The VAZ 2114 car was produced by the Volzhsky Automobile Plant in the period 2001-2013. The bottom of the VAZ 2114, unlike the sills, was not a common consumable. If immediately after the purchase the driver carried out routine inspections and fully protected the body from the aggressive effects of salt reagents and moisture, parking and overnight stays of the car in the open air were limited.

An exception is an accident or collision with an obstacle, as a result of which the bottom is deformed from mechanical damage.

How to save money?

If a car owner wants to save money, he needs to do a preliminary inspection of the bottom himself. For this you will need:

- Lift, inspection hole, overpass.

- Good lighting: a flashlight or a carrier with a powerful lamp.

- Hammer.

Using a hammer, it is necessary to tap all suspicious areas of the bottom and determine the extent of their damage in order to approximately know the volume of materials needed.

If all of the above is not at hand or there is simply not enough time for a thorough inspection, then a special mirror for inspecting the underbody of the car will come to the rescue. It will allow you to generally assess the condition of the metal and get an approximate idea of the amount of work. But the situation will become completely clear only after a thorough examination.

The welding process itself is simple; anyone can master it in the shortest possible time. Sometimes it takes longer to connect and set up equipment. The easiest way to overweld the underbody of a car is to use a semi-automatic welding machine. But often such repairs are simply impossible without the use of gas welding. Best of all, when both of these devices are used, they complement each other and improve the quality of underbody repairs.

Movili for the bottom

To prevent the occurrence of rust on the car body, before covering it with high-quality paint, it is recommended to apply Movil. Most car owners call any type of anticorrosive agent Movil, but this is absolutely false. Movil contains elements that prevent corrosion, these are:

To determine which Movil is needed, you should find out the type of corrosion. They exist in three subspecies:

- Paste. A paste-like product, most often packaged and sold in plastic containers, in the form of bottles or cans.

- Aerosol. They are considered more convenient in dealing with areas where rust has appeared.

- Liquid. Has the lowest price of all.

When Movil is purchased, you need to carefully prepare problem areas outside and inside the underbody, which you will have to clean, seal and coat with anti-corrosive.

Cost of the kit and work with it in the service

The service station carries out the full range of work to restore the body. You can weld the bottom of a VAZ 2115, the price of work without the cost of dismantling, materials and components starts from 15,000 rubles. It is also permissible to change rotten jacks, sills and replace part of the bottom, the cost of work is up to 10,000 rubles.

Repairing the underbody, like any other part of the body, is classified as labor-intensive and complex. The cost of the repair kit must be added to the cost of the work.

- original floor from AvtoVAZ - from 3,000 rubles;

- bottom with thresholds ─ from 5,000 rubles;

- sound insulation ─ from 500 rubles per 1 sq. meter;

- anticorrosive ─ from 600 rubles per 1 kg.

Simple calculations show that self-repair will cost three to four times less, but only if the driver understands the complexity of the work and has minimal skills in using electric welding and working with metal.

Sources

- infokuzov.ru/remont/dnishhe-vaz-2114

- studwood.ru/2119815/tehnika/tehnicheskoe_obsluzhivanie_remont_kuzova_avtomobilya_2115

- zen.yandex.ru/media/id/5b18432b57906a01b991210f/kak-sekonomit-na-remonte-kuzova-vaz-2108099-211315-5b3a363c64a96200a9028313

- drive2.ru/l/463139037704618688/

Tool for applying anti-corrosion mixture to the bottom of vehicles

Before treating the bottom of the car in order to paint it later, it should be prepared for applying anticorrosive. First of all, you need to clean the dirt from the places where corrosion has formed, and for this you need the following tools:

- stiff steel wire brush;

- goggles that protect your eyes from rust and dirt that can be cleaned off;

- a hand-held flashlight to inspect hard-to-reach areas of the body;

- fine and coarse sandpaper;

- a mirror to be able to inspect and identify all the defects formed on the bottom;

- brushes or sprayer for treating with anti-corrosion mastic;

- a means for degreasing the surface from cleaned areas, you can use regular acetone.

Device for applying liquid anticorrosive

The problem faced by car enthusiasts who decide to process hidden cavities on their own is the lack of necessary equipment. They can use a relatively simple device that operates on the principle of air spraying of drugs under a pressure of 4-6 kg/cm2.

The simplest design of such a device is as follows: a nozzle for it can be made from a cologne spray bottle by drilling out the nozzle in its tip to a diameter of 1.2 mm. A brass tube must be soldered to the inner wall, through which the anti-corrosion agent will be supplied.

The pump is connected with a hose to the spray tube going to the container with Movil. To supply the drug to the tube, you can use a polyvinyl chloride tube lowered into the vessel. For greater clarity, a diagram of such a device is shown below.

With the constant creation of air pressure by the pump, the torch emerging from the Movil nozzle is ensured within 14-20 cm, which is enough to apply it inside hidden cavities.

Before applying Movil to hidden surfaces of cavities, it is necessary to ensure that the sprayer has access to the required areas. For this:

- remove the seals of the front wings, headlights and their rims (VAZ - 03, -02);

- remove the spare tire, tools and floor covering (VAZ - 013), upholstery (VAZ - 03, -07 and -06) from the trunk;

- open the rear door (VAZ - 02) and remove the carpet, trim, spare tire and its cover;

- remove the door signal lamps (VAZ - 03, -06) and the reverse signal lamp (VAZ - 03).

Then you should perform a somewhat unpleasant, but technically necessary operation - drilling holes (9 mm) in the sills, and for VAZ-013, -21 and -05 - also in the end surfaces of the rear doors.

If possible, accessible treatment areas should be washed with water, blown with air and dried. In garage conditions, where it is impossible to carry out effective drying, it is enough to limit yourself to wiping them with a damp cloth, followed by natural drying. Considering that the largest number of points requiring treatment are located in the bottom area, it is advisable to carry out all work on a lift or overpass.

