The main function of the clutch hydraulic drive is to provide short-term separation of the flywheel and transmission when changing gears. If the VAZ 2107 clutch pedal is pressed very easily or immediately falls through, you should think about bleeding the hydraulic cylinder of the release bearing drive. To accurately identify the problem, it is necessary to check the level of working fluid in the master cylinder reservoir. You can repair the clutch without contacting a car service specialist.

- Design of the main elements of the hydraulic drive

Design and purpose of the clutch master cylinder - Replacing the master cylinder

- Dismantling and assembling the master cylinder

Video: replacing the clutch master cylinder VAZ 2101–07

- Video: replacing the clutch slave cylinder VAZ 2101–2107

- The clutch does not disengage completely (the clutch “drives”)

- Tools and materials

Video: bleeding the clutch VAZ 2101–07

When do you need to adjust the clutch on Lada 2107?

It is recommended to check the settings regularly at every car maintenance. But there are still signs when the procedure should be started immediately, so it wouldn’t hurt any owner to know how to bleed the clutch on a VAZ 2107 on their own. Malfunctions in the operation of the coupling during operation are expressed by the following symptoms:

- Slipping – the clutch disc slips when the pedal is fully released, and is unable to transfer all the power from the internal combustion engine to the transmission.

- Drives - the disc does not move away from the flywheel when the pedal is fully depressed, which makes it difficult to change gears.

What should I check?

The clutch may engage too early or late due to the pedal not moving properly, resulting in jerking while driving. The free play of the pedal should be within 0.4-2.0 mm; if these indicators are violated, then adjustments are necessary.

If you look under the car, you can check the free play between the pusher (indicated by the red arrow) and the release fork (blue arrow). Before adjusting the clutch on a VAZ 2107, you need to pump the fork by hand; if there is no free play or exceeds 5 mm, then adjustment of the unit is necessary, because the release bearing will be subject to constant loads.

If all adjustment parameters are normal, the pedal stroke before the clutch starts engaging should be 25-35 mm. This is determined using a ruler; if the indicator does not correspond to the norm, then you will have to adjust some components of the clutch drive system.

It's simple: how to properly adjust the clutch on a VAZ 2107 without the help of specialists?

The procedure for fully setting up the friction clutch control system consists of two parts, one is performed in the cabin, and the other is performed under the car from the inspection pit. To work you will need a set of tools:

- Set of keys.

- Set of screwdrivers and pliers.

- Ruler or square.

Adjusting the initial travel of the clutch pedal

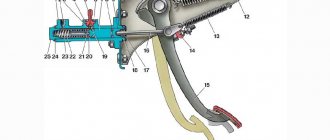

A bracket with a pusher is installed under the steering column in the cabin. By rotating the nuts, you can achieve the desired clearance between the pusher and the clutch master cylinder piston. It is this parameter that is responsible for the initial free play of the pedal; the adjustment technology is quite simple:

- Use a wrench (no. 1 in the photo) to hold the travel stop, and use a second wrench to unscrew the lock nut two turns.

- Rotate the limiting pin with the first key (screw in or unscrew), set the desired initial free play of the pedal - 0.4-2.0 mm.

- Check the free play using a straight edge and, if necessary, repeat the adjustment operation.

- Tighten the locknut with a wrench.

How to adjust the free play of the release fork?

Before you bleed the clutch on a classic VAZ 2107, you need to perform the second adjustment stage, which is done on an overpass or inspection hole. The technology for checking and adjusting the free play of the clutch release fork is as follows:

- Using pliers, remove the spring from the fork and then from the working cylinder. The check can be done without dismantling the spring, but when checking the free play, you will have to apply force to overcome its resistance.

- Check the stroke of the fork with a ruler, pressing it all the way. The readings should be within 4-5 mm; if there are deviations, then the following points should be followed.

- Clean the cylinder of dirt and spray the nuts with WD-40.

Why and how to bleed the clutch on a VAZ 2107 in your garage?

Bleeding is necessary if the clutch does not disengage completely. For example, the pedal is depressed, the first gear is turned on, but before you even have time to release the pedal, the car is already moving. A slight pedal stroke also indicates the need to remove air from the system. The procedure must be performed with an assistant who will press the pedal. To work you will need:

- Brake fluid.

- Rubber hose 50-100 cm long.

- "8" wrench.

- Container for liquid.

- Brake fluid.

Car owners who are interested in how to properly adjust the clutch on a VAZ 2107 should know that bleeding is carried out through a fitting located on the working cylinder under its bottom. The operation is no more complicated than adjusting wheel alignment ; even a novice car enthusiast can perform it.

Pumping technique

It is advisable to carry out the work on an overpass or inspection hole; in extreme cases, the machine should be raised on supports. Further actions are carried out according to transitions:

- Pour new fluid into the clutch reservoir.

- Place one end of the hose onto the working cylinder fitting and lower the other end into a container.

- Ask an assistant to press the clutch pedal 5-6 times and hold it pressed.

- Loosen the fitting on the cylinder with a “8” wrench and release the liquid with air into the container, then tighten the fitting and ask to release the pedal.

- If necessary, add liquid to the tank and repeat the operation until there are no air bubbles in the liquid.

During pumping, do not allow the liquid level in the tank to drop below 15 mm, and top it up in a timely manner. Finally, you need to check the functionality of the coupling:

- Start the car and put the car in reverse gear; the appearance of jamming or extraneous noise is unacceptable.

- Check the gear shift while driving; if acceleration and shifting occur without jerking or extraneous noise, then the clutch control system is configured normally.

Procedure for bleeding the clutch

To bleed the clutch hydraulic drive you will need:

A rubber or plastic hose (tube) with a diameter suitable for tightly fitting the hose onto the drain fitting. Wrench (usually 8 by 10). A transparent vessel or reservoir for 200 ml of fresh liquid, for placing the second end of the hose into it. Fresh fluid to add to the clutch expansion tank. Important! Old contaminated fluid drained from the clutch hydraulic system cannot be poured back into the system. On some car brands, the drain fitting is located at the bottom, so you may need an inspection hole to get to it. To find out exactly where and how the clutch slave cylinder drain fitting is located in your car, study the “Operator's Manual”, in the “Clutch” section. It is advisable to wear rubber gloves, since brake fluid is considered toxic.. Important! In this case, it is necessary that the heavy object used not only prevents the pedal from returning back, but also exerts constant pressure on it, since when the fitting is unscrewed, the pedal will be pushed through and fall through.

