this direction yet. By the way, we don’t have anything in our city either, so I order all the stray stuff from postavto.ru. I don’t think it’s worth it. In principle, the only gain from them is an increase in caster by a degree, which is certainly good. But the bad thing is that they are very durable, and our TV is frail. The standard ones are even weaker, so if something breaks on their own, saving the TV, but these ones do the opposite. About the blue thing, I still want it, it also strengthens the carts and if anything happens, then nothing bad will happen, but I found out the other day that because of it more little things come into the steering wheel. Here the guy tuned Priorka https://www.priorovod.ru/showthread.php?t=17622 described everything drop dead. By the way, the blue thing, which I also read somewhere with polyurethane silents, is not usable at all because it’s a nightmare on the steering wheel. In general, I will probably install it for myself, at the same time as the Acomi supports (guess where I saw this solution), and I will install them when either the stock supports or the racks bend. Something like this . By the way, I recently installed a TM engine mount. How good it has become!