To process the sills, the place of the spare tire and the cross member of the front part, you need to pull out the plugs. Two plugs are installed on both sides under the front fenders, a plug on both sides in the rear arches, in the center in the spare tire niche, and one on both sides in the cross member under the front seats. The drainage holes also need to be cleaned.

Before anti-corrosion treatment of thresholds, arches, and bottoms is carried out, they should first be washed with ordinary water and blown with a compressor (this will dry them out faster). It is advisable to dismantle the wheels so as not to complicate the process, and place the car on reliable supports. Cover wheel rims, brake mechanisms, and transmission elements with something to prevent anticorrosion. After this, open all doors, lids and begin application.

Stages of the mastic processing process

The process of treating a vehicle body against corrosion has several stages:

- Before treating the bottom of the car, it must be washed with washing powder and lifted to prepare the rotten area of the bottom, and not just the surface of the body.

- Then you need to dry all cleaned areas thoroughly. The drying process can be accelerated by using a hot air blower.

- When the car is dry, inspect problem areas. Identified cracks, gaps and breaks must be cleaned.

- Having completed these manipulations, you can begin the anti-corrosion process.

How to save on body repairs for VAZ 2108-099, 2113-15

To repair rusty or broken car parts, AVTOVAZ produces various spare parts, but often a small part of the entire part requires replacement, which can be very expensive. In this article we will tell you how you can save money when repairing the body of VAZ Samara family cars.

A common problem with these cars is that the corner of the windshield window frame is rotting.

AVTOVAZ stamps the entire frame, but third-party manufacturers make a repair insert - a corner of the wind window frame.

Spare part for repair from AVTOVAZ

Third party solution

The savings in this case are about one and a half thousand rubles.

If the lower part of the frame is rotten, then there is a repair for this too. insert. In this case, the savings are about seven hundred rubles.

Another common problem is rotten rear arches and sills.

For 2108-09 and 2113-14 AVTOVAZ stamps the entire sidewalls. They are also made for 21099 and 2115, but they consist of two parts.

Option from AVTOVAZ - sidewall 2109

For 21099

That is, to replace, for example, only a threshold you need to buy this spare part.

Third-party manufacturers offer their own options for repairing various parts. There are different repair parts for the rear fenders. Savings can range from approximately three to seven thousand rubles.

And for rapids from three and a half to six and a half thousand.

From top to bottom: External Threshold, Amplifier, Internal Threshold, and Threshold Connector

If the floors are rotten, then AVTOVAZ makes an entire floor panel for repair.

Factory floor

But third-party manufacturers also make different repair inserts for floors. You can change only the front floors, you can change the jacks - there are enough options.

Front right floor 2108

Savings of about four and a half thousand. Various fastenings, etc., are sold separately for floor repairs.

Front jack

Seat bracket

We hope this article will help you save money!

Which anti-corrosion agent is better to buy?

Any anticorrosive agent is a solvent-based chemical. When it dries, it leaves a dense, hard film on the surface, which blocks the access of oxygen and moisture to the metal. Various additives increase the strength of this coating, protecting against mechanical damage.

Anticorrosive is not able to get rid of rust that has already appeared, but it can slow down the process of its spread.

There are hundreds of anti-corrosion drugs on sale, which are divided into two types: products for internal (hidden) and external surfaces. For treating internal hard-to-reach areas, paraffin or wax anticorrosives are recommended. They form a waterproof film that is resistant to sudden temperature changes. Their only drawback is that they freeze and can crumble on a moving base. There are also products based on synthetic oils. These are capable of flowing into micropores and cracks in steel, repelling moisture from moving parts. Synthetic anticorrosive material does not freeze or dry out during the entire period of use.

For external coatings choose:

- Mastics on bitumen (synthetic resin). The hardened substance applied in a thick layer protects the body not only from corrosion or mechanical damage, but also provides good sound insulation.

- Rubber and PVC products are very durable, adhere well to any metal, do not react to temperature changes and form strong mechanical protection for the bottom. It is this coating that is deposited by manufacturers using special equipment.

- Liquid plastic - fits well on most paintwork materials and provides sufficient protection against rust. Its disadvantage is low mechanical resistance, so the product is usually used only on sills, hidden cavities of arches, and elements of the engine compartment.

- Mastic with the addition of slate - a mineral component of high strength. Ideally protects the underbody, wheel arches and fenders. The material resists mechanical abrasion well and is easy to apply.

There are also anti-gravel coatings that are used to treat body parts to protect against mechanical damage. They consist of rubber polymers, phenol and carbide. This product can be used to treat existing rust - preservative components will slow down its spread. However, it is quite difficult to apply it yourself; it is better to contact a car service specialist.

Principles of inverter welding

Inverter is a welding machine with a high frequency of current conversion (30–40 kHz instead of the usual network 50 Hz). This is a compact but powerful unit of small size and light weight, working with which has a number of advantages:

- the light weight of the device makes it easier to work with;

- welding with an inverter occurs quickly, the metal heats up to a high temperature instantly;

- the welding current remains stable during voltage fluctuations and does not create unnecessary loads on the network;

- the device is economical - consumes 15–20% less electricity compared to other units;

- the spattering of molten metal is not intense;

- the basics of welding with an inverter are simple; every car enthusiast can master the process.

Learning to work with an inverter is not difficult, practice on some iron scraps

Causes of corrosion

The occurrence of rust in the bottom leads to the formation of holes, which causes a decrease in the strength of the entire body structure. This may lead to an emergency situation. Therefore, it is important to know effective methods to help eliminate existing corrosion.

