Lada Kalina body

Lada Kalina, the body of which is of great interest to motorists today, is considered one of the best creations of the Togliatti plant. Kalina is not a separate model, but a whole family of Russian small-class cars produced since 2004. We will find out from the article how much it costs to repair body parts, whether the body of this car can be replaced, and what are the features of its design.

VAZ Body dimensions and geometry, control points

This section shows the body dimensions of the VAZ, provides drawings, shows the geometric distances between control points, a table with the geometric dimensions of the openings of LADA/Zhiguli cars, provides data for checking the geometry of door, window and other openings, control dimensions of the VAZ and standards for adjusting the camber/toe.

The most well-known way to determine the quality of the load-bearing part of a car is to measure the distances between control points and compare them with factory parameters. More detailed information about the magnitude of measurements and the location of control points can be obtained by selecting the appropriate model.

Typically the geometry of the following body elements is checked:

1) Diagonals.

Before measuring body dimensions using reference points, you can take just two measurements that will help clarify the picture. Drive the car onto an overpass or pit and use a tape measure from below to measure the body diagonally. The diagonals must match.

2) Racks.

You definitely need to check the racks. At the beginning - from the unbroken side of the body (if such is known), then - from the bat. In principle, in this case you can choose any body points (the main thing is the same data on both sides). For example, from the pillar to the edge of the bend on the rear doors. Also on the front ones. If the data matches, great. Let's move on;

3) Roof.

To make sure that the car’s roof does not “sag”, you need to measure the door diagonals - from the lower rear corner diagonally to the upper front corner. Naturally, the result on both sides should be the same. In addition to this, it is advisable to measure the diagonals of the roof itself;

4) Front and rear glass.

For some reason, many people believe that if the windshield “fits” normally, then control measurements are not needed, they say, the geometry of the VAZ body is fine. This is mistake. You need to measure - moreover, diagonally, and choosing points at the same distance on both sides.

5) Visual inspection

standing car from all sides. Particular attention should be paid to gaps. On VAZ cars they are quite noticeable. But the main thing is that the gap sizes must be the same on both sides of the machine.

Geometry Lada Largus 2012-2020

Geometry of Lada Largus (including Largus Cross) for checking and restoring body parameters, followed by straightening damaged parts of Lada Largus cars. A selection from various bench databases for Lada Largus, bench (slipway) data maps and control points of Lada Largus.

Body of Lada Largus / Lada Largus

Body parts: 1 – left luggage compartment door; 2 – right luggage compartment door; 3 – rear bumper; 4 – right side window of the rear compartment; 5 – right rear door; 6 – front door right; 7 – hood; 8 – outside rear view mirror; 9 – right front wing; 10 – front bumper

The Lada Largus body is a one-piece welded structure. It is welded on a robotic line. All body parts that are prone to corrosion are galvanized. The main method of connecting body parts to each other is resistance welding, and electric welding is used in hard-to-reach places. All welds and joints of parts are coated with mastic. When making a body, after connecting its main parts, it is immersed in a special bath with an anti-corrosion compound. Then the primer and paint coating are applied. Hidden cavities are treated with a wax auto-preservative, and the bottom is covered with anti-corrosion mastic.

The body is designed taking into account the most advanced requirements for passive vehicle safety. One of the most important elements of passive safety is the front subframe, which has the property of redistributing impact energy. Car bumpers are made of impact-resistant material that absorbs impact energy. The car doors have metal stamped reinforcements in case of a side impact.

Due to the fact that the body has a very rigid structure, and the plastic interior parts have a gap between each other and are secured with special fasteners, there is virtually no vibration noise in the cabin (the so-called “crickets”).

The LADA Largus windshield is three-layer, it is glued into the body frame and is part of its load-bearing structure. All other car windows are tempered. The side door windows are sliding and, depending on the configuration, have either a manual or electric drive.

The side windows of the rear compartment can be opened slightly (7-seater version).

The luggage compartment doors can be opened completely, or up to two fixed positions provided for this, which is very convenient if the car is in a cramped loading/unloading space.

A modification of the car called LADA Largus Cross has unpainted black front and rear bumpers, as well as protective covers on the wheel arches and sills made of black plastic.