Important! The pumping procedure is as follows:

Important! In this case, it is necessary that the heavy object used not only prevents the pedal from returning back, but also exerts constant pressure on it, since when the fitting is unscrewed, the pedal will be pushed through and fall through.

Important! The pumping procedure is as follows:

The first step is to check the fluid level in the clutch expansion tank. The tank must be filled completely, up to the neck. When inspecting the tank and adding fluid (if necessary), maintain cleanliness and prevent debris from entering the tank. Release the head of the working cylinder drain fitting from the protective cap and place a hose (tube) on it. The opposite end of the hose should be lowered into a container with fresh brake fluid

When air comes out of the hose into the liquid, air bubbles will be clearly visible. Important! During pumping, you cannot remove the second end of the hose from the liquid. Pump up pressure in the system using the clutch pedal. An assistant in the cabin must press the clutch pedal sharply and all the way 3-4 times

In this case, it is necessary that the pedal not only goes down to the stop, but also returns back to the stop. If the pedal “falls to the floor” and does not return to its original position on its own, you will have to return it with your hand or toe. The key here is to build up the pressure using maximum pedal travel. The interval between pressing the pedal should be approximately 2 seconds. Having pressed the pedal for the last time (the third or fourth), it must be left and held in the pressed position until it stops. While your partner holds the pedal all the way down, another person should unscrew the drain fitting of the working cylinder with the hose attached to it, about half a turn. After opening the drain fitting, old fluid from the working cylinder will begin to flow into the container with new brake fluid through the hose. With the old liquid leaving the cylinder, air will also come out, the presence of which can be judged by the air bubbles in the container with the new liquid. As the old contaminated fluid exits the clutch hydraulic system, the pedal pressed all the way by the second partner will begin to be pressed and lowered. You need to wait until the pedal is pressed all the way to the floor, and then immediately screw in (close) the drain fitting. The pedal cannot be released until the drain fitting is closed. Repeat the procedure of squeezing the pedal and opening/closing the fitting several more times until clean liquid without air begins to come out of the hose. If aired fluid continues to come out of the hose even after the system has been completely pumped and the fluid has been completely changed (approximately 1 liter), then you need to look for the reason why air is penetrating into the clutch hydraulic system. Important! During the pumping process, it is necessary to carefully monitor the liquid level in the expansion tank and not allow it to fall more than 35 mm from the edge of the neck. During the pumping process, the old fluid will drain into a container and leave the hydraulic system. Accordingly, the level in the tank will decrease, and if during the pumping process the liquid completely leaves the tank, then air will again enter the hydraulic system. Then you will not only have to start all over again, but also additionally waste new liquid, since the new liquid that has already been poured will merge into the container and mix there with the old one, and it will no longer be possible to pour it back. After pumping and obtaining the desired result, the fitting must be screwed in well, remove the hose and put a protective cap on the head of the fitting.

Dismantling the hydraulic drive

To perform the operation we will need:

- container for operating fluid and a large-volume syringe.

- set of wrenches and sockets;

- screwdriver and pliers.

The order of work is as follows:

- Brake fluid is pumped out from the expansion tank of the master cylinder of a VAZ 2107 car using a syringe. A rubber tube is disconnected from the drive, from which the remains are also poured into the prepared container. If liquid gets on paint surfaces, they must be wiped with a damp cloth.

- Using an open-end wrench set to “10”, unscrew the fitting of the pipeline connecting the main and working hydraulic drives.

- Using a “13” socket and an extension adapter, unscrew the nuts holding the assembly to the engine compartment panel.

- To remove the master cylinder from the studs, simply press the clutch pedal, this will move it out of place, after which you can pull it out by hand.

Product location

The master cylinder on a VAZ 2107 is located under the hood, directly on the wall separating the interior from the hood, near the driver’s feet. Directly above it is the expansion tank, and next to it are the vacuum booster and the brake master cylinder. Usually, simply looking at the product is enough to determine the problem. The presence of a leak indicates that the part is faulty and requires repair or replacement.

Purpose of the device

Cars are equipped with clutch master and slave cylinders, without which the operation of the mechanism is impossible. The VAZ 2107 clutch master cylinder is designed to push out brake fluid. Below is a diagram from which you can visually find out the operating features of the unit.

When you press the clutch pedal, the piston moves in the device in question, thereby pushing out the brake fluid. This liquid enters the working cylinder through a tube, where the reverse process is observed (the liquid pushes out the piston). Brake fluid drives a piston, which is connected by a fork to the clutch disc. As a result, the clutch disc and flywheel are separated, allowing you to change gear. The GCS is also called the main one, since it is with its help that force is supplied from the pedal when it is pressed.

The need to replace the device: when required

Like all parts of any car, the GVC tends to wear out, resulting in the need for repair or replacement. The simplest breakdown of a product is wear of the boot, which can be determined by the characteristic signs of a fluid leak.

To identify a cylinder malfunction, an initial visual inspection is required. It is possible to repair a failed main circulation system on a VAZ 2107; for this you can look for repair kits, but this is not always rational due to the quality of modern spare parts, so it is easier and faster to replace it entirely. The malfunction can also be determined by the characteristic loss of pressure in the system, which is determined by pressing the pedal. Let’s take a closer look at how to change a faulty VAZ 2107 mechanism.

We change it ourselves

Replacing the VAZ 2107 clutch master cylinder begins with the need to pump out the brake fluid from the hydraulic reservoir. This can be done using a syringe or a rubber bulb. Together with this socket or a 10mm wrench, unscrew the bracket securing the expansion tank and move it to the side to gain access to the cylinder.

The next step involves removing the clutch expansion tank hose. To do this, you need to loosen the hose clamp, then disconnect the hose and position it so that it does not interfere with further work. If you want to remove the tank completely, this is done very simply.