Every time the bottom of a car interacts with bumps on the road or crushed stone that flies out from under the wheels while driving, the integrity of the protective coating is compromised. This leads to the appearance of cracks in the mastic layer. This is where water and dirt will collect - they are obligatory companions of a rusty body. That is why it is important to carry out high-quality anti-corrosion protection of the underbody of the car.

Processing of models 2105, 2107

Before applying anti-corrosion material to the VAZ-05 and -07 you need to:

- dismantle all parts that interfere with access to the cavities being processed, that is, shields under the front fenders, spare tire, trunk cover, sidewall linings;

- cover the oval openings of the sills at the base of the pillars with something so that when washing, water does not penetrate into the interior;

- Rinse all areas where anticorrosive is applied with water. But before that: pull out the plugs in the rear wheel arches, in the beam of these arches, in the cross member under the front seats, in the niche for the spare tire, and clean the drainage holes. After washing, blow everything with air and dry it.

The following cavities are treated with anticorrosive agents first:

- Between the rear fender and the wheel arch

- Rear side members

- Rear floor cross members

- Recess under the fuel tank

- Rear lower cross member

- Recess for spare wheel

- Mudguard strut

- At the connection of the front flap with the side of the wing

- In the hood pockets

- At the connection of the front panel with the side of the wing

- Front upper cross member

- Front lower cross member

- To the front suspension buffer bracket

- In the front fender pockets

- Doors

- Thresholds

- In the jack bracket

- Cross members between rear wheel arches

- Rear side members

- Front side members and their reinforcements

For more affordable shown in the picture

Places where anti-corrosion material is applied to the surfaces of parts and hidden sections of the body of VAZ-2105 and 2107 cars

After the anti-corrosion treatment of the car with your own hands is completed, you need to remove traces of mastic using a swab moistened with white spirit or kerosene, then replace the previously removed parts, including plugs, plugs, covers, etc.

This article indicates only the key points in the anti-corrosion treatment of VAZ bodies. In the process, each of the models may have its own specific nuances. But in general, any car enthusiast can perform such body treatment.

Anti-corrosion compounds and sound-proofing mastics applied at manufacturing plants protect wheel arches, trunk, engine compartment and other surfaces of the car, primarily from mechanical damage. To preserve the attractive appearance of the car and increase the resistance of its individual elements to rust, they carry out independent anti-corrosion treatment.

What to process?

Modern manufacturers offer a huge variety of materials that differ in composition, purpose and application features:

• special compounds for the bottom; • mastics; • anti-gravel coatings; • varnishes; • enamel; • preservatives for hidden cavities; • soils.

Important: no treatment can restore a completely rotten metal frame! Make sure that the car is at least in satisfactory condition before purchasing the necessary materials

We treat the bottom with anticorrosive

This category of materials includes mastics, as well as special compounds for the underbody of a car, containing aluminum (crushed to a powder) and corrosion inhibitors. Another useful function of underbody mastics is the ability to improve the vibration-acoustic parameters of the body. In this regard, of great interest are inexpensive domestic bitumen mastics filled with crumb rubber, which makes the “lower armor” of the vehicle much thicker.

Before you begin, make sure the bottom is 100% illuminated and has easy access. After this, use neat, even layers to treat the entire surface, including bolted joints, ball joints, technical seams, and suspension parts.

We treat wheel arches with anticorrosive

A peculiarity of the arches is that their surface, much larger than the bottom, suffers from abrasive wear due to snow, ice, small stones, sand, and dirt, which continuously fall from the spinning wheels directly onto the arches. The problem can be effectively solved by using a liquid locker - a durable material applied to the surface in two or three layers.

Noteworthy anticorrosive brands

To reliably treat the bottom of your vehicle from emerging pockets of rust, you need a high-quality anti-corrosive agent. Below we list the main brands from well-known manufacturers.

Manufactured on a wax basis

The most popular are the following:

- TURBO is a highly effective anti-corrosion mastic that provides long-term protection of steel surfaces. It penetrates welds and seals surface defects. TURBO forms an elastic brown wax-like film, self-healing in case of destruction. It can also prevent existing corrosion and provide long-term protection to pre-corroded and non-corroded surfaces.

- WAXOYL - is applied and forms an elastic waterproof film. It helps prevent new rust and kills old rust, and is used on car interiors, inside doors, on sills and anywhere water collects. Does not crack, dry out or wear off.

Manufactured from rubber, polymer and bitumen

Quality brands:

- DINITROL is highly valued by consumers. Creates a protective barrier on the external surfaces of the car body. There is no unpleasant odor. Complete drying is not required. You can coat the surface with DINITROL mastic in areas that are free of rust.

- MERCASOL - protects the body and surfaces from rusting and maintains a protective barrier for a long time.

- TECTYL - has the ability to displace water so wet surfaces are protected, delays and prevents corrosion on rusty surfaces and provides self-healing ability if the protective barrier is damaged.

- BODY - forms a waxy layer, creates a barrier on the surface, has penetrating properties. The main disadvantage is considered to be rapid erasure.

Anti-corrosion treatment of VAZ 2110. Theory

Any car needs anti-corrosion treatment and it doesn’t matter what year, model or class it is. But in what places does corrosion eat metal most often and how can you stop it? Rust is the body's biggest enemy. That is why the car owner carefully examines the car body in order to identify the source of damage in time.

It is impossible to completely stop the corrosion process; such is the nature of things, they age and collapse. But this does not mean that nothing can be done in this case

That is why the car owner carefully examines the car body in order to identify the source of damage in time. It is impossible to completely stop the corrosion process; such is the nature of things, they age and collapse. But this does not mean that nothing can be done in this case.