About choosing paint to match the body color

Theoretically, the paint can be selected according to the code that is indicated on the nameplate on the car or is stamped by the VIN code. However, very often the resulting color differs significantly from the body color. This is due to two factors: production features and the abundance of color matching systems (programs). The problem is that there is no uniform production of paint of certain shades. At automobile factories, the desired tone is obtained according to a certain recipe: a package of pigments is added to a barrel with the main color. For each batch of machines a new batch is made. And just as parts can differ from each other by a tolerance, so paints also vary slightly in shade.

At a car plant, you won’t find two barrels with a 100% color match—even cars from neighboring batches have different colors. Factory-prepared paint is not supplied to the secondary market, and during body repairs at any service center you have to select the tone. There are color matching systems for this.

largus-mcv.ru

About Lada Kalina

ATTENTION! A completely simple way to reduce fuel consumption has been found! Don't believe me? An auto mechanic with 15 years of experience also didn’t believe it until he tried it. And now he saves 35,000 rubles a year on gasoline! Read more"

Having replaced the outdated “classics”, Lada Kalina embodied the expectations of many lovers of VAZ models. It continued to be produced as a budget car option that the average Russian family could afford to buy.

Today, cars of the Kalina family series are presented in 3 body variations: a station wagon called VAZ 21117, a VAZ 21118 sedan and a VAZ 21119 hatchback.

All these car modifications are characterized by a large interior and compact shape. New-fangled design, body strength and modern technologies - all of these modifications of the Kalina family combine to the fullest.

Among the main advantages of the Kalina body are a wide variety of colors, rigidity and much more. But among the shortcomings, many note the insufficient level of sound insulation.

The world's first Kalina was released in 2004. A lot of time has passed since then. Owners of used Kalinas are often interested in the features of repairing individual body elements.

Approximate cost of repair work on the Kalina body at a service station

Here are the prices offered today at various repair services.

In principle, the prices are not that low. It would be better to learn how to replace (which is much easier) or repair it yourself. We are not talking about competently taking body dimensions to compare geometry. This, of course, should be done only with high-quality equipment, which is almost impossible to provide in a garage workshop.

On the other hand, useful information about the geometric dimensions of Kalina’s bodies will be presented below, which will make it possible to remove them yourself using a regular tape measure.

Watch a video about problem areas of the Lada Kalina body

"sedan" version

Let's start with the sedan:

- From the new family of Kalina cars, AvtoVAZ is produced;

- The modern elegant appearance and comfortable interior are called the root reasons for the sedan's good sales;

- It has good handling at high speeds;

- It maneuvers well in the city traffic rhythm;

- Practical and incredibly convenient for daily use;

- The sedan body received wedge-shaped silhouette lines, visually creating the image of a strong, brutal car;

- The opening angle in the luggage compartment has been increased by 120 degrees, which makes loading easier. Inside the trunk, the manufacturer has wisely provided special loops that allow you to secure the cargo being transported.

Convenient trunk

The body as a whole is very durable, and its seat crossbar is subject to reinforcement. This rail saves passengers in the event of a side impact. In addition, the manufacturer provides special pads designed to protect the heads of the driver and passengers.

These are the body dimensions of the Lada Kalina sedan shown in the photo.

Lada Kalina body control dimensions

Geometric dimensions of the openings of the VAZ 2118 sedan (Lada Kalina)

Measurements of geometric dimensions should be carried out correctly. So, if a car has a roof leak, you need to measure the diagonals of the roof; if there are problems with the openings, then the openings accordingly.

The causes of geometry violations can be not only accidents or serious accidents. If you often drive on uneven roads, encountering various obstacles, the position of certain body elements may change. In principle, suspension is provided for such cases, but over time it weakens, and its vibrations, like it or not, are transmitted to the body.

In most cases, the geometry is tested before purchasing a used Kalina. An event carried out competently provides information about whether the previous owner’s car has been in an accident or not, what the condition of the body is, etc. In addition, diagnostics of this kind are recommended to be carried out regularly by car owners for preventative purposes.

Many experts recommend that owners examine the body geometry even after any repairs carried out at a service station. It happens that in the process of these repair manipulations the qualifications of service workers turn out to be insufficient. They only restore the body and its parts externally, but in reality the distances turn out to be shifted.

Obvious features of body damage are visible even without measurements. For example, if Kalina’s doors begin to close or open poorly, it is recommended to do a full geometry check.

Another symptom of body displacement is the unstable behavior of the car on the road at high driving speeds. It moves around, it vibrates, etc.