Further actions are performed in the following sequence:

- Using a “10” wrench, you need to unscrew the pipeline securing nut to the device. Once the nut is unscrewed, the tube can be moved to the side.

- There is a hose nearby near the steel pipeline, which also needs to be disconnected from the main device. This can be done by loosening the fixing clamp.

- The GCS is fixed to the body using two fastening nuts. To unscrew them, you will need to use a wrench with an extension and a “13” socket. After unscrewing the two nuts, you can remove the product and drain the remaining brake fluid from it. If it is not possible to dismantle the unit, you can press the clutch pedal, as a result of which it will move.

- But repairs are usually not rational, so after removing the old one, a new unit is installed in its place. Installation is carried out in the reverse order of removal. After installation, it is necessary to carry out the process of pumping the hydraulic drive, first pouring fuel fluid into the tank. You can find out how the system is pumped from the relevant material on the website.

After the work is completed, you can test the operating features of the new GVC. If necessary, the RCS (working cylinder) should also be replaced, but you can find out more about this in the corresponding material.

Cars of the Volzhsky plant models 01-07 have a hydraulic clutch drive. The main actuator of this mechanism of the VAZ 2107 is replaced in the event of its breakdown or failure. The cylinder is secured to the engine compartment shield on the driver's side with two studs and nuts, and a reservoir with brake fluid is installed in the upper part. A pipeline is laid from it to the working unit.

Hydraulic drive installation

Replacing a mechanism involves purchasing it in a retail network or via the Internet. Installation work is performed in the following sequence:

- The clutch master cylinder of the VAZ 2107 is put on the studs and pushed all the way to the base.

- The nuts are screwed onto the fasteners and tightened with a wrench to “13”.

- The union nut of the pipeline laid to the working hydraulic drive is screwed into the main cylinder.

- The rubber tube is connected to a plastic connecting element and secured with a clamp.

- The expansion tank is filled with brake fluid, which enters the main and slave cylinders of the clutch through tubes. Replacing the fluid in the system is mandatory due to wear products.

Upon completion of installation of parts, it is necessary to inspect and check the tightness of the nuts. Replacing the main or working clutch drive of a VAZ 2107 car ends with bleeding the system.

About brake fluid for VAZ 2106

As mentioned above, the “six” clutch is actuated by a hydraulic drive running on conventional brake fluid. This fluid is poured into the brake reservoir, located in the engine compartment, to the right of the engine. The operating instructions for the “six” indicate the exact volume of brake fluid in the system: 0.55 liters. But experienced owners of “sixes” recommend filling in a little more - 0.6 liters, since they remember that sooner or later the clutch will have to be pumped, and a small leak of fluid is inevitable.

Brake fluid is divided into several classes. In our country, DOT4 class fluid is most popular among 6 drivers. The basis of the liquid is ethylene glycol, which includes a set of additives that significantly increases the boiling point of the liquid and lowers its viscosity.

Video: adding brake fluid to the “classic”

Clutch VAZ 2107

If, when you press the pedal, the clutch does not disengage (“drives”), and the pedal itself is soft, you should pay attention to repairing or adjusting the clutch drive. To do this, it is necessary to remove and repair (or replace) the main and slave cylinders of the clutch hydraulic drive and bleed them.

VAZ 2107 clutch: device

The “Seven” has a dry single-disc clutch. The clutch hydraulic master cylinder is located directly under the pedal, when pressed, the pusher moves, acting on the master cylinder piston, creating pressure. The brake fluid that fills the hydraulic drive is squeezed out and flows into the working cylinder.

The piston of the working cylinder is connected to the clutch fork by a pusher. When you press the pedal, the latter moves the fork, it displaces the release bearing and separates the support and pressure discs. As a result, the torque from the crankshaft flywheel is no longer transmitted to the gearbox and it becomes possible to change gear.

If the clutch unit malfunctions, when you press the pedal, the gearbox shaft continues to rotate and changing gears becomes difficult or even impossible. If the clutch is adjusted incorrectly, the discs may slip, which is accompanied by accelerated wear.

You cannot continue to drive a car with a faulty clutch - both the clutch discs and the gearbox may be damaged. Therefore, at the first sign of a malfunction, you should start repairing and adjusting it.

Replacing brake fluid in hydraulic brake and clutch drives

When you press the brake pedal, the cylinder is compressed by filling it with liquid.

This, in turn, is supplied to the caliper under high pressure. As a result, the vehicle speed drops and movement slows down. Often, during maintenance, car owners may be told that the clutch brake fluid needs to be replaced. You can do this yourself, which will allow you to save a lot on service station services. The brake system should be checked at least twice a year.

The service life of brake fluid is, for the most part, strictly limited and regulated by the manufacturer. It is advisable to change it twice a year in the spring. During replacement, it is advisable not to neglect banal safety rules.

Replacing the clutch master cylinder VAZ 2107

The simplest way to repair a VAZ 2107 clutch is to change the worn cylinders (main and slave). Their price is low, and the labor intensity of the operation is much lower than when carrying out repairs. Therefore, car owners often prefer to replace rather than repair clutches.

Let's start by replacing the master cylinder. The order of operations is as follows:

- Drain the brake fluid from the clutch reservoir into another container. This can be conveniently done using a syringe.

- Loosen the clamp and remove the hose from the master cylinder fitting.

- Unscrew the fitting of the metal tube going from the master cylinder to the slave cylinder and disconnect the tube.

- Using a 13mm wrench or a socket with an extension, unscrew the two nuts securing the master cylinder to the body bulkhead and remove the master cylinder.

The new clutch master cylinder can now be installed. Before doing this, you should check the condition of the flexible hose of the clutch reservoir. If it cracks at the end, it needs to be trimmed slightly or replaced with a new one.

When installing a new cylinder, it is necessary to ensure that the clutch pedal drive rod fits inside the cylinder. For convenience, you can ask your partner to slightly press the clutch pedal and hold it. Then follows:

- Install the master cylinder onto the studs and tighten the nuts.

- Attach and tighten the metal tube fitting.

- Place the pipe from the clutch reservoir and tighten the clamp.

- Fill the reservoir with brake fluid, following the level marks.