Our goal is not to stop corrosion forever, we just need to delay its onset. Electrochemical rust begins to develop during rain, snowfall or temperature changes. The body does not immediately become covered with the familiar brown rust. First, a thin film of water forms on the surface of the VAZ 2110 body, and as soon as acids and alkalis enter this environment, a classic electrolyte is formed, which begins to corrode the metal. You may ask, where do alkalis and acids come from? Everything is very simple, all these elements are contained in sufficient quantities in the reagents that cover roads in winter and even in the air we breathe. Although the root causes arise not only during the operation of the VAZ 2110, but also at the production stage. After the parts have been stamped and welded, inhomogeneous areas are formed on the surface

It is important to know that corrosion progresses especially actively in a humid climate, which includes the entire central zone of Russia, where humidity remains at 60% almost all year round. So, how to deal with this scourge? There are two options: galvanic coating and anti-corrosion metal treatment. In the first case, the process can be called body galvanization

But what to do if the bottom has fallen out, and you are standing 150 km from the nearest populated area? We need to call friends or call a tow truck, which means we will need mobile communications. It is very important that at such moments there is a positive balance.

In the first case, the process can be called galvanizing the body. But what to do if the bottom has fallen out, and you are standing 150 km from the nearest populated area? We need to call friends or call a tow truck, that is, we will need mobile communications

It is very important that at such moments there is a positive balance.

It is known that machines that have undergone such treatment at the production stage last many times longer. But this is not a panacea; sooner or later the surface will begin to rust, especially for various edges or joints where small stones and sand get caught during driving. It would not hurt to additionally treat these areas with an anti-corrosion compound. The manufacturing plant performs this during assembly by applying various chemicals to all surfaces of the body. The bottom is usually treated with a special mastic, and hidden cavities are treated with a protective compound. In this case, the car manufacturer provides a guarantee during which no damage to the body will occur due to natural causes. However, even this is not enough; preventive procedures must be carried out periodically and this should happen approximately once a year. It is not so easy to treat a car with anti-corrosion agent on your own, because you need to provide sufficient access to all elements of the bottom and apply the product in a thick layer

Now everything depends on the quality of the product you purchased, so you need to pay a lot of attention to this too. It’s never too late to treat the body, so even if the car is already well-corroded, apply the product anyway and this will stop its further harmful effects

Types of anti-gravel for car thresholds

The number of anti-corrosion treatment agents for car sills is large. By and large, they are not much different from each other.

Means for protecting car thresholds from rust can be divided into several groups:

1. Period of use.

- permanent protection;

- temporary protection;

2.Packaging.

- aerosol can ready for use;

- aerosol can for a special gun;

- metal cans;

- plastic containers.

3.Color.

- transparent;

- white;

- black;

- gray;

- color.

4.Additional effects.

- containing a rust converter;

- anti-corrosion substances;

- increased adhesion;

- enhanced strength.

VAZ 2115 | Preparation and anti-corrosion treatment of hidden cavities

Due to the use of complex technological equipment and the need for high-quality work, it is recommended that the treatment of hidden cavities be performed only at car service stations.

Before starting work, place the car on a lift, remove parts and upholstery that prevent access to hidden cavities. Rinse the hidden cavities (Table 8.2) and the bottom of the body with water heated to a temperature of 0–50 °C through the technological and drainage holes until clean water flows out. In this case, the sliding door windows must be raised. Remove moisture that has entered the passenger compartment and luggage compartment, blow with compressed air all areas where anti-corrosion compounds are applied.

| Cavity name | Injection point | Injection direction | Additional instructions |

| Hood pockets | In the openings of the internal panel | Over the entire inner surface | Open the hood |

| Door pockets | In the panel openings under the upholstery | Along the inner surface of the bottom | Remove the upholstery |

| Cavities between wheel arches and rear fenders | From the trunk | Over the entire inner surface | Open the trunk |

| Rear floor rails | Below the body, in the trunk and under the rear seat | Forward and backward | Open the trunk, lift the seat cushion |

| Middle floor cross member | Below the body and under the rear seat | Right and left | Raise the seat cushion |

| Front floor cross member | From the interior and from below the body | Right and left | Remove the floor mats |

| Door thresholds | From the interior, from the front and rear ends of the sills | Forward and backward | Remove the floor mats |

| Front floor members | From the interior and from below the body | Forward and backward | Hang up the car |

| Bulkhead reinforcement cavities | From the interior and engine compartment | Right and left | Open the hood, remove the floor mats |

| Floor thresholds | From below the body, from the interior, rear and front | Forward and backward | Hang up the car |

| Front side members Rear floor cross member | Under the front fenders From below and from the interior | Forward and backward Right and left | Jack up the car Remove the rear bumper |

| Rice. 8.8. Hidden body cavities (front view): 1 – middle floor cross member; 2 – rear floor cross member; 3 – rear floor spars; 4 – sidewall and front connectors; 5 – hood pockets; 6 – upper amplifiers of mudguards; 7 – lower cross member of the radiator frame; 8 – front mudguard amplifiers; 9 – front side members; 10 – floor thresholds |

| Rice. 8.9. Hidden body cavities (rear view): 1 – lower surfaces of door pockets; 2 – floor thresholds; 3 – front floor sill connectors; 4 – cavity between the front panel and the floor; 5 – cavities of the front floor spars; 6 – cavities between the mudguards and the front strut reinforcements; 7 – cavities between the outer and inner panels of the sidewalls; 8 – rear side members |

| Rice. 8.10. Hidden body cavities (bottom front view): 1 – lower cross member of the radiator frame; 2 – cavity between the front panel and the floor; 3 – front floor spars; 4 – cavity of the front connector of the floor threshold; 5 – floor thresholds; 6 – rear floor cross member |

Drive the car into the chamber and place it on a lift. Spray anti-corrosion compound to the areas shown in Fig. 8.8,8.9, 8.10. Lower the car from the lift, clean the front surfaces of the body from dirt with a rag soaked in white spirit.