Editing a damaged body

Car body Lada Kalina 01/09/201102/08/2016

BODY FRAME REPAIR for Lada Kalina

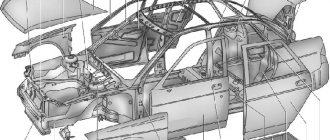

The structure of the body frame is shown in Fig. 8.2.

Welded body with attached elements - in Fig. 8.1.

Editing a damaged body- A significant part of the repair work on cars, especially those arriving after road accidents, falls on body repairs.

- In most cases, repairs require checking the geometry of the attachment points of components and assemblies of the vehicle chassis.

Damage to car body can be very different. Therefore, the repair rules in each individual case must be different, most suitable for these damages, and it is necessary to make maximum use of the possibilities of straightening damaged panels.

- If possible, it is necessary to avoid thermal effects on the metal so as not to disrupt the factory welding and anti-corrosion protection of the body.

- Remove the front body panels only in extreme cases, to determine the location of damage, straighten or align the body.

- In cases of significant body damage, it is recommended to remove all interior trim to facilitate measurement, inspection and installation of hydraulic and screw jacks to correct distortion and damage to the body.

- Protrusion of the front surfaces and removable parts relative to adjacent panels is eliminated by fitting and adjusting them.

- Repair of deformed surfaces of parts

- Repair of damaged body parts is carried out by drawing, straightening, straightening with metal shrinkage, cutting out areas that cannot be repaired, making repair inserts from rejected body parts or sheet metal and giving them the shape of the part being restored.

- Deformed areas of panels are usually straightened manually using special tools and devices.

Straightening with heating is used for upsetting (pulling) highly stretched surfaces of panels. To prevent sudden swelling and deterioration of mechanical properties, the panels are heated to a temperature of 600 - 650 degrees (cherry-red color). The diameter of the heated spot should be no more than 20 - 30 mm.

- Tighten the surface as follows:

- — using a carbon electrode of a semi-automatic welding machine or a gas torch, heat the metal from the periphery to the center of the deformed area and, with blows of a wooden mallet and hammer, knock down the heated areas using a flat support or an anvil;

- — repeat the heating and deposition operations until the required panel surface is obtained.

- Unevenness in panels can be smoothed out using polyester putties, thermoplastics, cold-curing epoxy mastics and solder.

https://www.youtube.com/watch?v=upload

Polyester putties such as “Hempro-pol-P” or PE-0085 form reliable connections with panels that have been stripped down to metal. They are two-part materials: an unsaturated polyester resin and a hardener, which is a catalyst for the rapid hardening of the mixture.

The temperature in the workroom should not be lower than 18 degrees C.

The prepared polyester putty must be used in no more than 10 minutes. It completely hardens 60 minutes after application.

- The thickness of the putty layer should not exceed 2 mm.

- Thermoplastic is available in powder form.

- It acquires the elastic properties necessary for applying it to the metal surface of the panel at a temperature of 150-160 degrees C.

- The surface to be filled must be thoroughly cleaned of rust, scale, old paint and other contaminants.

- Thermoplastic adhesion is better to a rough metal surface.

- To apply thermoplastic, the area to be leveled is heated to 170-180 degrees C and the first layer of powder is applied, which is rolled with a metal roller.

- Then a second layer is applied and so on until the unevenness is filled.

- Each layer is rolled until a monolithic layer of plastic mass is obtained.

- After hardening, the layer is processed using conventional methods.

- Solders such as POSSu 18-2 or POSSu 25-2 are used to level areas previously filled with solder, build up the edges of parts and eliminate gaps.

- In case of significant damage, the panels are replaced with new ones using electric welding in a shielding gas environment.

In a station wagon

Today, many experts see the station wagon as the best creation of the Kalina family. Indeed, although its exterior is not distinguished by noticeable and catchy solutions, in order to appeal to a certain caste of consumers, it is an ideal vehicle of the classic type.

Initially, the designers were given the goal of inventing and constructing a car that would meet the needs of the masses. It was supposed to become a universal vehicle for every day. Both men and women had to like the car.