The clutch master cylinder has been replaced.

Review of Manufacturer Prices

| Name/catalogue number of brake fluid | Price in rubles |

| DOT4 250ml TRW PFB425 | From 145 |

| DOT5.1 250ml TRW PFB525 | From 180 |

| DOT4 500ml TRW PFB450 | From 220 |

| DOT5.1 500ml TRW PFB550 | From 220 |

| DOT5.1 ESP 500ml TRW PFB750 | From 220 |

| DOT4 1L TRW PFB401 | From 220 |

| DOT5.1 1L TRW PFB501 | From 220 |

| DOT4 ESP 1L TRW PFB440 | From 220 |

| DOT4 ESP 1L TRW PFB440 | From 220 |

| DOT4 5L TRW PFB405 | From 220 |

| *prices are as of May 2022 | |

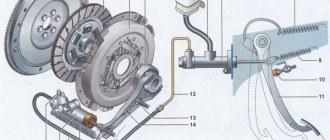

Replacing the clutch slave cylinder VAZ 2107

Removal of the working cylinder should be done from the inspection hole or using a lift. The order of operations is as follows:

- Remove the return spring from the slave cylinder bracket.

- Unscrew the fitting of the tube coming from the master cylinder. To prevent brake fluid from leaking from it, you can put a cap on it, removed from the cylinder bleeder fitting, or direct it into a container prepared in advance.

- Unscrew the two bolts connecting the slave cylinder to the gearbox and remove them together with the plate.

- Remove the clutch slave cylinder.

The new working cylinder is installed in the reverse order of removing the old one.

After replacing any of the cylinders, the hydraulic drive system must be pumped. The work must be carried out together with a partner. This is done like this:

- Place a hose on the fitting of the working cylinder and immerse its end in a prepared container for brake fluid.

- Depress the clutch.

- Unscrew the fitting on the working cylinder 1 turn.

- Wait until air bubbles stop coming out and tighten the fitting.

- Repeat the operation until air stops coming out of the fitting. At the same time, monitor the fluid level in the clutch reservoir.

- Tighten the fitting and put on the cap.

There are several ways to bleed the clutch on a VAZ 2107, here is a video about the most popular ones

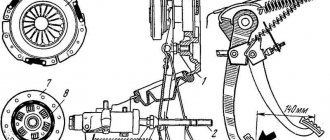

Design of the main elements of the hydraulic drive

The clutch on the VAZ 2107 is controlled using a hydraulic drive, the pressure in which is created using an outboard pedal mechanism. The main elements of the hydraulic drive are:

- clutch master cylinder (MCC);

- pipeline;

- hose;

- clutch slave cylinder (CLC).

The performance of the drive depends on the volume and technical characteristics of the operating fluid, which for the VAZ 2107 is usually DOT-3 or DOT-4 brake fluid. DOT is a designation for a system of requirements for the physical and chemical properties of diesel fuel, developed by the US Department of Transportation Institute (DOT - Department of Transportation). Compliance with these requirements is a prerequisite for the production and certification of the liquid. The composition of TJ includes glycol, polyesters and additives. DOT-3 or DOT-4 fluids have a low price and are recommended for use in drum-type brake systems and hydraulic clutch drives.

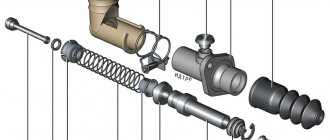

Design and purpose of the clutch master cylinder

The GCS is designed to create working fluid pressure by moving a piston connected to the clutch pedal. It is installed in the engine compartment just below the pedal mechanism, mounted on two studs and connected to the working fluid reservoir with a flexible hose. The cylinder is arranged as follows. Its body has a cavity in which a return spring, a working piston equipped with two O-rings, and a floating piston are located. The internal diameter of the GCS is 19.5+0.015–0.025 mm. No rust, scratches or chips are allowed on the mirror surface of the cylinder and the outer surfaces of the pistons.

Replacing the master cylinder

Replacing the GCS is quite simple. To do this you will need:

- set of wrenches and sockets;

- round nose pliers for removing the retaining ring;

- long thin slotted screwdriver;

- disposable syringe 10–22 ml;

- a small container for draining the working fluid.

The work is performed in the following order:

- The working fluid is drained from the hydraulic clutch drive. To do this, you can use a medical syringe or simply pull off the sleeve from the GCS fitting.

Dismantling and assembling the master cylinder

After carefully removing the GCS from its seat, you can begin to disassemble it. This is best done on a table or workbench with good lighting in the following order:

- Clean the outer surfaces of the housing from dirt.

- Carefully remove the protective rubber cover. Unscrew the fitting of the hose going to the reservoir with the working fluid.

Assembly and installation of an assembled or new GCS is carried out in the reverse order.

Video: replacing the clutch master cylinder VAZ 2101–07

The RCS ensures the movement of the pusher due to the pressure of the fuel fluid created by the main cylinder. The cylinder is located in a hard-to-reach place on the bottom of the gearbox and is secured to the clutch housing with two bolts. The easiest way to get to it is from below.

VAZ 2107 clutch repair

Repairing clutch cylinders is somewhat more difficult than replacing them, but much cheaper.

Once the cylinders are removed, disassembly can begin. Let's start with the master cylinder:

- Use a thin screwdriver to remove the retaining ring.

- Remove the fitting and gasket.

- Remove the boot by prying it off with a screwdriver.

- Unscrew the cylinder plug using a 22mm wrench.

- Pull out the retaining ring and use a screwdriver to remove the inside of the cylinder.

To restore the master cylinder, the rubber seals must be replaced. It is also necessary to check the condition of the spring, the inner surface of the cylinder and the piston. If there are burrs or damage, parts must be replaced.

Before assembly, parts should be thoroughly cleaned and dried. It is unacceptable for gasoline or oil to get inside the cylinder - they destroy the rubber seals.

Assembly is carried out in the reverse order of disassembling the cylinder.

The clutch slave cylinder, despite some design features, is repaired in the same way as the main one.

After repairing the cylinders and installing them in place, it is necessary to bleed the hydraulic clutch drive.