Table 8.2 Hidden cavities treated with anti-corrosion compounds

| Cavity name | Injection point | Injection direction | Additional instructions |

| Hood pockets | In the openings of the internal panel | Over the entire inner surface | Open the hood |

| Door pockets | In the panel openings under the upholstery | Along the inner surface of the bottom | Remove the upholstery |

| Cavities between wheel arches and rear fenders | From the trunk | Over the entire inner surface | Open the trunk |

| Rear floor rails | Below the body, in the trunk and under the rear seat | Forward and backward | Open the trunk, lift the seat cushion |

| Middle floor cross member | Below the body and under the rear seat | Right and left | Raise the seat cushion |

| Front floor cross member | From the interior and from below the body | Right and left | Remove the floor mats |

| Door thresholds | From the interior, from the front and rear ends of the sills | Forward and backward | Remove the floor mats |

| Front floor members | From the interior and from below the body | Forward and backward | Hang up the car |

| Bulkhead reinforcement cavities | From the interior and engine compartment | Right and left | Open the hood, remove the floor mats |

| Floor thresholds | From below the body, from the interior, rear and front | Forward and backward | Hang up the car |

| Front side members Rear floor cross member | Under the front fenders From below and from the interior | Forward and backward Right and left | Jack up the car Remove the rear bumper |

automn.ru

Procedure diagram for used cars

Most often they try to do only anti-corrosion on doors; advice suggests that with full processing you will have to find a way to the most hidden parts of the car. This means that the treatment is carried out even from the inside.

1 – middle floor crossbar; 2 – rear floor cross member; 3 – rear floor spars; 4 – sidewall and front connectors; 5 – hood pockets; 6 – upper amplifiers of mudguards; 7 – lower cross member of the radiator frame; 8 – front mudguard amplifiers; 9 – front side members; 10 thresholds">

Markings of hidden body cavities for anticorrosive treatment: 1 – middle floor cross member; 2 – rear floor cross member; 3 – rear floor spars; 4 – sidewall and front connectors; 5 – hood pockets; 6 – upper amplifiers of mudguards; 7 – lower cross member of the radiator frame; 8 – front mudguard amplifiers; 9 – front side members; 10 – thresholds

In this case, it is necessary to use either standard holes that are already on the equipment, or drill new ones. Upon completion of work, they are closed with special valves. Anti-corrosion protection for Lada is no exception. After the substance is introduced inside, it is thus deposited from within the thresholds. So anti-corrosion protection creates an additional film on the surface.

When the process ends, you need to spend at least 3 hours drying the car.

Vehicles dry completely in 7–9 hours, depending on the brand. Bitumen anti-corrosion can completely set in only two days. It is not recommended to actively operate the machine during this time. Do not wash the car.

Anti-corrosion coatings are available on the market in a wide range. But two large groups can be distinguished:

The question of where to smear should not arise; the rules in almost all situations remain the same. Each manufacturer has its own recipes, each adds certain additives to the composition to give the material certain properties.

One car cosmetic differs from another only in the state they are in after processing is completed.

Do-it-yourself materials for applying anti-corrosion protection to the VAZ 2114.

Do you need to do anticorrosive treatment often? No, once a year is enough if everything is in order. Among the most popular brands worth noting are:

Metal thickness

To repair the underbody of a car with your own hands without any problems, you need to choose metal of optimal thickness. Its recommended thickness varies from 1 to 2 mm. But here you should take into account the qualifications of the person who will carry out the welding work. When working with thinner metal, you must strictly observe the temperature requirements during welding. Which, in turn, depends on the debugging of equipment and the quality of consumables.

Thicker metal is more difficult to process, but it is also more difficult to damage or spoil. Therefore, before purchasing consumables, you need to realistically assess your qualifications as a welder.

Anticorrosive recipes

In order to save money and get a better quality product, you can prepare the product yourself.

Recipe No. 1

To prepare the first mixture, which can be used to treat the underbody of a car, you will need:

- Two parts of Movil.

- One part cannon fat.

- One part of Akor preservative.

All components are mixed, after which the underbody anticorrosive is ready. Next, it is heated and applied to the damaged areas in 2 stages.

Recipe No. 2

- Mastic Movil.

- Cannon fat.

- Motor oil (used).

- Diesel fuel.

All components are added one piece at a time. The result is a composition that becomes like wax in the cold, and like a flowing liquid in the heat.

Recipe No. 3

To prepare it, take in equal parts:

Replacing the bottom of a VAZ 2114

Today we will talk about replacing the bottom of the Samara and Samara-2. Here's everything that will change in the near future:

Packed for 16 pieces

So, let's get straight to the topic. Before starting car repair work, I would like to remind you about safety precautions, because I think everyone will agree that you want to see the finished result with two eyes, and not one... Part 1: Drilling and cutting out the bottom

. To cut out the bottom, we need to disassemble the interior. We completely disassemble the interior, remove everything, including the steering wheel and pedals. We take the Bulgarian wife (Bulgarian) in our hands and CAREFULLY cut off parts of the bottom along the lines (indicated in the photo in blue), so as not to touch the elements that will be useful to us in the near future.

After that, take a drill and put an attachment on it to remove rust from the metal.

We begin to process with a drill the places where we will drill out the points (indicated in the photo in red). Then we take a “7” drill, sharpened for drilling out points, and drill it out. For those who don’t know what it is, look here When all the work is completed, we dismantle the remains of the bottom using a hammer and chisel. Final result.

Part 2. Preparing the new bottom for installation.1.

We take a new bottom trough and begin to clean the transport soil with a brush using a drill.

