A fairly common malfunction that is typical of gasoline injection and carburetor internal combustion engines, as well as diesel engines, is the problem of floating engine speed.

It is important to understand that if the engine speed is floating at idle or under load, this indicates the need for comprehensive diagnostics in order to identify and eliminate faults.

In this article we will talk about why the speed floats, what danger this problem can pose to the power unit, and also for what reasons the speed floats when hot.

Engine power problems

Malfunctions in the engine power system can be caused by the use of low quality fuel. Solving them is quite simple - you need to refuel the car in a trusted place. As a rule, after this the problem is solved

It is important to select the correct octane number of fuel; in the VAZ-2112 it is strictly forbidden to use AI-80, which has now practically disappeared from gas stations

To get rid of engine vibration, additionally clean the injectors. You will have to disassemble the assembly where they are located and clean the dampers with a special compound. It is strictly forbidden to pour chemical compounds into the fuel tank. It is best to thoroughly flush the unit; it will take more time, but will definitely solve power problems. Additionally, replace the spark plugs.

When the engine warms up, the speed of the VAZ 2110 injector 8 valves floats

- Registration

- Entrance

- To the beginning of the forum

- Forum Rules

- Old design

- FAQ

- Search

- Users

When the VAZ 21103M warms up (from about 40 to 50 degrees), the engine idle speed “floats”. This has been happening since new. Help if anyone has encountered this problem. Personally, I am guilty of either DPKV or high-voltage wires. I need your advice plz

_________________I'm not WEAK-willed, I'm STRONGLY lazy.

What is the complete code for the new firmware?

The revs were floating, but J5D07T02 is no longer floating.

A similar “walk” of revolutions occurs when the IAC is stuck in the open position. “Hanging” of idle speed at 2000 and normalization, after applying the gas, is typical for a faulty TPS.

_________________I'm not WEAK-willed, I'm STRONGLY lazy.

I began to experience a similar situation, but not long ago (at 4,500 km of total mileage - before that everything was fine). The revolutions begin to fluctuate slightly (from 1300 to 1700), stopping when warming up above 50%. Not long ago I didn’t really warm up (I had to drive the car away from the curb - I was going to paint it) - I put it in reverse, and in neutral the revs soared to 2000, then they dropped again, then they soared again. I gave it more gas and everything returned to normal. I constantly refuel at the 1st gas station 95. And in the morning the car began to resemble a diesel

For some reason they are hanging out with you a lot. I have 1100-1300, in winter it was 1100-1400. But nothing more. At 50 degrees. The revs also stop at 1000. Then they smoothly drop to 800-900. And at the end of the “swimming” I begin to move.

For some reason they are hanging out with you a lot. I have 1100-1300, in winter it was 1100-1400. But nothing more. At 50 degrees. The revs also stop at 1000. Then they smoothly drop to 800-900. And at the end of the “swimming” I begin to move.

That's exactly what happened to me: it started up like crazy, smooth speed, which gradually decreased as it warmed up. But that was before. It's different now.

And regarding the IAC, TPS - I’ll go to the warranty - though it’s a little early - with a mileage of 4500 and then change the sensors

This is how it should be, because... This ensures rapid heating of the neutralizer. According to unverified data, this FEATURE has been observed for more than a year and a half on 12 engines with JANUARY. In my opinion, there is no such thing at BOSH.

That's right. Approximately at the moment the coolant is heated to 45C, the neutralizer warms up to operating temperature and the DC readings begin to be taken into account when preparing the mixture. The revolutions decrease from 1300..1500 to 1000 and below.

And regarding the IAC, TPS - I’ll go to the warranty - though it’s a little early - with a mileage of 4500 and then change the sensors

I don't think they are to blame. I just said what the symptoms LOOK LIKE. You had neither one nor the other, in its pure form.

If the TPS malfunctions, the speed “freezes” at 2000 (rarely 2500) and may slowly drop, or not drop at all, if you do not “accelerate”. Nature of the phenomenon: TPS, due to wear of the conductive track, when the gas pedal is released, gives 1% opening of the DZ, instead of 0%, hence the speed. The IAC jams in the open position not during movement, but, so to speak, immediately, at the moment of start-up. And it remains in the open (or rather, starting) position. Hmmmm. This, however, is slightly similar to your case. But the engine was not warmed up. He still needed a lot of extra (past the throttle) air. The revs shouldn't have fluctuated like that.