Keep in mind

There is no special clutch fluid. This is regular brake fluid. It is poured into the clutch master cylinder. The method described above is not universal and may not be suitable for your car model. If you have doubts, it is better to consult a specialist.

The working fluid in the clutch hydraulic drive is brake fluid.

RECOMMENDATION Type of brake fluid: “Tom” or “Rosa” with a class of at least DOT-4.

WARNING Brake fluid is toxic. Observe safety precautions when working with brake fluid. Do not allow brake fluid to come into contact with wires, plastic or painted parts. If brake fluid gets on such parts, wipe them off immediately. Use only brake fluid recommended by the manufacturer of the VAZ 2106. Do not reuse fluid drained from the system - such brake fluid is contaminated, saturated with moisture and air. Beautiful sex with your daughter's mother and your favorite friend Add brake fluid to the clutch reservoir of the brand that is already used in the system, or compatible with it.

On a VAZ 2106 car, the hydraulic clutch reservoir is located in the engine compartment in the left rear corner next to the brake reservoir.

1. This should be the normal level of brake fluid in the clutch reservoir.

2. To add fluid to the clutch reservoir, unscrew the cap and remove it. Place the lid on a clean cloth, avoiding either soiling the lid or allowing liquid to drain from it.

3. Carefully add brake fluid to the clutch reservoir to the bottom edge of the filler neck. 4. Close the lid. NOTE

A compensation cavity combined with a gasket is fixed on the inside of the cover with a slight interference fit.

If there are signs of aging, cracks, tears or other damage, replace the cavity.

Replacing the clutch master cylinder on a VAZ-2104-2107

The main purpose of the clutch master cylinder is that it transmits force to the slave cylinder from the clutch pedal using working fluid.

If the master cylinder is faulty, vehicle control will be impaired and it will be impossible to disconnect the transmission from the engine.

How to determine if the clutch master cylinder is faulty:

- Periodically check the level of working fluid in the tank. A sharp decrease in it will indicate a system malfunction;

- check for leaks in the main and working cylinder housings;

- failure of the clutch pedal, which occurs due to the entry and accumulation of air in the clutch system;

- underpressure of the pedal and vibration of the gear shift lever.

Main types of faults:

- there is a leak in the master cylinder;

- cuff wear;

- piston wear;

- the inside of the case is damaged (chips, scratches, etc.);

- For all classics of the Auto VAZ family, the clutch device is the same, including for 2107. The sequence of actions is the same.

Design and principle of operation of the clutch

The clutch pedal is connected to the clutch master cylinder through a rod. The same rod acts as a piston in this cylinder. There is also a working cylinder - it is installed on the clutch housing. The piston of this cylinder is connected to the release fork.

The force from the driver's foot is transmitted through fluid, so the clutch cylinders are connected to each other by a pipeline.

Fluid is supplied to the master cylinder from the reservoir. The working element is ordinary brake fluid.

It all works like this: the driver presses the clutch pedal, the rod enters the master cylinder and pushes the fluid out of it.

To prevent the liquid from flowing back into the tank, the piston closes the supply fitting from the tank.

Since the fluid is not compressed, it moves through the pipeline and begins to press on the piston in the working cylinder. This piston comes out and pushes the fork, which acts on the release bearing.

When the pedal is released, the fork spring pushes the piston back into the slave cylinder and the fluid returns to the master cylinder.

This scheme seems simple, but may not always be reliable. If air gets inside the drive system, the efficiency of the clutch will decrease.

Air bubbles in the system will be compressed when pressure arises, this will lead to the fact that the full force will not be transmitted.

Because of this, even with the pedal fully depressed, the output of the working cylinder rod will be incomplete, the fork will not fully depress the bearing - as a result, the clutch “drives”.

Replacement

The cost of this type of work in a car service starts from 550 rubles. But for most car enthusiasts, this operation is not so difficult to perform on their own.

- new GVC;

- brake fluid;

- set of wrenches with extension;

- syringe or rubber bulb.

- Pump out the fluid from the hydraulic drive reservoir using a syringe or rubber bulb.

- Remove the expansion tank and move it to the side so that it does not interfere with work.

- Unscrew the tube with a 13mm wrench. Move it a little.

- Loosen the clamp and disconnect the rubber hose that goes from the tank to the cylinder.

- Unscrew the two nuts with a 13mm socket wrench and an extension.

- Remove the master cylinder from the studs.

- Replace the GCS with a new one.

- Reassemble everything in reverse order.

Bleeding the clutch

The replacement has been made, but you should not hit the road without bleeding the clutch system. The process is similar to bleeding the brakes and is carried out in the following sequence:

- Brake fluid is poured into the reservoir.

- A hose is put on the master cylinder fitting, the other end is lowered into a bottle filled with liquid. This will show how air leaves the system during the pumping process.

- The operation requires an assistant. One sits in the car and presses the clutch pedal 5-6 times on command, after which he leaves it pressed. The second one opens the fitting until the release of air stops. This is done several times until all air is removed from the clutch system.

- Tighten the fitting and add fluid to the reservoir.

Conclusion

After replacing the clutch master cylinder and bleeding the entire system, you can safely hit the road without fear that the clutch will fail and the car will lose control because of it.

What kind of service is this?

Like any other part of the car, the clutch requires constant maintenance. Changing the clutch fluid, changing the engine oil or replacing the brake fluid is a simple but very important procedure to ensure the normal operation of this mechanism. The clutch in a car is necessary to temporarily disconnect the engine crankshaft from the gearbox. This procedure is needed to change gears. This mechanism also allows you to move off smoothly without significant jerks. Untimely replacement of brake fluid in the clutch hydraulic drive or untimely change of oil in the transfer case leads to disruption of these functions, which significantly complicates the operation of the vehicle. Using the example of the “classics” we will analyze this procedure.

Replacing brake fluid in the clutch

Only brake fluid is poured into the clutch drive due to its special properties, due to which it resists compression. This helps to avoid depressurization, leading to complete breakdown of the mechanism. When you fill the fluid, the main thing is not to mix up the brake and clutch reservoirs. The latter in the “classic” is closer to the wing.

Replacing clutch fluid is carried out in several steps:

Merging

- Before starting work, it is recommended to wipe the tank to remove dirt and dust.