(Sometimes you don’t need to remove the shipping primer. It’s easy to check. We take a rag, wet it with 646 solvent and throw it on the area of the shipping primer. After 10 minutes, we carry out a test with another rag (clean): take it and lightly rub the shipping primer. If the primer is cleaned off or the rag turns dark , then we remove such primer. If the rag remains clean and the primer does not come off, then we leave it, having previously filled it with sandpaper R120, so that the anticorrosive will adhere better)

in the process

The process is quite hectic, but I managed it in 3.5 hours of continuous work.

Afterwards, we take sandpaper with a p80 mark and matte the metal so that the soil lays down normally and does not fly off in the future.

When the metal is matted, we dilute primers (acid and epoxy) and prime the bottom. First, prime with acid primer in one layer. Leave it for an hour to dry (you don’t have to do this step)

The best friend will not leave you in trouble)))

Then we prime with epoxy primer (I used novol protect 360 primer) in 2 layers. interlayer drying 15 minutes

The bottom is reliably protected

2.

When the bottom is primed, we leave it in the garage overnight and come back only the next day.

Why did I recommend not touching the lower elements of the bottom (all sorts of hooks, brackets) when cutting? Because we will weld them immediately in place, measuring all the dimensions as they were. I strongly recommend not to repeat my mistake, but to first weld the trough into the car and only then weld everything else to it.

, although if you have a flat floor, you can do it like I did. Only if the bottom moves a little with the propeller, it’s not my fault))) We weld all the studs, brackets, hooks and other elements, measuring everything from the old bottom.

We weld all the upper elements of the bottom, measuring all the old dimensions and marking everything with a marker.

All we need: a middle floor reinforcement, seat reinforcements, seat brackets, and those two little crap on which the outer slides are placed (the rightmost ones in the photo).

tried it on and circled it with a marker.

cleaned with R80 sandpaper

Covered with epoxy primer.

3.

We clean the side members from rust.

What is anticorrosive?

Anticorrosive is the abbreviated name for the so-called anti-corrosion treatment of the vehicle body, during which a special agent is applied to the car body that will protect the metal from rust.

True, anti-corrosion agents cannot provide complete protection to the body for a long time, since the aggressive external environment on the roads quite quickly damages the protective coating, which will subsequently lead to the formation of rust elements on those elements of the car body that have been damaged by stones, branches and chemicals. reagents.

Square pipe instead of thresholds on a VAZ

To change the thresholds on a VAZ 2114 with your own hands, in half of the cases profile pipes are used. This method has proven itself well when replacing similar parts on classic VAZs. The profile has suitable dimensions of width and height, and the metal thickness reaches 2 mm, which ensures the reliability of the body for at least 7 years. In addition, profile pipes in 40% of cases have an additional zinc coating, which ensures the metal’s resistance to corrosion.

To work you will need:

- profile pipe 60x60x2 mm: 180 cm for one threshold, 70 cm for the cross member that will connect the spar to the part;

- profile with dimensions 40x20x2 mm: 70 cm for an additional cross member, 25 cm for jacks, if you have to reinstall the old ones;

- metal plate 15x5 cm to strengthen the part to the bottom;

- anticorrosive for the bottom - bitumen mastic 500 g;

- Bulgarian;

- electric or gas welding, 3 mm electrodes.

- Remove moldings and panels.

- Using a grinder, cut off the outer part along the top seam and bend the metal.

- Cut off the inside, remove the amplifier.

- Attach the pipe, cut off the excess part, weld plugs at the ends of the profile.

- Tack the profile to the bottom by welding at two points, front and back.

- Boil the outer part of the profile to the body, moving from the central pillar. If the body has a bend in this area, tap the pipe during welding to align the profile.

- Weld the cross members that will connect the threshold and the spar.

- Weld fasteners under the jack, weld plates to the bottom to strengthen the structure.

- Clean the weld seams with a grinder and treat with mastic.

- Paint and install decorative panels.

Power profile thresholds have maximum resistance to mechanical damage. If the original body elements bend under a strong impact, for example when driving incorrectly on a difficult section, on potholes, etc., then with installed profiles only the paintwork and plastic linings will suffer.

Quality

It is quite possible to learn the processing scheme on your own. The main thing is to treat the body with high quality, the service life of the coating in the future depends on this. A good result cannot be achieved without using appropriate high-quality equipment. Especially if you need to go through hidden cavities. Lada 2114 is no exception.

Factory anti-corrosion protection can also last a long time, but it needs to be updated from time to time.

Such treatment is especially necessary for cars aged 3 years and older. Especially if the vehicle is already purchased with mileage, and no one plans to change it in the near future. Protection also makes sense in situations where damage is local in nature.

We repair a VAZ 2114 car ourselves:

- Soundproofing VAZ 2114 on your own

- Do-it-yourself VAZ 2114 bumper repair

When repairs are required

For all VAZ models, the body was made of black or low-carbon steel of class 08Yu, 08KP. The parts were not galvanized, but were coated with a polymer anti-corrosion composition; the film protected the bottom from moisture for up to 6 months, then natural oxidation processes began. After the purchase, drivers had to carry out thorough anti-corrosion treatment of the metal.

Repair or complete over-welding of the bottom of the VAZ 2114 will be required in the following cases:

- It is impossible to jack up the car; the jacks fall through.

- The floor in the car became uneven, the metal sagged from corrosion.

- The driver's seat cannot be adjusted; when the doors are closed, increased gaps appear.

- Noticeable areas of corrosion on the sills and wheel arches. If you lift the car onto an overpass and check it with an awl, the anti-corrosion layer from the bottom will fall off, and traces of rust will be clearly visible.

Choosing a product for treating car thresholds with your own hands

Despite the abundance of various means of protecting thresholds from corrosion, many car enthusiasts are wondering: how to treat thresholds? We will give a complete and comprehensive answer to this question. It will help the car enthusiast make the right choice.