By the way, don’t call the IAC sensor, it’s a Regulator

Idling speed (although in the store you can read the price tag Sensor.

_________________I'm not WEAK-willed, I'm STRONGLY lazy.

Causes

There may be several reasons for the lack of proper speed gain:

- There are problems with the air supply;

- The ignition has failed;

- Fuel system malfunctions have occurred;

- There were problems with the exhaust system.

Fuel system problems are common in gasoline engines. They are the most common. Therefore, you should start with checking it.

Fuel system

If problems arise when accelerating the car, start checking by inspecting the fuel system.

- Most often, the engine stops gaining momentum because the fuel pump fails. At first, this may have a slight effect, sometimes unnoticed. Over time, as the pump wears out, the speed and power will begin to drop, and the acceleration dynamics will decrease.

- If the fuel pump is partially damaged, it still partially performs its functions, but is no longer capable of delivering the same volumes of fuel. This results in fuel starvation and power loss.

- The best solution to a problem with the pump is to replace it. It is better to trust repairs to specialists.

Ignition

If the ignition fails, you will have to conduct a comprehensive check of all system components that may cause a drop in engine power and speed.

What to check

Peculiarities

Checking timing marks

If the marks are installed incorrectly, fuel will not be injected in a timely manner, and the correct frequency of spark supply will be disrupted.

You will have to check all the sensors that take part in the operation of the ignition system

Pay special attention to the crankshaft and camshaft position sensors. A regular test allows you to quickly determine whether the sensors are really to blame

If the belt has been in use on your vehicle for a long time, it may be at the end of its service life. Or it was installed incorrectly when replacing it. After all, it is enough to make a mistake by one tooth, and the performance of the car will be impaired, the car will not be able to accelerate properly

In some cases, they do not allow the car to start at all if there is a malfunction, but sometimes they lead to a noticeable drop in power. Remove them, check their condition, clean them, measure the distance between the electrodes. If they fail, simply replace them with new ones.

To finally verify the presence or absence of problems in the ignition system, it is recommended to conduct more detailed diagnostics.

Diagnostics

We suggest you familiarize yourself with several steps aimed at diagnosing the condition of the ignition system. This may help determine why the engine is not revving up.

- Make sure that the electronic control unit is performing its functions. First of all, turn on the ignition and listen to whether the fuel pump starts working.

- Measure the pressure in the fuel line. If the readings fall within 2.5-3.0 kg/cm3, then everything is fine.

- If the measurement readings are normal, check the BitStop parameter using scan tools while cranking the crankshaft. If the parameter is indicated “no”, then the ECU receives the command to create a spark at the plugs and works well.

- Using a high-voltage spark gap, you can check for the presence of a spark. After all, it’s not uncommon for worn-out, dirty spark plugs to be to blame.

Air supply

It is not uncommon for engine thrust to deteriorate due to a disruption in the normal air supply to create the air-fuel mixture.

If there is more air, the mixture will be lean because the amount of oxygen will exceed the amount of fuel. Hence the drop in power and decrease in traction.

The easiest way to solve an air supply problem is to replace the air filter. In order to prevent and prevent problems from occurring, this element should be changed twice a year.

Checking the mass air flow sensor

If the engine speed increases, but the speed does not increase, there are several possible explanations for this phenomenon:

- The pressure in the fuel system is too low;

- The operation of the mass air flow sensor is disrupted. The sensor most often returns to its previous performance after cleaning. If it doesn't help, replace it;

- The air filter is clogged. It is better to replace it;

- The nozzle is clogged. This is mainly due to the low quality of the fuel you fill your car with.

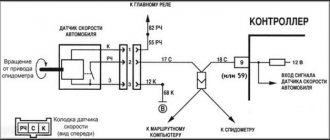

Speed sensor

The sensor is located directly in the gearbox. One of the signs of its breakdown is unstable idle. Sometimes the engine stalls in this mode, but more often the speed fluctuates. An additional symptom is the speedometer not functioning properly.