- Unscrew the lid and set it aside in a visible place.

- Call an assistant while you unscrew the cylinder fitting with a wrench. Take the container, point it to the desired location and ask an assistant to press the clutch pedal until all the liquid has drained.

Pouring

- Once all the liquid has been pumped out of the tank, ask an assistant to stop his actions. At this time, tighten the fitting yourself to the initial position.

- Fill with new fluid and check the cap for defects. If they are present, this may cause a lack of tightness and replacement of the lid.

Removing and replacing the VAZ 2107 clutch master cylinder

Welcome, friends, to the DIY auto repair website. From today's article you will learn how to replace the VAZ 2107 clutch master cylinder yourself, how to bleed it, and what malfunctions there are.

Clutch master cylinder VAZ 2107

On all classic cars, the design of the clutch master cylinder is the same, so this instruction is suitable for different car models, the sequence of actions is as follows: removal, repair, installation, bleeding.

Over time, many vehicle components become unusable and the clutch master cylinder is no exception, so first let’s look at what malfunctions it has.

Possible malfunctions of the clutch master cylinder:

- Master cylinder leaking.

- Wear of rubber cuffs.

- Cylinder piston wear.

- Damage to the interior of the case (scratches, shells).

These are the main failures of the VAZ 2107 clutch master cylinder and there are two options here, repair or replacement.

The repair consists of replacing the rubber cuff, as well as the piston, if it has worn out or any defects; in rare cases, the cylinder (body) itself is changed, but this is only if its inner surface is damaged.

All these repair actions, to be honest, are not always effective, especially if the cylinder has never been changed, so if the car is already quite old, it is better and more reliable to replace the clutch cylinder completely.

What should I use instead of brake fluid?

Do-it-yourself repair and replacement of the VAZ 2107 clutch master cylinder

It will not be possible to pour any liquid into the system. It’s all about the characteristics of the brake substance, so you need to select a fluid that is as close in properties as possible.

According to the rules for using brake fluid, mixing substances with different indicators or using other products is prohibited. However, in some cases, for example, when a fluid leak occurs and an emergency replacement cannot be made, the following can be used instead:

- soapy water;

- power steering or automatic transmission oil;

- regular motor oil;

- alcohol.

Soapy water

Regular water cannot be used. This will lead to an accelerated corrosion process. In addition, it evaporates at 100ºC, and the brakes constantly heat up. It is better to use soapy water. At the same time, a large amount of soap must be dissolved in it.

Adding soap reduces the hardness of the water and does not cause much harm to the brakes, so you can safely use this method to urgently get to the service station.

Power steering and automatic transmission oil

Power steering oil has characteristics similar to brake fluid. In an emergency, you can use it and get to the service center.

Engine oil

Its structure is very thick, so it needs to be diluted before use. Water should not be used to avoid corrosion. In this case, you can use diesel fuel.

Alcohol

Oddly enough, alcohol has very similar characteristics to brake fluid. In addition, it does not pose serious harm to the mechanisms.

Replacing the VAZ 2107 clutch master cylinder, simply and quickly

Replacing the clutch master cylinder does not present any difficulties, the main thing is that your hands grow from the right place and you have the necessary tools.

What you need to replace the cylinder:

- New cylinder.

- Brake fluid.

- Keys.

So, let's get started, first you need to take the brake fluid from the reservoir, this can be done using a rubber bulb or a regular medical syringe. Also, don’t forget to read the article on replacing brake fluid yourself.

Next, you need to remove the expansion tank and put it aside, otherwise it will simply not be convenient to carry out further repair work.

Next you need to unscrew the metal tube with a thirteen key and move it carefully to the side, then disconnect the rubber hose that goes from the tank to the cylinder, as in the photo below.

Now you can safely unscrew the clutch master cylinder; it is attached to two thirteen nuts; it is better to unscrew it with a socket wrench with an extension (extension), after which all that remains is to remove the cylinder from the studs. Installing the new one is done in reverse order.

What is required to bleed the clutch?

The clutch bleeding process can be done in the field or in the garage as it does not require many tools. To bleed the clutch alone you will need:

- New brake fluid;

- Empty container for draining brake fluid from the system;

- Automotive tool set (standard);

- Rubber hose that fits the diameter of the drain fitting;

- A device that allows you to fix the clutch is most often a “gas stop,” but other tools can be used.

Please note: You can dispense with the clutch locking device if you have a friend who can take on this task.

How to bleed the clutch master cylinder

If you know how to bleed the brakes of a VAZ 2107, then bleeding the clutch will not be difficult for you either.

We fill the reservoir with brake fluid, put a hose on the fitting located on the clutch slave cylinder and lower it into the bottle, pouring a little liquid into it, so you can clearly see how the air bubbles will come out.

This whole procedure is done by two people, one presses the clutch pedal, the other unscrews and tightens the fitting on command until the release of air stops.

We press the pedal five, six times and keep the pedal pressed, the assistant unscrews the fitting on the working clutch and the liquid with air goes into the bottle, after which he tightens the fitting.

We release the pedal and repeat the process described above several times until all the air has left the system, while not forgetting to add fluid to the tank. That's it, have a good trip and no breakdowns.

Filling the clutch release hydraulic system with working fluid

Only special brake fluid is poured into the clutch release hydraulic drive system (TU MXP 1608-47, TU 35-ХП-430-62 or TU 35-ХК-482-64).

You cannot mix brake fluids of different brands and add to the system even the smallest amount of mineral oils, glycerin, gasoline, kerosene or mixtures thereof, which cause swelling and then complete destruction of rubber parts and, as a result, failure of the system. The use of ethylene glycol is also unacceptable due to the corrosion it causes to metal parts.

If special brake fluid is not available, you can use a mixture of 50% (by weight) castor oil and 50% butyl alcohol. It is possible to replace butyl alcohol with isobutyl or ethyl alcohol. It is important to keep in mind that ethyl alcohol evaporates more easily than butyl alcohol, and the composition of the mixture will change (especially in hot weather).