1. Anti-corrosion spray BODY-950, capacity 400 ml

Anti-gravel, created on the basis of special resins. Has high adhesion and is resistant to damage. Application requires the use of a special gun. Dries quickly. Cost 4-6$.

Anti-gravel aerosol ELTRANS, capacity from 400 to 1000 ml.

Inexpensive but effective remedy. Does not require the use of a special gun. Consumption of one layer is 400 grams per 1 m². It is recommended to apply in 2-3 layers. Cost for 400 ml. 2-3$.

Preparing for replacement

For the entire VAZ family, thresholds are non-removable body elements; in 80% of cases, repairing an element involves completely cutting or cutting out the part. Overcooking requires preparation

- The car is installed on a flat surface.

- The negative terminal is removed from the battery. In some cases, the battery is removed.

- The wiring from the inside of the doors from the electric windows is dismantled, all sensors are removed.

- The seats are removed from the interior, the inner trim of the pillars and the floor covering are removed.

- Doors are dismantled.

When planning to repair only the threshold, drivers have to partially change the bottom, install new jacks, and strengthen the central pillar. The metal for the body of the VAZ 2114, as well as for other models in the Lada Samara line, did not undergo anti-corrosion galvanizing.

Rolled steel was puttied, primed and painted. The inner part of the bottom and the box were not treated with anticorrosive; the first layers of rust appear on the internal parts of the body in the second year of operation. If the threshold is being repaired for the first time, and the “youngest” VAZ 2114 model is 6 years old, we can confidently say that the owner will find completely rotten metal under the bottom trim.

Main types of corrosion

There are different degrees of corrosion, in terminology they are called:

- subsurface - formed on the surface and spreads throughout the metal;

- slotted - occurs in the gaps of the car body, in threads, under metal gaskets, etc.;

- continuous - appears on the outside of the metal in a continuous layer;

- intercrystalline - occurs in areas of metal products damaged by impacts;

- local - originates on the surface of metal products in the form of spots;

- selective - occurs and destroys only one component structure of the metal.

VAZ 2199 2003

VAZ 2199 2003

Body repair painting polishing Auto service +7 ;

Stavropol; Mikhailovsk;

- Examples of work Video

. Shop . About us Who and Where are we? News Sitemap

A client contacted us

Good evening..

Available 99th 2003 Guards

Tired of the body.

The years take their toll. There are shoals on the body, rust has appeared here and there...

What will be the total cost of body treatment, complete repainting, Movil?

I can post a photo as soon as I can, I’m not in the city

Properties of anti-corrosion coating

Any anti-corrosion coating must have the following important qualities:

- abrasion resistance – the ability to protect car parts from regular exposure to abrasives;

- environmental friendliness - rust removal products must be environmentally friendly;

- frost resistance - the product must retain all its properties even at low temperatures;

- high activity - the drug must be well saturated to stop corrosion;

- plasticity - since constant vibrations and deformations are possible during movement;

- the material must be retained on the surface of the car at high temperatures.

Design Features

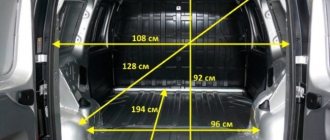

Model 2114 was built on the basis of the VAZ 2109, it is a restyled version. The hatchback received a new steering column, a modernized dashboard, an updated one and a half liter engine, redesigned for Euro 2 protocol. The VAZ 2114 shares the same wheelbase with the Nine, 2460 mm. The configuration of the bottom panel is the same for the models.

Are there any differences between 2114 and 2115

The VAZ 2115 model is considered a related model. The hatchback is built on the basis of the VAZ 21099 with various transport sizes and shares one wheelbase with the entire Lada Samara family. The standard dimensions of the bottom and sills for VAZ 2108, 2109, 21099, 2113, 2114, 2115 models are the same and interchangeable.

The bottom of the VAZ 2114 structurally consists of the following parts:

- central reinforced panel;

- driver's side panel;

- side passenger;

The factory stock bottom is a one-piece stamped part, primed and painted black. The polyethylene coating acts as protection.

When is underbody treatment necessary?

Often car owners think about protecting the car body only when it begins to rust. But a rusty bottom is already quite a big problem; to restore it, you often have to use welding, apply patches, and carry out quite labor-intensive work. The machine should not be allowed to rust; it is necessary to carry out anti-corrosion treatment:

- once every 3-4 years (or more often, the frequency depends on how well the body of a particular car model resists corrosion);

- immediately after purchasing a used car;

- in case of collision with an obstacle with the bottom and damage to the anti-corrosion layer (its tearing off).

It is no secret that many new cars do not receive high-quality treatment, so immediately after purchase it is recommended to look under the car and assess the condition of the anti-gravel coating. With a thin protective layer of anti-gravel, additional treatment is required; the anti-corrosion composition should be applied before the car begins to be used. If the car has not yet been driven on the roads, it will take less time to prepare; you do not need to thoroughly wash the bottom and wheel arches.

Preparation for repair

Repairing the underbody of a VAZ involves a set of measures:

- preparation of the necessary material and tools;

- interior dismantling;

- installing the car on a lift or repair plane;

- cutting out rotten elements of the bottom during partial or complete replacement of a part, if it is necessary to completely digest the body;

- patch welding or bottom welding;

- anti-corrosion treatment;

- installation of interior, replacement of sound insulation, additional work.

To repair the body yourself, you will need to prepare the following materials and tools:

- A new bottom or part of it for a complete replacement, metal patches for a partial repair. It is recommended to take industrial steel with a thickness of up to 1-1.2 mm. The standard metal on the body of the VAZ 2114 has a thickness of 0.9 mm for the bottom, 0.8 for the sills.

- Angle grinder, grinder with a set of replaceable discs from metal, for processing a weld seam, stripping metal from corrosion, to a soft attachment for grinding soil.