First of all, the sensor must be checked for integrity. Be sure to consider its contacts and the wiring leading to them. Contaminants are removed, and it is better to apply Litol to the cleaned surface.

If cleaning does not help, you will have to test it. For this:

- remove the sensor;

- straighten the cable and turn the unit with the drive towards you;

- the first contact on the right on the connector is ground, the middle one goes to the speedometer, the left one supplies power (12 volts);

- clamp the drive in a screwdriver (set to unscrew);

- connect the red probe to the central wire, and ground the black probe to the body;

- start the screwdriver;

- If the multimeter shows an increase in voltage when rotating, then the sensor is working.

In this case, you should find out whether the wiring is working properly - this is another reason for floating speed. Make sure all the wires are intact, the insulation is not cracked, and there are no signs of a short circuit anywhere. At the slightest suspicion, change the cable.

Consequences of engine tripping

A malfunctioning power unit not only leads to discomfort while driving, but also to more serious problems. The fuel that enters the idle cylinder and does not burn flows into the crankcase with oil. The fuel mixture makes the engine oil more liquid and loses its properties.

If the problem in the engine is not corrected immediately, the pistons and rings will begin to wear out over time. The lack of a lubricating film leads to the formation of nicks and scuffs on the cylinder walls. Thus, the appearance of extraneous noise in the engine leads to the need for major repairs.

Eliminating the effect when a 16-valve VAZ-2112 stalls during acceleration turns out to be not so difficult with your own hands. Of course, if you are unable to fix the problem, you should go to a car service center, where they will do everything quickly and accurately.

Electrical system

A failure on the part of the electrical system is indicated by:

- increased fuel consumption;

- difficult starting of the engine and its unstable operation;

- tripling.

It should not be ruled out that your VAZ is faulty:

- power wiring;

- contacts in the generator;

- spark plug.

Start your inspection with the candles. The presence of soot, excessive clearance, or partial cable breakage on them increases the resistance. Failure of insulation also leads to voltage leakage. Therefore, the wires are inspected closely, paying attention to the wiring of the terminals and the contacts of the latter.

Causes of uneven engine idling

Experts divide the main reasons for rough idling into two categories:

- problems with fuel or fuel system;

- problems with electrical and electronic controls;

A malfunction of the air system (intake) can be considered separately, but it is more appropriate to include it in the list of problems with the fuel system. The fact is that both of them are inextricably linked and affect the stability of the power unit in idle mode and under load.

Fuel-air system and fuel. A poor fuel-air mixture is often the reason why the engine idles rough. Such a “poor” mixture is that there is too little fuel in it and too much air.

Excess air can be sucked in through damage in the line. For example, rubber fuel hoses of poor quality may initially have or acquire microcracks in their walls over time. Poor fixation of the hose also contributes to air leaks at the joints.

A more serious problem can be considered a problem with the idle air valve (also known as the idle air regulator, the secondary air regulator), which is sometimes called the idle air sensor. Owners of carburetor cars also know this part as the “solenoid valve.”

Excess air can also be sucked in through, for example, broken holes in the throttle valve axis on the carburetor. In this case, the problem may not become noticeable immediately: gasoline consumption will gradually increase, and interruptions in idling will appear.

Poor quality fuel. Because of it, the idle speed also often “floats”. This phenomenon is especially strong when using so-called eco-gasoline. It contains a certain amount of ethanol. Ideally, this not only makes the exhaust gases less toxic, but also helps clean the fuel system.

However, in practice, drivers either deal with counterfeit fuel, manufactured in violation of technology, or use such fuel incorrectly. The fact is that for normal engine operation of the specified “eco” type gasoline in the tank there should be no more than 40-50 percent.

The fuel pressure regulator (aka low pressure bypass valve) has failed. Its task is to maintain the required fuel pressure while the engine is running in any mode.

This breakdown is indicated not only by uneven engine operation at idle, but also by interruptions if you sharply press the gas pedal, a drop in power, and a strong increase in fuel consumption.