When switching to a different type of working fluid, it is necessary to remove the old one and thoroughly rinse the entire hydraulic clutch system with alcohol or new brake fluid. Brake fluid is poured into the body of the nutrient tank 3 without removing the strainer 2 from it in order to avoid foreign impurities entering the system. The brake fluid level should be 10-15 mm below the top edge of the reservoir.

It must be remembered that brake fluid leaves stains on the painted surface of the car body; therefore, you need to fill the system carefully, avoiding liquid getting on the body.

It is very easy to monitor the liquid level in the nutrient tank, since the tank is made of translucent plastic.

It is necessary to fill the hydraulic clutch release system with brake fluid and remove air from it in the following order:

- Fill the reservoir with liquid through a strainer to the normal level. To fill the tank faster, it is recommended to slightly raise the strainer.

- Clean the air release valve on the working cylinder from dust and dirt and, having removed the rubber protective cap 2 from the valve head, put a rubber hose (included with the car) on the valve head. Immerse the free end of the hose in brake fluid poured into a clean glass container with a capacity of at least 0.5 liters, which must be filled to half its height.

- Press the clutch pedal sharply with your foot 4-5 times in succession (with an interval of 1-2 seconds between presses), and then, leaving the pedal pressed, unscrew the air release valve 1/2-1 turn. Under the influence of the pressure created in the system, part of the liquid and the air contained in it will be released through the hose into the container with the liquid (the air will come out of the hose in the form of bubbles).

- After the liquid flows out of the hose stops, turn the air release valve all the way.

- Repeat operations 3 and 4 until the release of air from the hose immersed in a vessel with liquid completely stops (this will require up to 75-80 pedal presses).

During the operation of removing air from the hydraulic drive system, add brake fluid to the nutrient tank, preventing the level in it from decreasing by more than 2/3 of the normal value. Insufficient height of the liquid column above the bypass and compensation holes in the master cylinder body can lead to atmospheric air being sucked into the cylinder (and into the system).

After air bubbles stop coming out of the hose, keep the pedal pressed, turn the air release valve all the way, and only then remove the hose from its head. Next, put the protective cap on the valve head, add liquid to the tank to the normal level and replace the tank cap.

After bleeding is completed, wipe the surfaces of the clutch hydraulic drive parts with a cloth.

To completely fill the hydraulic clutch system, 150 g of brake fluid is required.

The brake fluid released into the vessel when pumping the system can be reused to refill it only after it has settled (at least 24 hours) and the air has been completely removed from it, then it must be filtered.

The quality of the system pumping should be judged by the full stroke of the clutch slave cylinder piston rod when pressing the clutch pedal all the way to the rubber mat of the body floor.

With a fully pumped system, the stroke of the piston rod, as indicated above, must be at least 10 mm. With a smaller amount of rod movement, if the system is in good condition and the full stroke of the clutch pedal is at least 150 mm, pumping should be continued, as indicated above, until air is completely removed from the system and normal stroke of the piston rod is obtained.

A properly pumped hydraulic clutch system should ensure shock-free engagement of first gear in the gearbox.

If, when the clutch pedal is pressed all the way, there is a shock engagement of the first gear, you should make sure that the free play of the outer end of the clutch release fork is installed correctly and that the clutch mechanism is in good condition.

Replacing fluid and pumping the hydraulic clutch of a VAZ-2107 car

It is recommended to replace the fluid in the clutch hydraulic drive every five years of vehicle operation. We pump the hydraulic drive when air gets into the system for one reason or another. The presence of air in the hydraulic drive leads to incomplete disengagement of the clutch (the clutch “drives”) and, as a result, difficult gear shifting.

We carry out the work together on an inspection ditch or a lift.

We clean the bleeding fitting of the clutch slave cylinder from dirt and, if necessary, add fluid to the reservoir.

| R

|

We remove the protective cap and put a rubber hose on the head of the fitting, the end of which is lowered into a container with a small amount of liquid. A transparent hose is convenient - the bubbles of the air being removed are clearly visible in it. An assistant presses the clutch pedal 3–5 times at press intervals of 2–3 s and holds the pedal depressed.

| R

|

Unscrew the fitting 1/4–1/3 turn. The pedal will move forward. When the flow of liquid with air bubbles from the hose stops, tighten the fitting, after which the assistant releases the pedal

We repeat the operation until air bubbles stop coming out of the system, monitoring the liquid level in the tank and adding it as necessary. When replacing the fluid, pump the system until fresh, lighter fluid comes out of the hose.

If, despite prolonged pumping, air bubbles come out of the hose, check the reliability of the connections, find out if there are cracks in the tubes or leaks in the connections with the fittings. Air may enter through damaged master or slave cylinder o-rings.

Step-by-step instruction

Bleeding the clutch on a VAZ 2107 should be performed after various repairs carried out with a hydraulic drive or after replacing the working fluid; in these cases, air may enter the system. If it is present in the hydraulic drive, the clutch does not completely disengage due to which the gears are difficult to shift.

What will you need?

To carry out the work, the car will need to be installed on an overpass or inspection groove. Before work you should prepare:

- new brake fluid (TF);

- transparent container for draining fuel fluid;

- hose with a length of 0.5 to 1 meter;

- wrench set to "8".

An assistant will be needed during the procedure.

Stages

Before performing work, you should check the integrity of the hose and the tightness of the connections on the VAZ 2107; there should be no leaks anywhere.

- First you need to pour TJ into the prepared container.

- The procedure is carried out using the clutch bleeder nipple, which is located on the working cylinder body. You need to remove the protective cap from it and put on the rubber tube.

- The lower end of the tube must be lowered into a container with liquid liquid and ensure that it is constantly below the liquid level in the container.

- Brake fluid should also be poured into the expansion tank.

Fill the fuel fluid into the tank. Next, you need to loosen the fitting by unscrewing it half a turn.

We loosen the bleeder fitting with a key. At this time, the team assistant presses the clutch pedal (PS) several times at intervals of 2-3 s and then holds it pressed.

Press the PS all the way

- Liquid with air bubbles should flow out of the tube through the hose.

- The procedure should be repeated until air stops escaping.

- After this, the assistant presses on the PS, and at this time it is necessary to tighten the fitting and put the cap on it.