Regarding body production technology:

- 33 new materials were used in assembling the station wagon body to ensure European quality standards and compliance with safety standards. This includes not only metal parts, but also plastics, paints and much more;

- The corrosion resistance parameter has been increased several times, thanks to competent and complete galvanizing of parts exposed to greater exposure to aggressive environments

- The design of the body and interior parts was obtained entirely using computer geometric modeling. Thanks to this, it was possible to increase the rigidity and safety coefficient several times. This also affected the quality of manufacturing and mating of the front body parts;

- Welding work is carried out exclusively by robotics. Today, according to the plant administration, about 360 robots are used.

Among other advantages of the body, we can highlight the large spaciousness of the interior and luggage compartment. This, in turn, was achieved due to a successful layout solution aimed solely at increasing the volume of internal space. In addition, the car was designed with a high seating position, which provided good visibility.

Regarding comfort:

- It's easy to get in and out of the station wagon thanks to the large door opening angles;

- The rear seats are equipped with convenient settings that allow you to place cargo of different sizes;

- The interior is well protected from excess noise. For this purpose, additional door seals are provided;

- The interior is protected at the highest level from fading and ultraviolet radiation due to athermal glazing;

- The cabin provides high sound comfort. This is facilitated by proper sound insulation.

- The Kalina station wagon has a durable design. A corresponding crash test was carried out. Body deformation measurements were carried out after impacts from the front, side and rear. The following weak areas were identified, which were immediately significantly strengthened: the floor near the driver’s feet, the central door pillar, the crossbar under the seats, upholstery, side members and much more;

- In a situation of poor visibility, when there is fog or twilight outside, visibility deteriorates. This directly affects the PB. To increase safety, it was decided to install electric and heated mirrors. True, such mirrors are installed only in the “Lux” configuration.

The body of the Kalina car is already history

Deputy Minister of the Ministry of Industry and Science of the Russian Federation S. G. Mitin presents the director of the Polytechnic Museum G. G. Grigoryan with a certificate of donation of the body of a LADA 1118 car.

Scientific Advisor to the Vice President for Technical Development of AVTOVAZ OJSC A.K. Tikhonov demonstrates welding points on the body of the LADA 1118 Kalina car.

Director of the Polytechnic Museum G. G. Grigoryan thanks metallurgists, machine builders and representatives of the ministry for donating the body of the LADA 1118 Kalina car.

Mitin said: “Today’s event is significant in that two leading industries in Russia - mechanical engineering and metallurgy - have solved a very important problem that has been puzzling over for the last 20 years, the task of providing automakers with modern metal sheets that allow them to produce high-quality cars.

This is the body of the most promising car in Russia in the coming years - LADA 1118 Kalina. The use of Russian automotive sheet metal with increased corrosion resistance increases the reliability and quality of the car by an order of magnitude, making its assembly and production modern, competitive, and corresponding to world standards.”

Just a couple of decades ago, all domestic car bodies were largely assembled from imported metal. The automotive industry has long outpaced the development of the metallurgical industry.

While metallurgists were fighting for a defect-free surface of automobile sheets and for its high plastic properties, the ideas and thoughts of automakers went further and further.

Important

The competition continued until the moment when the technologies of metallurgists and the technologies of mechanical engineers finally met and were embodied in a specific product.

The creation of the body of the LADA 1118 Kalina car became a milestone in the work of metallurgists and machine builders and marked a colossal step forward in the technical development of the country.

That is why representatives of the management of AVTOVAZ OJSC, Magnitogorsk, Novolipetsk and Cherepovets metallurgical plants, Lysvensky metallurgical plant - all those who brought today's event closer - gathered at the presentation at the museum. And the meeting of colleagues was organized by professor, academician of the Russian Academy of Engineering, scientific advisor to the vice-president for technical development of AVTOVAZ OJSC A.K. Tikhonov. With his direct participation, the ideology of sheet metal technology and its use in the manufacture of the body of the LADA 1118 Kalina car was created.

https://www.youtube.com/watch?v=ytpolicyandsafetyru

“We are not used to showing part of any scientific work, but the body frame of the Kalina car deserves it,” A. K. Tikhonov said at a meeting at the Polytechnic Museum. – Its design embodies all the latest requirements for safety and corrosion resistance. After all, what should an autosheet be like? Strong, thin, plastic, durable.

Now the domestic auto sheet has these properties! We must pay tribute to the Novolipetsk Metallurgical Plant, which mastered for the LADA 1118 KALINA car steel without introducing atoms for hot-dip galvanizing, which had not previously been produced in Russia. Severstal has achieved the surface quality we require on a large range of parts.