- The injectors are clogged (the channels are coked). Due to poor operation of the injectors, the fuel mixture is of inadequate quality in composition, which leads to disruptions in the operation of the power unit in different modes and increased fuel consumption.

- Air damper malfunction. This is usually a mechanical interference, which also leads to the formation of a poor-quality fuel-air mixture. As already mentioned, this causes the engine to run unevenly.

- The idle speed on the carburetor is not adjusted. In this case, under load the engine will operate normally, but at idle it will sometimes jerk, and at the same time there may even be a slight popping sound in the muffler. A relatively simple problem that you can deal with yourself by tightening the required adjusting screw.

Tips and tricks

Let's look at how you can eliminate some of the malfunctions that lead to floating and speed jumps, and do it yourself.

- As mentioned above, the leakage of excess air can cause surges. To exclude or confirm the possibility of supplying such air, you need to check the tightness of the air supply system to the intake. You can remove the air hose and feed it air from a compressor or pump by placing the hose in a container of water. This method helps to identify cracks.

- As for the idle air control, you need to measure the resistance with a multimeter. If the resistance is between 40 and 80 ohms, this means that the device is not working.

- Also, as part of diagnostic procedures, in some cases it is necessary to clean the crankcase ventilation valve. The valve must be removed and washed with carburetor cleaning fluid or kerosene. This approach will remove deposits from the valve.

We also recommend reading the article about why the speed fluctuates on a cold engine. From this article you will learn about the reasons for jumps and floating speed on a cold engine, as well as ways to determine the cause and eliminate this malfunction.

- As for the ECM sensors, in this case it is not advisable to try to repair such elements. For example, if the mass air flow sensor is faulty, it is better to immediately replace it with a new one.

- It is better to trust specialists to flush the throttle valve without proper experience, especially if such flushing is necessary with the removal of the valve. If we talk about the method of flushing the throttle without removing it, you can do the procedure yourself. The hoses are disconnected from the valve, then a cleaning aerosol is injected into the throttle.

The main thing is to disconnect the electrical contacts from the throttle valve. Let us add that on many cars where the damper was heavily dirty, you then need to additionally set the correct opening gap of the damper or “teach” the throttle using the appropriate equipment.

- On a car with a carburetor, you need to adjust the idle speed by setting it with the quality and quantity screws on the carburetor. The idle jet may also need to be cleaned. To do this, it is often enough to inject a carburetor cleaning aerosol and then blow it with compressed air.

Let’s also add that to remove rust from the fuel injection pump, you can use special cleaners that are poured into the fuel tank. Also, some sources mention a method where a little motor oil is added to the fuel (about 200 ml per full tank).

According to drivers, this helps protect the pump from corrosion and is a preventative measure. At the same time, we note that this method is suitable for construction equipment and it is highly not recommended to practice such solutions on modern diesel internal combustion engines.

VAZ 2110 works intermittently

When the engine of a VAZ-2110 passenger car begins to operate intermittently in some modes, it is not often possible to determine the cause of this malfunction on the fly. Sometimes, even “specialists” at service stations begin to “throw up their hands”, not knowing what to say to the owner of this car.

Considering that the vast majority of VAZ-2110 engines are injection engines, they begin to look for the cause of this malfunction by checking the serviceability of the sensors by viewing the instrument cluster on the screen and the error codes that the on-board computer produces. If there is an error, the cause of the malfunction is eliminated by replacing the corresponding sensor with a similar new sensor.

But sometimes it happens that there are no error codes, but the engine continues to operate unstably. Then they begin to check the operation of the spark plugs, unscrewing them one by one and checking for the presence of a spark between the central and side electrodes. There may be no spark for two reasons: either the gap between the electrodes has greatly increased, which is quite easy to adjust, or carbon deposits have formed on the insulator.

The presence of carbon deposits on only one of the spark plugs should alert the driver, as it may appear due to an enrichment of the combustible mixture, due to a malfunction of the electromagnetic injector, or due to engine oil entering the cylinder, which significantly complicates repairs to eliminate this malfunction.