During the procedure, you need to monitor the level of fuel fluid in the tank and add it if there is a shortage.

The liquid level in the tank after pumping should be at the lower edge of the filler neck.

Bleeding the clutch VAZ 2101 - VAZ 2107

The article you started reading will probably say that it’s new for an experienced motorist, but for a beginner who is faced with the need to bleed the clutch, this material may be useful. If the VAZ 2101 clutch pedal has become too light and the clutch grabs at the floor itself, the clutch system may have become airy. As a rule, the instructions recommend that two people perform the bleeding procedure, so that one sits behind the wheel and pumps the pedal, and the other opens and closes the fitting on the clutch slave cylinder, but this operation can be performed by yourself - it’s all very simple.

Preparing for pumping

Preparing to bleed the clutch

The fluid from the hydraulic system is not “poured out”, but is pushed out thanks to the cylinder piston pusher.

Preparation is carried out in stages:

- checking the volume of liquid in the expansion tank - the level should be within normal limits. If it reaches the desired level, you need to top it up;

- cleaning the valve cap on the cylinder from accumulated contaminants;

- removing the cap from the air inlet valve on the working cylinder;

- connecting the drain hose to the valve fitting.

The second end of the hose is lowered into a container into which fresh working fluid is poured. The end of the tube should be immersed 5-10 cm into it.

Do not remove the hose from the tank until work is completed.

After the preparatory work, the clutch is adjusted. This allows you to make sure that the movement is free and, in addition to airing the system, there are no other malfunctions.

How to bleed the clutch yourself

Welcome, friends, to the DIY auto repair website. The task of the clutch is to ensure a smooth start of the “iron horse”, as well as high-quality and precise gear shifting.

How to bleed the clutch

If it malfunctions, the service life of the gearbox is reduced and its wear increases. To eliminate problems, you may need to bleed the clutch. Why is this necessary? How to do this job correctly?

When to bleed the clutch?

The main symptom of the malfunction is problems when shifting gears (a clear sound of the gear teeth can be heard, although the clutch pedal is pressed to the floor).

One of the reasons is air entering the system due to a leak in the pipelines or poor connections.

Delay in such a situation can lead to a number of problems - gearbox failure or complete clutch failure. Further repairs will take more than one thousand out of your pocket.

Features of the work and tools for bleeding the clutch

Before bleeding the clutch, prepare everything you need. You will need:

- New brake fluid to replace,

- a regular set of tools from the trunk of a car,

- empty container (old brake fluid will be drained into it),

- hose of the required diameter (make sure it fits the drain fitting),

- an assistant who will press the clutch pedal.

If there is none, then you will have to fix the pedal with a special tool.

Before starting work, you need to adjust the clutches. Otherwise, replacing the fluid and removing air from the system may not give the expected results.

Pay special attention to the free play setting, the operation of the shut-off valve and the release spring.

How to properly bleed the clutch with your own hands

1. Find the master cylinder reservoir and add fluid. The optimal level is from one and a half to two centimeters from the neck of the tank. Fill the composition through the filter element to avoid various “garbage” and impurities from entering the system.

2. Remove the rubber cap from the bypass valve and pull the prepared hose in its place. Place the second edge in a special container with brake fluid. Make sure the container is at least one third full.

3. Make one turn of the bypass valve in the direction of unscrewing. This is necessary to give a path for air to escape.

4. Give the command to the assistant to press the clutch pedal to the maximum. This is done until air bubbles stop coming out of the hose.

5. During work, you need to monitor the liquid in the tank. Do not allow the level to drop below 3.5-4 centimeters from the edge.

Attention! If the volume decreases, immediately add fluid.

6. The pedal must be pressed until the bubbles stop coming out. As soon as this happens, close the bypass valve tightly.

7. Based on operating experience, the pumping process can be accelerated. To do this, tighten the valve after each press on the pedal. After this, release the clutch and repeat the operation again. After just 2-3 pedal presses, the air completely leaves the system.

8. Pull the hose off the fitting and return the protective cap to its place. After this, make sure that the fluid level is normal (one and a half, two centimeters from the top).

9. Check how well the work is done. Press the clutch and measure the stroke of the piston pusher. If everything is done correctly, it should be about 26-28 mm. If you deviate from this parameter, additional adjustment is required.

When is clutch bleeding required?

Bleeding the clutch hydraulic drive may be necessary in the following cases:

Scheduled replacement of old fluid with new one.

Any liquid loses its properties over time and requires replacement. For brake fluid, which is also used in the clutch hydraulic system, the shelf life (from the date of manufacture), even when unopened, can be 1 year in plastic containers and 2 years in metal ones.

That is, the working fluid can still lose its properties regardless of whether it was used or not. The recommendations should be followed when it comes to replacing the working fluid in the clutch.

Clutch system repair.

Like any mechanism, the clutch is subject to breakdowns and wear during operation, as a result of which it may require repairs (replacement of cuffs, seals, repair or replacement of the cylinder, elimination of leaks in the line, etc.). And as a result of repairs, the hydraulic system depressurizes with the leakage of working fluid or the entry of air into it.

Air entering the working fluid.

Air entering the line with the clutch fluid can occur both during clutch repair and fluid replacement, and due to air leaks through micro-holes in the hoses, through loose connections, worn rubber seals and cuffs in the master and working cylinders.

Point 3 deserves special attention: “Air getting into the working fluid.” This paragraph deals with malfunctions in which bleeding the clutch may not help, or may help, but only temporarily, since the malfunction will remain.

How quickly air gets back into the fluid will depend on the severity of the problem.

At the initial stage, while the microholes are very small, the penetration of air into the liquid occurs very slowly. But over time, wear increases, and along with it, the holes through which air penetrates increase. As a result, there comes a time when, after bleeding and removing air from the system, the clutch “disappears” again the next day or earlier.

Therefore, if there is a need to bleed the clutch not after a scheduled fluid change or after clutch repair, then you should be concerned about finding a malfunction that leads to air entering the system.

You should also troubleshoot if, after a full pumping cycle with complete replacement of the old fluid, air bubbles are still visible in the new fluid coming out of the drain fitting.