Lysvensky Metallurgical Plant reconstructed virtually all lines for electrolytic galvanizing. The Magnitogorsk Iron and Steel Works has installed a reversing mill and a modern hot-dip galvanizing line. The new body contains 35% hot-dip galvanized steel, 13% electro-galvanized steel, and 12% high-strength steel, mastered and used for the first time.

The remaining 40% is uncoated sheet steel from NLMK, Severstal and MMK. Metallurgists and automakers moved towards each other in their work. Considering that the body consists of 35% hot-dip galvanized steel, automakers primarily changed stamping and welding technologies.

Since traditional grinding in the manufacture of the frame and hinged parts before painting has become unacceptable (the parts after stamping should not be touched by tools), the requirements for the geometry of the front parts have increased.

Welding required reconstruction of welding lines for the LADA 110 car, as well as the use of double-sided electrodes on the mounted welding line for LADA 1118 Kalina cars, increasing the welding current and its automatic regulation. The result was worth the effort.

Advice

If the VAZ 2101 car had more than 500 parts and about 10 thousand welding points, then the LADA 1118 Kalina used about 350 parts. To connect them, 4.5 thousand welding points were required, that is, there were more than half as many of them.

This means that a new car has at least half as many points of possible corrosion, and much less labor is required for welding.”

https://www.youtube.com/watch?v=ytcreatorsru

On the presented body frame you can see all the parts, see what metal they are made of and how the welding was carried out. Employees of the Polytechnic Museum are already preparing to meet young visitors to tell them about new achievements of science and technology in our country using the example of the LADA 1118 Kalina car.

Volume and features of the trunk of Lada Kalina: station wagon, sedan and hatchback

Lada Kalina is a budget B-class car developed by AvtoVAZ in 1993. The car received its name, which became a recognizable trademark, in 1998. During the period from 1999 to 2001, modifications were developed in hatchback, sedan and station wagon bodies.

All body and power unit configurations were built using innovative computer technologies and were put into mass production in 2004. On the Internet you can find both positive and negative reviews about the Kalina 1 model; there are also controversial opinions about the carrying capacity parameters and trunk volume of the Lada Kalina station wagon, hatchback and sedan.

Lada Kalina hatchback

The body version of the Lada Kalina hatchback was launched into production in 2006 and was produced without modernizing the power unit or changing the interior for 7 years. In 2013, production of the second generation hatchback was launched. Speaking about capacity and total carrying capacity, let's consider the dimensions:

- length 3850 mm;

- width 1700 mm;

- height 1500 mm;

- ground clearance 160 mm.

With such dimensions, the hatchback has a relatively good trunk - its volume in liters is 240. If you fold the rear seats, the capacity can be increased to 550 liters.

Main dimensions: 94.7x64.4x49.2 cm.

With such modest dimensions, Kalina has a fairly impressive carrying capacity of approximately 500 kg (this takes into account the presence of 4 adult passengers in the car). The car meets the requirements for family cars: cross-country ability, safety, passenger comfort, acceleration dynamics, etc.

In addition to the classic hatchback VAZ-1119 Kalina, an off-road, sports version of the Lada Kalina Cross was also produced, as well as 2nd generation hatchbacks (VAZ-2192). Let's take a look at their cargo compartments:

- The trunk volume of Kalina Cross is 355 liters.

- Trunk Kalina 2 - 240 l.

Vehicle powertrain

Three engine options are available:

- 8-valve VAZ-2116 engine with a power of 90 horsepower;

- 16-valve VAZ-21126 engine with a power of 98 horsepower. The station wagon modification with engine 21126 (factory designation VAZ 217130) is the most affordable on the secondary market;

- The 16-valve VAZ-21127 engine, which produces 106 horsepower, wins in terms of efficiency and reliability.

The base engine of the Lada Priora 2171 model is a gasoline, four-stroke, four-cylinder (cylinders are arranged in a row) 16-valve VAZ-21127 engine with distributed injection. This engine appeared after the VAZ-21126 engine was modified to improve the intake system. On the VAZ 21127, instead of one mass air flow sensor, two are installed: absolute pressure and air temperature. This made it possible to get rid of the known problem of the previous model - fluctuations in the crankshaft speed at low speeds.