Oil can enter the combustion chamber through the valves if the oil seals are worn out or cracked, as well as as a result of coking or breakage of the piston rings, then the pressure in this cylinder will be below normal. In the first case, you will only have to remove the valve cover and dry out the valve to replace the oil seal; in the second case, the upcoming work will depend on what happened to the rings.

If they break, then you will have to disassemble the engine, and if they become coked, you can try to return them to working condition by using a ring decoking liquid, and for this you need to strictly follow the instructions for using this liquid (the engine must be warm, the piston is at bottom dead center , fill overnight through the spark plug hole). If, after the third application of this fluid, the compression in the cylinder remains below normal, then the rings are broken, and if the compression has increased, then the rings have returned to their working position.

Diesel trouble due to fuel supply

There are two reasons associated with the supply of fuel to a diesel internal combustion engine:

- Insufficient fuel supply pressure from the fuel pump.

- Fuel injection is provided in a small volume.

For these reasons, the engine efficiency is low, diesel fuel is not sprayed in the working combustion chamber and combustion of the mixture does not occur completely.

It may be that the high pressure fuel pump supplies diesel fuel at the required pressure, but the injectors supply different volumes to the cylinders. The ignition time for different volumes of fuel supply is different, so the diesel engine begins to shake.

If a portion of fuel does not flow through the injector at all for one cycle, then the diesel engine begins to stall.

After cleaning, repairing or replacing the injectors with new ones, you must also adjust the injectors before installation.

When carrying out repair work on the injectors, the fuel injection pump should be adjusted. Since the pump may be worn out or its operating modes may be incorrectly configured, it may supply diesel fuel with low pressure. If you replace only the injectors, without checking and adjusting the fuel injection pump, the diesel engine will detonate and run rough. Therefore, when working on injectors, the high-pressure fuel pump must also be checked. Diesel engine detonation will lead to major repairs. Detonation means the ignition of a flammable mixture is accompanied by an explosion, a shock wave.

Communities › Lada 2110, 2111, 2112, 112, Bogdan › Blog › RPM freezes.

Good day, comrades. Car 2112 1.5 16 When squeezing the clutch to change gear, the revolutions jump to 3 thousand for a couple of seconds, while the throttle valve is closed, the throttle cable does not touch anywhere and does not jam, there are no errors either, Xx is smooth, air leaks not found, I changed the throttle body to a known good one, it didn’t help, the throttle body is clean and not clogged. Tell me where to dig

DZ has nothing to do with it. Since there was a lot of bloodshed, go for diagnostics, only to a normal diagnostician, and not to the guys with ELM 327.

But there is no suction of excess air anywhere? It could be suction from the VUT. The check is done with the car stationary and idling, just press the brake and look at the speed. If they jumped, it means there is a leak.

I watched and listened, If there was a suction, it would constantly jump up to three thousand, and then every other three times

But there is no suction of excess air anywhere? It could be suction from the VUT. The check is done with the car stationary and idling, just press the brake and look at the speed. If they jumped, it means there is a leak.

I removed the throttle valve now to clean it, although it’s already clean

Well, what’s there? My advice to you is don’t worry about the price of the IAC, take the cheapest one (if that’s the case), all spare parts for a VAZ are a lottery, so it’s pointless to hope for its long-term reliable operation.))

Replacing rcx didn't help

There was the same problem with the speed. I replaced the Idle Speed Controller, and the problem went away. It returned 2 months after the replacement (the IAC turned out to be defective, I took it with a flat tip). I replaced it with an IAC with an aluminum tip, I’ve been driving it for three months now without any problems.

Warm up the car to 70 degrees, turn it off and remove the terminal from the IAC, then start it and try to drive it. The IAC will always be in the middle position without control from the ECU, the check should not light up because IAC malfunctions are not diagnosed by the ECU.

Has it always been like this? Or just started recently? I think this is the norm. My revs also jump when I shift. But there were cars with non-factory firmware and this was not the case.

It didn’t happen like that, sometimes it will jump by 100-200 rpm but not by a thousand or 1.5

Replacing rcx didn't help

If anyone you know has a dozen without such a problem, ask IAC for a while. There's business there for 10 minutes. But you’ll immediately understand whether it’s the problem.