- Welding machine. For self-repair, it is recommended to use a semi-automatic machine using wire in a carbon dioxide environment.

- Electric drill, set of drills.

- Sound insulation sheets.

- Metal brushes, coarse and fine sandpaper, chisel, set of screwdrivers.

- Zinc-based primer, putty, set of spatulas, anti-corrosive agent for final processing.

The first stage of work is dismantling the interior and lifting the car onto the overpass.

Dismantling the interior

The bottom 2114 is a stamped part that is welded to the reinforcements of the side members and hinged panels along factory lines. Original replicas require no trimming and are ready for installation. Description of replacement in stages:

- The fuel is drained from the car and the battery is removed.

- The electrics are turned off, the front and rear doors are dismantled.

- The chairs and flooring are pulled out, and the sound insulation is removed.

- All plastic lining of the pillars is dismantled, the dashboard must be covered with a thick piece of rags.

- The glass is sealed on both sides with thick paper.

- An inspection is carried out from the inside, rusty areas are tapped with a hammer, and the scale of work is determined.

Instructions for repairing and replacing the windshield on KIA RIO 3

The cost of repairs at a service station for a VAZ 2114 starts from 15,000 rubles. When replacing them themselves, owners can save at least 10,000 rubles. Repair kit price for independent work:

- replica – 3500 rub.

- anti-corrosion kit – 1000 RUR:

- rental of electric welding ─ 1000 rubles;

- sound insulation sheet ─ 300 rub.

Metal cutting process step by step:

- Use an angle grinder to clean the bottom from dirt and used anti-corrosion.

- Check the general condition of the metal and jacks.

- In case of partial replacement, cut out the rusty places with a grinder or chisel, and prepare patches.

- Sand the metal until white.

- Drill out spot welding points if the entire part is being replaced.

It is recommended to cut the metal for patches using metal scissors. Welding cutting is used if the driver has experience in welding. Otherwise, you may end up with a patch with convex edges, and the metal will be inconvenient to weld to the body.

Final processing

Primer, anti-corrosion treatment, installation of new sound insulation and installation of the interior with electrical connections are the final stage of work on the bottom. For external treatment, you will need bitumen mastic or anticorrosive Body 930. The product has a budget cost and is highly resistant. The mastic forms a dense but elastic protective layer that does not allow moisture to pass through and protects the iron. Final work step by step:

- Clean weld seams.

- Treat welding areas with a primer containing zinc.

- Cover the inner surface with mastic and install new sound insulation.

Rotten metal destroys the skimmer sheets in 3-5 months, so if the car needs the bottom to be overcooked, the sound insulation definitely needs to be changed.

- Treat the outer part of the bottom with bitumen anticorrosive. You can use paraffin aerosols; it is convenient to reach the hidden cavities of the bottom with an anticorrosive agent.

During operation, during routine inspection, it is recommended to periodically remove the plugs in the parts and pour the oil composition into the internal pockets.

- Install interior, doors. Connect the electrical.

Carrying out rust removal work

Anti-corrosion cleaning of the underbody of the car should be carried out only after washing, since this way you can see all the problem areas. After drying the body, you should begin examining the surface to identify pockets of rust or swollen paint.

The next stage of work is to clean the affected area. Cleaning time directly depends on the method used to remove the old layer of mastic. So, the most time-consuming and tedious method is cleaning with a wire brush or sandpaper. Using a grinding machine, you can prepare the surface for further work much faster.

Important: you need to clean the area 3-4 cm around the rust stain until a smooth and even surface appears.

After the cleaning work is completed, you need to treat the problem area with a degreasing solution and apply a rust converter. Its main task is to transform the rust remaining on the bottom into soil. It is applied using a regular rag. After waiting for the corrosion converter to dry, you can apply a new layer of anti-corrosion coating.

Approximate price

On average in Russia, it costs 8,500-29,000 rubles to digest the bottom of a VAZ-2112 car. Price of works included in this amount:

- Purchase of electrodes (about 3 kg per car) - from 550 rubles per 3 kg.

- Two cutting wheels for an angle grinder, two spare ones - about 270.

- A pair of metal brushes for a drill - from 200.

- Degreaser and solvent – 150-160.

- Paint – from 700 rubles.

- Epoxy glue - about 200 rubles.

- Rubber-bitumen mastic – 150.

- Polymer-bitumen mastic – from 350.

- Rust converter - about 85.

- Large Movil cylinder - 345.

- Paint brushes – about 160.

- Two amplifiers under the seat - 400.

- A pair of corners - 300 rubles.

- Floor panel – 4500.

- Jacks - 160 rubles for two pieces.

- The work of a car mechanic costs about 20,000 rubles.

If you independently overcook the bottom of a VAZ-2112 car, using the cheapest spare parts, the costs will be limited to 8,500 rubles. When purchasing consumables and equipment in a specialized store, repairs will cost 11,500 rubles. Restoring the bottom of a car at a car service costs about 29,000 rubles.

Car protection inside the cabin

Cleaning the underbody of the car from corrosion should take place not only outside, but also inside the cabin. The corrosion process is accelerated by snow that sticks to the soles of boots or the radiator of the heating system.

Therefore, the bottom inside the cabin also needs to be coated with a thin layer of mastic, after having previously dismantled the chairs, carpets and other interior elements.

Most modern cars have a galvanized body. But this is only partial protection against rust, so an additional anti-corrosion coating should be applied.

Methods for removing rust

Cleaning the underbody of a car from corrosion is carried out in two ways:

- in anti-corrosion centers - where they will quickly and efficiently carry out a complete anti-corrosion treatment of the car;

- Do the bottom treatment yourself, which will help significantly reduce costs, but it will require time and effort.

When choosing an anti-corrosion center, you should talk to the receiver and evaluate his competence and professionalism in order to be confident in the quality of the services provided.