The volume of this engine is 1596 cubic cm, the diameter of each of the four cylinders is 82 mm, the piston stroke is 75.6 mm, the compression ratio is 11. The octane number of gasoline used is 95. This engine develops power up to 106 horsepower at crankshaft rotation speed 5800 rpm, and its maximum torque is 148 Nm at 4200 rpm. It is obvious that the characteristics of the VAZ Priora with the 21127 engine are 8 horsepower and 3 Nm higher than those of a car of the same brand with the 21126 engine.

The dimensions of the restyled Lada Priora have not changed significantly. Although, due to the new front and rear bumpers, the length of the Lada Priora has changed by several millimeters.

As before, the restyled Lada Priora sedan has the longest length, which in the new version is 4,350 mm. The length of the station wagon is 1 centimeter shorter, but the Priora hatchback is even smaller, the length of this version of the body is 4210 mm. The width of the entire family is 1,680 mm and the wheelbase is the same for all 2,492 mm. But everyone’s height is different, the Lada Priora sedan is 1,420 mm, the hatchback is 1,435 mm, but the station wagon is generally 1,508 mm in height. The high height of the Priora station wagon is explained by the presence of roof rails. In a hatchback, the design of the rear part of the body is such that the car turns out to be taller than a sedan.

As for the ground clearance or ground clearance of the Lada Priora, the manufacturer indicates a figure of 165 mm for the sedan and hatchback, while the ground clearance for the Lada Priora station wagon is 170 mm. However, in fact, the ground clearance is greater; just pick up a tape measure and make sure of this. But the manufacturer is not mistaken; he simply indicates the vehicle’s ground clearance when fully loaded. At the same time, manufacturers of foreign cars are cunning and indicate the ground clearance of their cars in an unloaded state. therefore, the real ground clearance of foreign cars and their official data often do not coincide.

The luggage compartment volumes of the new version of Lada Priora in all three bodies have changed little. The sedan's trunk volume is 430 liters. The luggage compartment volume of the Priora hatchback is smaller, only 306 liters, but if you fold the rear seats (which cannot be done in a sedan), the volume increases to 705 liters. In the Priora station wagon, the luggage compartment volume is 444 liters, and with the seats folded down it reaches 777 liters. Unfortunately, the rear seats do not fold flat with the floor, and the large wheel arches eat up quite a lot of luggage space.

| Dimensions of Lada Priora | sedan | hatchback | station wagon |

| Length, mm | 4350 | 4210 | 4340 |

| Width | 1680 | 1680 | 1680 |

| Height | 1420 | 1435 | 1508 |

| Front wheel track | 1410 | 1410 | 1414 |

| Rear wheel track | 1380 | 1380 | 1380 |

| Wheelbase | 2492 | 2492 | 2492 |

| Trunk volume, l | 430 | 360 | 444 |

| Volume with seats folded | — | 705 | 777 |

| Fuel tank volume | 43 | 43 | 43 |

| Ground clearance, mm | 165 | 165 | 170 |

As for the tire size of the Lada Priora, the manufacturer recommends installing 14-inch wheels. The tire size can be 175/65 R14 or 185/60 R14 or 185/65 R14. The most interesting thing is that today, even on Lada Granta or Kalina in well-packaged trim levels, AvtoVAZ offers 15-inch wheels as standard. Why this is not the case on Priora is not clear, although this does not stop the owners of these cars, who put much larger wheels on their Lada Priora.

myautoblog.net

Lada Kalina station wagon

This version of the VAZ-1117 has been produced since December 2007 and immediately became the leader in the Kalina line in terms of load capacity:

- length 4040 mm;

- width is 1700 mm;

- height is 1500 mm;

- vehicle clearance 160 mm.

The trunk size of the Kalina station wagon is 355 liters, and with the passenger seats removed this figure can be increased to 670 liters.

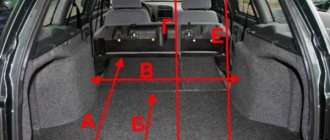

Its main dimensions are as follows:

- width – 1 meter 34 cm;

- length (depth) – 80.6 cm (to the backs of the seats);

- height – 52 cm.

The second generation station wagon VAZ-2194 has similar body dimensions and similar cargo compartment dimensions. Depending on the type of interior finishing, the trunk may be 10 liters more or less.

Trunk Kalina sedan

The configuration in this version is the first model whose dimensions were calculated by a computer program. The model has been produced since 2004. The sedan's dimensions are similar to the station wagon, but due to the difference in design types, the sedan's interior seems more spacious:

- length 4040 mm;

- width 1700 mm;

- height 1500 mm;

- vehicle clearance 160 mm.