It's not an icon, it's numbers. from 1 to 23 in my opinion but I could be wrong. The numbers are the steps of the idle speed control stepper motor drive. Simply put, the distance to which the regulator rod is extended. 1 step is approximately (roughly) 1 mm. When changing gears, the DS closes completely (you release the gas pedal), but the engine continues to work, and the IAC is responsible for this work, because the air does not flow through the remote control, but through it. Those. when you press the clutch, the idle steps should change (the meaning is different for everyone, because initially the IAC is adjusted to the fully closed position by itself, assigning a certain number of steps). A little confusing, but I would start with the IAC.

In general, you need to take the phx from someone and check it, because in my city it costs from 600 rubles

What bookmaker? Check the BC for idle speed steps while pressing the clutch. It looks like RHH wants to die, I would start checking with him

BC by state type, no instructions, Step xx is roughly displayed by what icon?

When releasing the gas, the speed is increased or “freezes”: common malfunctions

Let's start with the fact that on many cars with an injector, the ECU raises the speed while the internal combustion engine is warming up. This is necessary to ensure that the power unit operates stably after a cold start.

However, after the temperature rises, the control unit reduces the idle speed, bringing it to normal. On many cars with a carburetor, the driver independently increases the speed during warm-up, using the so-called “choke”.

Moreover, after the engine is warmed up, the normal idle speed is, on average, 650-950 rpm. If you press the gas and release the accelerator, the speed should increase, and then decrease again to the specified values.

So, let's start with common carburetor problems. Often the engine speed does not drop due to problems with the throttle valve. For example, when the driver steps on the gas, the throttle must be opened wider to allow more air to enter the cylinders to burn fuel. After the gas pedal is released, the throttle closes and the speed decreases.

If the damper does not close completely, an over-enriched mixture enters the cylinders, and the speed is increased. The cause may be severe contamination of the throttle assembly or damage to the valve itself (deformation). First you need to clean the damper; carburetor cleaning liquid is suitable as a cleaner.

We also note that the damper does not close tightly even when the drive cable is worn out. In this case, the cable must be replaced. On carburetor cars, engine speed often does not drop even if the gasket between the carburetor and the cylinder head has failed. The culprit may also be an intake manifold that is damaged.

The main task is to find the correct ratio of fuel and air. Often, a high level of fuel in the carburetor float chamber also leads to increased speed. The check should begin with the needle valve.

Now let's move on to the injector

Please note that on many injection cars, after cleaning the throttle valve, the assembly also needs to be additionally “trained”. As for problems, the injection system itself is more complex, that is, there are more reasons for high speeds compared to a carburetor

In simple words, if the specified sensor gives an incorrect signal, the ECU considers that the engine is cold and activates the warm-up mode. In this case, the control unit raises the speed so that the power unit operates stably and reaches operating temperature faster.

Read more: Bucharest Budapest how to get there

Special attention should be paid to gaskets, since air leaks can lead to disruption of mixture formation. This means that you need to separately inspect manifold gaskets, injector seals, etc.

Which TPS sensor to choose for replacement

For stable and long-term operation of the sensor, we advise you not to buy too cheap analogues of questionable quality. The factory installed throttle position sensor was GM 2112-1148200 .

- DPDZ /2110/ GM 2112-1148200 price from 300 rub.

- DPDZ /2110/ PEKAR 2112-1148200 price from 200 rub.

- TPDZ /2110/ StartVOLT VS-TP 0110 price from 200 rub.

- TPDZ /2110/ HOFER HF 750260 price from 150 rub.

- DPDZ /2110/ CJSC Account Mash 2112-1148200-05 price from 400 rub.

- DPDZ /2110/ JSC RIKOR ELECTRONICS 2112-1148200 price from 300 rub.

Features of failures

What all pedal failures have in common is that when you press the pedal, the engine does not respond in a timely manner, and therefore does not gain momentum. Such failures can appear in different situations and the behavior of the machine can also be different.