The trunk of the sedan is 400 liters. This figure can be increased by folding the passenger seats. Trunk volume Kalina sedan:

- trunk width – 97 cm;

- height – 51.5 cm;

- diagonal – 97 cm.

The sedan has a fairly spacious interior and a roomy trunk, although it is not specifically designed for transporting large cargo. You cannot put large items in the trunk, but it is easy to transport luggage up to 500 kg.

Dimensions value

The Kalina family is small but friendly. Some are a little bigger, some are a little smaller, but together they can make it to the parade. The body of the Lada Kalina is made in several modern modifications: sedan, hatchback, station wagon, cross and sport. Their overall dimensions do not vary much.

| Sedan | Hatchback | Station wagon | Cross | Sport | |

| Length, mm | 4040 | 3850 | 4040 | 4104 | 3943 |

| Width, mm | 1700 | 1700 | 1700 | 1700 | 1700 |

| Height | 1500 | 1500 | 1500 | 1560 | 1450 |

| Weight | 1098 | 1098 | 1128 | 1125 | 1150 |

| Base | 2476 | 2476 | 2476 | 2476 | 2476 |

| Clearance | 160 | 160 | 145-160 | 183 | 150 |

The width and wheelbase are the same for all, as it should be for related models. But the length, height and ground clearance are different. Accordingly, the volumes and masses are different. The history of Lada models has seen long stagnation and a period of failure. In 2004, the release of the first Kalina from the assembly line ushered in a new era. Since then, new items appear almost every season, and the ranks of owners of the most popular car in Russia are growing from year to year.

The geometric dimensions of the body are important, but no less interesting is the volume of the trunk. All Kalina models are designed to allow the rear seats to be folded forward and increase luggage compartment space. The most voluminous trunks are for the sedan, station wagon and cross: 355/670 liters. “Hatchback” and “sport” are more modest - 240/550 hp. It’s also not bad, as many city car owners will agree with.

In the ranks of Kalina there is another model - Lada Kalina City (Oka-3), made on the VAZ-1117 platform. It appeared in 2005 and for some time was considered a replacement for the Oka small car, but this assumption is incorrect. It has almost the same dimensions, height and width as other Kalinas, only the length is 3650 mm.

There is another dimensional indicator that is rarely interested in until they get stuck in a rut. At this point, some people discover the fact that the distance between the front wheels is different from the distance between the rear. This parameter is called: front and rear wheel track. For the “sedan” and “hatchback” with “station wagon” - 1430/1414 mm, for the “sport” - 1431/1432 mm and for the “cross” - 1430/1418 mm.

The difference in millimeters may not be noticeable to the eye, but it is easy to feel when a few millimeters are not enough to get out of an icy rut on a winter road. The track size turned out to be wrong.

Features of luggage racks

Cargo compartments for Lada Kalina vehicles have some special features. They must be taken into account by motorists who choose equipment for specific transportation conditions:

- Increasing cargo capacity due to the folded rear passenger seats of the Lada is much easier and faster than similar cars in this class.

- The luggage compartment lid rises 60 cm higher than on models in similar classes. This is quite convenient for frequent loading and unloading of Kalina.

- It is possible to install an additional non-standard roof box for transporting things. Kalina's load capacity increases by 40% if you use lightweight roof racks consisting only of crossbars and the main unit.

In addition to the advantages that the equipment has, there are also problems that are noted by owners of two- to three-year-old cars:

- At temperatures below 15 °C, frequent breakdowns of the shock absorber of the cargo compartment door are observed.

- Car enthusiasts note problems with the lock in the hatchback configuration in the second year of operation. The lock breaks, the cylinder falls out or the spring stretches, and in some cases the locking ring gets jammed. The lock has to be changed.

Initially, this AvtoVAZ line was planned as small family cars not intended for transporting goods. Hatchbacks have the smallest trunk; when transporting even small loads, you have to wisely use every centimeter of it, saving space. If you need a car specifically as a cargo carrier, we recommend choosing the station wagon option. Its cargo space is enough for family trips to the country, picnics and wholesale stores.

Let's look at what the design of a bearing puller is

A bearing puller is a device, usually made of steel, consisting of several claws and a metal rod. This type of tool is used to firmly grip the bearing in order to remove it. The bearing removal process occurs due to tightening force. The ease of operation of the puller and the absence of the risk of injury depend on the quality of the design.

Types of mechanical pullers:

- Pullers with two gripping arms.

- Pullers with three gripping arms.

- Internal pullers.

Pullers with two gripping arms are a fairly simple and reliable mechanism. Made from high strength steel alloys. Allows you to easily control the work process.

Pullers with three claws are the same pullers with two claws, but improved. As a rule, they are made of hard alloy tool steel.

Internal pullers are used to remove coupling shafts when the part is firmly attached to the structure.

There is also another unofficial type of puller - this is a special one. As a rule, it is used to remove generators, cylinders, and motors. These pullers are exclusive, made to your specific dimensions. This is the main advantage of such a product; you can be sure that the puller one hundred percent fulfills its promises.

Today we will look at how to make a reliable and, most importantly, simple puller that will help you out in difficult times. For this we need:

- A piece of thick pipe.

- Steel plate.

- Nut, bolt.

- Dye.

- Kernel.

- Welding machine.

- Bulgarian.

- Drill.

- Lathe.

- Sanding disc.

Dimensions Lada Kalina 2 station wagon

The overall dimensions of the car are shown in the diagram. The basic dimensions are as follows: length - 4084 mm, width - 1700 mm, height - 1504 mm.

The overall dimensions of the Lada Kalina Cross are slightly different from the basic version. The length of the body is 20 mm longer, the height is 56 mm larger, and the width remains the same. The interior dimensions of the regular version and the “off-road” version are the same. All these values are indicated in the diagram:

The trunk is this car's trump card. Its volume is 355 liters, and with the rear seats folded down it is as much as 670 liters. The dimensions of the trunk of the Lada Kalina 2 station wagon are shown in the diagram:

Dimensions of Lada Kalina 2 hatchback

The hatchback car is 191 mm shorter than the station wagon, 4 mm lower, the width has not changed. The interior dimensions also differ, for example, in a hatchback there is less space above the head of the rear passenger, as well as the distance from the knees to the back of the front seat. You can study in more detail the dimensions of the body and interior of the Lada Kalina 2 hatchback in the following diagram:

The trunk volume is 240 liters, with the rear seats folded down it increases to 550 liters. The dimensions of the hatchback trunk are significantly smaller, both in width and length. All sizes presented in the article are taken from the Autoreview website.

Let us remind you that on the website you can study in more detail the technical characteristics of the Lada Kalina, as well as find reports on tuning and modifications of this car.

Key words: trunk Lada Kalina

Main car body types

Sedan

The sedan version has been discontinued, but information about it may be useful to owners of this type of Lada Kalina car:

- practicality and convenience for regular use;

- good maneuverability on city roads;

- The opening angle of the luggage compartment is 120 degrees, which makes loading luggage easier;

- excellent handling at high speeds;

- there are special loops in the trunk, the purpose of which is to secure the cargo transported in the car;

- the presence of special linings aimed at protecting the heads of passengers and the driver.

The creators of the Lada Kalina sedan paid special attention to the car body, which received wedge-shaped silhouette lines. This creates the image of a stylish car compared to other previously released Zhiguli models. It is worth noting the strength of the body, especially its seat crossbar - it saves car passengers in a side collision.

Sports and 5 door hatchback

A five-door hatchback version in the Lada Kalina line appeared not so long ago. Changes were made not only to the appearance of the body. The model was equipped with the latest engines that meet all European standards regarding toxicity.

This model is ideal for city roads, since it has a power unit with ESVT. This ensures high speed characteristics with minimal fuel consumption.

Thanks to its compact body, the length of which is only 3.893 m, the Lada Kalina hatchback maneuvers perfectly among traffic.

Modern equipment makes this model even more attractive to motorists.

Signs of violation of factory geometry

- Vibrations appear, accompanied by atypical extraneous noise.

- The overall controllability of the car decreases: when moving, it is “pulled” to the side, making maneuvers difficult.

- The car loses stability when driving, especially at high speeds.

- The suspension, as well as the entire chassis of the car, often begin to fail.

- Tires wear out quickly and unevenly.

- Fuel consumption increases.

- It is impossible to adjust the wheel alignment correctly.

The presence of such symptoms indicates that urgent restoration of the geometry of the car body is necessary.