So, we can highlight:

- Short dips while driving (no more than a couple of seconds) followed by a quick response from the engine.

- Dips during acceleration.

- Dips at idle speed.

- Prolonged failures, as a result of which the car stalls.

- Jerking, characterized by a series of alternating short dips and subsequent jerks.

There are not many reasons for this phenomenon, so finding and eliminating them will not be difficult for an experienced driver.

Gas pedal dips

In 99% of cases, failures can be caused by one of the following reasons:

- clogged injectors;

- damage to the fuel system;

- injector damage;

- wear of temperature sensors;

- errors in the ECU;

- failure of spark plugs.

Throttle sensor

If the TPS is faulty, then the VAZ car often begins to work unstably. The main signs of a problem include:

- floating speed at idle;

- speed reduction;

- jerky acceleration;

- sudden engine shutdown.

The sensor in question most often fails for the following reason - abrasion of the coating on the base. This prevents the signal from reaching the controller, which causes the motor to malfunction. Failure of the slider leads to a similar result. Any of these problems can be recognized visually.

Manifestation of malfunction

First, you need to make sure whether your problem really fits the definition of “engine trouble.” To better understand the cause of the occurrence, you need to understand the very essence of the malfunction, and at the same time decide whether your dilemma is similar to the one described below.

So, what happens to the car and what changes in engine performance can occur? To begin with, as we said earlier, the engine life will noticeably decrease. This is especially noticeable in cars with manual transmission (we'll talk more about this below). In addition, the most likely thing is that the car will begin to shake and vibrate while driving. Vehicle acceleration deteriorates sharply, operating speeds decrease, and the level of fuel consumed increases by almost several liters.

Cylinders are the most important indicators of normal engine operation

We recommend: Clutch repair. Repair of discs and master cylinder

Checking the crankshaft position sensor

If the speed indicator on the VAZ-2110 is floating, and previous actions did not bring any results, then you need to make sure that the above sensor is working. Here too you will need a multimeter, and also a screwdriver.

Set the measuring device so that its maximum value corresponds to 200 millivolts. Connect the probes to the sensor wires (ignition is on). Bring the screwdriver closer - the multimeter will react to this by fluctuating readings. Lack of response indicates a breakdown.

Causes

General view of engine 21124 16V.

The VAZ 2112 engine has problems with the 16 valve injector for various reasons. To find out the specifics, the motorist needs to know the design features of the power unit, as well as have some vehicle repair skills.

So, VAZ 2112 has 16 valves and the engine is tripping, what could be the reasons for the effect:

- Poor quality fuel.

- Malfunction in fuel supply elements.

- Malfunction of air intake units.

- Malfunction in the ignition system.

- The problem lies in the electronic part of the car.

Solution methods

Before you begin the process of analyzing the causes in more detail, as well as methods for eliminating the malfunction, it is worth understanding that if the car owner is not sure that he can fix the breakdown or does not carry out the correct diagnosis, then it is better not to get involved himself. In this case, it is recommended to contact a professional car service.

Poor quality gasoline

Poor quality fuel is everywhere.

Troubleshooting on a VAZ can primarily occur if low-quality fuel gets into the air-fuel mixture formation system. Thus, most domestic gas stations do not have a very good reputation due to the fact that they sell fuel that does not meet the standards.

So, if gasoline has already entered the system, it most likely clogged the gasoline supply system, and possibly left its mark on the spark plugs. In the worst case, what all car enthusiasts fear is burnout of the valves or piston mechanism.

Therefore, it is better to take the choice of a gas station seriously, since major engine repairs will cost more than saving on good gasoline. It is recommended to overpay a little for fuel, to regularly change fuel cells and carry out constant repairs.

Fuel cells

The process of replacing a clogged fuel filter.

The first place to look for a problem is the fuel supply to the fuel mixture formation system. Thus, clogging of the elements can cause an insufficient amount of fuel to flow into the combustion chambers.

First, you need to check the performance of the fuel pump, or more precisely, an element such as a mesh filter. It is located on the pump itself and often becomes clogged due to the use of low-quality fuel. But, as soon as it is changed, the operation of the power unit returns to normal.